You've just received the pre-production samples. The stitching is off, the color doesn't match your Pantone, and the promised delivery date is now "maybe next month." You're 8,000 miles away, and the only response you get is "no problem, we fix." Sounds familiar? For Western brands sourcing apparel from China, this frustration often stems from a broken trust dynamic, not just bad luck. In a relationship where you can't walk the factory floor daily, how do you transform a transactional vendor into a true, trusted partner who protects your quality, timeline, and brand as if it were their own?

Building trust with a B2B garment supplier in China is a strategic process, not a single action. It requires moving beyond price-centric negotiations to establish mutual respect, professional transparency, and shared long-term goals. Trust is built on four pillars: clear and professional communication, demonstrable commitment to quality systems, fair and transparent financial dealings, and a partnership mindset that values stability over short-term gain. This isn't about making friends; it's about creating a business relationship so robust that both parties are invested in each other's success.

Think of it as constructing a bridge. You start with a solid foundation of due diligence, erect pillars of consistent processes, and pave the roadway with reliable results. The supplier on the other side must be building their half too. When done right, this bridge allows your designs to flow smoothly into production and finished goods to flow reliably to your warehouse, year after year, regardless of market volatility.

So, what are the actionable steps to lay this foundation? How do you communicate effectively across cultural and linguistic divides? And what behaviors signal to a supplier that you're a client worth going the extra mile for? Let's build that bridge, one strategic beam at a time.

Foundation First: Due Diligence and Strategic Onboarding

You cannot build trust on a shaky foundation. The first and most critical step happens before you place your first order: comprehensive due diligence. Rushing to production with the first supplier that gives you a cheap quote is the number one reason relationships fail. Trust must be earned from both sides, and your initial investigation shows the supplier you are serious, professional, and not a risky client.

This means moving beyond Alibaba storefronts. Conduct video factory tours, ask for and actually contact past client references (especially long-term Western clients), verify business licenses, and check for relevant industry certifications (like BSCI, ISO9001, or specific technical certifications for your product type). A professional supplier will welcome this scrutiny; it signals you are a legitimate partner.

This foundational work sets the tone. Let's focus on two high-impact actions that separate amateurs from professionals.

Why is a Virtual Factory Tour Non-Negotiable?

A virtual tour is your eyes on the ground. It's not about seeing shiny machinery; it's about assessing operational integrity. You want to see: Is the factory floor organized? Are workers using proper equipment? How is fabric stored? Is there a dedicated QC area? During a tour with a potential partner in Keqiao in early 2023, we noticed their fabric rolls were stored directly on a damp floor—a red flag for moisture damage they hadn't considered. We pointed it out, and they implemented racks immediately. This showed them we cared about the product's outcome, not just the price. More than that, it established our expertise. As a fabric supplier ourselves at Shanghai Fumao, we often facilitate these insights for our clients who are garment factories, emphasizing that evaluating production environment and workflow during a remote audit is as crucial as checking certificates.

How Should You Evaluate a Supplier's Response to Your Tech Pack?

Don't just send your tech pack and ask for a quote. Use it as a test. A trustworthy supplier will respond with intelligent questions: "For the seam strength you require, have you considered a different stitch density?" or "The fabric weight you specified may not achieve the drape in your sketch; here is an alternative suggestion." This demonstrates technical expertise and engagement. If the only response is a price and MOQ, proceed with caution. We advise our clients to include a "trap question"—a deliberate, subtle error in the spec—to see if the factory catches it. A partner who catches it earns immediate points. This process, akin to strategies discussed in forums on technical vetting for apparel manufacturers, filters out order-takers from problem-solvers.

The Pillar of Professional Communication & Process

Once the foundation is set, the first pillar you build is communication. In cross-cultural B2B, "clear" communication isn't just about English proficiency; it's about establishing structured, predictable processes that eliminate ambiguity. Trust is built when both parties know exactly what to expect and when.

Implement a standardized communication protocol. Agree on primary channels (e.g., email for official approvals, WeChat/WhatsApp for quick updates), set weekly standing meeting times, and designate single points of contact on both sides for technical and commercial issues. Most importantly, document everything. All sample approvals, change requests, and deadline agreements must be confirmed in writing (email). This isn't about distrust; it's about creating a shared, unambiguous record.

Structured communication prevents 80% of disputes. Let's operationalize it.

What Should Be in Your Weekly Status Update Template?

