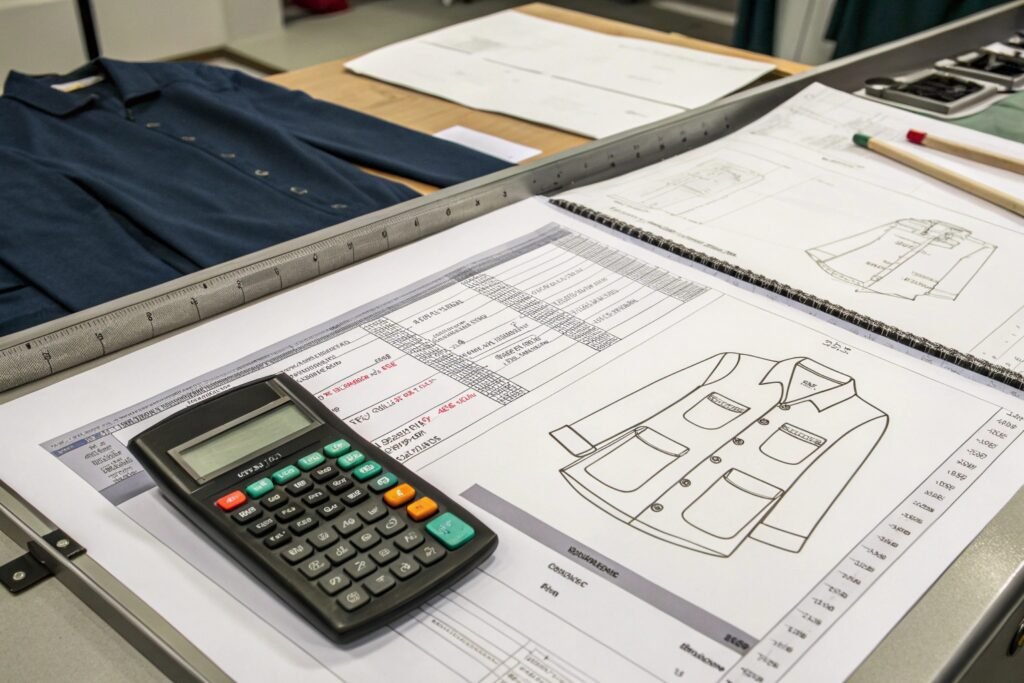

Fabric is one of the largest cost drivers in apparel manufacturing. Yet, many sourcing teams still rely on outdated estimates or over-ordering, which leads to excess stock, waste, or unexpected production delays. For cost-conscious buyers like Ron, mastering fabric consumption calculations isn’t optional—it’s critical.

To calculate fabric consumption for cost-efficient ordering, you must accurately determine fabric width, garment pattern layout, garment size grading, and wastage percentage. This allows for precision in budgeting, production planning, and supplier negotiation.

Whether you’re working with shirts, dresses, or sportswear, this guide walks you through the essential formulas, practical tools, and real-world tips to streamline your ordering process and control fabric-related costs.

What Are the Key Variables in Fabric Consumption Calculations?

Every garment uses a different amount of fabric depending on its size, style, and fabric width. Understanding how these variables affect consumption is the foundation of cost control.

Key variables include fabric width, garment size and style, pattern efficiency, fabric shrinkage, and cutting wastage—all of which must be factored into the final calculation.

Why Is Fabric Width So Important?

Fabric width, typically measured in inches or centimeters, determines how pattern pieces can be arranged. A 60-inch wide fabric allows for more efficient placement than a 44-inch one. For example, as explained on Fashion-Incubator, better width utilization means fewer meters needed per garment.

When using circular knits or non-directional prints, layout becomes even more efficient. We recommend reviewing your supplier's actual roll width, not just catalog specs, which may differ by ±2cm. At Fumao, we provide exact width measurements before cutting begins.

How Do Garment Sizes Affect Fabric Usage?

