Let's be real: you have a killer design idea. Maybe it's a unique floral, a geometric pattern you dreamed up, or artwork for a niche community. The big brands have no problem printing 10,000 meters. But for you, a startup or a small brand, that volume is a fantasy—and a financial death sentence. The traditional textile world has told you "no" for too long. You're stuck with stock prints or exorbitant sample fees. That old model is broken.

It is 100% possible to develop high-quality custom printed fabrics with low Minimum Order Quantities (MOQ). The secret lies in partnering with suppliers who have embraced digital printing technology and agile production models. At Shanghai Fumao Fabric, we've built our entire print service around this reality. We see low MOQ not as a problem, but as the future of creative fashion. It's about turning your vision into tangible fabric without needing a warehouse to store it.

The barriers are no longer about technology, but about finding the right partner with the right systems. I’ll show you the exact process, costs, and strategies to make your custom print a reality, even with an order as low as 100 meters.

What Printing Technologies Enable True Low-MOQ Production?

The core of the low-MOQ revolution is digital textile printing. Unlike traditional rotary or screen printing, which requires expensive, physical cylinders or screens for each color in your design, digital printing is like a giant inkjet printer for fabric. There are no setup costs per color. The design file is sent directly to the machine. This eliminates the massive upfront investment that made small runs economically impossible.

There are two main digital print types you should know:

- Direct-to-Fabric (DTF) Printing: Ink is jetted directly onto pre-treated fabric. Ideal for natural fibers like cotton, linen, and silk. It offers vibrant colors and excellent detail.

- Sublimation Printing: Ink is printed onto transfer paper first, then heat-pressed onto polyester-based fabric. The ink turns to gas and bonds with the fibers. The result is incredibly colorfast, stretchable prints perfect for sportswear and activewear.

The choice depends on your base fabric and end-use. For a client in 2023 creating limited-edition yoga sets, we used sublimation on our high-performance polyester, allowing for all-over prints with no feel of the print. Their MOQ was 200 meters per design. Digital printing's flexibility is well-documented on resources like Digital Textile Printing Today which explains the technical and economic advantages of DTF vs. Sublimation.

How does digital printing impact design freedom?

It's a game-changer. You are no longer limited by the number of colors (screen printing charges per color). Your design can have unlimited colors, photorealistic details, and subtle gradients. You can also print different designs back-to-back without stopping the machine, which is perfect for creating coordinating prints for a collection from a single, small fabric run. This is how we help brands develop "capsule collections" with 3-4 coordinating prints on just 500 total meters.

What about the quality and hand-feel?

Early digital prints could feel stiff. Technology has advanced. Using high-quality, pigment-based or reactive inks and proper finishing (like softener baths), the hand-feel can be as soft as unprinted fabric. The key is your supplier's finishing process. We run all our digitally printed fabrics through a specialized softening and fixing process to ensure durability and comfort. (A quick tip: always ask for a washed sample to check for colorfastness and hand-feel after laundry).

How to Prepare Your Artwork for Success (And Avoid Costly Mistakes)?

Your design file is the blueprint. A poorly prepared file leads to misprints, color mismatches, and extra charges—errors that hurt more on a small budget. You don't need to be a graphic designer, but you must understand the basic rules. A professional supplier will guide you, but being prepared puts you in control.

The golden rule: Communicate in the language of print professionals. This means providing high-resolution, correctly formatted files and clear color references. Don't just send a JPEG from Instagram. We provide all our clients with a detailed Artwork Guideline PDF, but here are the universal basics.

What are the non-negotiable file specifications?

- Format: Vector files (AI, EPS) are best for crisp logos and geometrics. For photorealistic work, provide high-resolution TIFF or PSD files (min. 300 DPI at print size).

- Color Mode: CMYK for most digital printing (sublimation often uses specific spot colors). Never use RGB.

- Repeat: If you want a seamless pattern (most fabrics do), you must provide a "half-drop" or "straight" repeat tile. Your designer should know this. If not, many suppliers (like us) offer a low-cost repeat creation service.

- Scale: Indicate the intended print scale (e.g., "Repeat size: Width 64cm, Height 48cm").

