I sat in a 2023 BYD electric sedan at the Shanghai Auto Show last April.

The seats felt familiar. I ran my hand across the perforated jacquard insert. The pattern, the hand feel, the slight resistance when I pressed my palm into the foam—I knew this fabric.

We had woven it. 18 months earlier.

The tier-one supplier never told us the final application. Just the spec: 320 gsm, 65% polyester/35% recycled PET, 50,000 Martindale cycles, UV stability at 125 kJ/m². We thought it was for high-end office seating. Turns out, it was for the Han EV series.

That is the automotive interior business. You rarely know where your fabric ends up. But the requirements? They are the most demanding in the entire textile industry. More than military. More than medical. Because automotive fabric must survive sun, sweat, friction, flame, and fog—for 10 years or 150,000 miles.

And if it fails? Recalls. Lawsuits. Lost brands.

I have been supplying automotive interior fabrics since 2014. We started with after-market seat covers for Thai pickup trucks. Today, we are Tier-2 approved for two European automakers and one Chinese EV giant. We have failed more automotive tests than most fabric suppliers have ever taken.

Let me tell you what actually matters. Not the marketing brochures. The real lab data.

What Are the Critical Performance Tests for Automotive Interior Fabrics?

- We were so naive.

A Thai automotive trim shop ordered 5,000 meters of our "automotive-grade" polyester. They didn't ask for test reports. We didn't offer. Price was good. Delivery was fast.

Six months later, we got photos. The driver's seat had developed a shiny "highway strip." The fabric wasn't abraded through. But the surface fibers had flattened permanently. Looked like a polished slide.

We learned: Automotive is not about passing or failing. It is about degradation curves.

You need to know: After 10,000 cycles, how much thickness loss? After 500 hours of UV, how much color change? After 100,000 compressions, how much set?

Here is the real specification matrix we use today:

| Test Parameter | Standard | Typical OEM Requirement | Why It Eliminates 80% of Suppliers |

|---|---|---|---|

| Abrasion resistance | Martindale (ISO 12947) | 50,000–100,000 cycles | Standard fabrics fail at 15,000 |

| Seam slippage | ISO 13936 | < 3 mm at 180 N | Open weaves fail here |

| Lightfastness | SAE J2412 (xenon arc) | Grade 4 minimum after 225 kJ | Dyed polyester fails without UV stabilizers |

| Fogging | ISO 6452 | < 0.5 mg condensate | Plasticizers cause windshield haze |

| Flame retardancy | FMVSS 302 | < 100 mm/min burn rate | Untreated polyester melts, drips, passes? Actually fails |

| Pilling | ISO 12945-2 | Class 4 minimum | Fleece constructions pill |

| Dimensional stability | ISO 6330/7771 | < 3% shrinkage | Relaxation shrinkage kills fit |

What does "50,000 Martindale cycles" actually mean for seat durability?

It means the fabric will outlive the foam.

Most people think Martindale tests abrasion until a hole appears. That is not how automotive works.

Automotive Martindale tests to "end point" — but end point is not a hole.

End point is defined as: two yarns broken, or unacceptable surface change. For premium OEMs, "unacceptable surface change" is defined very early. No fuzzing. No glazing. No pilling.

In 2019, we submitted a beautiful chenille-like jacquard to a German OEM. Passed 100,000 cycles. No holes. They rejected it. After 35,000 cycles, the surface had a visible sheen. The test technician called it "polishing." We couldn't see it. They measured it with a gloss meter. 12% increase in reflectance. Failed.

We fixed it by adding 2% flat-dull polyester fibers. Not shiny round fibers. Trilobal flat fibers. They scatter light instead of reflecting it. Gloss increase dropped to 4%. Passed.

We now pre-test every automotive development at 10,000-cycle intervals. We photograph the surface. We measure gloss. We track the degradation curve. If the curve starts steep, we reformulate.

