That first swatch of linen arrives – crisp, cool, promising effortless summer style. But then the doubts creep in. Will this be too sheer for a shirt? Too stiff for a flowing dress? Too heavy and hot instead of breezy? Choosing the wrong linen weight is a classic and costly mistake in summer collections. I’ve seen beautiful designs undermined by fabric that wrinkles into a crumpled mess, loses its shape, or simply doesn’t perform as the designer envisioned. The difference between a bestseller and a warehouse leftover often comes down to grams per square meter (GSM).

Linen weight isn't just about thickness; it's the DNA of the garment. It determines drape, opacity, structure, breathability, and wrinkle behavior. A lightweight linen might be perfect for a breezy blouse but a disaster for tailored trousers. The "right" weight is the one that perfectly aligns with the garment's function, desired aesthetic, and practical wearability. There's no universal "best" – only the best for the purpose.

Navigating this choice requires moving beyond vague terms like "medium weight" and understanding the specific GSM ranges and their applications. It's about balancing the inherent rustic charm of linen with the polished expectations of modern consumers. Let's decode linen weights to ensure your summer collection is as technically sound as it is beautiful.

What Do Linen Fabric Weight (GSM) Categories Actually Mean?

First, let's demystify the numbers. Weight is measured in Grams per Square Meter (GSM) or sometimes in ounces per square yard (oz/yd²). For linen, the range typically spans from ultra-light voiles to heavy canvases. Here’s the practical translation for apparel design:

- Lightweight Linen (90-160 GSM / 3-5 oz): This is your airiest, most breathable category. Think of it as "second-skin" linen. It has a beautiful, fluid drape, dries incredibly quickly, and offers a slightly translucent quality. However, it wrinkles most easily and offers minimal structure. It's the choice for scarves, lightweight blouses, loose tunics, and lining.

- Mid-Weight Linen (160-260 GSM / 5-8 oz): This is the Goldilocks zone and the workhorse of summer collections. It offers the ideal balance: substantial enough to be opaque and hold a shape, yet breathable and drapes well. It wrinkles less noticeably than lightweight linen and has a pleasing, casual structure. This is your go-to for shirts, dresses, skirts, lightweight trousers, and unstructured jackets.

- Heavyweight Linen (260+ GSM / 8+ oz): This category is all about structure and durability. The fabric has body, stiffness, and a pronounced textured hand. It wrinkles in a more deliberate, "chunky" way and is less prone to clinging. It’s too warm for very hot climates in fitted styles but excellent for structured blazers, coats, heavyweight trousers, bags, and home textiles like upholstery.

Why is weave density as important as weight?

Two linens can have the same GSM but behave differently based on the yarn thickness (count) and weave density (threads per inch). A fabric made with fine, tightly woven yarns at 180 GSM will feel smoother, denser, and more refined. A fabric made with thicker, slubbier yarns at the same 180 GSM will have a more rustic, open, and textured feel with better breathability but potentially more shrinkage. Always ask for both the GSM and the yarn count. For a polished city-summer look, you might choose a high-count, fine-yarn mid-weight linen. For a relaxed, artisanal vibe, a slubby linen in the same weight range is perfect.

How does finishing affect the final hand and weight?

The raw linen (grey cloth) is just the beginning. Finishing processes dramatically alter its character:

- Stone Washing / Enzyme Washing: Softens the hand, reduces stiffness, and gives a pre-loved, relaxed appearance. It can also pre-shrink the fabric.

- Mercerization: A chemical treatment that increases luster, strength, and dye affinity. It makes linen smoother and less prone to wrinkling.

- Calendaring (Pressing): Flattens the fabric for a smoother surface.

- Softener Application: Adds temporary softness which may wash out.

A stiff 200 GSM linen can be transformed into a soft, drapey fabric through finishing. When evaluating swatches, ask about the finish applied. The sample you feel has likely been finished, so specify that finish for your bulk order.

Lightweight Linen (90-160 GSM): When and How to Use It?

Lightweight linen is the essence of summer breeze. Its beauty lies in its ethereal drape and exceptional coolness. When you want a garment to float and move with the body, this is your fabric. It's ideal for styles that are intentionally loose, layered, or slightly sheer.

Perfect applications include:

- Oversized Button-Down Shirts: The light fabric avoids adding bulk.

- Flowy Maxi Dresses and Kimonos: Creates beautiful movement.

- Loose, Unlined Blazers: For a non-constricting layer.

- Sheer Panel Details: Used in yokes or sleeves for visual interest.

- Scarves and Lightweight Shawls.

How do you manage the sheerness and delicacy?

The key is intentional design and construction.

- Embrace Layering: Design pieces meant to be worn over camisoles or slip dresses.

- Use Fully Lined Sections: Line just the bodice of a dress or the yoke of a shirt.

