If you're sourcing men's wear fabrics and feel like you're navigating through endless technical jargon and vague promises, you're not alone. Many suppliers present certificates as mere paperwork—static documents filled with generic terms that don't translate to the real-world performance of a suit, shirt, or pair of trousers. The frustration peaks when the fabric that passed a lab test fails on the cutting table or in the customer's hands. So, what makes our certification different? It acts not as a simple stamp of approval, but as a dynamic, comprehensive blueprint that precisely details the exact specifications and performance benchmarks for every meter of men's wear fabric we produce.

Our Certificates of Analysis (CoA) and Compliance are living documents engineered for action. They go far beyond stating "100% Wool" or "Colorfast." For men's wear—where drape, durability, and consistency are non-negotiable—our certificates provide a granular breakdown of over 20 critical parameters, from pilling resistance and tensile strength specific to trouser seams to dimensional stability under steam pressing for suit linings. This level of detail transforms the certificate from a filing cabinet item into the single source of truth for your designers, pattern makers, and quality controllers, ensuring that what you engineer in your tech pack is exactly what arrives on your production floor.

Let me be direct: in men's wear, a vague certificate is a liability. A 2% variance in shrinkage can ruin the clean lines of a dress shirt. An unreported stiffness in a wool blend can affect the drape of a blazer. We've built our documentation to eliminate these risks. Rooted in our CNAS-accredited lab, every certificate is a fingerprint of the specific production batch, offering traceability and accountability that standard industry documents simply can't match. This is how we bridge the gap between Asian manufacturing specs and the exacting standards of global men's fashion brands.

What Specific Men's Wear Performance Metrics Are Detailed?

For men's wear, performance is king. The certificate is where promises become measurable data. We don't just test for generic standards; we test for the specific stresses men's garments endure. This means our certificates detail metrics that directly correlate to garment construction and end-use. Think about a suit jacket's elbow, a shirt's collar, or chino's knee—each area has unique demands. Our lab simulates these conditions and records the results in clear, quantifiable terms on the certificate, giving you the confidence to specify fabrics for specific applications.

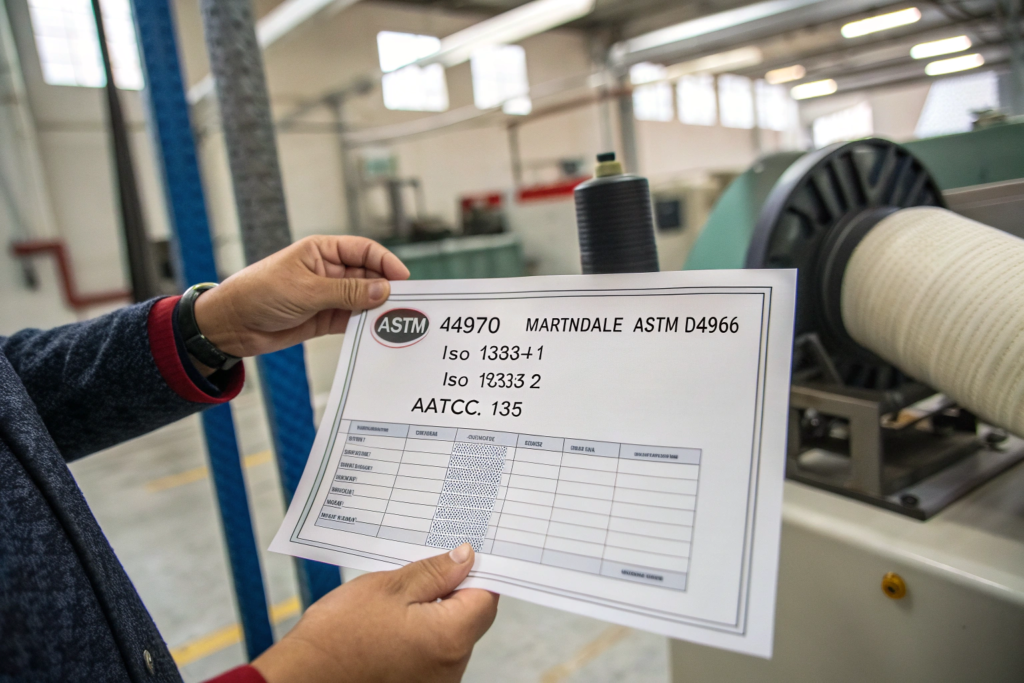

The certificate becomes a predictive tool. By reviewing the pilling resistance (ASTM D4970) and abrasion resistance (Martindale, ASTM D4966) grades, you can forecast how a wool blend will hold up in a high-friction area like a suit seat. The tensile and tear strength numbers (ISO 13934-1, ISO 13937-2) tell your production manager if the fabric can withstand the tension of automated sewing without yarn slippage. For formal shirts, the certificate meticulously lists dimensional change after washing and ironing (AATCC 135), crucial for maintaining a precise fit. This isn't just data; it's actionable intelligence for your entire supply chain.

