You're ready to produce GRS certified apparel, but you've heard horror stories about factories with fake certificates, outdated documentation, or systems that can't actually prove compliance. The market is flooded with manufacturers claiming GRS certification, but how do you separate genuine partners from those just using the terminology without proper credentials?

Finding a legitimate GRS certified factory requires verifying current certification status, assessing implementation systems, evaluating documentation practices, checking supply chain controls, and conducting onsite audits to ensure the manufacturer maintains genuine compliance beyond paperwork. The process involves multiple verification steps that go far beyond simply checking for a certificate number.

At Fumao Fabric, we've helped numerous brands navigate factory selection and have seen firsthand how manufacturers cut corners on GRS compliance. The consequences of choosing the wrong partner can include failed shipments, rejected products, and damaged brand reputation. Let me guide you through the exact steps to identify truly compliant manufacturing partners.

What Certification Documents Should You Verify?

The first step in verifying a legitimate GRS factory involves examining their certification documents carefully. However, having a certificate doesn't guarantee current compliance or proper implementation.

You should verify the factory's scope certificate, transaction certificate capability, audit reports, and certification body credentials to ensure they maintain legitimate, current GRS certification that covers your specific product needs. Each document provides different verification information.

How do you check certification validity?

Certification verification requires multiple steps: confirm the certificate number with the certification body, check expiration dates and scope limitations, verify the certification body is accredited, and ensure the certificate covers your product categories. Many brands make the mistake of accepting certificate copies without independent verification. We recommend using the certification body databases to verify GRS certificate status rather than relying on factory-provided documents alone. This simple step has prevented several brands from working with factories whose certifications had lapsed or been suspended.

What red flags indicate certificate problems?

Several warning signs suggest certificate issues: certificates from unrecognized certification bodies, scope that doesn't match your product needs, recent certification without established systems, inability to provide supporting documentation, and resistance to verification requests. When a factory hesitates to share full certification details or audit reports, it often indicates compliance problems. We've encountered factories with valid certificates but failing compliance systems - the paperwork looked good but the implementation was inadequate.

How Do You Assess Implementation Systems?

Certification documents prove eligibility, but robust implementation systems demonstrate genuine compliance. Assessing these systems requires going beyond paperwork to evaluate operational reality.

You assess implementation systems through facility tours, process observation, staff interviews, documentation review, and performance tracking that collectively reveal whether GRS requirements are integrated into daily operations. This assessment separates manufacturers with real compliance from those with paper-only certification.

What physical evidence indicates proper implementation?

Physical evidence reveals implementation quality: segregated storage areas for GRS materials, clear labeling throughout production, organized documentation systems, trained staff understanding their roles, and clean, organized facilities. During our facility assessment for GRS compliance, we specifically look for color-coded systems, proper material identification, and employee awareness of GRS requirements. These physical indicators often reveal more about compliance than documentation reviews alone.

How do you evaluate staff knowledge and training?

Staff knowledge assessment is crucial: interview operators about GRS procedures, question quality control staff about compliance checks, discuss material handling with warehouse staff, and review training records and materials. The depth of staff understanding often indicates whether GRS is truly integrated or just a surface-level certification. When employees can explain not just what to do but why it matters for GRS compliance, it demonstrates genuine implementation rather than just procedural training.

What Supply Chain Verification Is Necessary?

GRS compliance extends throughout the supply chain, making supplier verification essential for ensuring end-to-end certification integrity.

Supply chain verification requires checking material supplier certifications, reviewing transaction documentation, assessing subcontractor compliance, and verifying traceability systems that collectively ensure GRS integrity from raw material to finished product. This comprehensive approach prevents compliance breakdowns at any supply chain point.

How do you verify material supplier compliance?

Material supplier verification involves: checking supplier GRS certificates for validity, reviewing transaction certificates for material shipments, testing incoming materials to verify composition, and assessing supplier audit history. This verification ensures that GRS materials are genuinely certified rather than just claimed to be. We implement a supplier approval process for GRS material verification that includes regular re-evaluation and testing to maintain compliance confidence.

What about subcontractor and processor compliance?

