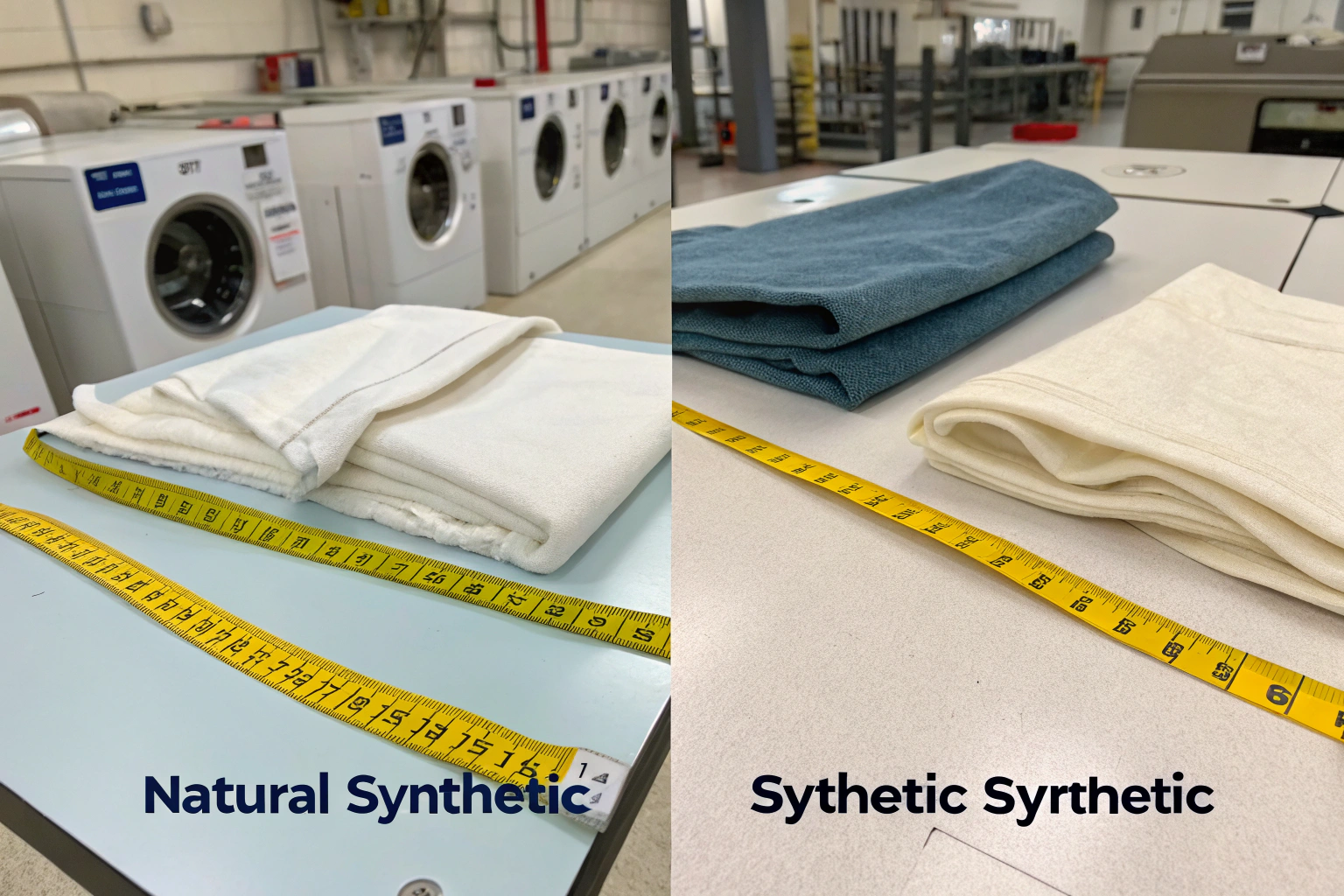

For apparel and textile brands, shrinkage isn’t just a post-wash nuisance—it’s a cost driver, a fit problem, and often a customer complaint waiting to happen. But shrinkage behavior differs dramatically between fiber types, especially when comparing natural vs. synthetic fibers. Understanding this distinction is key to quality control, fabric sourcing, and garment specification writing.

Natural fibers like cotton and wool shrink more noticeably due to moisture absorption and fiber relaxation, while synthetic fibers like polyester and nylon are more dimensionally stable but may still deform under heat.

At Fumao Fabric, we run shrinkage testing as part of our in-house CNAS-accredited quality control process for each production lot. In this article, I’ll break down why fabrics shrink differently based on fiber content, how much shrinkage to expect, and how to manage it effectively.

Why Do Natural Fibers Shrink More After Washing?

Natural fibers are derived from plant or animal sources. That means their internal structure is cellulose- or protein-based, and these polymers absorb water, expand, and then contract when drying—especially under heat.

