Looking at your 2026 collection mood board and then at last year's fabric invoices—does the gap feel impossible to bridge? With raw material prices fluctuating, sustainability mandates tightening, and supply chains still unpredictable, how do you create a realistic fabric budget that doesn't cripple your margins or compromise your vision?

The key isn't just about predicting prices; it's about strategic allocation. A smart budget assigns funds not just to fabric meters, but to risk mitigation, innovation, and partnership development. It transforms sourcing from a cost center into a value driver for your 2026 product line.

After guiding dozens of brands through post-pandemic planning cycles at Shanghai Fumao, I've seen a clear pattern: winners budget for flexibility, while losers budget for the best-case scenario. Let's build a 2026 budget that protects you from volatility and unlocks new opportunities.

What are the key cost drivers for 2026 fabrics?

Your fabric cost per meter is just the tip of the iceberg. For 2026, you must budget for the forces that will lift or sink that base price. These drivers aren't guesses; they're trends already visible in Q4 2024, from commodity exchanges to new EU regulations. Ignoring them is the fastest way to blow your budget.

Think of these as the "macro" layer of your budget. They set the stage for everything else and require you to look beyond your usual supplier quotes.

How will raw material and energy costs impact prices?

This is your foundation. Three factors will dominate:

- Cotton & Polyester Volatility: Cotton prices remain tied to weather and geopolitical tensions in key growing regions. Polyester, a petroleum product, is directly linked to oil prices, which are sensitive to global economic activity and OPEC+ decisions. Budgeting for a ±15-20% swing in these base fiber costs is prudent.

- "Green Premium" for Sustainable Fibers: Demand for certified organic cotton, recycled polyester (rPET), and next-gen materials (like Tencel™) continues to outstrip supply. This premium isn't shrinking; for 2026, allocate 10-30% more for these fibers versus their conventional equivalents. A reliable source for tracking this is the Material Exchange sustainability premium index.

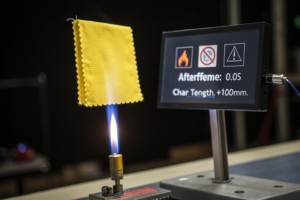

- Energy Costs in Production: Dyeing, finishing, and weaving are energy-intensive. Regions (like parts of China) transitioning to greener but costlier energy sources may pass these costs on. Factor in a 5-10% potential surcharge for energy-intensive processes like dyeing and coating.

For example, in late 2024, we advised a mid-sized UK brand to secure a forward contract on GOTS organic cotton for their Spring/Summer 2026 core basics. By locking in 70% of their estimated need, they hedged against a forecasted price spike and saved an estimated 12% versus the expected spot price in Q2 2025.

What new compliance and logistics costs are emerging?

Regulations are becoming direct line items in your budget:

- EU Sustainability Regulations (ESPR, CSDDD): Preparing and verifying documentation for recycled content, durability, and supply chain due diligence will add 2-5% in administrative and testing costs. This isn't optional for selling in the EU.

- Carbon Border Adjustments & Green Shipping: As carbon pricing mechanisms evolve, low-carbon production methods and slower, greener ocean freight options may carry a premium. Allocate a 3-7% contingency for preferred logistics and compliance.

- US Tariff Engineering: While broad tariffs may persist, savvy sourcing can minimize impact. Budget for potential costs associated with strategic fabric finishing in alternative countries (like Vietnam or Cambodia) to optimize origin rules. Understanding the latest updates on U.S. tariff codes for textiles is a non-negotiable research cost.

How should you allocate your budget across categories?

Throwing all your budget at the "hero" fabric is a classic mistake. A strategic budget is segmented, like an investment portfolio. You need a balanced mix of low-risk "core," growth-oriented "seasonal," and high-potential "innovation" fabrics. This allocation protects your business and fuels its evolution.

A practical rule we use with clients at Shanghai Fumao is the 60/30/10 Framework. Let's break down what each segment means for your 2026 planning.

What percentage should go to core, seasonal, and innovative fabrics?

- Core Fabrics (≈60% of Budget): These are your workhorses. The proven, reliable fabrics you use every season (e.g., your standard jersey, denim, chino twill, or suit wool). For 2026, this budget buys consistency and cost-optimization. Negotiate annual contracts with key suppliers here. The goal is price stability and guaranteed capacity.

- Seasonal/Trend Fabrics (≈30% of Budget): This funds your current season's look and feel—the special jacquards, this year's "it" satin, or the trending color in velvet. Budget here for shorter runs, faster turns, and higher style risk. This is where you build in flexibility for last-minute trends.

- Innovation & Development (≈10% of Budget): This is your R&D fund. It covers sampling of new biodegradable materials, piloting a recycled cashmere blend, or developing a custom finish. In 2026, this isn't a luxury; it's how you future-proof. This budget should fund sampling costs, minimum runs for new materials, and collaboration fees with mills.

For instance, a Los Angeles-based contemporary brand we work with allocates 8% of their annual fabric budget purely to developing performance blends for hybrid workwear. In 2024, this fund led to a wrinkle-resistant, stretch wool-blend that became their top-selling trousers, justifying the entire year's innovation spend.

How to budget for sampling and minimum order quantities (MOQs)?

These are often the hidden budget-killers. Plan for them explicitly:

- Sampling Budget: Dedicate 1-3% of your total fabric budget to sampling. This covers lab dips, strike-offs, and production yardage for prototyping. For a $200,000 fabric budget, that's $2,000-$6,000 set aside just to get samples right before bulk commitment.

