In recent years, many fashion, sportswear, and high-tech industries have been searching for textiles that are not only lightweight but also conductive and durable. Buyers like Ron in the United States often face barriers such as inconsistent quality, high tariffs, and weak supplier networks when exploring such advanced materials. These problems delay projects and increase costs, leaving many entrepreneurs and procurement managers frustrated.

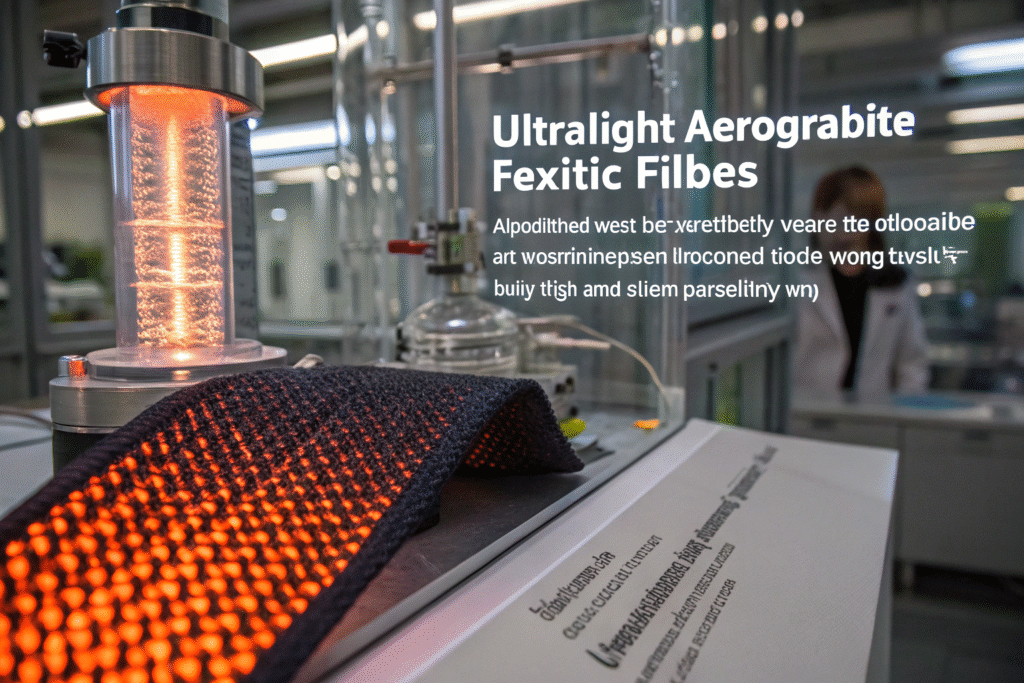

Aerographite-based conductive textiles offer a solution. They combine ultralight carbon structures with reliable conductivity, which can be integrated into next-generation smart fabrics. As the owner of Fumao Fabric, I know how crucial it is to navigate sourcing challenges with the right partners, certifications, and logistics planning.

Aerographite is still an emerging material, so sourcing strategies require careful planning. In this article, I will show you how to understand aerographite’s value, identify trustworthy suppliers, reduce sourcing risks, and plan your next steps.

Why Aerographite Matters for Future Fabrics

The textile industry is no stranger to innovation, but aerographite stands out because it is one of the lightest solid materials ever created. This carbon-based network structure has a density of only 0.18 mg/cm³, yet it is resilient, elastic, and conductive. For global buyers who demand high-performance fabrics, aerographite represents a breakthrough that could redefine conductive textiles.

Aerographite’s importance comes from its combination of strength and conductivity. It can maintain flexibility even under mechanical stress and offers conductivity ranges suitable for wearable sensors, EMI shielding, and flexible electronics. For brands that are developing smart textiles, this material opens the door to new applications that traditional fabrics cannot achieve.

Sourcing aerographite-based fabrics is not simple. They require advanced synthesis techniques such as chemical vapor deposition (CVD) and partnerships with institutions pioneering this technology. Buyers who succeed in securing access to these textiles gain a clear competitive edge in the global marketplace.

What Are the Core Properties of Aerographite?

Aerographite is unique because of its nanostructure. It consists of interconnected carbon tubes formed through a CVD process on zinc oxide templates. Unlike heavy metallic conductors, it provides strength without weight. This feature makes it suitable for sportswear, wearable devices, and aerospace fabrics. For more technical insight, see Aerographite on Wikipedia or explore Nature Communications research.

Another property is its elasticity. Aerographite can compress significantly and recover its shape. This gives textiles higher durability compared to standard conductive yarns. Its ability to integrate into coatings or fabric blends also supports hybrid textile development, as seen in experiments by TU Hamburg and University of Kiel.

How Can Aerographite Improve Conductive Textile Applications?