A client from the UK once sent a beautiful RGB file that looked vibrant on screen. Printed in CMYK, the neon greens turned muddy. We caught it in the pre-production proofing stage, but it cost them a 2-day delay. Learning this upfront is crucial. Communities like Printful's Design School offer excellent free tutorials on preparing artwork for textile printing.

How do you ensure color accuracy?

This is critical. Monitors lie. You must work with physical color proofs.

- Digital Proof: A simulated image of how the print will layout on the fabric. Good for checking placement and scale.

- Strike-Off / Printed Proof: This is the real deal. The supplier prints a small section (e.g., 1m x full width) of your design on the actual fabric you've chosen. You must approve this physically before bulk printing. This is where you check color, registration, and hand-feel.

We include one round of strike-off sampling in our development fee for low-MOQ orders. For a Brooklyn-based brand in 2024, the strike-off revealed that their black background was printing with a slight blue cast on our chosen cotton. We adjusted the ink profile, reprinted the strike-off, and got perfect jet black. This step is your insurance policy.

What Does the Real Cost Structure Look Like for Low MOQ?

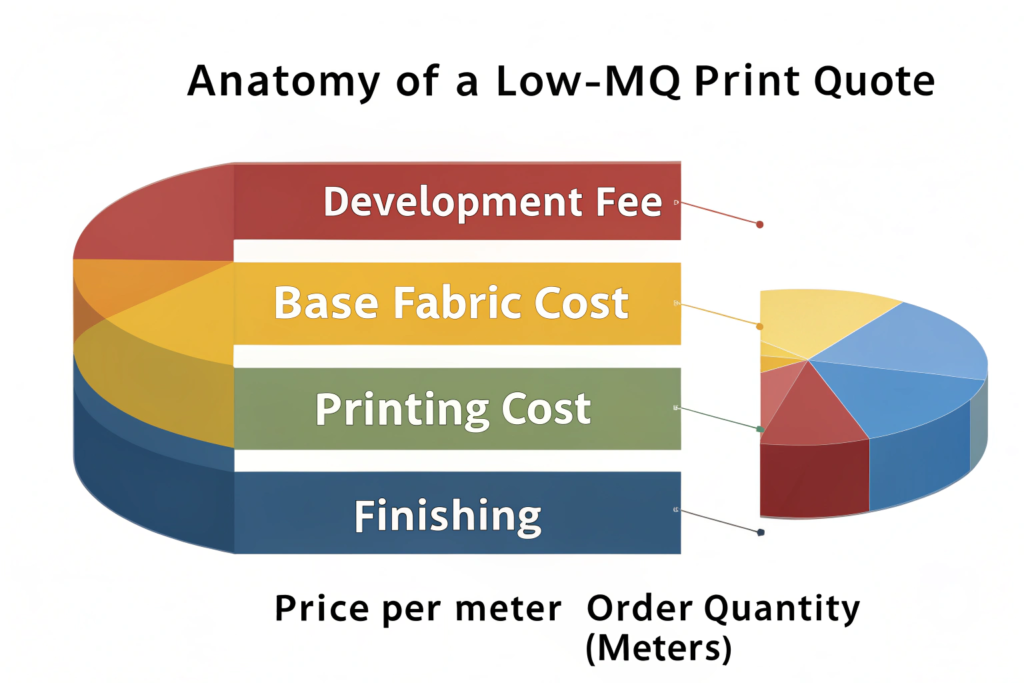

Transparency here is everything. The price per meter for a 100-meter order will naturally be higher than for 10,000 meters. But the total cost should be manageable and predictable. Be wary of suppliers who give a vague "per meter" quote without breaking down the components. A credible cost structure for low-MOQ custom printing has clear, separate line items.

A typical quote from us will include:

- Development/Sampling Fee: Covers the cost of creating the digital print file (separation, if needed), ink profile setup, and producing the strike-off sample. This is a one-time fee.

- Fabric Base Cost: The price of the unprinted "greige" fabric (e.g., cotton poplin, polyester satin).

- Printing Cost Per Meter: The cost to actually run the fabric through the digital printer. This decreases slightly as meterage increases.

- Finishing Cost Per Meter: Washing, fixing, and softening the printed fabric to ensure colorfastness and good hand-feel.

