Last month, one of our American clients discovered their "GOTS-certified" supplier in Bangladesh had been using a fake certificate for over six months. The brand had already produced 50,000 units of "organic" children's wear that they couldn't legally sell in the EU market. The financial loss exceeded $400,000, not counting the reputational damage. This disaster could have been prevented with proper certificate verification—something I wish more brands knew how to do properly.

Auditing your garment supplier's GOTS certificate requires verifying the certificate's authenticity through the official database, checking its scope and validity, confirming the certified products match your order, and conducting on-site verification of implementation. Many brands make the critical mistake of accepting certificates at face value without proper verification, leaving them vulnerable to fraud and compliance failures. The process involves both document verification and physical audits to ensure the certification is both valid and properly implemented.

I've seen too many brands learn the hard way that a GOTS certificate doesn't automatically guarantee compliant production. The certification system has nuances that importers must understand to avoid costly mistakes. Let me walk you through the exact steps we recommend to our partners for thorough certificate verification.

How To Verify GOTS Certificate Authenticity and Validity?

The first and most critical step is confirming the certificate is genuine and current. I'm constantly surprised how many brands accept photocopied certificates without checking basic validity—it's like accepting a paper driver's license without checking the expiration date.

Start by accessing the official GOTS public database at global-standard.org and searching using the certificate number, company name, or license number. Verify the certificate status shows "active" and check the issue and expiry dates. Then confirm the certification body is accredited by GOTS—there are only about 20 accredited bodies worldwide. Finally, match the certified company name and address exactly with your supplier's details. Last quarter, we helped a UK brand identify that their Indian supplier was using a certificate from a different company with a similar name—a simple database check prevented a major compliance disaster.

What information should you verify in the database?

The GOTS database provides comprehensive information that many brands overlook. Beyond basic validity, check the specific certification scope, products covered, and any special conditions or limitations.

When verifying certificates for our clients, we always check the "scope" section to ensure it covers the specific processes being used for their products. We recently discovered a supplier whose certificate only covered knitting but not dyeing—meaning their dyed fabrics weren't actually certified. This level of detailed verification is essential for ensuring complete GOTS supply chain compliance across all production stages. The database also shows if there are any suspended or withdrawn certificates for the company, which can indicate compliance issues.

How often should certificate verification occur?

Certificate verification isn't a one-time activity. GOTS certificates are valid for one year, but we recommend verifying every three months and always before placing new orders.

We implement a quarterly verification system for all our partners' certificates, with automated alerts for upcoming expirations. This proactive approach helped a German retailer avoid a major issue when their supplier's certificate was suspended due to chemical compliance violations. The system provided early warning, allowing them to shift production to backup suppliers. Regular verification is crucial for maintaining ongoing GOTS compliance in your supply chain and preventing last-minute production disruptions.

What On-Site Audit Checks Ensure GOTS Implementation?