- Choose Your Yarn: A finer, more tightly spun yarn in this weight range will be less sheer than a very open weave.

- Color Choice: Darker colors and prints naturally camouflage sheerness more than solid pastels or whites.

A case study: A Scandinavian minimalist brand wanted a perfectly opaque yet fluid linen for a minimalist tank dress. We achieved this not by increasing weight, but by sourcing a 140 GSM linen with a very high thread count and a tight plain weave. The density provided the opacity, while the low weight ensured the fluid drape they desired. It was more expensive per meter due to the finer yarns, but it created a unique product that justified the cost.

What are the care and shrinkage challenges?

Lightweight linen is most vulnerable to aggressive shrinkage (can be 5-10% if not pre-shrunk) and can be delicate during wet processing. Always:

- Specify Pre-Shrunk (Sanforized) Finishing: This is non-negotiable for consistent sizing.

- Use French Seams or Flat-Felled Seams: These clean finishes prevent fraying and add a touch of luxury to delicate fabric.

- Provide Clear Cold Wash / Lay Flat Dry Instructions: This preserves the fiber and minimizes wrinkles.

For high-volume production, discuss with your factory how they will handle cutting and sewing this delicate weight to prevent distortion.

Mid-Weight Linen (160-260 GSM): The Versatile Workhorse

This is where most designers should begin their exploration. Mid-weight linen delivers the classic linen look with practical wearability. It has enough body to be self-supporting, meaning it can be used in tailored pieces without a lining, yet it remains cool and breathable.

Its versatility is unmatched:

- Tailored Shirts and Blouses: Holds a collar and placket shape well.

- Skirts (A-line, Pencil, Wrap): Provides structure without stiffness.

- Dresses (Shirt Dresses, Shift Dresses, Sundresses): Offers the ideal blend of drape and substance.

- Trousers and Shorts: Drapes beautifully on the leg, resists bagging at the knee better than lightweight linen.

- Lightweight Suiting and Unstructured Jackets.

What is the "sweet spot" GSM for a classic linen shirt?

Based on countless productions, the 180-220 GSM range is ideal for a men's or women's button-down shirt. At this weight, the fabric:

- Is fully opaque.

- Has a crisp hand that softens beautifully with wear and washing.

- Holds tucks, pleats, and seams cleanly.

- Resists the most extreme wrinkling (it will still wrinkle, but in a pleasant, casual way).

- Maintains enough drape to avoid a boxy look.

For a client's bestselling linen shirt line, we standardized on a 200 GSM, stone-washed linen. The stone wash provided immediate softness and a slight lived-in texture that customers loved right out of the package, reducing initial stiffness and shrinkage complaints.

How do you enhance the performance of mid-weight linen?

Beyond basic finishing, consider these value-adds:

- Blending with Cotton or Tencel: A 55% Linen / 45% Cotton blend in this weight range reduces wrinkling, increases softness, and can lower cost. A Linen/Tencel blend adds incredible drape and a cooler hand.

- Wrinkle-Resistant (WR) Finishes: Special resin treatments can be applied to significantly reduce wrinkling. The trade-off can be a slightly stiffer hand and concerns about chemical use (look for eco-friendly WR finishes).

- Garment Dyeing: Dyeing the finished garment (instead of the fabric) results in a richer, more uniform color and an incredibly soft hand, as the entire process acts as a softener.

Heavyweight Linen (260+ GSM): Building Structure and Texture

When your design calls for architecture and presence, heavyweight linen is the answer. This fabric stands away from the body, creating silhouettes with volume and definition. Its wrinkles are bold and intentional, part of its textured, artistic appeal.

Ideal uses are all about structure:

- Structured Blazers and Jackets: Provides canvas-like body perfect for tailoring.

- Overcoats and Trench Coats (for cooler summer evenings or spring/fall).

- High-waisted, Wide-leg Trousers: Where you want the pants to hold their dramatic shape.

- Structured Bags, Hats, and Accessories.

- Home Décor: Upholstery, table runners, heavy curtain linings.

How do you work with the stiffness and drape?

Heavyweight linen has a mind of its own. Successful design acknowledges this.

- Simplify Patterns: Complex darts and seams can look bulky. Clean, minimalist lines work best.

- Consider Underlining: For a tailored jacket, underlining with a lightweight bemberg or cotton can help the fabric roll and behave more like wool.

- Embrace the Texture: Use topstitching with heavier thread to complement the fabric's substance.

- Pre-wash for Softening: If a slightly softer hand is desired for a heavy trouser, a garment wash can be specified to gently break down the starchiness.

Can heavyweight linen be comfortable in summer?