This hydrophilic behavior causes dimensional changes in the yarn and weave, making natural fabrics prone to mechanical and thermal shrinkage.

What Are the Common Shrinkage Rates?

| Fiber | Shrinkage % (Typical) | Conditions |

|---|---|---|

| Cotton | 3%–10% | Heat + moisture, especially in first wash |

| Wool | 5%–12% | Felting shrinkage under agitation/heat |

| Linen | 4%–7% | Shrinks if not pre-washed |

| Silk | 2%–5% | Delicate shrinkage, usually dry clean only |

Sources: AATCC 135 test standard, Textile Exchange

Why Does Cotton Shrink So Often?

Cotton is made of hydrophilic cellulose chains that absorb water easily. During weaving, the yarns are stretched and under tension. The first wash releases that tension, and the fabric reverts to its natural, shorter state. That’s why pre-shrinking or sanforization is critical.

We offer pre-shrunk and enzyme-washed cotton fabrics for clients in kidswear, underwear, and bedding where dimensional control is essential.

How Do Synthetic Fibers Behave Under Washing?

Synthetic fibers are derived from petrochemicals and have thermoplastic properties, meaning they respond more to heat than moisture. Most synthetic fabrics resist water-based shrinkage but may still deform when exposed to high dryer heat or poor dimensional stabilization during manufacturing.

Polyester, nylon, and acrylic fabrics usually shrink <2% unless exposed to excessive heat or incorrect processing.

What Are Typical Shrinkage Rates for Synthetic Fibers?

| Fiber | Shrinkage % (Typical) | Notes |

|---|---|---|

| Polyester | 0%–2% | Can melt or wrinkle under high heat |

| Nylon | 1%–3% | May shrink slightly with heat |

| Spandex | <1% (but may stretch) | Holds shape unless overexposed to chlorine/heat |

| Acrylic | 2%–4% | May shrink like wool if not stabilized properly |

We supply heat-set polyester knits for activewear and outerwear brands that require high shape retention over dozens of washes.

Do Synthetics Ever Stretch Instead of Shrink?

Yes. Spandex or elastane blends can stretch out with repeated stress if not combined with proper yarn tension and recovery agents. We recommend polyester-spandex interlock knits with high GSM for leggings or compressionwear to avoid bagging.

What Role Does Fabric Construction Play in Shrinkage?

Shrinkage isn’t just about fiber type—it’s about how the yarns are interlaced. Knits, with their looped structures, stretch more but can also shrink more unless stabilized. Wovens, especially tighter weaves, have better dimensional control but still respond to fiber tension and finishing.

Knit fabrics typically show higher shrinkage than woven fabrics due to yarn relaxation and loop contraction.

Which Fabrics Shrink the Most?

- Cotton jersey: Loosely knit, shrinks 5–8% if untreated

- Rayon twill: Weft-dominant, can shrink unevenly

- Wool knits: Prone to felting shrinkage with agitation

Which Fabrics Are Most Stable?

- Polyester poplin

- Nylon interlock knits

- Poly-cotton blends (if heat-set)

At Fumao Fabric, we test both lengthwise and widthwise shrinkage using ISO 6330 and AATCC 135 standards on each batch. We provide digital reports with ±1% tolerance zones for certified buyers.

How Can Shrinkage Be Controlled in Production?

Shrinkage control starts at the mill. To minimize post-purchase surprises, reliable manufacturers must:

- Pre-wash or sanforize natural fabrics

- Heat-set synthetic and blended fabrics

- Test shrinkage in-house using ISO/AATCC methods

- Provide clear shrinkage data in tech packs

Brands should define acceptable shrinkage thresholds and align with fabric suppliers to test and verify each lot.

What’s an Acceptable Shrinkage Limit?

Most brands accept:

- ≤3% length shrinkage

- ≤2% width shrinkage

- Total combined shrinkage under 5%

This is often listed in garment care labels and tech packs. High-stress products like uniforms or kidswear may have stricter thresholds.

Can Finishing Chemicals Help?

Yes. Anti-shrinkage agents, resin coatings, and enzyme finishes are often used—especially in rayon, viscose, and linen blends. These treatments reduce moisture sensitivity and fiber relaxation.

We offer low-formaldehyde resin finishes for buyers in Japan and Europe who need certified shrink resistance with OEKO-TEX® compliance.

Conclusion

Understanding how natural and synthetic fabrics shrink—and why—can save your brand from misaligned seams, poor fit, and unhappy customers. Whether you're using cotton poplin, viscose twill, or polyester interlock, shrinkage control starts with the right material choice and verified mill processes.

At Fumao Fabric, we offer tested, stabilized fabrics across both natural and synthetic categories, ensuring you get consistent performance and dimensional accuracy. Want to reduce returns, increase product life, and simplify garment specs? Contact our Business Director Elaine at elaine@fumaoclothing.com and let’s eliminate fabric shrinkage surprises—before your customers ever notice them.