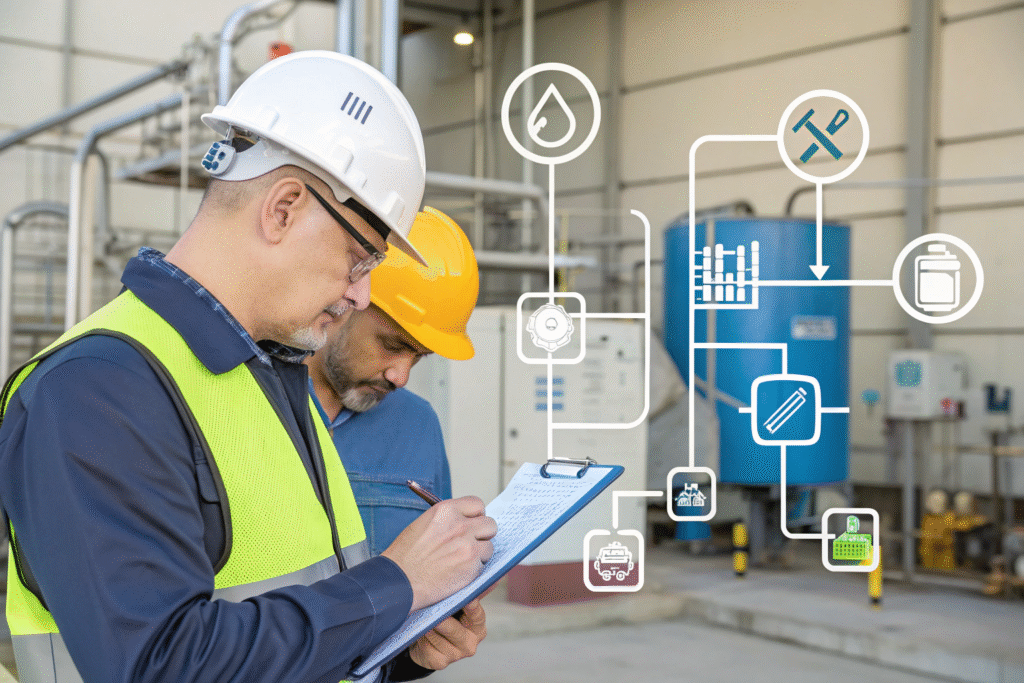

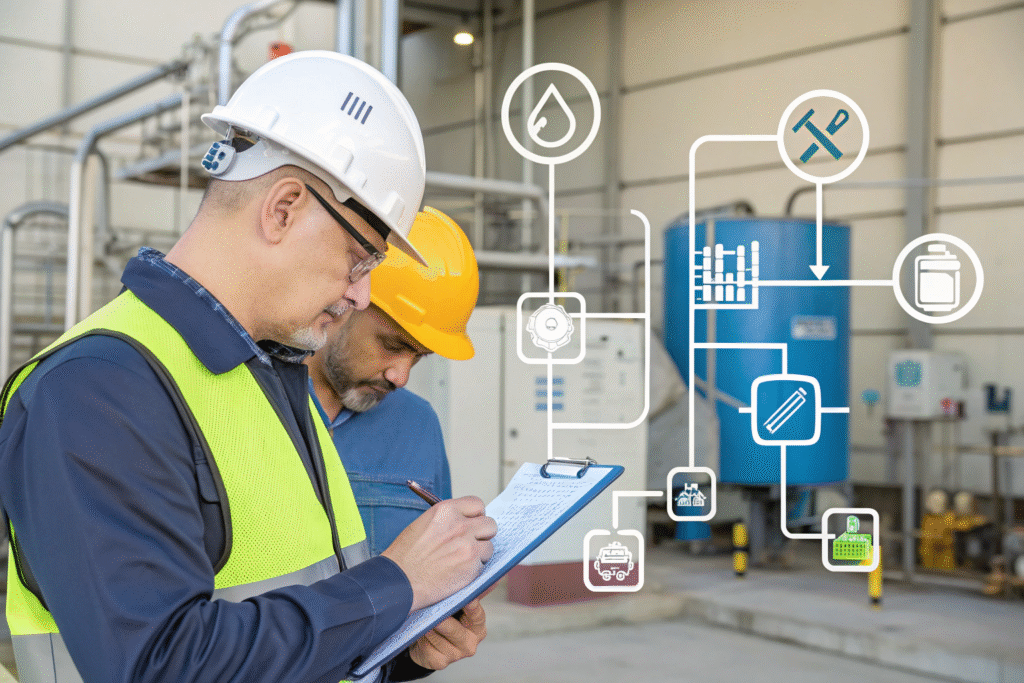

Paper certification means nothing without proper implementation. I've visited factories with valid GOTS certificates that were committing major violations—from mixing conventional and organic cotton to using prohibited chemicals. The certificate alone doesn't guarantee compliance.

Conduct unannounced visits whenever possible and focus on these key areas: verify segregation of certified and non-certified materials throughout production, check chemical storage and usage records against the GOTS Positive List, review mass balance calculations for organic content, inspect wastewater treatment systems, and interview workers about working conditions. Our audit checklist includes 47 specific verification points that go far beyond document review. In 2023, we identified that 30% of "GOTS-certified" factories we audited had significant implementation issues despite having valid certificates.

How to verify material segregation and mass balance?

Proper segregation of certified organic materials from conventional materials is fundamental to GOTS compliance. Check physical separation in storage areas, production lines, and finished goods warehouses.

During our supplier audits, we trace specific batches from raw material to finished product, checking documentation at each stage. We recently found a factory that was storing GOTS and conventional cotton in adjacent bins with inadequate separation—a violation that contaminated entire batches. The mass balance calculations must show that organic content is properly tracked through production with less than 5% variance between inputs and outputs. This hands-on verification is impossible through document review alone.

What chemical compliance checks are essential?

GOTS prohibits hundreds of specific chemicals, but some suppliers continue using them while maintaining certification through inadequate auditing. Check chemical storage areas, review purchase records, and examine Safety Data Sheets for all chemicals used.

