Fiber length is one of the most critical yet overlooked elements in determining a fabric's softness, durability, and resistance to pilling. Whether you're sourcing for luxury loungewear, high-performance sportswear, or durable workwear, understanding how staple length influences textile performance can help you make smarter decisions and improve product longevity.

Why Does Fiber Length Matter in Textile Engineering?

The term "fiber length" usually refers to staple length in natural fibers like cotton, wool, and flax, or filament length in synthetics like polyester and nylon. It directly affects how the yarns are spun and how the final fabric behaves during use and laundering.

What Is the Difference Between Short and Long Staple Fibers?

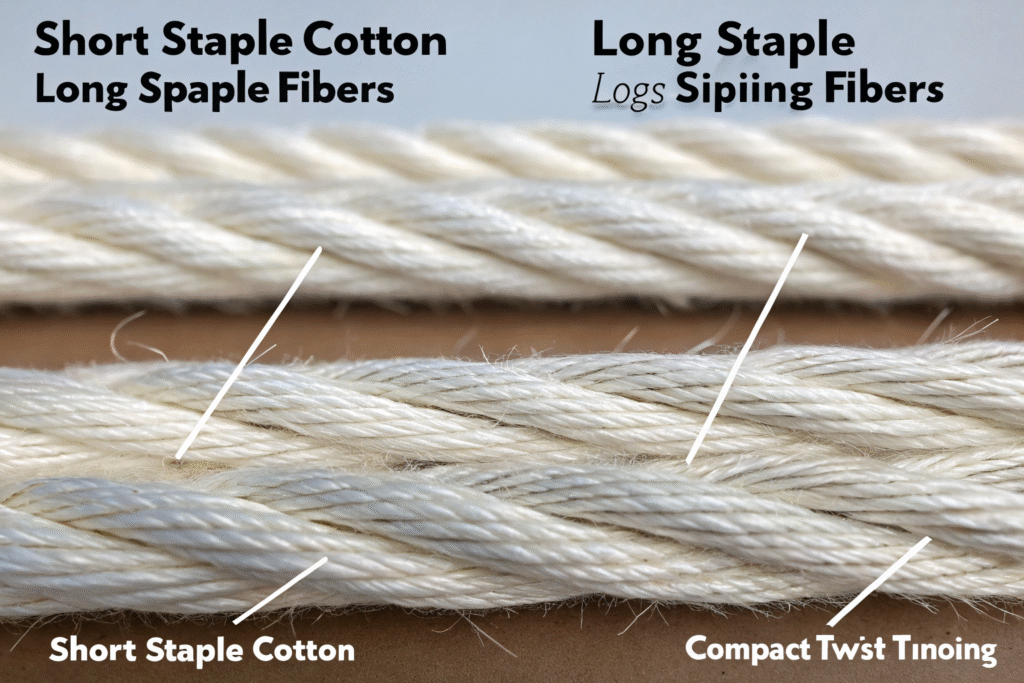

- Short staple fibers (e.g., <21mm cotton, carded wool) are more prone to loose ends sticking out of the yarn. This leads to surface fuzz and pilling.

- Long staple fibers (e.g., Supima cotton, Merino wool >70mm) twist more uniformly, reducing friction points and enhancing softness and strength.

Learn more at CottonWorks’ fiber glossary and IWTO on wool staple grading.

How Does This Impact Yarn Structure?

Shorter fibers:

- Require more twist to hold together, increasing stiffness.

- Shed more microfibers during abrasion.

Longer fibers:

- Yield smoother, tighter yarns with fewer protruding ends.

- Retain shape better after repeated use.

Read technical spinning comparisons at Textile School and Saurer’s Spinning Solutions.

