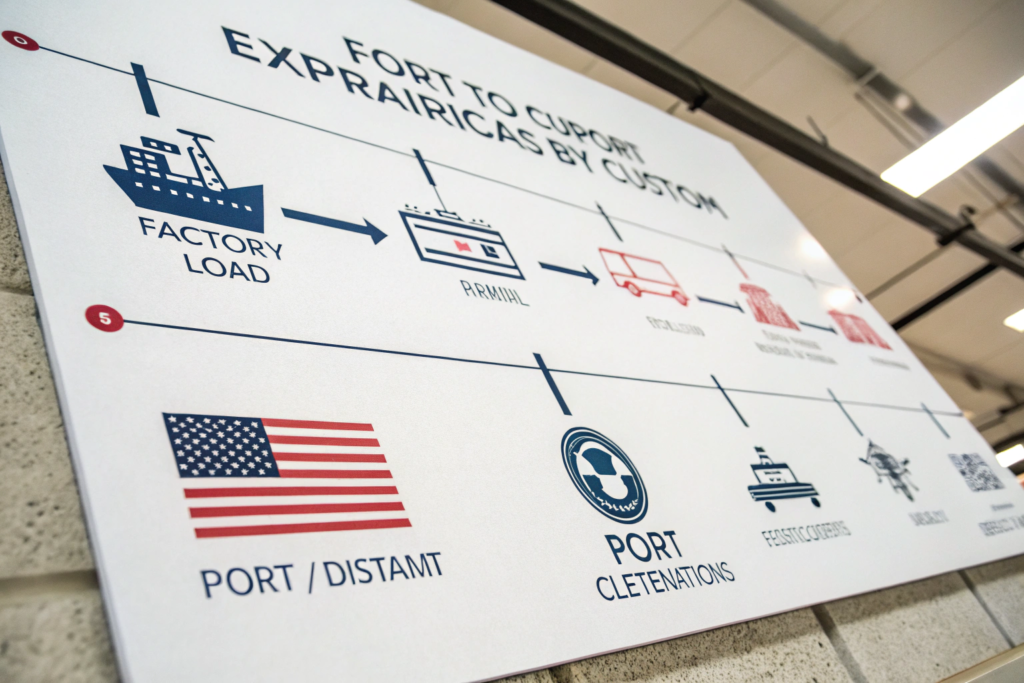

You’ve just approved the final pre-production sample. Your fabric is ready at the factory in Keqiao. Now, the real clock starts ticking: how long until it arrives at your warehouse in Los Angeles or New York? In 2026, this question has more layers than ever. It’s not just about distance; it’s about geopolitics, trade lanes, seasonal surges, and the hidden “invisible” time you never planned for. I recently had a client who budgeted 30 days for sea freight from Ningbo to Long Beach. The ship sailed on time, but their container sat at the destination port for 18 days waiting for chassis and truckers—a delay that wasn’t in any transit time calculator. Their entire production schedule collapsed.

So, how long does shipping fabric from China to the USA really take in 2026? The honest answer is a range: sea freight can take 25 to 55+ days door-to-door, while air freight can take 5 to 10 days. But quoting these numbers without context is useless. The real timeline is determined by your choice of shipping terms (FOB vs. EXW), the specific port pair and service level, the time of year you ship, and your preparedness for customs clearance. In 2026, with continued pressure on global logistics and evolving trade policies, understanding these variables is not optional—it’s critical for survival.

Let’s pull back the curtain on the shipping process. I’ll walk you through the current realities, the seasonal traps, and the strategic choices that will determine whether your fabric arrives as a strategic asset or a costly bottleneck.

Sea Freight vs. Air Freight: What Are the Real Timelines in 2026?

This is the fundamental trade-off: cost versus time. In 2026, the gap between the fastest sea option and the slowest air option is still vast, but the "sea" category has splintered into different services with wildly different speeds and reliabilities. A client shipping trendy spring fabrics in February simply cannot afford a 50-day sea journey; they must air freight. Another client importing basic canvas for year-round product can save 75% on freight and plan around sea schedules. The choice dictates your entire cash flow and inventory model.

What are the door-to-door timelines for different ocean services?