How can you minimize costs without sacrificing quality?

- Choose Standard Base Fabrics: Opting for a fabric your supplier keeps in stock (like our 30,000+ seasonal designs in stock) drastically reduces lead time and cost vs. a custom-woven base.

- Consolidate Orders: If you have multiple designs, print them in the same production run, even on different fabric types if possible. This spreads the machine setup cost.

- Understand the Breakpoints: Ask your supplier for price tiers. E.g., 100m, 300m, 500m. The jump from 100m to 300m often brings a significant per-meter reduction.

In 2023, a Parisian accessory brand wanted 4 different prints on silk twill. By grouping all designs into one production run, their effective MOQ per design was 75 meters, and the total cost was 25% lower than printing each separately. For budgeting, platforms like Maker's Row (though focused on US production) have blogs that help build cost models for small-batch production.

Are there hidden costs to watch out for?

Yes. Ask upfront about:

- Color Matching Fees: If you demand an exact Pantone match beyond standard CMYK, there may be an extra charge for custom ink calibration.

- Repeat Creation Fees: If you provide a non-repeating image and need them to create a repeat.

- Wash Test Fees: For critical applications, paying for a formal wash test on the strike-off is a wise investment.

We believe in no surprises. Our quotes list every potential fee, so you know exactly what you're paying for.

What is the Step-by-Step Process from Design to Delivery?

A smooth process is key to a stress-free experience. Knowing what to expect at each stage builds confidence, especially when you can't be on the factory floor. At Shanghai Fumao Fabric, we've streamlined this into a clear, 5-stage workflow for our low-MOQ clients.

Stage 1: Consultation & Quotation. You share your design ideas and target fabric. We advise on the best print method, suggest base fabrics from our stock, and provide a transparent, line-item quote.

Stage 2: Artwork Finalization & Deposit. You provide your final, print-ready artwork. We review it and may suggest optimizations. Upon approval, you pay the development fee and fabric deposit.

Stage 3: Strike-Off Sampling. We produce a physical strike-off on your chosen fabric and send it to you via express courier. You approve it (or request one round of adjustments).

Stage 4: Bulk Production & Final Payment. Upon your written approval of the strike-off, we proceed with the full print run, finishing, and final inspection. An invoice for the balance is issued.

Stage 5: Shipping & Tracking. The finished fabric is professionally packed, and shipping documents are prepared. You receive a tracking number and can monitor the journey via our portal.

How long does the entire process typically take?

For a standard order with an in-stock base fabric:

- Strike-Off Production: 5-7 working days after artwork approval.

- Bulk Production: 7-10 working days after strike-off approval.

- Shipping: Variable (e.g., 5-10 days for express air to the US, 30-35 days for sea freight).

So, from finalized artwork to fabric in your hands, plan for 3-5 weeks depending on shipping. This agility is a core advantage of the Keqiao ecosystem we operate in.

What quality checks happen during production?

Even for low MOQ, quality is not optional. Our process includes:

- Pre-Print Fabric Inspection: Checking the greige fabric for defects.

- In-Line Print Inspection: Operators monitor the print for streaks or misalignment.

- Post-Print Finishing Control: Ensuring washing and fixing temperatures are correct.

- Final Random Inspection: Checking for any print flaws or finishing issues before packing.

A dedicated resource for small brands navigating production is the Startup Fashion blog, which often features guides to working with offshore manufacturers for the first time.

Conclusion

Developing custom printed fabrics with low MOQ is not just a possibility—it's a vibrant, accessible pathway for creative brands to differentiate and thrive. The technology exists, the processes are proven, and the partners are ready. The old barriers of high volume and high cost have been dismantled by digital printing and agile supply chains.

Your unique design deserves to exist in the world, not just on your screen. By understanding the technology, preparing your artwork professionally, and partnering with a transparent, experienced supplier, you can turn that vision into a competitive advantage without excessive risk or inventory.

The future of fashion is personalized, responsive, and creative. Your fabric should be too. At Shanghai Fumao Fabric, we are committed to being the partner that makes small-batch custom printing not just easy, but exceptional. Let's create something unique together. Contact our Business Director, Elaine, to start the conversation about your next custom print: elaine@fumaoclothing.com.