Scrolling through thousands of Alibaba listings for "cotton fabric supplier" feels like searching for a needle in a haystack—blindfolded. You see beautiful product photos, glowing "Gold Supplier" badges, and tempting low prices, but you've also heard the horror stories: bait-and-switch on quality, shipment delays that kill a season, and communication that vanishes after payment. For a US buyer, the stakes are incredibly high—your brand reputation, timeline, and profitability all depend on getting this single relationship right.

Finding a reliable textile supplier on Alibaba in 2026 requires a shift from superficial filtering to deep, forensic verification. It's no longer enough to check transaction history and send a generic inquiry. You must become a detective, using Alibaba as a discovery tool to identify potential partners, and then employing a rigorous, multi-stage vetting process off-platform to verify their true capabilities, integrity, and alignment with your specific needs—from sustainable certifications to US customs compliance.

This guide will move beyond the basic "check the trade assurance" advice. We'll walk through a modern, actionable framework that leverages Alibaba's features intelligently while teaching you to spot the subtle red and green flags that separate real manufacturers from skilled resellers. You'll learn how to structure your first inquiry to attract serious suppliers, ask the right technical questions, and validate claims before you ever place an order, turning a risky endeavor into a strategic sourcing advantage.

What Are the First 5 Filters to Apply Before You Even Contact a Supplier?

Your search begins long before you hit "Contact Supplier." In 2026, Alibaba's algorithm and interface are more sophisticated, but so are the tactics of less-reputable sellers. Your initial filters must be brutally efficient to surface only the most credible candidates from the overwhelming list.

First, immediately filter for "Verified Suppliers." This is Alibaba's foundational check, but it's just the starting line. Next, look beyond the generic "Gold Supplier" status to more meaningful indicators. Filter by "Transaction History" and set a minimum—aim for suppliers with at least 50 completed transactions visible, and read the buyer country details. A supplier with consistent sales to the USA, Canada, or the EU is more likely to understand Western quality and compliance standards. Third, use the "Response Rate" and "Response Time" filters. Prioritize suppliers with a rate above 98% and an average response time under 8 hours. This signals a professional, dedicated sales team, not a one-person operation that might disappear.

Fourth, and this is critical, filter by "Product Type" to focus on "Manufacturers" rather than "Trading Companies." While some trading companies are excellent, for textiles, direct access to the factory means better cost control, clearer communication on technical issues, and more reliable production scheduling. Finally, manually scan the "Main Products" list. A true manufacturer usually has a focused, deep range within a category (e.g., multiple types of jacquard, velvet, and satin), not a chaotic mix of unrelated items like fabric, machinery, and home goods.

How Can I Decode a Supplier's Profile Page Like a Pro?

The profile page is a treasure trove of clues. Don't just look at the pretty banner; inspect the details.

- Business Type: This should say "Manufacturer." Click on the factory location link. Is it in a known textile cluster like Keqiao, Shaoxing (Zhejiang), Guangzhou, or Jiangsu? This is a strong positive indicator. A factory registered in a non-industrial city might be a red flag.

- Year Established: Preference suppliers with 5+ years of operation. They've survived market cycles and likely have more stable processes. For context, Shanghai Fumao has over 20 years in Keqiao, which is evident in our deep supply chain roots.

- Product Videos & Virtual Factory Tours: These are gold. A supplier confident enough to show real-time factory footage—looms running, QC inspections, packing lines—is usually legitimate. Look for organized, clean workspaces. Grainy, generic stock footage is a warning sign.

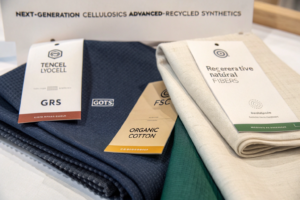

- Certifications Section: Don't just see logos; ask for the certificate numbers and expiry dates later. Look for relevant ones: OEKO-TEX® STANDARD 100, GOTS (for organic), GRS (for recycled), and ISO 9001 for quality management.

A resource like the "Sourcing Playbook" on the China Law Blog provides excellent frameworks for this initial due diligence phase.

What Are the Hidden Red Flags in Product Listings?

The devil is in the details of the listings themselves.

- Unrealistically Low Prices: If a price for organic cotton twill is 30% lower than every other serious supplier, it's almost certainly too good to be true. They may be quoting for inferior quality, or it's a scam to collect deposits.