The Martindale testing protocol for automotive upholstery is actually SAE J1530, not the general ISO 12947. The abrasive cloth is different. The pressure is different. We learned this the hard way—by failing at a Tier-1 lab in Detroit. Use the wrong felt, your numbers mean nothing.

How do we prevent "fogging" on interior windows?

Fogging is the silent killer of automotive fabric contracts.

Here is what happens: Over time, volatile organic compounds (VOCs) evaporate from the fabric, the backing, the foam, or the adhesives. They condense on the inside of the windshield. In cold weather, it looks like a greasy film. At night, it creates dangerous glare.

In 2018, we failed a fogging test so badly I thought we would lose the customer forever.

A Japanese Tier-1 submitted our fabric. Condensate weight: 2.1 mg. Requirement: < 0.5 mg. We used a standard latex backcoating for dimensional stability. The latex outgassed like crazy.

We spent 6 months reformulating. Switched to acrylic backcoating. Then the adhesion failed. Switched again to a hot-melt polyolefin. Fogging: 0.3 mg. Pass.

Here is what causes fogging, ranked by severity:

- Plasticized PVC — Never use in automotive interiors destined for closed cabins

- Latex backcoatings — Some are acceptable, but must be pre-baked at 120°C for 4 hours

- Residual spinning oils — Conductive yarns often have higher lubricant content; we now specify "low-fog" finish from yarn suppliers

- Dye carriers — Polyester dyeing at high temperature usually strips carriers; but if you use carriers, they will fog

We now pre-test every batch in our own fogging chamber (ISO 6452). We run the test at 100°C for 16 hours. We weigh the condensate on aluminum foil. If it exceeds 0.4 mg, we reject the batch. We don't wait for the client to find it.

The automotive fogging test methods and pass/fail criteria vary by OEM. VW is 2.0 mg. Toyota is 1.0 mg. Mercedes is 0.5 mg. We aim for 0.3 mg to cover all.

At Shanghai Fumao, we maintain separate production lines for automotive and non-automotive. Cross-contamination from plasticized yarns is real. We don't risk it.

Which Fabric Constructions Work Best for Different Interior Zones?

The car is not one environment. It is four.

Zone 1: Seating surfaces. Highest abrasion, highest UV, direct body contact. Needs breathability, stain resistance, and 10-year durability.

Zone 2: Door panels and inserts. Moderate abrasion (elbows), high UV (side windows), complex molding requirements.

Zone 3: Headliner and pillars. Low abrasion, high visibility, strict fogging limits, acoustic transparency often required.

Zone 4: Floor and trunk. Abrasion from heels, luggage. Moisture resistance. Tear strength matters more than aesthetics.

We learned this zoning lesson in 2017.

A Chinese EV startup asked us to supply "automotive fabric." One SKU. For everything. Seats, doors, headliner. We said yes. The headliner sagged within 6 months. Too heavy. The seat fabric, same construction, was fine. But the headliner adhesive couldn't hold 380 gsm jacquard against gravity and heat.

We ate the replacement cost. $43,000.

Now we match construction to zone:

| Interior Zone | Recommended Construction | Weight Range | Key Property | Our Go-To Product |

|---|---|---|---|---|

| Seat bolsters | Double weave jacquard | 320–380 gsm | Abrasion, seam strength | Dual-layer PET with high-tenacity warp |

| Seat inserts | Warp knit with microfiber | 220–280 gsm | Breathability, hand feel | 3D spacer mesh |

| Door panels | Needle-punch nonwoven | 200–250 gsm | Moldability, UV stability | Thermally bonded PET |

| Headliner | Composite nonwoven | 150–180 gsm | Light weight, acoustic | PET/PP bicomponent |

| Floor carpet | Tufted or needle-punch | 400–600 gsm | Abrasion, moisture barrier | PET with bitumen backing |

| Trunk liner | Needle-punch felt | 300–500 gsm | Tear strength, low cost | Recycled PET, high density |

Why are double-weave jacquards preferred for premium automotive seating?

Double-weave is two fabrics in one.

