You’ve just received another email from your Chinese fabric supplier—the quote is missing half the specifications you asked for, the lead time seems unrealistically short, and you’re not even sure they understood your quality requirements. Sound familiar? As the owner of a fabric company in Keqiao for over two decades, I’ve seen this communication gap derail countless projects. International buyers often feel they’re speaking a different language, even when using English. The core issue isn't just translation; it's about bridging a vast cultural and procedural divide.

Effective communication with your Chinese fabric supplier hinges on three pillars: technical precision in your requests, proactive timeline management around China's production calendar, and building a relationship-based partnership rather than a transactional one. It's not about sending more emails; it's about sending the right information in the right way at the right time. When done correctly, this turns your supplier from a passive order-taker into an active problem-solving partner for your brand.

Miscommunication costs more than just time. It leads to wrong samples, delayed shipments, quality rejections, and lost sales. But when you align your communication style with how Chinese manufacturing ecosystems operate, you unlock reliability, innovation, and value that pure price-shopping can never deliver. Let me guide you through the practical steps, forged from years on both sides of the table.

How to Prepare a Technical Pack That Actually Gets Understood?

The single most important document you will ever send is your technical pack. A vague or incomplete tech pack is the root cause of at least 70% of sourcing errors we see. To your supplier, a good tech pack is like a precise medical prescription; it leaves no room for interpretation.

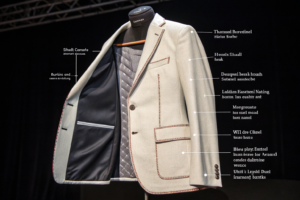

An effective tech pack must be visually driven, numerically specific, and reference globally recognized standards. Don't just write "heavy cotton twill." Specify: "100% Cotton, 3/1 Right-Hand Twill, 340 GSM (±5%), Pre-shrunk finish, Color matched to Pantone 19-4052 TCX." Include a photo of the Pantone chip next to a physical reference fabric swatch taped to the page. This combination of digital and physical reference is golden.

What Are the Non-Negotiables in a Fabric Tech Pack?

Beyond basic composition, these elements are critical and often overlooked:

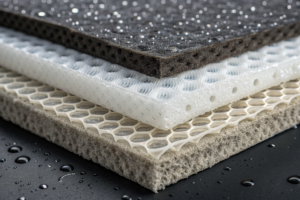

- Physical Reference Swatch: Always courier a physical sample. The tactile hand-feel, weight, and drape cannot be communicated digitally.

- Finishing Specifications: This is where magic or disaster happens. Specify exactly: "Brushed back, peach-skin finish," or "Water-repellent finish meeting AATCC 22 rating of 90+."

- Testing Requirements & Certifications: List them explicitly. "Fabric must pass: AATCC 135 Dimensional Change after 5 washes: <3%. Provide full test report from SGS. OEKO-TEX Standard 100 Class II is mandatory."

In 2023, a German sportswear brand sent us a tech pack asking for a "soft, durable brushed fabric." We requested clarification and learned they needed a bi-elastic circular knit with a double-sided brushing for premium athleisure. Without that conversation, we might have produced a cheaper, single-brushed fleece that would have pilled instantly. For a comprehensive breakdown, the Fashion Incubator's guide to creating a bulletproof tech pack is an excellent external resource.

How to Structure Your Email for Maximum Clarity?

Your email subject line and structure are your first filters for attention.

- Subject Line: Be specific. "RFQ: 10,000 yards - Cotton Sateen for Bedding - Tech Pack Attached"

- Email Body: Use numbered lists.

- Project Overview.

- Attachments Checklist.

- Key Questions for Supplier.

- Next Steps & Deadline.

This structure shows you are professional and organized. At Shanghai Fumao, we prioritize clients who communicate like this because it signals a serious, long-term partnership.

What Are the Best Practices for Samples and Prototyping?

The sampling phase is your project's safety net. The most common mistake is rushing through it or treating sample fees as a nuisance. A well-managed sampling process validates your tech pack and tests the supplier's capability.