Forget “port-to-port” times. You need to plan from your supplier’s factory door to your receiving dock. Here’s the 2026 breakdown for a standard 40-foot container (40HQ) from a Keqiao factory to a Los Angeles warehouse:

| Service Type | Port-to-Port (Ningbo to LA/LB) | Typical Door-to-Door Timeline | Key Characteristics |

|---|---|---|---|

| Standard Ocean (Slow Steaming) | 18 - 22 days | 35 - 45 days | The baseline. Most common, least expensive. Subject to port congestion and rollovers (being bumped to a later ship). |

| Premium Ocean / Expedited | 14 - 16 days | 25 - 35 days | Guaranteed space on faster vessels, priority loading/unloading. Costs 15-30% more. Crucial for tight deadlines. |

| Sea-Air Intermodal | Varies | 18 - 25 days | Ships to a hub like Seoul/Incheon or Vancouver, then flies to USA. Cost and time are between pure sea and pure air. |

The Invisible Time: This “door-to-door” range includes:

- Pre-carriage: 2-5 days for truck from factory to Chinese port, customs export clearance, and waiting for vessel.

- Post-carriage: 7-14+ days for US customs clearance, drayage (port to local warehouse), and inland trucking. This is where unpredictable delays now lurk. Planning resources like updated guides on China-US shipping timelines and costs are invaluable.

When does air freight make financial sense for fabric?

Air freight is not just for emergencies. Run the math for high-value, low-volume, or time-sensitive fabrics. For example:

- Small Batches & Samples: Air shipping a 100kg roll of luxury silk for sampling and quick production is a no-brainer.

- Avoiding Obsolescence: Shipping fast-fashion jersey by air for a specific, short-lived trend can mean selling at full price versus being marked down later.

- When Sea Cost Savings Are Eaten by Delay: If a 15-day sea delay causes a missed production window and $10,000 in factory idle time, the extra $5,000 for air freight suddenly looks cheap.

A rule of thumb we use at Shanghai Fumao: if your fabric value is over $30/kg and your retail margin is high, air freight is a serious option. For a New York designer in October 2025, we air-freighted 500kg of a unique embroidered velvet. The $8,000 freight bill was 20% of the fabric cost, but it allowed them to launch for Black Friday, generating over $200,000 in sales they would have otherwise missed.

How Do Peak Seasons and Port Congestion Impact Shipping in 2026?

If you ship at the wrong time, you can easily double your expected transit time. The global supply chain has predictable “heart attack” periods. Shipping is seasonal, and in 2026, this seasonality is sharper than ever due to concentrated demand around key shopping events and manufacturing cycles. The pre-Chinese New Year rush is the classic example, but there are others that catch importers off guard.

What are the absolute worst times to ship from China?

Mark these red zones on your 2026 calendar:

- The 5-7 Weeks Before Chinese New Year (CNY): Late December 2025 through January 2026. Factories rush to ship everything before the holiday shutdown. This creates a massive surge. Vessels are overbooked, rates spike, and containers get “rolled” (left behind). You must have your cargo ready to ship at least 6-8 weeks before CNY to secure space.

- The Peak Season (August – October): This is the rush for Christmas and Black Friday inventory. All importers are competing for space. Congestion at US West Coast ports (like LA/Long Beach) historically builds during this period. Transit times can stretch by 10-15 days.

- The Week After Chinese New Year: Factories reopen, but logistics are restarting. Trucking and port labor may not be at full capacity immediately, causing initial delays.

The antidote? Ship during the troughs: June-July and November-December (for non-holiday goods) often have better rates and faster, more reliable transit times.

How can you mitigate port congestion and rail delays?

Congestion has shifted from ships waiting offshore to land-side logjams. Your container might arrive on time, but then get stuck. Key strategies:

- Diversify Your Port of Entry: Don’t default to LA/Long Beach for all West Coast goods. Consider Tacoma, Seattle, or Oakland. For East Coast, consider Savannah, Charleston, or Norfolk via the Panama Canal. This spreads your risk.

- Use Premium Inland Services: If shipping to the Midwest, paying for a premium rail service from the West Coast can be worth it. Standard rail can be a bottleneck.

- Have a “Drayage Partner” Lined Up: Don’t wait until your ship arrives. Pre-arrange the trucking company that will take the container from the port to your warehouse. This is a step many importers leave to the last minute, causing demurrage and detention fees. Proactively understanding current drayage and chassis shortage issues at your target port is critical.

What Are the Hidden Steps in the Shipping Process That Add Time?

The voyage is just the middle act. The prologue and epilogue are where timelines silently expand. As an exporter, we see importers constantly underestimate the time needed for documentation, compliance checks, and final-mile logistics. These steps aren't delays; they are the process. Ignoring them is like planning a cross-country drive but forgetting to account for gas stops.

How long does export clearance and loading really take in China?

From the moment your fabric is packed at the factory, count on 5-10 days before it’s even on the water.

- Trucking to Port (1-3 days): From inland like Keqiao to Shanghai/Ningbo.

- Export Customs Declaration (1-2 days): Your forwarder submits the manifest. This is usually smooth but requires perfect documentation (Commercial Invoice, Packing List, etc.).