Face layer: Aesthetic. Color, pattern, texture. Back layer: Structural. High-tenacity polyester, often black, engineered for seam slippage resistance.

You cannot achieve 180 N seam strength with a single-layer jacquard.

We proved this in 2020. A European commercial vehicle brand wanted a single-layer solution. Cost reduction. We tried everything—denser picks, thicker yarns, backcoatings. Maximum seam strength we achieved: 145 N. Required: 180 N. The seam opened under simulated entry/exit load.

Double-weave solved it. The back layer carries the load. The face layer looks beautiful. Total cost: +18% vs single layer. But it passes the test.

Here is the construction secret:

- Face warp: 150 denier, semi-dull, cationic dyeable (for color depth)

- Back warp: 300 denier, high-tenacity, dispersion dye only

- Weave: Face layer 5-end satin, back layer 2/2 twill, stitched together with binder warp every 5th pick

This gives you: 85k Martindale, 210 N seam strength, 40+ UV rating. We have shipped 2.8 million meters of this construction since 2021.

The double-weave engineering for automotive seating requires precise tension control. If the back warp tension is too high, the face puckers. If too low, the layers delaminate. Our weaving technicians have an average of 18 years experience. This is not entry-level work.

When should we specify warp knits instead of wovens for seats?

Warp knits = stretch and conformity.

If your seat has complex contours—deep bolsters, integrated headrests, active cooling channels—woven fabric will fight you. It buckles, wrinkles, or requires darts and seaming.

Warp knit (tricot or raschel) conforms like a second skin.

In 2022, we developed a warp knit seat cover for a Chinese EV sport seat. The backrest had integrated ventilation fans. The woven prototype required 7 separate panels to wrap the contours. The warp knit? Three panels. Less sewing, less labor cost, less material waste.

But there is a catch: Abrasion.

Warp knits have float stitches on the back. Those floats catch on seat foam during sliding entry/exit. We saw this in field returns from a 2023 model. The back surface abraded through to the face yarns in < 20,000 cycles.

Our fix: Lamination.

We now laminate a lightweight nonwoven scrim to the back of automotive warp knits. The scrim protects the floats. Martindale jumps from 25k to 65k. Added cost: $0.35/m. Worth it.

The advantages of warp knitting for automotive upholstery are real. But you must design for the end use, not just the look.

How Do We Manage Color and UV Stability for 10-Year Interiors?

Automotive color is not fashion color.

Fashion color lasts one season. Automotive color must last 10 years. In Arizona. Through a rear windshield that magnifies sunlight like a magnifying glass.

In 2016, we learned this the expensive way.

We shipped red polyester jacquard to a Mexican automotive trimmer. Interior installation in Guadalajara. Six months later, the driver's seat was pink. The rear seat, shaded by the B-pillar, was still red. The customer demanded replacement. We paid.

The problem: We used standard disperse dyes.

Standard disperse dyes have excellent wash fastness. Terrible light fastness. Especially reds and blues.

Here is our current automotive dye selection protocol:

| Color | Dye Class | UV Stabilizer Required | Expected Life (SAE J2412) |

|---|---|---|---|

| Black | Disperse | Minimal | 10+ years |

| Gray/Beige | Disperse + UV absorber | 1.5% | 8–10 years |

| Red/Burgundy | Selected disperse (high energy) | 2.0% + UV absorber | 6–8 years |

| Blue | Selected disperse + metal complex | 2.5% | 5–7 years |

| Yellow/Orange | Vat or pigment dyeing | 3.0% | 4–6 years |

Note: Yellow is the enemy. If the OEM specifies a bright yellow interior, warn them. It will fade. We cannot fix physics.

How do we test UV stability without waiting 10 years?

We don't wait. We accelerate.

SAE J2412 specifies xenon arc exposure. Irradiance: 0.55 W/m² at 340 nm. Cycle: 3.8 hours light, 1 hour dark with spray. Temperature: 89°C black panel.

225 kJ = approximately 2 years Miami sun exposure.