- Vague or Inconsistent Specifications: Listings that say "customization" but lack basic details like GSM (grams per square meter), composition, or width. Or, the title says "100% Cotton" but the description mentions "polyester blend."

- Overly Professional, Stolen Imagery: Use Google Reverse Image Search. If the same "factory" photo appears on five different company profiles, they are likely not the actual manufacturer. Authentic suppliers often have slightly less polished but original photos.

- Stock-Only Focus: If every listing is for "ready stock" with no mention of custom development, weaving, or dyeing, you're likely dealing with a reseller, not a factory with production control.

How Should You Structure Your First Inquiry to Avoid Generic Replies?

Your initial message is your audition. A message that says "Hi, I need cotton fabric, what's your price?" will get a copy-pasted price list from a junior sales rep—or be ignored by top-tier suppliers. You need to demonstrate you are a serious, knowledgeable buyer to attract the right partner.

Subject Line: Be specific. Instead of "Fabric Inquiry," use "RFQ: Custom 300GSM Organic Cotton French Terry for US Activewear Brand - MOQ Discussion."

Body Template:

- Introduce Your Business Briefly: "We are a [e.g., sustainable womenswear brand based in California] launching a new line of [e.g., lounge sets] for Fall 2026."

- Reference a Specific Product: "We saw your listing for Item #XXXX, the 280GSM Brushed Cotton Fleece, and are interested in a similar but customized fabric."

- Provide Clear, Technical Specifications: Attach a simple tech pack or list:

- Target Composition: (e.g., 95% GOTS Organic Cotton, 5% Spandex)

- Target GSM/Weight: (e.g., 300 GSM +/- 5%)

- Width: (e.g., 180cm)

- Key Finish/Performance: (e.g., enzyme wash for softness, anti-pilling finish)

- Target Use: (e.g., Premium hoodies and joggers)

- Ask Strategic Questions to Gauge Capability:

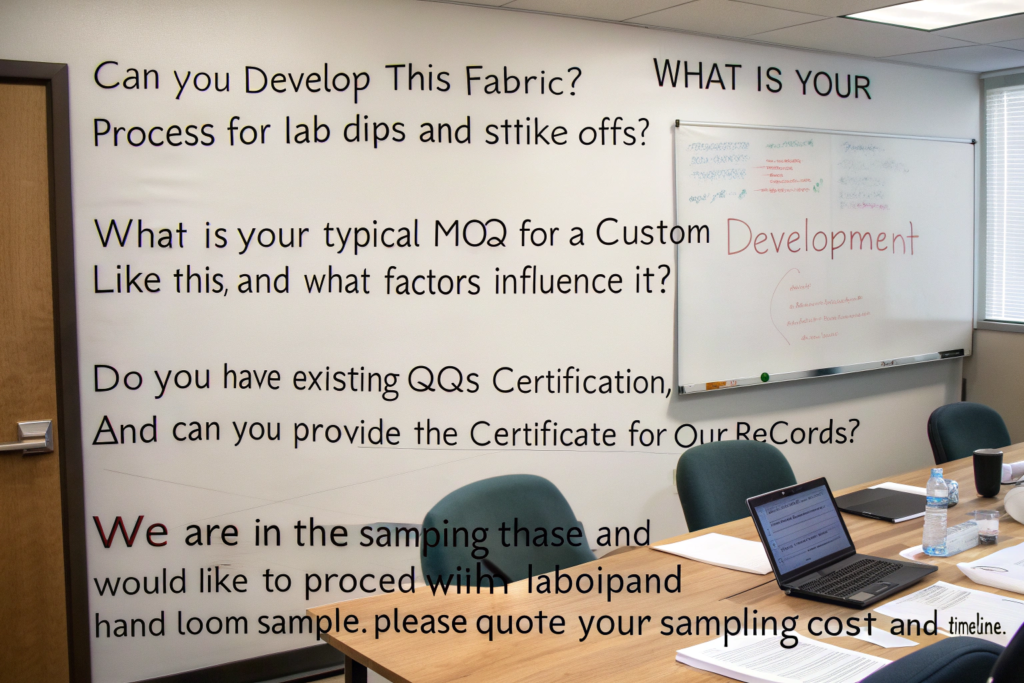

- "Can you develop this fabric? What is your process for lab dips and strike-offs?"