- MOQ Strategy Budget: For small-batch or innovative categories, the cost-per-meter might be low, but the MOQ cost is high. Create a separate line item for "MOQ Access Fees." This is the cost of meeting the minimum for a special fabric. Sometimes, it's worth paying a 10-15% premium per meter on a 500m order versus being forced to buy 2000m you don't need.

A smart tactic is to ask suppliers about fabric sourcing programs for low MOQ development. Some mills, including ours, offer curated libraries where you can access premium fabrics at lower minimums for a development fee—a cost that should come from your "Innovation" bucket.

What contingency plans should you budget for?

If your 2026 budget is a single, rigid number, it will break. The past few years have taught us that disruption is the norm. A contingency fund isn't for emergencies; it's a strategic tool for capitalizing on opportunities and navigating inevitable shocks. You need to budget for both "Plan B" and "Plan A+".

This fund gives you the agility to switch suppliers, absorb a cost spike, or jump on a trending fabric without derailing your entire financial plan.

How much should you set aside for supply chain disruption?

Aim for a 5-8% "Buffer & Pivot" fund of your total sourcing budget. This covers:

- Sudden Surcharges: A rapid increase in shipping costs or a new environmental levy from a local government.

- Supplier Failure: Needing to source an alternative fabric at short notice, which always costs more.

- Quality Rejection: Having to re-order fabric if a bulk shipment fails QC, requiring expedited production and shipping.

In late 2023, a European client's main dye house was temporarily shut down for an environmental audit. Because they had a 7% contingency fund, they could immediately move the order to our backup dyeing partner, which had capacity but at a 15% premium. The contingency covered the gap, and their production timeline slipped by only one week instead of two months.

Why budget for opportunity purchasing and trend acceleration?

Sometimes, you need to buy more or different fabric than planned. Your contingency fund enables this:

- Spot Purchases of Opportunity Goods: A mill may overproduce a fantastic fabric or discontinue a line, offering it at a 20-30% discount. Having cash ready lets you snap it up for future seasons.

- Trend Acceleration: If a particular fabric or color in your line starts selling out instantly in pre-orders, you need to re-order immediately to catch the full trend wave. This requires fast cash that isn't tied up in other production.

This part of the budget requires staying informed. Follow platforms that track emerging textile trends and surplus fabric markets to identify where such opportunistic buys might arise. Allocating 2-3% of your budget here can yield disproportionate returns.

What tools and partnerships maximize budget efficiency?

Your budget's effectiveness depends on the systems and relationships you put in place. In 2026, leveraging digital tools for price transparency and deepening key supplier partnerships will be more valuable than ever in stretching every dollar. Efficiency isn't about cutting corners; it's about making smarter decisions faster.

Invest part of your budget in these enablers. They provide the data and trust needed to execute your financial plan effectively.

Which digital tools provide real-time cost visibility?

Relying on quarterly emails from suppliers for pricing is outdated. Budget for access to or integration with tools that offer:

- Raw Material Price Trackers: Subscription services that monitor indices for cotton, polyester, wool, etc.

- Digital Sourcing Platforms: Platforms like Prime-Source or SwatchOn provide transparent, up-to-date pricing from multiple mills, allowing for quick comparisons. Factor in subscription fees or transaction costs.

- PLM (Product Lifecycle Management) Software: While an investment, a good PLM system tracks every cost associated with a fabric—from sample fees to freight—in one place, preventing budget leakage.

For example, one of our tech-savvy clients in San Diego uses a PLM that integrates with our system at Shanghai Fumao. They can see real-time adjustments in their fabric cost based on yarn index changes, allowing them to adjust product pricing or promotional strategy months before the goods arrive.

How does strategic supplier collaboration save money?

This is the highest-return item in your budget. Allocate resources (time and money) to deepen 2-3 key supplier relationships. This can mean:

- Co-Development Agreements: Sharing the cost of developing a custom base fabric you'll use for years.

- Early Involvement in Sourcing: Bringing your main supplier into your 2026 trend discussion in Q1 2025. They can advise on cost-effective ways to achieve the look, potentially saving 10-20% versus a last-minute custom order.

- Vendor-Managed Inventory (VMI) Programs: For core fabrics, some suppliers will hold greige or finished stock for you, reducing your need for large, upfront capital commitments and minimizing risk.

The most effective step you can take? Visit your top suppliers. The cost of a trip to Keqiao or other industrial clusters is easily justified by the trust built and the efficiencies discovered. As the owner of a mill, I can tell you that the brands we host and collaborate with intimately always get our best pricing, first access to innovations, and our most flexible terms. It’s the human element that no digital tool can replace.

Conclusion

Planning your 2026 fabric sourcing budget is an exercise in strategic foresight, not just accounting. It requires a clear-eyed analysis of macro cost drivers, a disciplined yet flexible allocation across fabric categories, the wisdom to fund contingency plans, and the initiative to invest in tools and partnerships that drive long-term efficiency. The budget that wins in 2026 isn't the lowest number—it's the most resilient and intelligent framework that empowers your creative and commercial goals.

Move beyond viewing fabric as a simple commodity purchase. See your budget as the financial blueprint for building a stronger, more adaptable, and more innovative supply chain. By planning for both risks and opportunities, you transform sourcing from a reactive cost into a proactive competitive edge.

Ready to build a 2026 sourcing budget that works as hard as you do? At Shanghai Fumao, we partner with brands to provide not just fabrics, but the market intelligence, flexible programs, and collaborative development needed to execute your financial plan successfully. From securing stable pricing on core materials to co-investing in groundbreaking new fabrics, let's make your 2026 vision a financially sound reality. Contact our Business Director, Elaine, to start planning: elaine@fumaoclothing.com.