You’ve found a promising supplier on Alibaba with great prices. The product photos look perfect. You’re ready to pull the trigger on a 10,000-meter order for your next collection. But then, a knot of anxiety tightens in your stomach: “What if the real fabric is nothing like the picture?” This is the moment that separates successful importers from those stuck with costly, unusable inventory. Ordering fabric from China without a physical sample is like buying a car based solely on the brochure—you might get lucky, but you’re risking a major disappointment.

So, how do you get the right fabric samples from China before committing to a bulk order? The professional process isn’t just about requesting a “sample”; it’s a strategic, step-by-step dialogue that tests both the material and the supplier’s capability. It involves specifying exactly what you need, understanding the costs and timelines, and using the sample to audit quality and compatibility with your production. A systematic approach here is your most powerful risk mitigation tool.

Getting this step right can save you tens of thousands of dollars, prevent production delays, and build the foundation for a reliable long-term partnership. Let’s walk through the exact process I guide my clients through, from the initial request to the final evaluation.

How to Communicate Your Sample Request Effectively?

The biggest mistake buyers make is sending a vague email: “Please send me samples of your cotton fabrics.” This yields random, useless swatches and signals to the supplier that you are not a serious professional. Effective communication is precise, technical, and sets clear expectations. It filters out unqualified suppliers immediately. For instance, last month, a client from Seattle sent us a request for “stretch canvas for bags.” We replied with three options: a 600D polyester-cotton blend, a 1000D pure polyester, and a 98%C/2%Sp twill. Without her specific weight, composition, and finish requirements, we were just guessing. She wasted a week receiving irrelevant samples.

What specific information must you include in your request?

Think of your sample request as a mini tech pack. The more data you provide, the higher the chance of getting a perfect match. Here is your essential checklist:

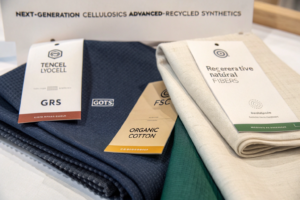

- Full Fabric Specifications: Don’t just say “cotton.” Specify: Fiber Content (e.g., 100% Cotton, 65% Polyester / 35% Cotton), Fabric Construction (e.g., 2x2 Twill, Plain Weave, Single Jersey Knit), Weight (in GSM or Oz/yd²), Width (in cm or inches), and Key Finish (e.g., garment-washed, peach-finish, waterproof coating).

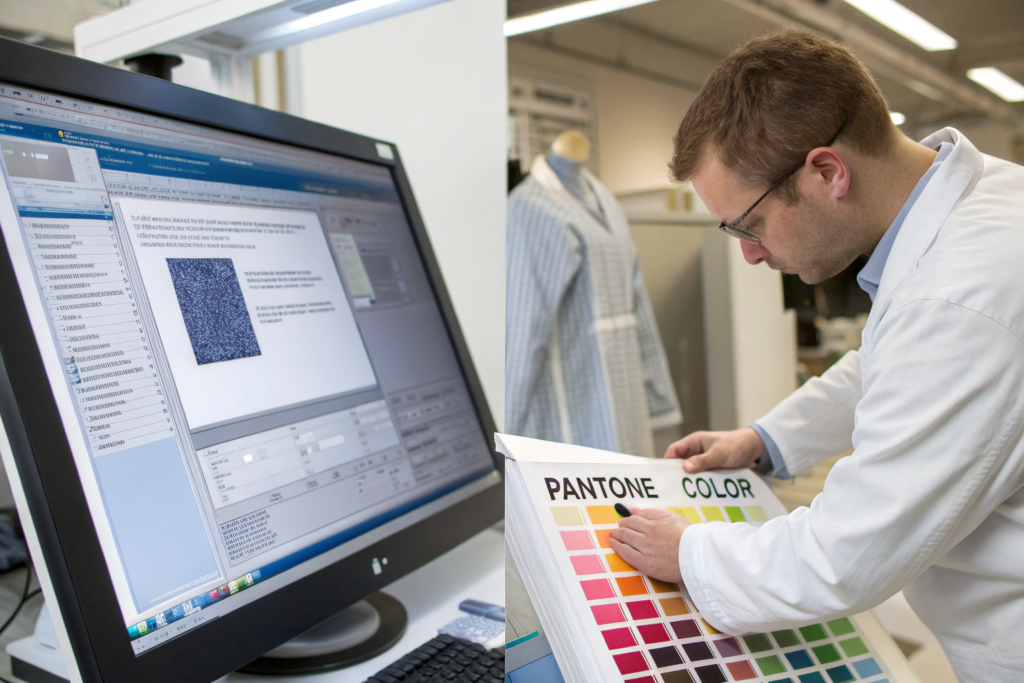

- Exact Color Requirement: Never say “navy blue.” Provide a Pantone (PMS) number, or better yet, send a physical color swatch by courier. For prints, provide a high-resolution AI/PDF file with color codes. Mention the light source (D65 for daylight) under which color will be checked.

