Sourcing boron-infused neutron shielding fabric can be challenging without knowing the industry landscape, the technical standards, and the key suppliers that specialize in this niche. Many buyers, from nuclear research facilities to advanced manufacturing plants, struggle to secure consistent quality while managing costs and lead times. If you go into the market without preparation, you may face delays, higher-than-expected costs, or even non-compliance with safety regulations.

The good news is that with the right sourcing strategy, you can find reliable suppliers and secure the exact boron-infused fabrics your project demands. By understanding material properties, supplier networks, and logistics considerations, you can create a streamlined procurement plan that works in your favor.

This article draws from my two decades of experience in textile manufacturing and global exports, guiding you through every step—from identifying top sources to verifying quality—so you can source with confidence.

Best Global Sources for Boron-Infused Shielding Fabrics

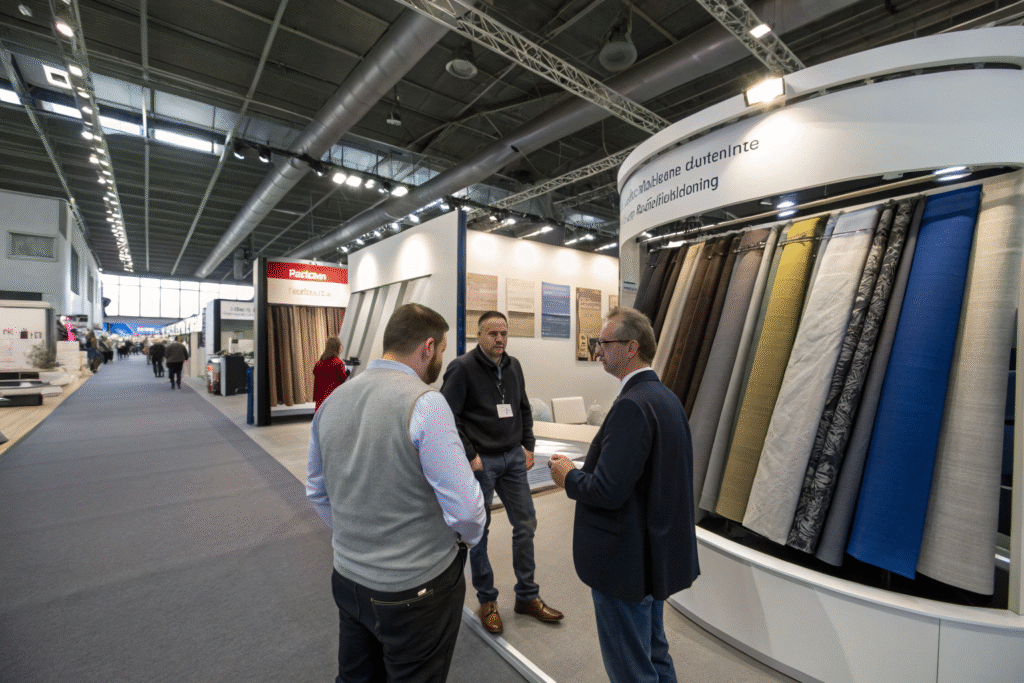

Finding the right suppliers for boron-infused neutron shielding fabrics begins with understanding who dominates this specialized segment. While general textile suppliers are abundant, neutron shielding materials require highly specialized production processes.

Major suppliers such as MarShield and Röchling Industrial have built reputations in borated polyethylene and composite shielding products. These companies not only supply rigid shielding panels but also develop flexible, textile-based solutions for unique applications. For high-performance woven composites, research collaborations with institutions cited in Springer’s Materials Research have introduced innovations such as boron nitride nanotube (BNNT) textiles.

What Are the Top Countries for Sourcing?

Countries like the United States, Germany, and Japan are home to advanced boron composite manufacturing. They possess both the R&D infrastructure and regulatory frameworks to produce high-quality neutron shielding fabrics. In recent years, China has risen as a cost-competitive manufacturing hub, with many suppliers meeting ASTM International and ISO neutron attenuation standards.