How Are Durability Tests Tailored for Different Garment Types?

The certificate differentiates tests based on the end garment. For worsted wool suiting, we emphasize:

- Seam Slippage (ASTM D434): Critical for trouser crotch and jacket shoulder seams. We report the force required to cause a 6mm gap, ensuring seams hold under stress.

- Drape Coefficient: Measured using a drape meter, this quantifies the fabric's stiffness and fall, predicting how well it will shape to a jacket's canvassing.

For men's dress shirts (poplin, oxford), the focus shifts: - Yarn Count and Thread Density: Precisely listed to verify the fabric's hand and opacity.

- Colorfastness to Perspiration (AATCC 15): Non-negotiable for a garment worn close to skin. We report the specific grey scale rating for both color change and staining.

A client from Germany in 2023 was producing high-end cycling trousers that needed to look like formal wool but perform like stretch technical fabric. Our certificate detailed not only the standard metrics but also the elastic recovery rate (ISO 20932) at specific elongation points (30%, 50%), which was the key data their pattern-making software needed to create the correct block. This level of tailored detail is standard for us. For deeper insight, resources like The Textile Institute's guide to fabric performance testing explain the science behind these metrics.

Why is Dimensional Stability Data So Critical for Men's Tailoring?

In men's wear, fit is everything, and fit is destroyed by shrinkage. A generic "shrinkage <3%" is useless. Our certificate provides a dimensional stability profile. For a wool suit fabric, it details residual shrinkage after:

- Steam Pressing: Simulating industrial fusing and pressing.

- Cold Water Immersion: Accounting for dry cleaning or spotting.

- Multiple Wash Cycles (if applicable): For blended or performance suiting.

Each test reports separate percentages for warp (length) and weft (width). This allows a pattern maker to pre-shrink their digital patterns with precision—for example, adding 1.2% to the length and 0.8% to the width—to achieve a consistently perfect fit across thousands of garments. This data is what separates mass production from precision manufacturing. Industry forums like StyleForum's deep dives on fabric shrinkage highlight how vital this specific data is for bespoke and ready-to-wear alike.

How Does Fiber & Construction Data Guide Design and Costing?

The "Fiber Content" section of a standard certificate is often its most basic part. Ours is a starting point for deep material intelligence. For men's wear, the blend percentage isn't just a label requirement; it dictates hand feel, thermal properties, wrinkle recovery, and cost. Our certificate breaks down not only the primary fibers (e.g., 85% Wool, 15% Polyester) but, upon request, can include data on the wool's micron count (fineness) and the polyester's filament type (semi-dull, bright), which influences the fabric's luster. This precise construction data directly informs your design choices and accurate cost forecasting.