- Terminal Handling & “Cut-off” (3-5 days): The container must be gated into the terminal before the vessel’s “cut-off” date (often 3-5 days before sailing). Then it’s stacked, loaded, and the ship departs.

Pro Tip: Work with a supplier who handles this professionally. At Shanghai Fumao, we have a dedicated logistics team that manages this process end-to-end, ensuring documentation is accurate and submitted early to avoid last-minute holds.

What determines US customs clearance time, and how can you speed it up?

US Customs and Border Protection (CBP) clearance can be a 48-hour process or a 2-week nightmare. It depends on:

- Accurate and Complete Documentation: The #1 cause of delay. Your Commercial Invoice must precisely match your Packing List and Bill of Lading. Fabric descriptions, weights, and values must be consistent.

- Your Fabric’s HTSUS Code: Is it correct? Using an incorrect tariff code can trigger a manual review or audit. For example, a woven polyester fabric for apparel (HTS 5407.61) is different from a knitted one (HTS 6005.39).

- Whether You Are a “Trusted Trader”: If you are certified under CBP’s Customs-Trade Partnership Against Terrorism (CTPAT), your shipments get “green lane” treatment with fewer exams.

- Random Inspections: Sometimes it’s just luck. A USDA inspection for plant-based fibers (like cotton or linen) can add several days.

To speed it up, hire a experienced US customs broker and provide them with perfect documents before the ship arrives. They can pre-file and resolve issues in advance. Resources like the CBP's official guide to importing basics are essential reading.

What Incoterms and Logistics Partners Should You Choose in 2026?

The shipping terms you agree on with your supplier (the Incoterms® 2020 rules) define who is responsible—and who pays—for each leg of the journey. This isn’t just about cost; it’s about control and visibility. In 2026, with supply chain volatility, maintaining control over the logistics chain is a major advantage. Choosing the wrong term can leave you powerless when delays happen.

FOB vs. EXW vs. DDP: Which gives you the best balance of control and cost?

- EXW (Ex Works): You take control at the supplier’s factory door. You arrange and pay for ALL transportation, China export formalities, and ocean freight. Most risk, most work, but potential for lower cost if you are a large, sophisticated importer. Not recommended for beginners.

- FOB (Free On Board): The standard and recommended choice for most importers. The supplier’s responsibility ends once the goods are loaded on the ship at the Chinese port. You take over from there: ocean freight, insurance, US import. This gives you control to choose your own freight forwarder and negotiate rates for the main ocean leg while the supplier handles the complex local Chinese logistics.

- DDP (Delivered Duty Paid): The supplier arranges and pays for everything door-to-door, including US customs duties. This is the easiest but most expensive option. You lose visibility and control. The supplier marks up every step. Only use this for small, simple shipments where convenience trumps all else.

How to select a reliable freight forwarder in 2026?

Your forwarder is your quarterback. Don’t just pick the cheapest quote.

- Look for Specialization: Find a forwarder with strong textile/apparel experience. They understand fabric classifications, quota categories (if any), and common inspection triggers.

- Demand Tech & Visibility: They should provide a real-time online dashboard for tracking, not just sporadic email updates.

- Check Their Network: Do they have strong partnerships with drayage companies at your destination port? Can they handle issues on the ground?

- Get References: Ask for references from other similar-sized importers in your industry.

A good forwarder is worth their fee. They will alert you to potential problems before they become crises. For a client in Chicago last year, our recommended forwarder spotted a looming rail strike and re-routed their container via all-water to the East Coast, adding a week to transit but avoiding a potential 3-week rail delay.

Conclusion

Shipping fabric from China to the USA in 2026 is a complex equation with variables you can and cannot control. The baseline transit time is just the starting point. Your final door-to-door timeline will be shaped by your strategic choices: sea vs. air, shipping season, port of entry, Incoterms, and partner selection. The key to success is planning for the range, not the average. Build at least a 10-15 day buffer into your production schedule for sea freight, and always have your US customs clearance pre-arranged.

Proactive importers treat logistics as a core competency, not a back-office task. They use trough seasons to their advantage, diversify their routes, and partner with experts both in China and the USA. This approach turns a potential bottleneck into a reliable, predictable part of the supply chain.

If managing this complexity feels daunting, you don’t have to do it alone. At Shanghai Fumao, our logistics team integrates seamlessly with our fabric production, offering expert-guided FOB or even DDP services. We handle the China side with precision, coordinate with vetted forwarders, and ensure you have full visibility every step of the way. To discuss a shipping strategy that aligns with your production calendar and risk tolerance, contact our Business Director, Elaine. Let us help you ensure your fabric arrives on time, every time. Email: elaine@fumaoclothing.com.