How to Choose Between Domestic and Overseas Suppliers?

Choosing domestic suppliers offers advantages such as faster communication, easier compliance verification, and shorter shipping times. Overseas suppliers—particularly those in China—often provide more competitive pricing and broader customization. When evaluating overseas partners, ensure they have proven expertise in neutron shielding materials, not just general industrial fabrics, and verify through IAEA Technical Reports.

Technical Specifications You Must Consider

When dealing with neutron shielding fabrics, technical details directly affect performance. This is not a space where you can compromise.

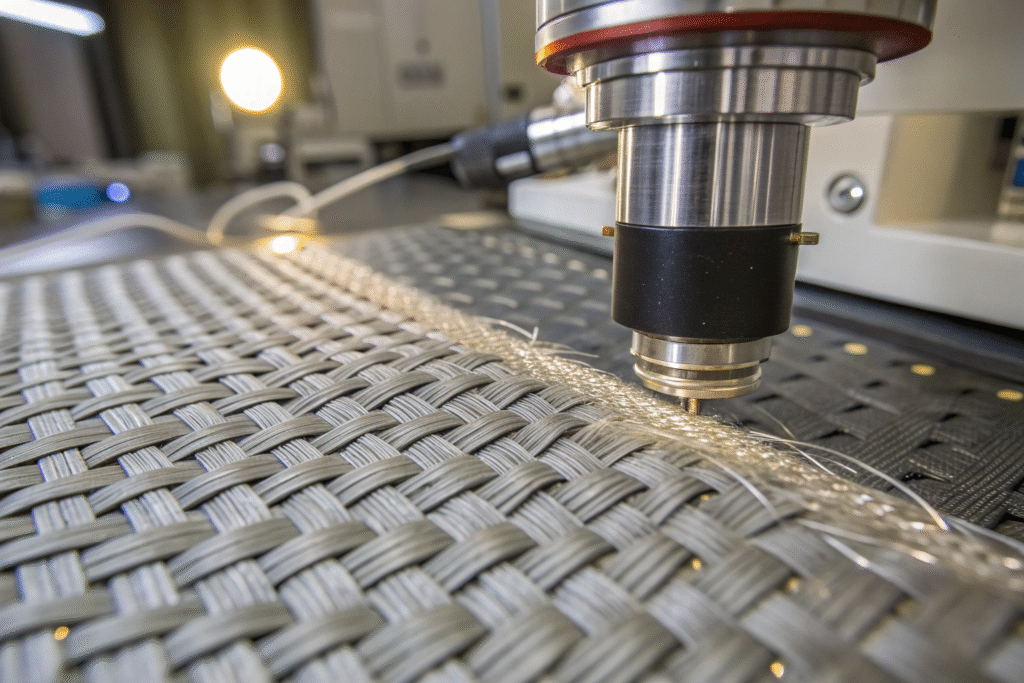

What Boron Content Should You Look For?

Boron concentration affects neutron attenuation capability. Standard grades often contain 5–10% boron by weight for industrial use. High-security applications, such as nuclear containment, may require 20–30%. Boron is typically integrated as boron carbide (B₄C) or boron nitride (BN), each offering different density and shielding profiles (ScienceDirect Boron Carbide Study). Always request a certificate of analysis (COA) to confirm both boron percentage and uniform distribution (ISO 9001 Certification Info).

How to Test for Neutron Attenuation?

Testing should follow ASTM E722 or equivalent standards, ideally performed in a certified neutron physics lab. If the supplier does not have in-house capabilities, they should provide verified third-party reports. Independent validation, possibly through NIST Neutron Physics Lab, ensures compliance before full-scale orders are placed.

Cost and Logistics Planning

Cost efficiency and delivery reliability are essential for sourcing success.

What Factors Influence Pricing?