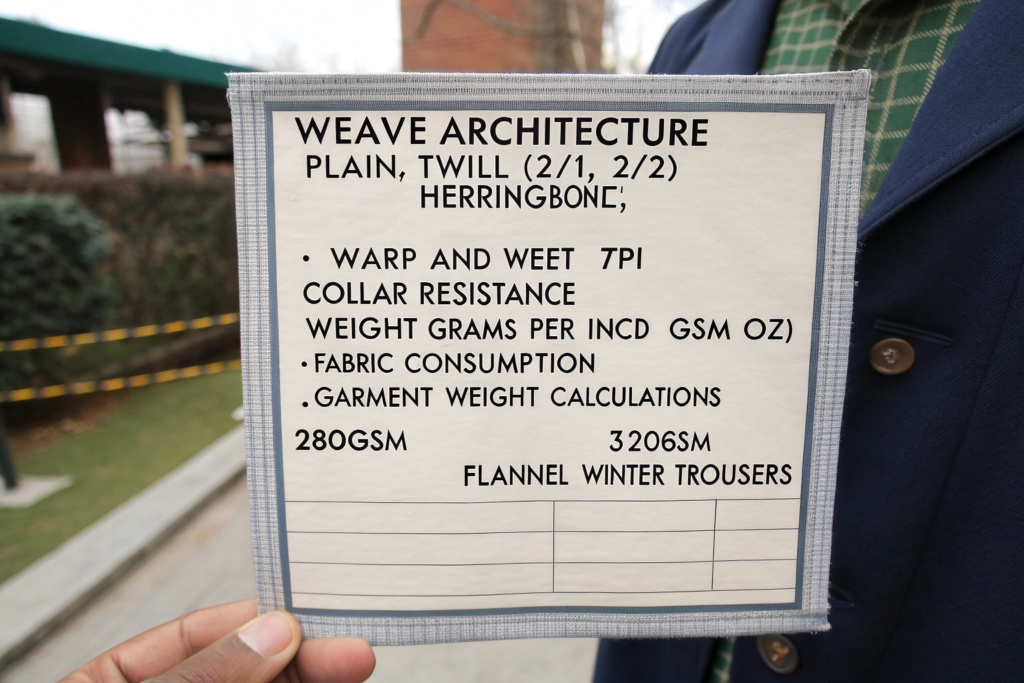

Beyond fiber, the certificate details the fabric architecture. For woven men's wear, this includes:

- Weave Type: Plain, Twill (2/1, 2/2), Herringbone. This affects durability, drape, and visual appeal.

- Threads per Inch (TPI): Separate counts for warp and weft. A higher warp count in a shirt fabric indicates better resistance to collar curling.

- Weight per Unit Area: In grams per square meter (gsm) or ounces per square yard (oz). This isn't an average; it's a verified measurement from the batch, crucial for calculating fabric consumption and final garment weight.

This data allows your team to make informed decisions. Choosing between a 280gsm and a 320gsm flannel for winter trousers? The certificate gives you the factual basis for that choice, impacting both the product brief and the bill of materials.

How Can Construction Data Prevent Production Issues?

Detailed construction data acts as an early warning system. For instance, a certificate showing a lower weft density than specified might indicate a looser weave that could lead to seam grinning or bias distortion during cutting. We flag such variances with notes. In one case for a US client producing structured blazers, our certificate for a super 120s woolen fabric showed a slightly higher-than-expected feltability rating. We included a note recommending a specific interlining weight and fusing temperature to prevent shrinkage during canvassing, preventing a potential production disaster. This proactive use of data saved their batch. Understanding how to read fabric construction specifications is a core skill, and we ensure our certificates are educational tools.

How Does This Data Enable Accurate Fabric Sourcing and Costing?

Accurate data eliminates guesswork in costing. When your procurement team has the exact gsm, width, and fiber blend from our certificate, they can calculate the yardage needed per garment with minimal waste allowance. This precision directly translates to accurate fabric cost per unit. Furthermore, the technical data supports value engineering. If a design calls for a fabric with specific tensile strength, our certificate might show that a slightly different blend ratio achieves the same performance at a lower cost. We act as a partner in this analysis. For broader context on costing, platforms like Maker's Row resources on apparel costing breakdowns demonstrate how foundational precise fabric data is.

What Do the Finish & Colorfastness Details Truly Guarantee?

The "finish" of a men's wear fabric—its hand, luster, and surface character—is what sells it off the rail. Our certificate details the applied finishes (e.g., mercerization for cotton luster, anti-pilling for wool, Teflon® coating for stain resistance) and, crucially, their durability. Colorfastness, however, is where many certificates fall short, offering a simple "pass." Ours provides a matrix of results from a battery of tests, each relevant to a man's daily life. This isn't about passing a minimum standard; it's about documenting performance under real-world conditions that affect garment longevity and customer satisfaction.

We test colorfastness to an exhaustive degree because a fading shirt or a suit discolored by rain is a guaranteed return. Our certificate will clearly list ratings (on a 1-5 scale) for:

- Washing (AATCC 61): For shirting and casual wear.

- Light (AATCC 16): Critical for jackets and trousers that may be exposed to sunlight.

- Rubbing/Crocking (AATCC 8): Both dry and wet, essential for dark indigo denim or black suiting.

- Water (AATCC 107): Simulating rain exposure.

- Chlorinated Pool Water (AATCC 162): For performance or swimwear blends.

Each rating is a guarantee. If the certificate says "Lightfastness: Grade 4," you know that fabric will resist fading significantly longer than one with a Grade 3 rating.

How are Functional Finishes Documented and Verified?

For modern men's wear, functional finishes are common. Our certificate doesn't just state "wrinkle-resistant"; it details the method (e.g., "DMDHEU resin cross-linking") and provides the test results. For a wrinkle-resistant cotton dress shirt fabric, we include:

- Smoothness Appearance (AATCC 124) after multiple home launderings.