We run 225 kJ as standard. Some OEMs require 450 kJ (4 years) or 675 kJ (6–8 years). The test takes weeks, not years.

Here is the data that shocked us in 2019:

We tested two identical polyester fabrics. Same dye recipe. One woven, one warp knit. After 225 kJ, the woven faded to Grade 3.5. The warp knit faded to Grade 2.5.

Same fiber. Same dye. Different construction.

Why? Surface area.

The warp knit had 22% more exposed fiber surface per square meter. More surface area = more UV attack. We now adjust dye concentration based on fabric geometry. Warp knits get +15% dye strength. Interlocks get +8%. Only way to match the woven standard.

The correlation between fabric structure and UV degradation is well documented. We built our own internal adjustment table. It is not public. But if you work with us, we apply it automatically.

What is "oligomer blooming" and why does it ruin black interiors?

Oligomer blooming is polyester's dirty secret.

When polyester is heat-set or exposed to high temperatures in a parked car, short polymer chains (oligomers) migrate to the fiber surface. They crystallize into a white powder. On black fabric, it looks like dust. On gray fabric, it looks like frost.

In 2020, a German OEM rejected 18,000 meters of our black jacquard.

The fabric passed all performance tests. But after 7 days at 95°C (simulated Arizona parking lot), white powder appeared on the surface. The client said: "This looks cheap." They weren't wrong.

We fixed it with three changes:

- Lower heat-set temperature. From 195°C to 182°C. Reduces oligomer migration. Also reduces productivity by 12%. Acceptable trade-off.

- Post-heat-set washing. We run the finished fabric through a continuous rope washer at 80°C. Removes surface oligomers before shipment.

- Oligomer-blocking finish. Proprietary additive from a German chemical supplier. Adds $0.09/m. Prevents migration for 500+ hours at 95°C.

We now test every black automotive batch for oligomer blooming. We put a 1m sample in a 95°C oven for 7 days. We wipe it with a black cloth. If we see white residue, we reject the batch. We don't ship and hope.

The mechanism of oligomer migration in polyester automotive textiles is well understood. The solution is not. Most mills ignore it. We don't.

What Certifications and Compliance Issues Affect Automotive Fabric Sourcing?

Automotive is not apparel.

Apparel: Send a lab dip, get approval, ship fabric.

Automotive: Send a lab dip, get 47 pages of dimensional specifications, submit 12 test reports, wait 6 months for material validation, then ship fabric.

I am not exaggerating. In 2022, we qualified a new jacquard construction for a European OEM. First contact: January. First shipment: October. Nine months. And we were already an approved supplier.