A simple, shared spreadsheet or form can work wonders. Key columns should include: Style Number, Current Stage (e.g., Fabric Sourcing, Pattern Grading, Sample Sewing), Next Milestone, Target Date, Issues/Blockers, and Actions Required (and from whom). This becomes the single source of truth. For instance, a UK menswear brand we work with shares a Google Sheet with us. If we, as their fabric supplier, see the "Fabric Delivery" status is green, but their "Cutting Start" date is red and flagged, we can proactively check if there's a logistics issue we can help solve. This transforms the relationship from "vendor-client" to "co-pilot." Adopting such project management frameworks for fashion production minimizes surprises and builds immense confidence.

How to Handle Bad News Constructively?

Things will go wrong. A fabric shipment is delayed, a dye lot is inconsistent. How you, as the client, react to bad news is a massive trust-builder. Blaming and issuing threats destroys the relationship. The professional approach is to be solution-oriented: "I understand the fabric is delayed. What is your proposed recovery plan? Can we expedite shipping or adjust the sewing schedule? What support do you need from me?" This shows you are a reasonable partner invested in solving problems, not just assigning blame. We once had a coating process fail for a client's waterproof order. We immediately informed them, presented two alternative solutions with cost/ time implications, and shared the correction timeline. They appreciated the transparency and worked with us on the fix. That client is now one of our largest. This principle of managing supply chain crises with collaborative problem-solving turns crises into trust-building moments.

Demonstrating Commitment to Quality and Investment

Trust cannot exist without consistent quality. But demanding quality is not enough; you must demonstrate your commitment to it through your actions and investments. This shows the supplier that you view quality as a shared responsibility and a long-term investment, not just a stick to beat them with.

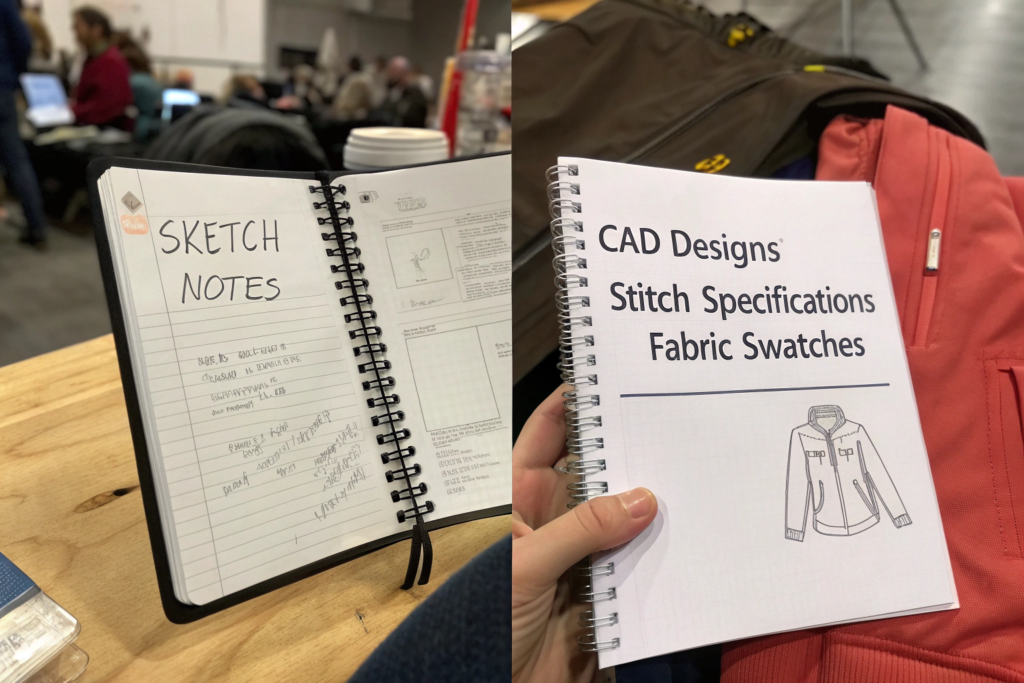

Invest in comprehensive pre-production. This means providing exceptionally clear tech packs with CADs, detailed spec sheets, and approved physical fabric swatches and trim kits. Pay for perfect proto samples and pre-production samples (PP samples). A supplier trusts a client who is willing to spend time and money to get it right upfront, as it drastically reduces the risk of costly bulk errors. It signals you are serious and not cutting corners.