- "What is your typical MOQ for a custom development like this, and what factors influence it?"

- "Do you have existing GOTS certification, and can you provide the certificate for our records?"

- "What is your lead time from confirmed sample to bulk production for a 3,000-meter order?"

- State Your Next Step: "We are in the sampling phase and would like to proceed with a lab dip and hand loom sample. Please quote your sampling cost and timeline."

This approach filters out resellers immediately. Only a true manufacturer with R&D capability can answer these questions in detail.

What Are the Must-Ask Technical Questions in the First Follow-Up?

Once a supplier responds positively, drill deeper in your second communication. Their answers reveal their expertise and transparency.

- On Yarn Sourcing: "For this organic cotton, which spinner do you typically work with? Can you provide the yarn count and origin documentation?"

- On Production Control: "Which production stages do you manage in your own facility? Do you weave, dye, and finish in-house, or through controlled partners?" (For example, at Shanghai Fumao, we are clear about our large-scale weaving factory and cooperative dyeing/printing units).

- On Quality Control: "What is your fabric inspection procedure? Do you use a 4-point system, and can you provide inspection reports before shipment?"

- On Logistics: "What are your standard Incoterms? Can you handle shipping from your door to a US port, including preparing commercial invoices and packing lists for US customs?"

Why Is a Video Call More Important Than Ever?

A live video call is non-negotiable in 2026. It builds trust and allows for real-time verification. Insist on a video tour of the factory floor or warehouse—not just a showroom. During the call:

- Ask them to walk you through the production line for a fabric similar to your needs.

- Have them show you their QC station and testing equipment.

- Meet the sales manager and, if possible, a technical person.

- Gauge their English proficiency and professionalism.

A supplier unwilling to do a video call is a major red flag. Platforms like Alibaba's built-in video call tool or DingTalk (common in China) make this easy. For cultural and negotiation tips, resources like the podcast "The Sourcing Code" often feature experts discussing effective communication with Chinese suppliers.

How Do You Verify Supplier Claims Before Placing an Order?

Trust, but verify. Everything a supplier tells you must be corroborated before money changes hands. This due diligence phase separates amateur buyers from professionals.

Step 1: Sample Order Integrity. Ordering a sample is your first test. Pay for it, even if it's small. Evaluate:

- Communication: Were they proactive with tracking?

- Quality: Does the sample match what was promised in specs and feel?

- Packaging & Documentation: Was it professionally packed with a content label? This foreshadows how they'll handle your bulk order.

Step 2: Third-Party Verification.

- Factory Audit Reports: You can hire a third-party inspection company like SGS, BV, or Asia Inspection to conduct a pre-production audit. This checks business licenses, production capacity, and social compliance. It's an investment, but for large orders, it's essential.

- Check Certificates: For any claimed certification (GOTS, OEKO-TEX), ask for the PDF certificate with the license number. Verify it on the certifier's official website (e.g., OEKO-TEX® buyer portal).

Step 3: Due Diligence on Business Legitimacy.

- Ask for Business License: A legitimate company will provide a copy of their Chinese business license . You can cross-reference the company name and legal representative.

- Search Online Beyond Alibaba: Look for their own website, LinkedIn page, and any mentions in industry news. A supplier like us with a professional digital presence (Shanghai Fumao's website) and active content is investing in long-term credibility.

What Should a Reliable Supplier's Contract Include?

Never rely on a Proforma Invoice (PI) as your only contract. A reliable supplier will work with you on a more detailed Sales Contract or Purchase Agreement. Key clauses to ensure are included:

- Product Specifications Appendix: A detailed, legally attached document listing all specs (composition, weight, width, color standard, physical test requirements).

- Inspection Rights: Clause stating you have the right to conduct a pre-shipment inspection (often called Final Random Inspection) by a third party, with clear pass/fail criteria (e.g., AQL 2.5 for major defects).

- Delivery & Liability: Clear delivery date (consider a "window"), Incoterms (e.g., FOB Shanghai), and penalties for late delivery due to supplier fault (Liquidated Damages).

- Payment Terms: Clear schedule (e.g., 30% deposit, 70% against copy of Bill of Lading). Always use secure methods: Bank Transfer (T/T) to the company's verified account. Never use Western Union or direct wire to a personal account.

- Force Majeure: Definition of events beyond their control.