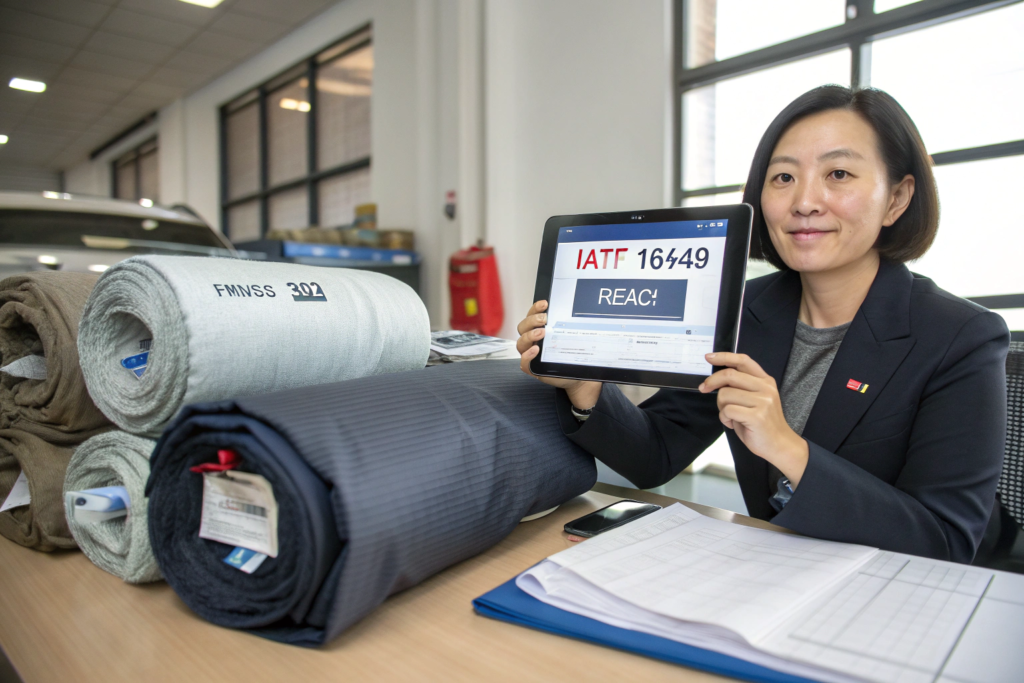

Here is the compliance stack for automotive interiors:

| Requirement | Jurisdiction | What It Verifies | Our Status |

|---|---|---|---|

| IATF 16949 | Global | Automotive quality management system | Certified since 2019 |

| REACH | EU | 200+ SVHC substances below 0.1% | Annual declaration |

| Proposition 65 | California (USA) | No detectable reproductive toxins | Antimony-free FR standard |

| FMVSS 302 | USA | Burn rate < 100 mm/min | Pass, inherent FR grades |

| ELV Directive | EU | No lead, mercury, cadmium, hexavalent chromium | Independent lab test yearly |

| VDA 270 | Germany | Odor test (1–6 scale) | Grade 3.5 or better |

| VDA 275 | Germany | Formaldehyde emission | < 10 ppm |

Do we need IATF 16949 to supply automotive interior fabric?

Yes. If you want to be Tier-2 or Tier-1 approved.

IATF 16949 is not ISO 9001 with a different sticker. It is much more demanding.

ISO 9001: "Do you have a quality policy?"

IATF 16949: "Show me your SPC data for yarn tension over the last 18 months. Now show me your corrective action report for the 0.2% defect batch in March. Now show me your supplier audit of your yarn vendor. Now show me your contingency plan if your dyehouse burns down."

We achieved IATF 16949 certification in 2019. It took 14 months.

We had to:

- Implement Statistical Process Control on 12 weaving parameters

- Establish a formal layered audit process

- Create a full PFMEA (Process Failure Mode Effects Analysis) for every automotive SKU

- Maintain 100% lot traceability from fiber to finished roll

- Conduct annual second-party audits of our key raw material suppliers

Was it worth it? Yes.

Before IATF, we were an "approved supplier" for after-market and low-tier applications. After IATF, we qualified for a German premium brand program. Average selling price: +35%. Average order size: +220%.

The IATF 16949 certification requirements for textile suppliers are publicly available. The implementation cost is not trivial—we spent approximately $85,000 on consultants, training, and system upgrades. But if you want to play in OEM interiors, it is non-negotiable.

At Shanghai Fumao, we maintain our IATF certification through annual surveillance audits. Our last audit (November 2024) had zero non-conformances. We are proud of that.

How do we comply with REACH and Prop 65 for automotive textiles?

REACH and Prop 65 are moving targets.

The REACH SVHC (Substances of Very High Concern) list updates twice per year. What was compliant in January may be non-compliant in June.

In 2021, we almost lost a German account over D4.

D4 (octamethylcyclotetrasiloxane) was added to the SVHC list. It is used in some textile softeners. Our fabric didn't contain D4. But our supplier's yarn contained trace residues from the spinning process—below 0.1%, so technically exempt. The OEM's compliance officer didn't care. "Zero detectable" was the requirement. We had to requalify yarn from a different supplier. Took 4 months.