Several elements affect cost: boron percentage, weave complexity, production volume, and additional coatings. High boron levels and advanced weaves naturally push prices higher. Specialized treatments for moisture resistance or high-temperature tolerance also increase unit cost (GlobalSpec Materials Pricing). Evaluate whether layered lower-boron fabrics could match the performance of single-layer high-boron fabrics (Materials Performance Journal).

How to Manage International Shipping for Hazard-Class Materials?

While pure boron is non-hazardous, certain compounds or coatings may require special handling. Working with freight forwarders experienced in industrial textile logistics for nuclear applications ensures correct documentation and HS code use (Freightos Shipping Guide).

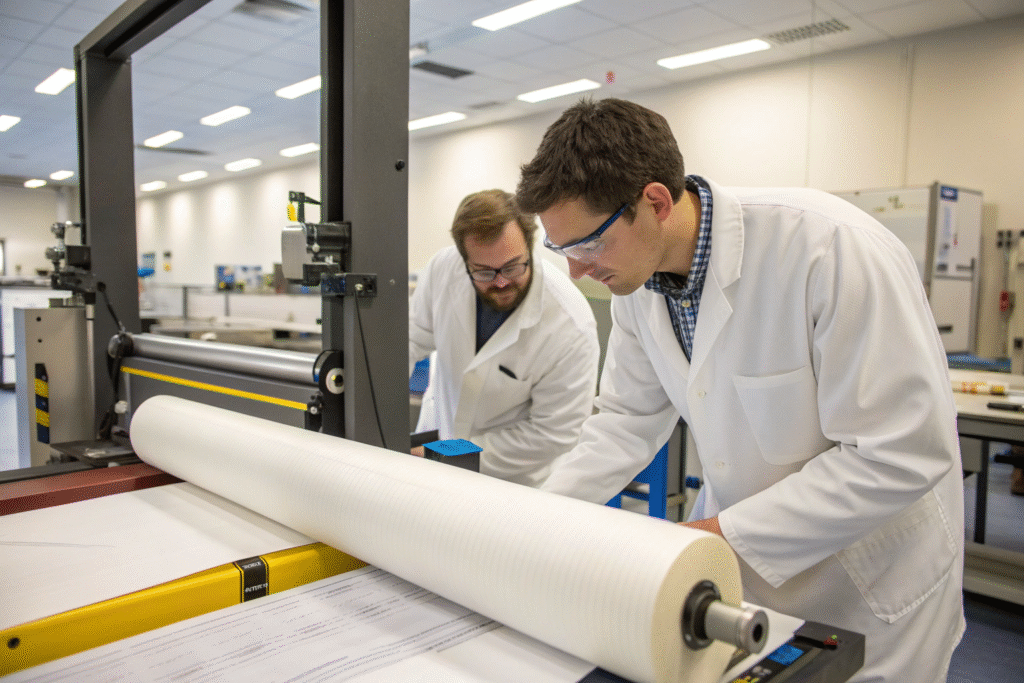

Quality Assurance and Long-Term Supplier Relationships

Quality consistency over time is as important as initial compliance.

How to Set Up Ongoing Quality Checks?

Routine pre-shipment inspections and randomized batch testing should be standard practice. These can include neutron attenuation tests, visual inspections, and tensile strength checks. Trusted QC agencies like SGS and Intertek can execute these inspections globally.

How to Negotiate Better Terms for Long-Term Supply?

Long-term purchase agreements often result in cost savings and priority production scheduling. Demonstrating consistent demand and payment reliability encourages suppliers to offer better terms. Resources like Harvard Business Review Supplier Negotiation provide negotiation frameworks.

Conclusion

Sourcing boron-infused neutron shielding fabric requires expertise, diligence, and structured supplier engagement. The right strategy balances technical precision, cost control, and supplier trust.

If you’re ready to explore tailored production for neutron shielding fabrics, Shanghai Fumao can be your partner. We bring advanced textile engineering, certified quality control, and global logistics to your project. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your requirements.