Using Alibaba's Trade Assurance for the order adds a layer of platform mediation, but understand it is a dispute resolution mechanism, not a quality guarantee. Your contract is your primary protection.

How Do You Assess a Supplier's US Import Experience?

This is crucial for smooth logistics. Ask direct questions:

- "Can you provide a picking list (packing list) in English with clear carton marks, contents, weights, and dimensions?"

- "Are you familiar with preparing a commercial invoice that meets US CBP requirements, including the correct HTS code suggestion?"

- "Do you have experience shipping to the West Coast (LA/LB) vs. East Coast (NY/NJ)? Can you recommend freight forwarders you work with regularly?"

- "What is your process for ensuring 'Made in China' labels are correctly applied to fabric rolls?"

A supplier experienced with the US market will answer these confidently and may even offer advice on avoiding tariff issues under Section 301. For ongoing logistics intelligence, subscribing to updates from a freight forwarding news source like FreightWaves is invaluable.

What Are the Final Steps to Secure a Long-Term Partnership?

Finding a supplier is one thing; building a productive, long-term partnership is another. Your goal is to transition from a transactional buyer to a valued partner.

Start with a Pilot Order. Before committing to your full seasonal volume, place a smaller, but still meaningful, pilot order (e.g., 30-50% of your typical MOQ). This tests their bulk production consistency, logistics, and communication under real pressure. In 2023, a Texas-based brand we worked with started with a 1,500-meter pilot for a custom sateen before scaling to 15,000 meters annually. This de-risked the relationship for both sides.

Conduct a Post-Order Review. After the pilot order arrives, hold a debrief call with the supplier. Discuss what went well and what could be improved. A professional supplier will welcome this feedback—it shows you're in it for the long haul.

Plan for Growth Together. Share your rough forecast for the next 12-18 months. This allows them to plan capacity and yarn sourcing for you, potentially securing better prices and guaranteeing production slots. This collaborative planning is the hallmark of a true partnership and is a core part of how we work with clients at Shanghai Fumao.

How Do You Manage Quality Control Remotely?

You cannot be there for every production run, so you need a system.

- Pre-Production Meeting: Confirm all details from the approved sample are locked in a "golden sample" that is signed off by both parties.

- During Production (DUPRO): Request photos or short videos of the fabric on the loom, coming out of the dyeing machine, etc.

- Pre-Shipment Inspection (PSI): This is mandatory. Hire a third-party inspection company or, if you trust the supplier's own QC, insist on a detailed report and video of the inspection process. They should check for defects, weight, width, and color matching against your standard.

- Digital Documentation: Use cloud folders (Google Drive, WeTransfer) for all communications, tech packs, and reports to avoid confusion.

What Are the Signs It's Time to Find a New Supplier?

Even with due diligence, some relationships don't work out. Be prepared to walk away if you see:

- Consistent quality degradation from sample to bulk.

- Chronic communication breakdowns or unprofessionalism.

- Unwillingness to take responsibility for errors.

- Lack of innovation or ability to scale with your growing needs.

The goal is to find a supplier that grows with you. A partner invested in your success will proactively suggest improvements, keep you informed of new sustainable materials, and help you navigate challenges like tariff changes or logistic snarls.

Conclusion

Finding a reliable textile supplier on Alibaba in 2026 is a systematic process of discovery, verification, and relationship building. It requires moving beyond the platform's basic filters and engaging in deep, technical due diligence. By learning to decode profiles, ask the right questions, insist on verifiable proof, and structure orders with clear contracts, you transform Alibaba from a risky bazaar into a powerful portal to capable manufacturing partners.

Remember, the most reliable suppliers are not always the ones with the shiniest profiles or the lowest prices. They are the ones who demonstrate transparency, technical expertise, and a willingness to build a partnership based on clear communication and mutual success. They understand the specific needs of the US market, from quality expectations to import logistics.

If you are looking for a partner that combines the discoverability of Alibaba with the deep-rooted reliability of a vertically-integrated manufacturer, we invite you to look beyond the platform. Shanghai Fumao is built on over two decades of expertise in the Keqiao textile cluster. We offer the transparency, quality control, and US import experience that discerning brands require. Visit our website to see our capabilities, and then let's connect directly. For a conversation about how we can meet your specific fabric needs with reliability and professionalism, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build your supply chain on a foundation of trust, not just transactions.