- Purpose of the Sample: State clearly: “For hand-feel and color approval” or “For lab dip and physical testing (shrinkage, colorfastness).” This tells the supplier what level of sample to prepare. A hand-feel sample is often cut from stock; a lab dip is custom-dyed, taking 7-10 days.

- Target Price & Quantity: Giving a target FOB price range (“target $3.5-4.0/meter for 5,000m order”) filters out suppliers who cannot meet your budget. It also ensures they send a sample representative of that price point, not a premium quality they can’t replicate in bulk.

How to handle sample fees and shipping costs?

This is a crucial test of the supplier’s professionalism and your own seriousness. Expect to pay for samples. A supplier who offers “free samples for all” often sends generic stock swatches or hides the cost elsewhere. Our policy at Shanghai Fumao is clear: standard stock swatches are free, but custom-made lab dips or large cut samples incur a fee (usually $30-80), and express shipping is always paid by the client. This fee is typically credited against your first bulk order. Always use a trackable courier (DHL, FedEx) and ensure the supplier provides the airway bill number. For a UK client in March 2024, we advised paying for DHL. The sample arrived in 3 days, allowing them to approve and start production immediately, saving 3 weeks versus sea freight.

What Are the Different Types of Samples and Their Purpose?

Not all samples are created equal. Requesting the wrong type is a common pitfall. The sampling process is a funnel: you start broad and end with a perfect, contract-binding reference. Understanding the hierarchy prevents confusion and ensures you and the supplier are aligned at each stage. I’ve seen clients reject a “bulk sample” because they expected it to match a “pre-production sample” in every detail—a mismatch that caused a painful two-week delay.

When do you need a lab dip vs. a handloom sample?

These are two fundamental, yet different, early-stage samples.

- Lab Dip: This is a color approval tool. It’s a small strip of fabric (often in 3-5 dyeing depths) dyed specifically to match your provided color standard. Its sole purpose is for you to approve or correct the color under controlled lighting. It says nothing about the fabric’s hand-feel or construction. You approve it by stamping and signing the physical swatch and returning a scan to the supplier. This becomes the legal color standard for bulk production.

- Handloom/Small Cut Sample: This is a fabric quality approval tool. It’s a piece (usually 0.5m x 0.5m or an A4 size) cut from existing stock or a small trial run. Its purpose is for you to feel the weight, texture, drape, and construction. You cannot judge color accurately from this unless it’s from the same dye lot as a lab dip.

Rule of Thumb: First, get a handloom sample to approve the fabric base. Once approved, request lab dips to approve the color. Only then should you proceed.

What is the critical role of a pre-production sample (PP sample)?

The Pre-Production Sample (PP Sample) is your final and most important checkpoint before the factory runs your entire order. It is produced using the exact bulk fabric (from the approved lab dip) and on the actual production lines. Its purpose is to confirm that the bulk fabric matches all previously approved parameters in color, weight, hand-feel, and performance. You should subject this sample to your full battery of in-house or third-party lab tests for shrinkage, pilling, and colorfastness. In 2023, a client from Australia almost skipped the PP sample to save time. We insisted. The test revealed a 6% vertical shrinkage, exceeding their 3% limit. We adjusted the finishing process before bulk production, saving them from a catastrophic batch of unsellable garments.

How to Properly Evaluate a Fabric Sample?

The sample arrives. Now what? Relying on a subjective “I like it” is dangerous. You need a systematic, almost clinical, evaluation process. Set up a small evaluation station: good lighting (daylight lamp), a weighing scale, a tape measure, and a notepad. Compare the sample directly against your original standard or benchmark fabric. This is where you shift from buyer to quality inspector.

What are the key physical tests you can do in-house?

You don’t need a full lab to perform basic due diligence. Here are 5 simple tests:

- GSM Check: Cut a 10x10 cm square of the sample, weigh it on a precision scale (costs ~$20). Multiply the weight in grams by 100. Compare this to the supplier’s stated GSM. A variance >5% is a red flag.

