The email subject line read "URGENT: 50,000m Order at Risk." It was from a fast-growing DTC lingerie brand in Los Angeles. Their breakout product—a bralette with a unique scalloped lace trim—was selling out, but their boutique Italian supplier couldn't scale or meet their target price. The trim cost alone was eating 40% of their margin. They needed to pivot to bulk sourcing, fast, without sacrificing the delicate look that defined their brand. In eight weeks, we helped them transition production. The key wasn't just finding a cheaper supplier; it was re-engineering the trim itself for large-scale efficiency. The result? A 35% reduction in trim cost while maintaining 98% visual and tactile fidelity. This story is the rule, not the exception. Sourcing cost-effective lace trim in bulk is a strategic operation that blends design savvy, material science, and supply chain logistics.

Sourcing cost-effective lace trim and edging in bulk requires a holistic strategy that moves beyond simple price negotiation. True cost-effectiveness is achieved by optimizing the Total Landed Cost, which includes the trim price, minimum order quantity (MOQ) feasibility, tooling/setup costs, yield efficiency, shipping, duties, and the risk of defects or delays. The most effective approach combines three actions: 1) Designing for Manufacturability by simplifying patterns and standardizing widths, 2) Strategic Supplier Selection focusing on vertical manufacturers in specialized clusters, and 3) Consolidated Ordering and Planning to leverage economies of scale and favorable production seasons. The goal is to build a partnership where your volume provides you leverage, and the supplier's expertise drives down their cost to produce, which they can then pass on to you.

If you're just emailing suppliers asking for a "price per meter for this lace," you're leaving massive savings on the table. Let's deconstruct the process to secure both quality and value at scale.

What are the Key Cost Drivers in Bulk Lace Trim Production?

To lower cost, you must first understand what you're paying for. The price per meter isn't arbitrary; it's the sum of specific, tangible inputs.

- Yarn Cost and Composition: This is the foundation. A trim made of 100% silk will always cost more than one made of polyester or nylon. However, modern synthetic yarns can expertly mimic the sheen and hand of natural fibers. Blends (e.g., 85% Polyester / 15% Cotton) offer a balance. For bulk, synthetics are king for consistency and cost. Question: Does your design truly require a natural fiber, or can a high-quality synthetic achieve 95% of the look for 50% of the cost?

- Production Method & Complexity:

- Raschel Knitted Trim: Generally the most cost-effective for bulk. High-speed warp knitting produces continuous trim with built-in stretch, ideal for edges. Setup costs are moderate, and MOQs are relatively friendly (as low as 500-1000 meters per design/color).

- Embroidered Trim (Schiffli/Embroidery): More costly. It involves stitching onto a base band (tulle, satin). Cost increases with stitch density, number of colors, and the delicacy of the base fabric. MOQs are higher.

- Leavers/Chemical Lace: The premium, artisanal option. Extremely high setup and low production speed make it prohibitively expensive for true bulk sourcing, reserved for luxury capsules.

- Design Complexity: Every additional detail costs money.

- Pattern Repeat Size: A smaller, simpler repeat is more economical to produce than a large, intricate one.

- Number of Colors: Each color requires a separate yarn beam or thread change, adding to setup and complexity. Ombre or dip-dye effects are a cost-effective way to add visual interest without multi-yarn setups.

- Edge Shape: A simple straight edge is cheapest. A complex scallop requires precise cutting (often laser) and potentially a stabilizing tape to prevent curling, adding steps and cost.

- Finishing Processes: Post-production steps like dyeing, softening, anti-snag treatments, or adding a clear silicone backing for grip all add cost. Standardizing on a few stock colors (black, white, ivory, nude) can yield huge savings over custom dye lots.

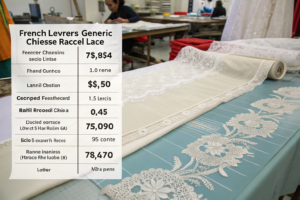

How Does the Sourcing Geography Impact Cost and Value?

Where you source is as important as what you source. The global landscape is specialized.

| Region/Cluster | Typical Specialization | Cost Profile | Key Advantage | Best For |

|---|---|---|---|---|

| Keqiao, China (Our Base) | Full spectrum, especially Raschel & embroidered trims. Unmatched vertical integration (yarn, dyeing, finishing). | Highly competitive. The benchmark for bulk value. | Scale, Speed, and Flexibility. MOQs can be negotiated, and lead times are optimized within the Chinese manufacturing calendar. | Bulk orders (>5,000m), brands needing fast iteration, cost-sensitive lines. |

| India (Surat, Mumbai) | Intricate embroidered trims, metallic threads, hand-look effects. | Competitive, but variable quality. Can be excellent value for ornate designs. | Artisanal Embellishment at semi-industrial scale. | Bohemian, ornate styles, trims with ethnic-inspired motifs. |

| South Korea | High-tech, innovative trims. Excellent synthetics, technical lace, and precision dyeing. | Mid-to-High. Premium for advanced materials and R&D. | Innovation and Consistency. Superior dye labs and quality control. | Performance activewear, luxury contemporary brands needing high-tech fabrics. |

| Europe (France, Italy) | Heritage Leavers lace, ultra-fine guipure, luxury embroideries. | Very High. The cost is for craftsmanship and prestige. | Unmatched Artistry and Brand Prestige. | Haute couture, flagship luxury products, heritage branding. |