Subcontractor management is often overlooked: verify that all processors (dyers, printers, finishers) maintain GRS certification, check that subcontractors are included in the factory's scope, review documentation for outsourced processes, and ensure proper material tracking through all production stages. Many GRS failures occur at subcontractor facilities where controls may be weaker. Comprehensive verification must include every facility touching GRS materials.

How Can You Conduct Effective Facility Assessments?

Onsite assessments provide the most accurate picture of GRS compliance, but they require specific approaches to uncover real implementation rather than staged performances.

Effective facility assessments involve unannounced visits, detailed process observation, thorough documentation review, staff interviews, and verification of physical evidence that collectively reveal genuine compliance beyond prepared presentations. The assessment approach significantly impacts findings accuracy.

What should you look for during facility tours?

Facility tours should focus on operational reality: observe material handling and segregation, check labeling and identification systems, verify storage organization, watch production processes, and examine quality control procedures. The most revealing moments often come from observing everyday operations rather than guided tours. We recommend visiting cutting rooms, warehouses, and production lines without advanced preparation to see normal operations rather than staged compliance.

How do you review documentation effectively?

Documentation review requires specific focus: examine mass balance calculations for accuracy, check transaction certificate completeness, review training records for adequacy, verify testing reports for compliance, and assess internal audit findings. The quality and consistency of documentation often indicates whether systems are functioning properly or just created for audits. Look for documentation that appears used rather than created specifically for your visit.

What Questions Should You Ask Potential Partners?

The questions you ask potential GRS manufacturing partners can reveal their compliance depth and operational maturity. Specific, detailed questions separate knowledgeable partners from those with superficial understanding.

You should ask about mass balance calculations, problem resolution processes, training approaches, supply chain management, and continuous improvement practices that collectively indicate whether the factory maintains robust GRS systems. The answers often reveal more than the certification documents.

What technical questions test GRS knowledge?

Technical questions should cover: how they handle mass balance for complex products, their approach to chemical management and compliance, procedures for maintaining material segregation, methods for training new employees, and systems for addressing non-conformities. The specificity and confidence of answers indicate real operational experience versus theoretical knowledge. Factories with genuine compliance can provide detailed, practical answers rather than generalities.

How do you assess their continuous improvement approach?

Continuous improvement questions reveal commitment: ask about recent compliance improvements, inquiry about audit findings and corrections, discuss performance metrics they track, question how they stay current with standard updates, and explore their approach to innovation. Factories truly committed to GRS will have specific examples of improvements and clear processes for ongoing enhancement. This approach indicates whether GRS is a living system or a static certification.