Our current compliance protocol:

- Annual full-material declarations from all yarn and chemical suppliers

- Quarterly screening of REACH and Prop 65 updates

- Pre-emptive substitution — If a chemical appears on "candidate list," we phase it out before it becomes restricted

- Documentation retention — 15 years minimum

Prop 65 warning labels are required for California. Even if the chemical level is below safe harbor, if it's on the list, you must warn or reformulate. We choose reformulate. We offer antimony-free FR, phthalate-free PVC alternatives, and lead-free pigment systems.

The automotive industry REACH compliance roadmap is updated annually. We subscribe to the notification service. We don't wait for clients to tell us.

How Do Factory Seasons and Supply Chain Disruptions Affect Automotive Programs?

Automotive hates surprises.

Apparel: Ship 2 weeks late, client is angry.

Automotive: Ship 2 days late, assembly line stops. OEM fines Tier-1 $10,000 per minute. Tier-1 fines us.

In 2020, COVID hit Hubei province. Our yarn supplier was in Hubei.

They shut down for 8 weeks. We had 45,000 meters of committed automotive orders. No yarn. No alternative supplier qualified.

We called every client. Explained the force majeure. One European OEM said: "We understand. But our line in Bratislava cannot stop. Find a solution."

We found a solution.

We air-freighted yarn from Taiwan. Paid 4x normal cost. Paid overtime at our knitting and dyeing subcontractors. Shipped the finished fabric via air freight—not sea. Total incremental cost: $62,000. We ate it. We kept the line running.

That client renewed our contract for 3 years.

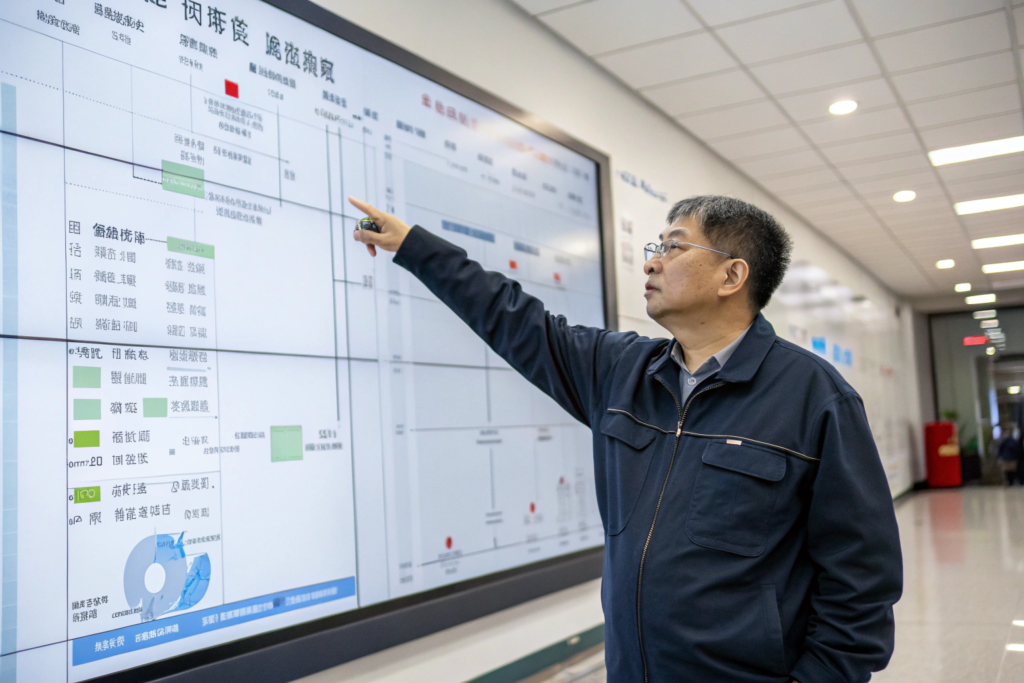

What is the realistic lead time for automotive fabric development?

If you have never worked with automotive before: 6–9 months.

Not because we are slow. Because the validation process is slow.