Larger sizes obviously consume more fabric. However, inconsistency in grading rules can lead to surprises. Tools like Optitex or Tukatech’s CAD suite allow you to simulate fabric usage across size ranges and reduce consumption fluctuations between sizes.

At Fumao, we support clients with multi-size marker making to ensure average consumption figures reflect real demand, not just sample size data.

How Can You Use a Standard Formula to Estimate Consumption?

A standard formula for woven garments (shirts, trousers) is:

Fabric Required (meters) = (Garment Length × Number of Panels) / Fabric Width + Allowance

This gives a base value, which should then be adjusted with a buffer for shrinkage and wastage.

Using simplified formulas based on garment type and production method helps buyers create consistent benchmarks for pre-ordering fabric accurately.

What Are Example Formulas for Common Garments?

Let’s say you're producing a men's short-sleeved shirt with a finished length of 80cm and using 150cm wide fabric. With 2 panels per shirt and 10% waste buffer:

(0.8m × 2) / 1.5 + 0.1 = ~1.17m per shirt

Resources like Textile Learner and OnlineClothingStudy offer garment-specific calculation guides.

We also provide Excel-based consumption calculators for T-shirts, hoodies, and yoga pants on request—customized to fabric types and widths.

How Do You Factor in Shrinkage and Fabric Defects?

Always request a shrinkage report from your mill before bulk ordering. For cotton fabrics, allow 3–8% shrinkage depending on finish. Fabrics with digital printing may need higher buffer. At Fumao, all fabrics are tested in our CNAS-certified lab using ISO 6330 and ASTM D4974 protocols. Reports are available via QR code tracking on each roll.

What Tools Help Automate Fabric Yield Optimization?

Manual methods are error-prone, especially for bulk orders. Today’s technology enables pattern simulation, yield forecasting, and real-time adjustments across fabric types.

Using CAD tools, AI-powered layout optimization, and cloud inventory trackers significantly reduces fabric waste and over-purchasing.

Which Software Tools Do Global Brands Use?

Brands like Nike, H&M, and PVH rely on tools such as Lectra Modaris, Gerber AccuMark, and Browzwear to simulate pattern layouts and consumption on virtual fabrics.

Even mid-sized brands can use freemium versions like Tailornova or Seamly2D for basic consumption planning. We integrate with client CAD exports and adjust our cutting orders accordingly.

Can AI Improve Fabric Efficiency?

Yes. AI-driven systems like CutPlan or Autometrix use machine learning to analyze past layout data and forecast the most efficient cutting arrangements. Fumao collaborates with AI-integrated partners to help clients reduce consumption by up to 18%.

How Much Fabric Should You Order to Minimize Overstock?

Overordering ties up capital and storage space. Underordering disrupts production. The solution? Calculate a precision range and negotiate buffer flexibility with your supplier.

Order based on calculated average consumption plus a realistic buffer, and build in a fallback margin based on past consumption variance.

What’s a Safe Buffer Percentage to Include?

Generally, 3–8% is a good range depending on the fabric type and production process. For knits, 5–7% is typical due to shrinkage. For stable wovens, 3–4% may suffice. Review your historical yield reports, and set reorder alerts at 90% utilization.

Sites like Sourcing Journal and Apparel Resources often publish benchmarks across regions.

How Do We Support Buffer Management at Fumao?

We offer clients the option to reserve up to 15% additional rolls per color at no extra deposit for 30 days. This “soft overage” system supports on-demand agility without locking up excess funds. Buyers receive alerts via email or our online dashboard when fabric consumption nears the forecasted threshold.

Conclusion

Accurate fabric consumption calculation isn’t just a technical skill—it’s a strategic advantage. With the right data, formulas, and software, you can avoid costly overages, reduce waste, and streamline production. At Fumao Fabric, we support cost-efficient ordering through shrinkage-tested fabrics, digital sample tracking, and integrated planning tools. Whether you’re sourcing for fast fashion, activewear, or premium lines, our team ensures you only pay for what you truly need—without sacrificing delivery speed or quality.