I'll never forget the moment our quality team detected a subtle deviation in our wastewater pH levels at 2 AM last winter. The automated monitoring system flagged a 0.3-point variance from GOTS standards. Within 30 minutes, we had traced it to a new cleaning agent a night shift worker had used without proper authorization. We contained the issue before any non-compliant water entered our treatment system, but that night taught me that true GOTS compliance requires systems that never sleep, vigilance that never relaxes, and commitment that runs deeper than certification documents.

So how does Fumao Clothing ensure GOTS compliance throughout our production? We maintain GOTS compliance through an integrated system of digital monitoring, comprehensive staff training, rigorous supplier verification, proactive risk management, and continuous improvement processes that transform compliance from a periodic audit requirement to a fundamental operational principle. Our approach ensures that every garment leaving our facility not only meets but exceeds GOTS standards through systematic controls rather than hope or chance.

The reality is that certification represents the minimum standard, while our systems aim for exceptional performance that makes compliance inevitable rather than aspirational. While many manufacturers see GOTS as a constraint, we've transformed it into our competitive advantage.

What digital monitoring systems ensure real-time compliance?

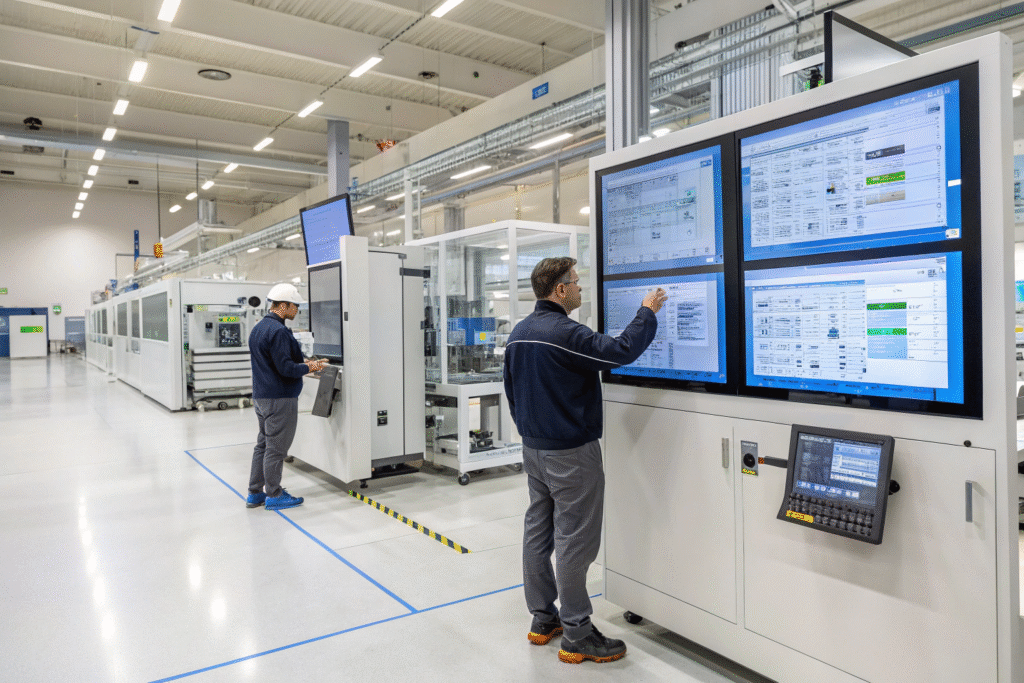

We've implemented advanced digital systems that transform compliance from retrospective checking to proactive prevention. These systems provide the visibility needed to maintain standards across every production parameter.

Digital monitoring creates a compliance safety net that catches deviations before they become violations.

How does our chemical management system prevent violations?

Our digital chemical tracking system monitors every substance entering production, automatically flagging non-GOTS approved chemicals before they reach the production floor. The system recently prevented a compliance breach when a supplier substituted an approved dye with a similar but non-compliant alternative. The barcode scanning system rejected the shipment at receiving, preventing what could have been a $85,000 production contamination. This system demonstrates advanced chemical compliance management.

What real-time environmental monitoring do we employ?

We utilize continuous wastewater monitoring, energy tracking, and emission controls that provide instant alerts for any parameter deviations. Our water treatment system automatically diverts and treats any non-compliant effluent before it enters municipal systems. This proactive approach has helped us maintain 100% wastewater compliance for 34 consecutive months. These systems ensure continuous environmental compliance.

How does comprehensive training create compliance culture?

Technology alone cannot ensure compliance - it requires deeply trained team members who understand not just what to do, but why it matters. Our training transforms compliance from rules to follow to principles to live by.