Your approach to quality control is where commitment meets reality.

Is On-Site QC a Trust-Builder or a Trust-Breaker?

Hiring a third-party inspector to show up unannounced can feel adversarial. Instead, frame it as a collaborative safeguard. Discuss your QC plans upfront: "To ensure we are both protected, we will have a third-party perform Final Random Inspection (FRI) before shipment. We will share the AQL standard with you in advance. Let's view this as a final check to catch any issues before the goods leave your control." Better yet, for key milestones, consider joint inspections. We have clients who fly in for the first production batch or do a live video inspection with our QC team. At Shanghai Fumao, we often stream fabric inspection for our clients. This transparency, aligning with best practices for collaborative quality assurance in overseas production, shows you are engaged and fair, not hostile.

How Does Fair Pricing Build Long-Term Quality?

Pushing for the absolute lowest price per unit often forces the factory to cut corners on fabric, labor, or processes to maintain their margin. This erodes quality and trust. Instead, negotiate a fair price that allows the factory to use good materials and pay workers properly. Be open to cost adjustments for genuine material inflation, provided they are documented. A factory that knows you won't squeeze them to the brink is more likely to be honest about challenges and invest in doing the job right. For example, when cotton prices spiked in 2022, we communicated openly with our clients. Those who accepted a modest, justified adjustment are still with us today. Those who refused and chased a cheaper price elsewhere often returned months later after facing quality disasters. Understanding the true cost drivers in garment manufacturing fosters a realistic and trusting partnership.

Cultivating the Partnership Mindset

The final pillar is the mindset shift from "vendor-client" to "strategic partner." This is where you move beyond individual orders and start building a shared future. A partner thinks about your next season, your market challenges, and how to grow together. This is the ultimate expression of trust.

You cultivate this by offering predictability and loyalty. Place repeat orders. Give realistic forecasts so they can plan capacity. Be their reference for new clients. In return, expect priority production slots, support during your peak seasons, and collaborative innovation on cost-saving or quality-improving ideas.

This stage unlocks the highest level of value and resilience.

What Does "Shared Growth" Look Like in Practice?

It means involving them in your development process. Ask for their input on designing for manufacturability (DFM). Can a seam be simplified to reduce cost without affecting look? Could a different fabric yield a similar hand feel at better value? At Shanghai Fumao, some of our most successful fabric developments came from a client's rough idea that our R&D team perfected. We co-owned the development cost. That fabric became a bestseller for them and a new product category for us. This deep collaboration, moving into co-development models for fabric and apparel, is the pinnacle of a trusted B2B relationship.

How to Navigate Annual Agreements Successfully?

A formal annual or seasonal framework agreement is a powerful trust instrument. It should outline agreed pricing mechanisms (e.g., fixed for 6 months, then review based on yarn index), quality standards, payment terms, and communication protocols. It provides stability for both sides. The negotiation of this agreement is a key moment. Be transparent about your volume expectations and flexible on terms that support their operational health. We have such agreements with several EU brands. During the pandemic, when shipping was chaotic, these partnership agreements meant we prioritized their containers and worked together on alternate routes, while spot buyers were left stranded. This mutual commitment, as outlined in resources on structuring strategic supplier framework agreements, is the ultimate safety net.

Conclusion

Building trust with your B2B garment supplier in China is a deliberate journey, not a destination. It requires you to be a professional, communicative, fair, and strategic client, just as you expect your supplier to be professional, transparent, reliable, and quality-focused. By laying a foundation of thorough due diligence, erecting pillars of clear communication and quality commitment, and culminating in a genuine partnership mindset, you construct a bridge that can weather any storm—be it logistical chaos, market inflation, or last-minute design changes.

This bridge turns your supplier from a necessary cost into a competitive advantage. It ensures your samples are right the first time, your production stays on schedule, and your quality remains consistent. In the high-stakes world of global apparel, that trust is your most valuable asset.

Ready to transform your sourcing relationship from transactional anxiety to strategic confidence? Partner with a supplier who understands and values this trust-building journey. At Shanghai Fumao, we operate on these very principles. From our transparent communication and robust quality systems to our fair partnership approach, we are built to be the reliable, long-term fabric partner your brand deserves. Let's build the foundation for your next successful collection together. Contact our Business Director Elaine to start a relationship based on mutual success: elaine@fumaoclothing.com.