For buyers focused on smart fashion and technical wear, aerographite can be applied in multiple ways:

- As a conductive layer laminated onto lightweight polyester.

- As a blended coating with graphene or silver nanoparticles.

- As part of flexible wiring integrated into wearable electronics.

In addition, industries such as aerospace or defense can apply aerographite for electromagnetic shielding. Researchers from DepositOnce TU Berlin have highlighted its use in advanced shielding solutions. Combining these benefits with traditional fabrics allows suppliers like us to deliver cutting-edge performance.

What Are the Challenges in Sourcing Aerographite Textiles?

Many international buyers ask why they cannot find aerographite textiles on Alibaba or at large sourcing fairs. The answer lies in the production challenges. Unlike polyester or nylon, aerographite cannot be mass-produced easily.

The main challenge is limited commercial supply. Aerographite is mainly produced in laboratories and pilot-scale facilities. Its manufacturing involves complex CVD techniques, making it cost-intensive and rare in global fabric markets.

Buyers must also consider certification. Since aerographite is still new, few suppliers provide SGS or ITS test reports. This is why partnering with companies that own CNAS-certified labs, like Fumao Fabric, ensures proper verification.

Why Is Commercial Scale Production Limited?

Aerographite production depends on ZnO templates and precise CVD processing. This makes scaling costly. Most manufacturers who explore this field are still in pilot programs. For context, check IRIS Publishers Journal of Textile Science and Marktek’s conductive textile resources.

Buyers often expect fast delivery, but with aerographite, lead times can be longer. Planning sourcing schedules around these realities prevents unnecessary project delays.

What Risks Do Buyers Face Without Trusted Suppliers?

When sourcing advanced textiles, risks include poor quality, lack of documentation, and delays in shipping. For aerographite, these risks are higher due to limited supplier experience. To reduce them, buyers must look for suppliers with strong financial partnerships, like those supported by strategic banks, and reliable logistics systems such as Keqiao’s multimodal hubs. More information about sourcing risks is available at Export.gov and SGS testing services.

How to Source Aerographite-Based Conductive Textile Solutions

The best strategy for buyers is to combine research partnerships with trusted fabric exporters. At Fumao Fabric, we guide international clients to access pilot-scale materials, integrate them with standard textiles, and test performance in our accredited labs.

You should start by building alliances. Work with universities, CVD labs, and conductive textile producers. Then, partner with suppliers who understand fabric scaling and certification requirements.

How Can Research Partnerships Support Buyers?

Universities such as the University of Kiel and Technical University of Hamburg have pioneered aerographite development. Collaborating with these institutions helps buyers access early prototypes. At Fumao, we also run joint R&D with dyeing and coating factories to turn laboratory concepts into scalable textile products.

For buyers, this reduces risk. Instead of waiting for full commercialization, they can test hybrid fabrics that combine aerographite layers with polyester, cotton, or nylon.

Which Textile Companies Provide Compatible Solutions?

While pure aerographite textiles are rare, some companies specialize in conductive fabrics that complement aerographite:

- Bekaert provides stainless steel fiber blends for conductivity.

- V Technical Textiles offers EMI shielding fabrics and yarns.

By combining these existing materials with aerographite prototypes, buyers can achieve real-world applications faster.

What Steps Should Buyers Take Next?

To succeed in sourcing, buyers need a clear roadmap. Aerographite is promising but requires careful planning and integration with conventional fabrics.

The next steps are simple: inquire, sample, and test. Buyers should start with small R&D inquiries, request certified samples, and then develop prototypes with suppliers who can ensure traceability and logistics.

How Can Buyers Initiate Pilot Projects?

Pilot projects help test aerographite integration in fabrics. A two-phase approach is effective:

- Apply aerographite coatings or laminates to polyester samples.

- Test conductivity, elasticity, and durability through certified labs.

For more detail on lab testing, see SGS textile services or ITS Intertek. At Fumao Fabric, our QR-code-based tracking guarantees each meter meets international standards.

How Can Logistics and Finance Reduce Sourcing Risks?

Strong logistics and banking support ensure smooth delivery of high-value textiles. By working with exporters that have established banking partners and diversified markets, buyers can avoid tariff shocks and payment risks. To explore financing solutions, visit HSBC trade finance or Silk Road Keqiao initiative.

Conclusion

Aerographite-based ultralight conductive textiles represent a future-oriented material with unmatched potential. While commercial supply is limited today, forward-thinking buyers who build partnerships with universities, R&D centers, and specialized suppliers will gain early access to this next generation of fabrics. By combining these breakthroughs with traditional textile expertise, sourcing becomes not only possible but profitable.

At Shanghai Fumao, we help global buyers reduce risks and bring innovative fabrics into reality. If you are ready to co-develop aerographite-based or other advanced textiles, please contact our Business Director Elaine at elaine@fumaoclothing.com. We look forward to working with you on your next project.