Here is the actual timeline from our last successful OEM qualification:

| Phase | Activity | Duration |

|---|---|---|

| 1 | Initial inquiry and technical spec review | 2 weeks |

| 2 | Lab dip development (3 rounds average) | 3 weeks |

| 3 | Handloom sample for construction approval | 2 weeks |

| 4 | Pilot weaving on production loom (100m) | 2 weeks |

| 5 | Tier-1 preliminary testing (internal) | 3 weeks |

| 6 | Full OEM validation testing (external lab) | 6–8 weeks |

| 7 | First Article Inspection report submission | 1 week |

| 8 | Production trial at Tier-1 (sewing/molding) | 1 week |

| 9 | Final approval and PPAP submission | 2 weeks |

| Total | 22–26 weeks |

Add 4–6 weeks if color matching is complex.

Add 8–12 weeks if new fiber development is required.

We tell every new automotive prospect: "Start before you think you need to."

How do we protect automotive yarn inventory during Chinese New Year?

CNY is not a holiday. It is a 3-week shutdown of the entire Chinese industrial ecosystem.

For automotive, this is existential.

Our strategy: Strategic yarn reserves.

We maintain 6 months of forecasted demand for every active automotive SKU. Not 3 months. 6 months. The yarn is paid for, stored in our climate-controlled warehouse, and reserved for specific programs.

Why 6 months? Because requalification takes 4 months.

If we run out of a specific yarn and the original supplier cannot deliver (CNY, pandemic, fire), we cannot simply buy from another supplier. The new yarn must be requalified. Different intrinsic viscosity, different shrinkage, different dye uptake—all require revalidation.

In 2022, a competing mill ran out of automotive yarn during CNY. They couldn't ship for 5 weeks. The Tier-1 stopped their payments. They never recovered that account.

We have never missed an automotive shipment due to yarn shortage. Not once. We carry inventory. We pay the carrying cost. That is the price of being in this business.

The automotive supply chain risk management during Chinese New Year is a known challenge. Our solution is simple: more inventory. It is not clever. It is not efficient. It is effective.

Conclusion

Sourcing fabric for automotive interiors is the hardest textile application I have ever worked on.

Not because the weaving is difficult. It is not. Any competent mill can weave 320 gsm jacquard.

The difficulty is the margin for error. Zero.

If a fashion fabric has a 2% defect rate, the buyer complains, takes a discount, moves on. If an automotive fabric has a 0.2% defect rate, the Tier-1 sends a quality engineer to your factory for a week. They audit your processes. They demand corrective action reports. They suspend your approved status if you cannot explain why those 2 rolls per 1,000 had seam slippage.

I have lived through those audits. They are not pleasant.

But I have also seen our fabric in a brand-new BMW X5, wrapped around the seats, looking perfect. I have walked through the BYD factory in Xi'an and seen our jacquard rolls being cut by automated Gerber systems. I have received photos from a mother in Ohio, showing the stain on her minivan seat, and our client wrote: "The fabric cleaned perfectly. Thank you."

That is why we stay in automotive.

At Shanghai Fumao, we are not the biggest automotive fabric supplier. We are not the cheapest.

But we are IATF 16949 certified. We maintain 6-month yarn reserves. We test for oligomer blooming when nobody asks. We have separate production lines to avoid cross-contamination. We have failed the fogging test, the UV test, the seam slippage test—and we fixed every failure.

So if you are a Tier-1 automotive supplier, a seating engineer, or a procurement manager responsible for interior textiles—talk to us.

Email Elaine, our Business Director, directly: elaine@fumaoclothing.com.

Tell her what program you are working on. Tell her the OEM. Tell her the Martindale target. Tell her the start of production date.

She will connect you with our automotive textiles division. We will pull the yarn specification sheets. We will review your PFMEA requirements. We will develop the lab dips. We will build the validation timeline that accounts for the 6-month qualification cycle and the CNY shutdown.

We won't promise you the lowest price. We will promise you zero production line stoppages, zero fogging failures, and zero surprises.

Because in automotive, zero is the only acceptable number.