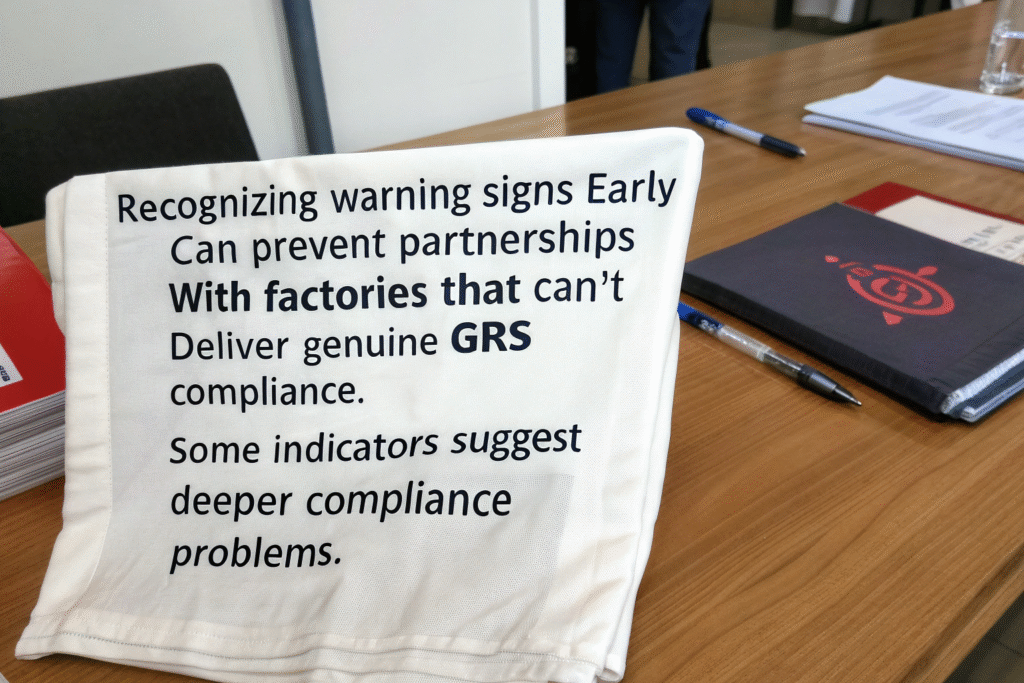

What Are the Red Flags in Factory Selection?

Recognizing warning signs early can prevent partnerships with factories that can't deliver genuine GRS compliance. Some indicators suggest deeper compliance problems.

Red flags include resistance to verification requests, incomplete documentation, staff inability to explain processes, poor facility organization, limited testing capabilities, and unrealistic promises about certification simplicity. These signs often indicate compliance problems beyond surface issues.

What behaviors suggest compliance problems?

Several behaviors indicate potential issues: reluctance to share full audit reports, inability to provide specific implementation examples, defensive responses to detailed questions, over-reliance on certification documents rather than operational evidence, and promises that seem too good to be true. These behaviors often mask inadequate systems or compliance shortcuts. We've learned to trust these behavioral indicators as much as documentary evidence.

What operational signs indicate risk?

Operational warning signs include: disorganized material storage, poor labeling systems, untrained staff, inadequate documentation, limited testing capabilities, and resistance to unannounced visits. These operational issues typically correlate with compliance problems, even when certification documents appear valid. The physical reality of operations often reveals more than paperwork about genuine compliance.

How Can You Verify Certification Long-Term?

GRS compliance requires ongoing maintenance, making long-term verification essential for ensuring continued partnership success beyond initial factory selection.

Long-term verification involves regular documentation reviews, periodic facility assessments, performance monitoring, audit report examination, and continuous communication that collectively ensure maintained compliance throughout your partnership. This ongoing approach prevents compliance drift over time.

What ongoing monitoring should you implement?

Regular monitoring should include: review of updated certificates and audit reports, periodic testing of finished products, assessment of mass balance documentation, evaluation of problem resolution effectiveness, and verification of continuous improvement. This monitoring ensures that compliance doesn't deteriorate after initial qualification. We recommend quarterly documentation reviews and annual facility reassessments for critical manufacturing partners.

How do you maintain compliance confidence?

Maintaining confidence requires: establishing clear communication protocols, conducting regular performance reviews, addressing issues proactively, staying informed about standard updates, and building transparent relationships. The most successful GRS partnerships involve open communication and shared commitment to compliance rather than adversarial verification. This approach creates partnerships where both parties work together to maintain and improve GRS compliance.

Conclusion

Finding a legitimate GRS certified factory requires moving beyond certificate verification to assess implementation systems, supply chain controls, staff knowledge, and operational practices that collectively demonstrate genuine compliance. The process involves multiple verification steps and ongoing monitoring to ensure partners maintain the standards required for credible GRS certification.

The most successful brand-manufacturer relationships for GRS production involve transparency, shared commitment, and continuous improvement rather than simple compliance checking. Partners who approach GRS as a collaborative effort typically achieve better compliance outcomes and stronger business results.

At Fumao Fabric, our experience with GRS certification has taught us that the manufacturers delivering consistent compliance are those with integrated systems, trained staff, and genuine commitment rather than those focusing only on audit requirements. If you need assistance identifying legitimate GRS manufacturing partners, contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how our experience can help you find partners capable of delivering genuine GRS compliance and quality production.

One Response

Yo, tai188bet looks promising. They’ve got a solid selection of games and the site’s not clunky like others I’ve tried. Worth a look if you’re into online betting. Check out tai188bet and let me know what you think!