Yes, but with caveats. Its breathability remains high because linen is a hollow fiber. However, its insulating properties also increase with weight. Therefore, for summer comfort, design for airflow. Use it in oversized, non-fitted styles like boxy jackets, wide-leg jumpsuits, or A-line coats that allow air to circulate between the fabric and the skin. A fitted, lined heavyweight linen blazer will be warm; an unlined, oversized one can be surprisingly comfortable.

How to Test and Specify Linen Weight for Your Collection?

Never commit to a linen based on a small swatch alone. Your sourcing process must include physical testing.

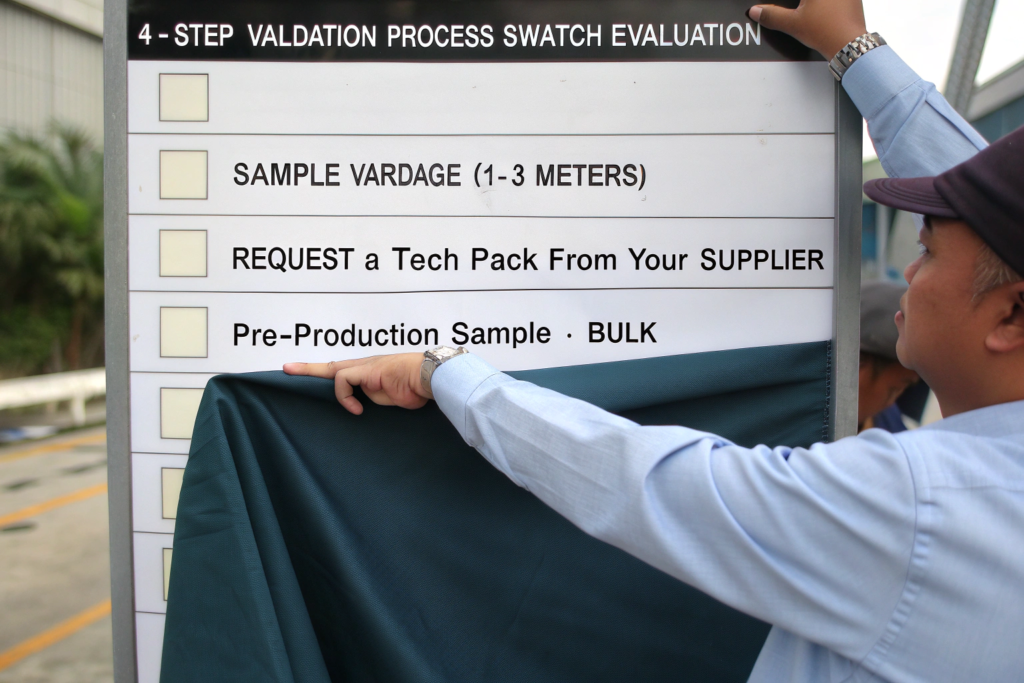

The 4-Step Validation Process:

- Swatch Evaluation: Feel the hand, check the drape by holding it up, and assess the opacity by placing it over print.

- Sample Yardage (1-3 meters): This is critical. Have your factory make a prototype in your actual pattern. Wear it, sit in it, wash it (following intended care instructions). Does it behave as expected? Does the weight work with the design lines?

- Request a Tech Pack from Your Supplier: A professional supplier should provide a fabric specification sheet stating: exact GSM, yarn count, weave, finish, width, shrinkage rate, and colorfastness test results.

- Pre-Production Sample from Bulk: Once the bulk fabric is produced, test a sample cut from it to ensure it matches your approved swatch and sample yardage in weight and hand.

What key questions should you ask your linen supplier?

- "What is the exact GSM of this fabric? Can you provide a test report?"

- "What is the yarn count and construction (e.g., 2-ply, plain weave)?"

- "Has it been pre-shrunk? What is the residual shrinkage percentage?"

- "What finish has been applied (e.g., stone washed, mercerized, calendared)?"

- "What is the MOQ for this specific quality and for custom colors?"

- "Can you provide wash testing results for pilling and colorfastness?"

Asking these questions separates serious suppliers from catalog merchants. At Shanghai Fumao, we provide this data upfront for our core linen qualities and guide clients through this selection process, because the right weight is the foundation of a successful linen garment.

Conclusion

Choosing the right linen weight is a deliberate act of aligning material science with design vision. It requires moving beyond aesthetic attraction to a functional understanding of how GSM, weave, and finish interact to create the final garment's character, performance, and customer satisfaction.

By categorizing your designs by intended use—airy layers, versatile separates, or structured statements—and matching them to the appropriate weight category, you build a technically sound collection. Remember to validate choices with physical prototypes and partner with a supplier who provides transparent technical data.

Ready to source the perfect linen weight for your summer line with confidence? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to request our curated linen swatch library, complete with GSM specifications and finish details. At Shanghai Fumao, we help you translate the timeless appeal of linen into summer collections that are as smartly constructed as they are stylish.