- Stretch & Recovery Test: For stretch fabrics, stretch it widthwise and lengthwise. Does it return smoothly to its original shape, or does it sag? This basic test can reveal poor-quality spandex or improper knitting tension.

- Colorfastness (Crocking) Test: Rub the fabric vigorously with a piece of white cotton cloth. See if any color transfers. This quick rub test can spot potential dyeing problems.

- Pilling Test (Martindale Simulator): Rub the fabric surface in a circular motion against itself for 30 seconds. Observe if fuzz or pills form quickly. This indicates poor yarn quality or spin.

- Water Drop Test: Place a drop of water on the surface of a fabric claimed to be water-resistant. Does it bead up and sit on top, or does it soak in immediately?

How to interpret technical data sheets from the supplier?

A professional supplier like Shanghai Fumao will provide a test report, often from an in-house or third-party lab. Don’t just glance at the “Pass” stamp. Look at the actual numbers:

- Shrinkage: Is it within your tolerance (e.g., ±3%)? Is the shrinkage balanced (warp vs. weft)?

- Colorfastness to Washing (AATCC 61): A grade of 4-5 is excellent, 3-4 is acceptable for most apparel, below 3 is problematic.

- Tear/Tensile Strength: Does it meet the minimum requirements for your product’s end-use (e.g., higher for workwear, lower for lingerie)?

If the supplier cannot provide a data sheet, consider it a major warning sign. You can also reference guides on how to understand standard textile test reports to better decipher the information you receive.

How to Navigate Logistics and Build the Relationship?

Securing the perfect sample is only half the battle. Getting it efficiently and using the process to build trust is the other half. The logistics and communication around sampling are a microcosm of what your bulk order experience will be like. A supplier who is responsive, transparent about delays, and proactive with solutions during sampling will likely be reliable for production. Conversely, one who is slow, vague, or resistant to feedback will only cause bigger headaches later.

What are the best practices for sample shipping and customs?

To avoid delays and unexpected costs:

- Clearly Mark the Package: Insist the supplier marks the commercial invoice and package with “COMMERCIAL SAMPLE, NO COMMERCIAL VALUE” and declares a low value (e.g., $10). This helps clear customs quickly.

- Choose the Right Service: For a single swatch, international express (DHL/FedEx/UPS) is the only sensible choice. For larger PP samples (several meters), express air freight might still be worth it to save time. Never ship samples by sea.

- Provide a Complete Importer of Record (IOR): If you have a registered business, provide your company details and EIN to the courier for smooth clearance. If you don’t, the courier will act as the IOR, which may involve a small fee.

- Plan for Iterations: Rarely does a sample get approved on the first try. Factor in at least 2-3 rounds of sampling and shipping into your pre-production timeline. A good supplier will offer to re-make a lab dip at their own cost if the first submission is off.

How to use the sampling process to vet the supplier?

The sample is a test of the product and the partner. Ask yourself:

- Responsiveness: Do they answer technical questions clearly and promptly?

- Proactivity: Do they suggest alternatives if your request is hard to meet? For example, when a Miami-based client wanted a specific wool blend that was out of stock, we proactively suggested two alternative blends with comparable warmth and hand-feel, complete with new samples, within a week.

- Transparency: Are they upfront about extra costs and time needed? Do they share process photos (e.g., of the fabric on the loom or in the dyeing machine)?

- Attention to Detail: Is the sample neatly labeled, packaged, and accompanied by a spec sheet? This reflects their organizational standards for bulk orders.

Treat the sampling phase as a paid audition. The fee you pay is an investment in due diligence. Document all communications and agreements. This “paper trail” becomes invaluable if misunderstandings arise later.

Conclusion

Getting the right fabric sample from China is not a simple transaction; it’s the first and most critical phase of your production project. It’s a process that demands clarity, technical knowledge, patience, and a systematic approach to evaluation. By specifying your needs precisely, understanding the different sample types, conducting thorough in-house checks, and using the process to assess your supplier’s reliability, you transform sampling from a gamble into a powerful strategic tool.

This diligence upfront is what protects your bulk investment, ensures your product quality, and builds a supply chain partnership based on transparency and trust. Don’t rush it. The few weeks spent perfecting the sample will save you months of headaches and financial loss down the line.

Ready to test a supplier who understands this process from the inside? At Shanghai Fumao, we treat every sample request as the start of a potential long-term partnership. We guide you through this exact framework to ensure you get a sample that truly represents what we can produce for you at scale. To begin a transparent and efficient sampling process for your next project, contact our Business Director, Elaine. She will connect you directly with our technical team to handle your request. Email her at: elaine@fumaoclothing.com.