The Keqiao Advantage, in practice: For the LA lingerie brand, we moved production to our network here. Because we control the dyeing and finishing in-house, we could standardize their signature "blush nude" into one of our stock shades, saving $0.80/meter on custom dyeing fees. Furthermore, by producing in the quieter period of November, we secured a 10% capacity discount from the knitting mill. This is the kind of insider optimization that defines true cost-effectiveness.

What are the Hidden Costs in "Cheap" Bulk Sourcing?

A low unit price can hide catastrophic downstream expenses. You must audit for:

- Inconsistent Dye Lots: If black trim from roll A doesn't match roll B, your production line stops for sorting, or you face massive waste. This is often a symptom of poor chemical management in the dye house.

- Poor Yield on the Spreading Table: Trim that stretches, shrinks, or has inconsistent width causes your cutters to waste time and material. A trim that costs $1/meter but causes $2/meter in cutting losses is not cheap.

- Low Colorfastness or Durability: Trims that bleed in wash tests or snap during garment stretching lead to customer returns and brand damage—the ultimate cost.

- Unreliable Lead Times & Communication: Delays in trim shipment can idle an entire garment factory, incurring penalties. A supplier who doesn't proactively communicate about delays (like those around Chinese New Year shutdowns) is a high-risk partner.

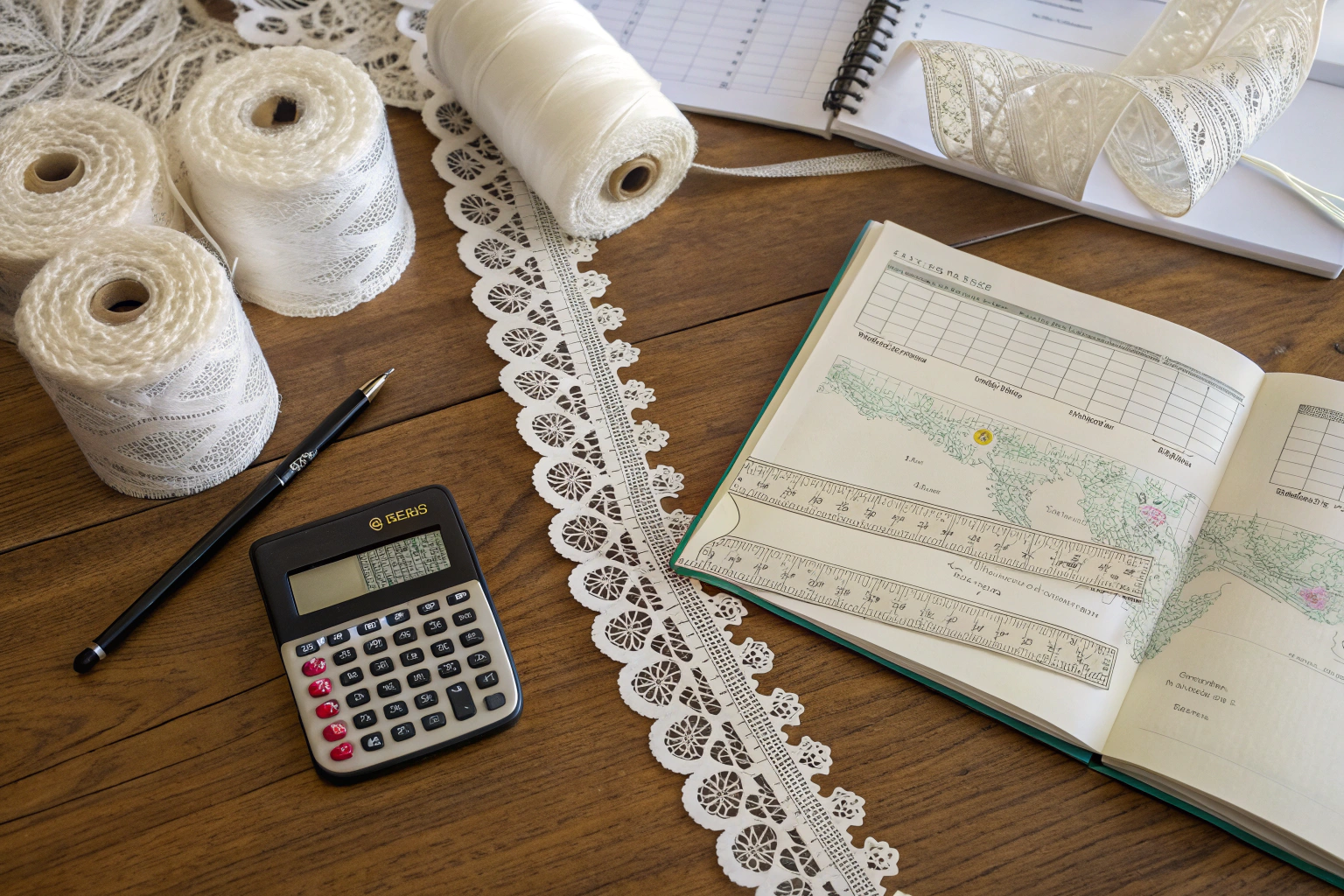

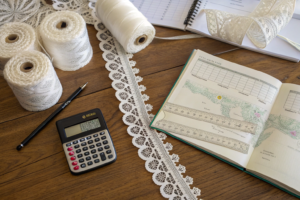

How to Design Your Trim for Bulk Cost-Efficiency (DFM)?

The greatest leverage you have is at the design stage. Design for Manufacturability (DFM) means creating a beautiful trim that is also efficient to produce in the thousands.

- Simplify Within Your Brand Aesthetic: Work with your supplier's design team. Can a 7mm scallop work instead of a 5mm? The larger one may be more stable and less prone to curling, saving a finishing step. Can a two-color effect be achieved with a single yarn that has a heather twist? At Shanghai Fumao, we regularly provide value engineering suggestions that save clients 15-25% without perceptible change to the end product.

- Standardize Widths and Colors: Limit your palette. If you use a "warm white" and an "ivory," see if you can consolidate to one. Every unique SKU you add increases complexity and reduces your volume leverage per item.

- Opt for Raschel Over Embroidery Where Possible: For most fashion applications, a well-designed Raschel trim is indistinguishable from a more expensive embroidered one. It's more durable, has natural stretch for comfort, and is faster to produce.

- Provide Clear, Digital Tech Packs: Ambiguity costs money. Your supplier should not have to guess. Provide:

- Precise width (e.g., 32mm +/- 1mm)

- Stretch percentage (e.g., 30-40% crosswise)

- Fiber composition (exact percentages)

- Color standard (physical lab dip or Pantone)

- Reference photos of how it will be used on the garment.

What are the Critical Questions to Ask a Potential Bulk Supplier?

Your supplier vetting must be surgical. Go beyond Alibaba chat.