The golden rule is sequential confirmation. Don't ask for a bulk-production sample before approving the lab dip. The standard sequence is: Lab Dip -> Handloom Sample -> Bulk Production Sample (PPS). Approve each stage in writing via email.

How to Evaluate a Lab Dip or Strike-Off Correctly?

This is about color and hand-feel under correct conditions.

- Lighting: Evaluate color under multiple light sources—daylight (D65), store fluorescent, and indoor incandescent. Metamerism is a common issue.

- Approval Note: When you approve, state: "Lab Dip #3 approved for bulk production under D65 daylight standard."

- Handloom Sample: Check the weight (GSM), weave structure, and hand-feel against your reference.

A resource like The Source Report's article on navigating fabric sampling with offshore suppliers offers a great third-party perspective.

Why is the Pre-Production Sample (PPS) the Final Gatekeeper?

The PPS is made from the main production line. It represents exactly what you will get in your 10,000-yard shipment.

- Test it Destructively: Cut a piece and have it tested at a third-party lab.

- Check Consistency: Request samples from the beginning, middle, and end of the PPS run.

- Formal Approval: Send a formal, signed "PPS Approval" email. This is your legal green light.

Never approve a PPS with the comment "It's okay, go ahead." Ambiguity is your enemy.

How to Navigate Quotes, Negotiations, and Contracts?

The quote is more than a price list; it's a reflection of understanding. A detailed quote shows the supplier has read your tech pack thoroughly.

The sampling phase is your project's safety net. The most common mistake is rushing through it or treating sample fees as a nuisance. A well-managed sampling process validates your tech pack and tests the supplier's capability.

What Should Your Purchase Order Absolutely Include?

Your PO is your legal document.

- Clear Reference: "All specifications as per Tech Pack #2024-001 and approved PPS #2."

- Quality Tolerance: State acceptable tolerances.

- Inspection Rights: "Goods are subject to final inspection prior to shipment."

- Liability Clause: For defective goods.

Don't rely on default templates. Create your own. This level of detail prevents 90% of disputes.

How to Negotiate Beyond Just Price?

Price is important, but the best value isn't always the lowest price.

- Ask for Staggered Shipments: Can they split the order? This de-risks your inventory.

- Discuss Payment Terms: Can you move from 50% deposit to 30%?

- Focus on Yield: "If you can guarantee a 98% cuttable width yield, that saves me 2% fabric waste."

This aligns your incentives with theirs for better quality control.

How to Manage Timelines and Avoid Holiday Pitfalls?

This is where proactive communication separates the amateurs from the pros. You must understand and plan around the Chinese Manufacturing Calendar.

What is the Critical Path for Chinese New Year (CNY)?

CNY planning is your annual strategic test. The rule is: Finalize all pre-production and place your deposit at least 8 weeks before CNY.

A real case: A French brand we work with has a rule: all fabric for their Summer collection must be in their European warehouse by December 1st. This forces their development timeline with us to finish in early October. Because of this discipline, they have never missed a launch date in 5 years.

How to Use Communication Tools for Daily Updates?

Move beyond email for timeline management once an order is placed.

- Weekly Video Call: A 15-minute standing call every Monday morning (their time) to review status.

- Shared Spreadsheet: A simple Google Sheet with columns for Milestone, Planned Date, Actual Date, and Status. The supplier updates it weekly.

- WeChat for Urgent Issues: For quick photo/video checks. But keep all formal approvals on email.

This structured yet personal approach ensures you are never in the dark.

Conclusion

Effective communication with your Chinese fabric supplier is a learnable skill. It’s built on precise technical documentation, a disciplined sampling process, clear commercial agreements, and proactive timeline management. When you master these, you stop being just another buyer and become a valued partner.

The goal is to build a bridge of mutual understanding where expectations are not just shared but are met, consistently. This reliability becomes the most valuable component of your supply chain.

If you're ready to transform your supplier communication from a source of stress into a strategic advantage, we should talk. At Shanghai Fumao, we are not just executing orders; we are facilitating clear, professional partnerships. To discuss how we can bring clarity to your next project, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build not just fabrics, but a seamless partnership.