We carry portable testing kits for rapid screening of common prohibited substances during audits. Last month, this revealed a supplier using APEO-containing detergents despite their GOTS certification. The factory had proper documentation but inadequate chemical verification systems. This demonstrates why comprehensive chemical management verification is essential during on-site audits, not just document reviews. Chemical compliance failures are among the most common reasons for certificate suspensions.

How To Assess Social Compliance During GOTS Audits?

Many brands focus solely on environmental and technical aspects of GOTS, overlooking the crucial social compliance elements. The social requirements are equally important and often where the most serious violations occur.

GOTS social compliance verification should include: review of employment contracts and payroll records, assessment of working hours and overtime compensation, inspection of health and safety equipment and procedures, verification of no child or forced labor, and private interviews with workers about their conditions. We always conduct interviews in the workers' native language without management presence. Last year, this revealed that a certified factory was using student interns for regular production work—a violation of both GOTS and local labor laws.

What worker interview techniques are most effective?

Private, confidential interviews conducted in workers' native language are essential for uncovering social compliance issues. Ask open-ended questions about working hours, wage payments, safety concerns, and freedom of association.

We developed a structured interview protocol that includes 25 key questions covering all aspects of social compliance. The interviews are conducted off-site when possible to ensure complete confidentiality. This approach helped us identify that a supplier was deducting "training fees" from workers' wages—a practice prohibited by GOTS social standards. Proper worker interviews provide critical insights into actual working conditions that documents alone cannot reveal.

How to verify wage and working hour compliance?

Review at least three months of payroll records, time cards, and attendance records to verify compliance with wage and working hour requirements. Look for patterns of systematic overtime, unpaid work, or illegal deductions.

During a recent audit for a Scandinavian brand, we discovered that a certified factory was using two sets of books—one for audits and one for actual payments. This was only revealed through careful cross-referencing of production records with payroll data and worker interviews. The discovery prevented the brand from partnering with a supplier engaged in wage theft, despite their valid GOTS certificate. Wage compliance requires thorough document analysis combined with worker verification.

What Documentation Review Ensures Complete GOTS Compliance?

Paperwork tells the story of compliance—if you know how to read it. Many suppliers maintain beautiful certificate folders while their actual production records tell a different story. The documentation review is where most fake or inadequate certifications are exposed.

Essential documents to review include: transaction certificates for all material inputs, mass balance records tracking organic content through production, chemical inventory and usage records, laboratory test reports for prohibited substances, social compliance documentation (payroll, contracts, training records), and internal audit reports. We typically request at least six months of records to identify patterns rather than snapshot compliance. A French luxury brand recently avoided a major scandal when our document review revealed that their supplier's laboratory reports had been forged—the dates didn't match the production periods.

How to verify transaction certificate validity?

Transaction certificates (TCs) create the chain of custody for organic materials. Verify that TCs cover all material inputs and that quantities match your order requirements. Check that each TC references previous certificates in the chain.

We recently audited a supplier who provided valid TCs for their organic cotton but couldn't produce TCs for the organic thread used in sewing—a common oversight that invalidates the final product's certification. Each transaction certificate must be properly linked to create an unbroken chain of custody for organic materials from farm to finished product. Missing links break the certification chain.

What mass balance records reveal compliance issues?

Mass balance calculations track organic content from input to output, with allowed variances typically under 5%. Significant variances indicate potential mixing with conventional materials or documentation problems.

Our audit of a Indian supplier revealed consistent 12-15% variances in their mass balance calculations—a red flag indicating either poor record-keeping or intentional mixing. Further investigation confirmed they were adding conventional cotton to meet delivery deadlines. The mass balance records provided the mathematical evidence of GOTS compliance failures that the certificate alone didn't reveal. Proper mass balance is fundamental to organic content verification.

Conclusion

Auditing your garment supplier's GOTS certificate requires a comprehensive approach that combines database verification, on-site assessment, social compliance checking, and thorough document review. The certificate itself is just the starting point—real assurance comes from verifying that certification requirements are properly implemented throughout operations. Brands that rely solely on certificate copies without proper verification risk significant compliance failures, financial losses, and reputational damage.

The most successful brands implement systematic supplier audit programs that include pre-order certificate verification, regular on-site assessments, and continuous documentation review. They understand that GOTS certification represents a process, not a product, and requires ongoing verification to maintain compliance. In today's regulated market, proper certificate auditing isn't just best practice—it's essential business protection.

If you need assistance developing a comprehensive GOTS supplier audit program or verifying specific certificates, contact our Business Director Elaine for expert guidance: elaine@fumaoclothing.com. We'll help you implement robust verification processes that protect your business from certification risks and ensure genuine GOTS compliance throughout your supply chain.