- "Are you the factory, or a trading company?" Direct factories offer better cost control and technical communication. As a vertically integrated supplier, Shanghai Fumao manages the process from yarn sourcing to finishing.

- "What is the real MOQ for this design, broken down by color?" Understand if MOQ is per color or for the total order. Can you meet it?

- "Can you provide a detailed cost breakdown?" A professional supplier should be able to outline yarn, knitting/embroidery, dyeing, and finishing costs. This transparency builds trust and identifies areas for potential savings.

- "What is your process for ensuring color consistency across batches and bulk rolls?" Listen for answers about lab dips, spectrophotometers, and batch approval.

- "What is your lead time from approved strike-off to finished goods in your warehouse?" Factor this into your critical path timeline. Ask how they manage holiday periods.

- "Can you provide samples of your standard yarns and base materials?" Testing the hand and stretch of their base offerings can often lead to discovering a perfect, cheaper alternative.

How to Structure Your Order for Maximum Financial Advantage?

Ordering strategically is your final lever.

- Consolidate and Forecast: Instead of placing ten small orders per year, consolidate into 2-3 larger ones. This gives you volume pricing and reduces repetitive setup fees. Share a realistic 12-month forecast with your supplier to help them plan material purchases.

- Utilize Stock/Stock-Modified Programs: Many large mills, including our partners, offer a range of stock lace trims. You can often modify a stock design (e.g., change the color or minor detail) at a fraction of the cost of a fully custom design.

- Plan Around Production Cycles: Place orders for your Q3/Q4 collections during the slower periods in China (June-July or November-December). You'll get more attention, potentially faster turnaround, and may be able to negotiate better terms.

- Consider FOB vs. EXW/DDP: Understand Incoterms. FOB (Free On Board) Shanghai gives you control over your shipping and logistics, which can often be cheaper than a supplier's all-in DDP quote, especially for large volumes. However, it requires you to manage the freight.

Conclusion

Sourcing cost-effective lace trim in bulk is not a one-time transaction; it's about building a strategic partnership with a supplier who has the technical capability to produce efficiently and the business acumen to help you optimize. The lowest price on a spec sheet is a mirage. The true win is a lower total cost of ownership: a reliable, consistent, and beautiful trim that arrives on time, performs on the garment, and allows your brand to scale profitably.

This requires investing time upfront in design optimization, thorough supplier due diligence, and clear communication. It means treating your trim supplier as a key extension of your product development team.

Ready to transform your trim sourcing from a cost center to a competitive advantage? Let's apply this strategic framework to your specific needs. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your bulk trim requirements. With our vertical integration in Keqiao and focus on DFM, we can help you achieve the perfect balance of aesthetics, quality, and cost for scalable growth.