- DP Rating (Durable Press Rating) after one and five washes.

Similarly, for an anti-odor finish, we reference the test method (e.g., ISO 20743) and the percentage reduction in bacterial growth against a control fabric. This scientific documentation allows you to make valid marketing claims, backed by third-party-verifiable data from our lab. To understand the scope of these tests, references like The Chemical Finishing of Textiles by W.D. Schindler explain the technologies behind the terms on our certificate.

Why is a Separate Color Standard Deviation Report Important?

Consistency across rolls is paramount in men's wear, where a jacket and trousers are often sold as separates. A standard certificate might only confirm the color matches the initial lab dip. Our system generates an additional Colorimetric Data Report for bulk production. Using a spectrophotometer, we measure the DEcmc (Delta E) value across multiple points in multiple rolls. A low DEcmc value (typically below 1.0) is reported, guaranteeing that the navy in roll #501 is visually indistinguishable from the navy in roll #530 under standard lighting. This prevents the costly nightmare of two-tone suits or mismatched shirt plackets. Discussions on Printing and Dyeing Forums about color tolerance highlight how critical this control is for large orders.

How to Use Our Certificate for QC and Supplier Alignment?

The ultimate value of a detailed certificate is realized when it's actively used as a tool, not filed away. We design our certificates to be the cornerstone of your Quality Control protocol and the unambiguous reference point for communication with all downstream partners—from your garment factory to your logistics provider. By providing a clear, numeric benchmark for every critical attribute, we turn subjective quality disputes ("this fabric feels too stiff") into objective, data-driven conversations ("the drape coefficient measured 0.58, within the 0.55-0.60 range specified").

Here’s how it works in practice: Your QC team in Vietnam receives the fabric shipment alongside the digital certificate. They don't need to guess what to test. They can perform a spot-check on the 3-4 most critical parameters (e.g., shrinkage, color rub, weight) using the exact same test methods listed, and compare their results to our certified numbers. This streamlines inbound QC, speeds up approval, and builds trust in the supply chain. Furthermore, the certificate's batch ID (tied to our QR system) allows full traceability if any issue arises downstream, enabling rapid root-cause analysis.

What Should Your Garment Factory Check Against the Certificate?

We provide a recommended Incoming Fabric QC Checklist derived from the certificate's highlights. For a men's wool overcoat fabric, the checklist would prioritize:

- Verify Weight (gsm): Simple spot check with a GSM cutter.

- Confirm Width: Against the certificate's stated width after relaxing.

- Spot Check Colorfastness to Rubbing: Using a basic crockmeter.

- Visual Inspection for Defects: Using the AQL levels referenced in the certificate.

This focused approach is efficient. In 2024, a client's factory in Bangladesh raised a concern about potential shrinkage in a linen-cotton blend fabric for summer suits. By referring to the certificate's pre-tested dimensional stability data, we were able to resolve the concern within hours, avoiding a production halt, because the data proved the fabric was pre-shrunk. For factories, guidelines from the American Apparel Producers' Network on fabric inspection align with this data-driven method.

How Does the Certificate Facilitate Dispute Resolution?

In international trade, disputes often arise from mismatched expectations. Our detailed certificate acts as a binding technical annex to the commercial contract. If a claim arises that the fabric is "not as specified," the first reference point is the certificate. For example, if a claim is made about pilling, both parties can test a retained sample against the documented ASTM D4970 method and compare the result to the certified Grade 4 rating. This objective framework moves discussions from blame to problem-solving and is a core reason our long-term clients, like Shanghai Fumao, value our partnership. It establishes a clear, professional standard that protects both buyer and supplier. Resources on Fashion Law Blog about quality claim arbitration underscore the importance of such detailed documentation.

Conclusion

A certificate should be a powerful tool, not a piece of bureaucratic trivia. For men's wear production, where precision, durability, and consistency are non-negotiable, our Certificate of Analysis is engineered to provide exactly that: clear, actionable, and verifiable specifications for every critical aspect of your fabric. It translates the complex language of textiles into a reliable blueprint for your designers, a precise guide for your production team, and an objective standard for quality assurance.

In an industry rife with ambiguity, we choose to provide clarity. We believe that trust is built on transparency, and transparency is delivered through data. Our certificates embody this philosophy, ensuring that when you source from us, you're not just buying fabric—you're investing in a documented promise of performance.

Don't let vague specs compromise your next men's wear line. Request a sample and its corresponding detailed Certificate of Analysis from us. See the difference precise documentation makes. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to get started with fabric that is fully specified, fully tested, and fully guaranteed.