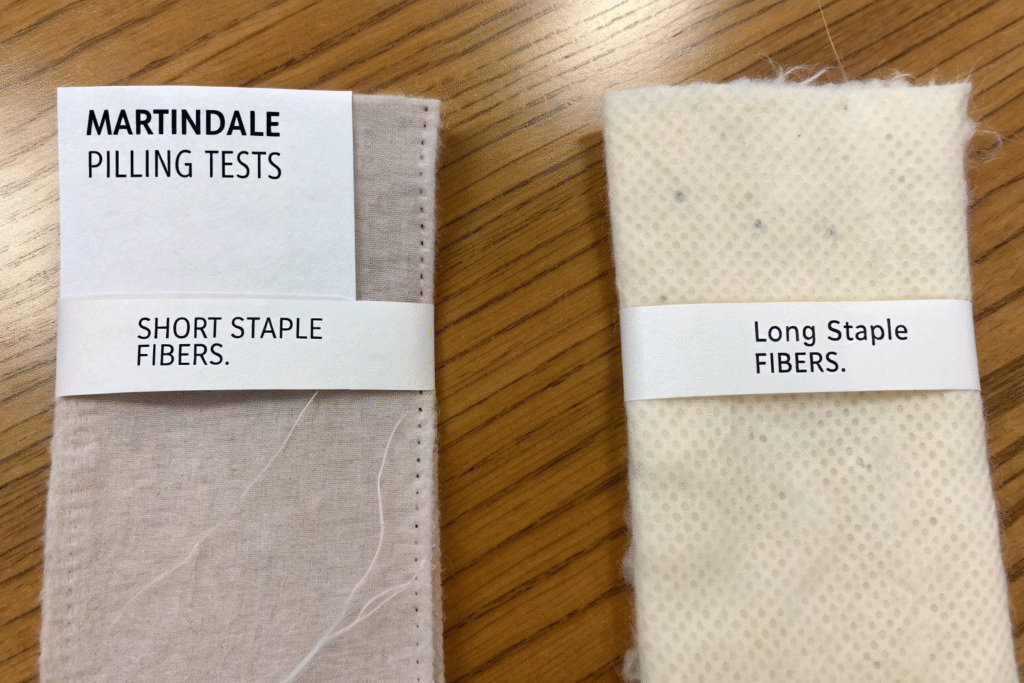

How Does Fiber Length Influence Pilling Resistance?

Pilling is the formation of small fiber balls on the surface of a fabric due to abrasion. While other factors like weave type and fiber blend also affect it, fiber length is a primary contributor.

Why Do Short Fibers Pill More Easily?

Short staple fibers have:

- More exposed ends that break away from yarn during rubbing.

- Weaker cohesion, making it easier for individual fibers to migrate to the surface.

That’s why basic ring-spun cotton T-shirts pill sooner than combed or Supima cotton garments.

Explore ASTM D4970 and ISO 12945 pilling standards at SGS and Intertek.

How Do Synthetic Filaments Compare?

Continuous filament fibers (e.g., filament polyester):

- Have no cut ends, which significantly reduces pilling.

- Are commonly used in anti-pilling fleece and activewear fabrics.

Microfiber filaments, especially below 0.9 denier, also reduce pill size due to limited abrasion surfaces. See comparative test data at The Microfiber Council.

What’s the Relationship Between Fiber Length and Softness?

Softness is not just about touch—it’s how the fiber interacts with skin. Longer fibers contribute to a smoother yarn surface, which reduces irritation and improves comfort, especially in garments worn close to the body.

Why Are Long Staple Fibers Softer?

Longer fibers:

- Create fewer yarn joins and splices.

- Have fewer loose ends, making fabrics less scratchy.

- Result in finer, stronger, and more uniform yarns.

That’s why Egyptian and Pima cottons are prized for high-end sheets and underwear. Supima explains that its extra-long staple fibers create 30% stronger and 45% softer fabrics than regular cotton.

What About Blends and Finishing?

Softness can also be enhanced through:

- Combing (vs. carding) to remove short fibers

- Peach finishes or enzyme washes for cellulosics

- Anti-pilling chemical treatments

For instance, modal-cotton blends leverage long modal filaments to smooth out the short cotton staple base. See Lenzing’s fiber comparison and Albini Group’s softness R&D.

How to Choose the Right Fiber Length for Your Product?

Selecting the right fiber length isn’t just about softness—it’s about the balance between performance, cost, and intended use.

What’s Best for Everyday Apparel?

For T-shirts, leggings, and underwear:

- Aim for combed cotton, Supima cotton, or modal/TENCEL™ blends.

- Look for fabrics tested to ASTM D3512 or ISO 12945 pilling standards.

- Use ring-spun or air-jet yarns with long fibers for smoother feel and longevity.

Sources like Fumao Fabric and Textile Exchange offer sustainable long-staple options with certified performance.

What About for Upholstery or Heavy-Duty Uses?

In workwear and home textiles:

- Blends of long staple cotton and high-tenacity polyester offer durability.

- Core-spun yarns with filament center reduce pilling while maintaining cotton handfeel.

- Favor tight twill or sateen weaves to lock fibers in.

You can find performance-certified fabrics via OEKO-TEX listings and GRS/BCI programs with enhanced staple grading.

Conclusion

Fiber length is foundational to how a fabric looks, feels, and lasts. Longer fibers mean fewer pills, greater softness, and better wear—making them a smart investment for brands that care about quality and sustainability.

At Fumao, we source and develop fabrics using long-staple cotton, modal, and recycled polyester filaments to offer pilling resistance and superior comfort. Whether you’re building premium basics or durable upholstery, understanding fiber length empowers better choices at every step of production.

To request swatches or testing data for our long-fiber fabrics, email our team at elaine@fumaoclothing.com.