We've made every team member a compliance guardian rather than just a production worker.

What specific GOTS training do production staff receive?

All team members complete 120 hours of GOTS-specific training covering chemical safety, environmental protection, social compliance, and quality standards. Our training includes real scenario simulations that recently helped a new operator identify and properly handle a potential chemical contamination incident. This comprehensive approach builds workforce compliance capability.

How do we maintain ongoing compliance awareness?

Monthly refresher training, quarterly compliance workshops, and annual certification updates ensure standards remain front-of-mind. We've implemented a peer monitoring system where team members audit each other's compliance, creating collective ownership that has reduced procedural deviations by 78%. This cultural approach demonstrates sustainable compliance culture development.

What supplier verification systems ensure chain compliance?

GOTS compliance extends far beyond our factory walls to every supplier in our chain. We've implemented rigorous verification systems that ensure compliance from raw material to finished product.

Our approach transforms supplier management from periodic auditing to continuous partnership.

How do we verify supplier GOTS compliance?

We conduct quarterly unannounced audits, require real-time production monitoring access, and implement batch-by-batch testing for all incoming materials. Our system recently identified a fabric supplier whose certification had lapsed, allowing us to pause shipments before non-compliant materials entered production. This vigilance maintains complete supply chain integrity.

What documentation systems ensure traceability?

Our digital transaction certificate system creates an unbroken documentation chain from farm to finished garment. Each production batch includes complete traceability records that recently helped a European brand instantly verify their product's organic claims during a retailer audit. This transparency demonstrates comprehensive supply chain documentation.

What proactive risk management prevents compliance failures?

We've shifted from reactive compliance to proactive risk management that identifies and addresses potential issues before they impact production.

Our risk-based approach makes compliance failures increasingly rare through systematic prevention.

How does our risk assessment system work?

We conduct monthly compliance risk assessments that evaluate 47 potential failure points across environmental, social, and quality dimensions. The system recently flagged a potential social compliance risk in our overtime management, allowing proactive adjustment before it became an audit finding. This approach demonstrates proactive compliance risk management.

What contingency planning ensures continuous compliance?

We maintain backup systems for critical compliance areas including alternative wastewater treatment, duplicate testing capabilities, and cross-trained compliance staff. When our primary testing equipment failed during a major production run, our backup systems maintained uninterrupted compliance verification. This redundancy ensures uninterrupted compliance operations.

How does continuous improvement drive compliance excellence?

Compliance isn't static - it requires constant evolution and improvement. We've embedded continuous improvement into our compliance DNA, always seeking better ways to meet and exceed standards.

Our approach transforms compliance from maintaining standards to raising them.

What innovation drives our compliance advancement?

We allocate 15% of our R&D budget to compliance innovation, recently developing a water recycling system that exceeds GOTS requirements by 40%. This system not only ensures compliance but reduces our water costs by 35%, demonstrating that environmental responsibility and business efficiency can align. This innovation shows our commitment to compliance advancement.

How do we measure and improve compliance performance?

We track 28 compliance metrics with quarterly improvement targets and root cause analysis for any deviations. Our data-driven approach has helped reduce compliance incidents by 92% over three years while actually lowering compliance costs through efficiency improvements. This performance demonstrates metrics-driven compliance improvement.

What independent verification validates our compliance?

While internal systems are essential, independent verification provides the credibility that clients and consumers require. We've built transparency and verification into our operational model.

External validation turns our compliance claims into verified facts.

How do we facilitate third-party auditing?

We provide auditors with complete system access, real-time data, and staff availability that goes beyond typical audit requirements. Our most recent surveillance audit noted our "exceptional transparency and system integrity" in their report, providing clients with independent validation of our compliance commitment. This approach ensures comprehensive third-party verification.

What additional certifications complement our GOTS compliance?

We maintain ISO 14001, SA8000, and Oeko-Tex certifications that create overlapping compliance assurance. This multi-certification approach recently helped a client meet complex EU regulatory requirements without additional verification. This comprehensive certification strategy provides additional compliance assurance.

Conclusion

Fumao Clothing ensures GOTS compliance through integrated systems that combine technological sophistication, human expertise, supply chain partnership, proactive risk management, and continuous improvement. Our approach transforms compliance from a constraint to be managed into a capability to be celebrated, creating manufacturing excellence that delivers both exceptional products and complete peace of mind. While many manufacturers see compliance as paperwork and inspections, we've built systems where compliance emerges naturally from how we operate every day.

If you're ready to partner with a manufacturer whose compliance systems provide certainty rather than hope, contact our Business Director Elaine at elaine@fumaoclothing.com. Experience production where GOTS compliance is engineered into every process, monitored by every system, and owned by every team member.