As a textile professional based in Keqiao for over twenty years, I've seen countless international buyers make the same mistake: they source yarns from one region, weaving from another, and dyeing from a third—then wonder why their lead times stretch to 60-90 days. What they're missing is the incredible efficiency of Keqiao's fully integrated dyeing-weaving-finishing ecosystem that can compress these timelines by up to 60%. Being at the heart of the world's largest textile cluster isn't just about variety; it's about revolutionary speed through vertical integration.

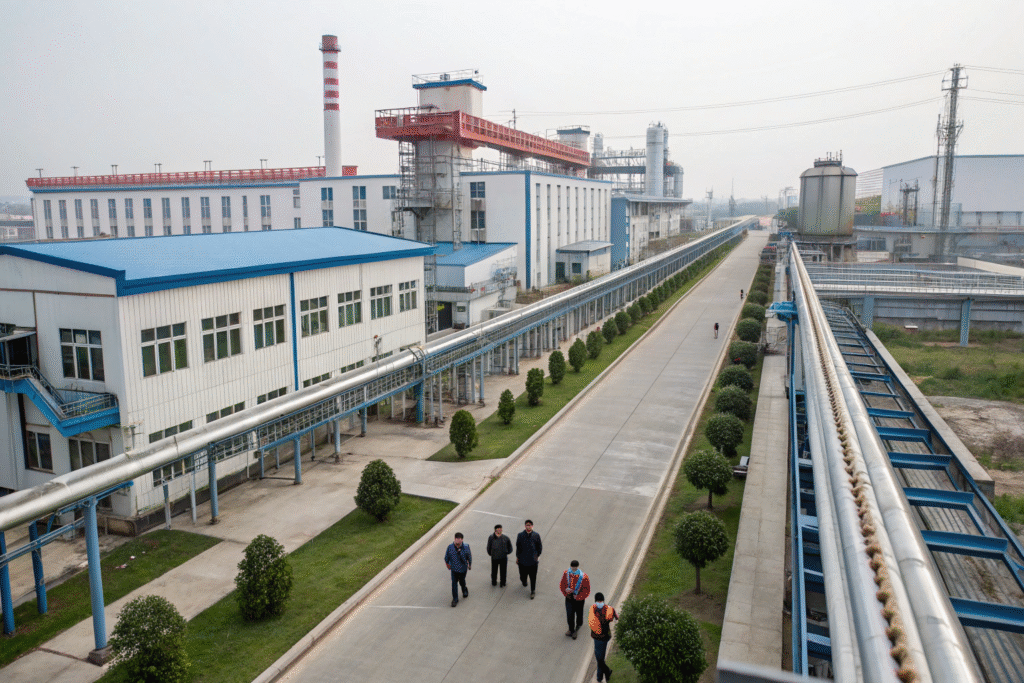

Keqiao's unique advantage lies in its geographic concentration of every textile production stage within a 30-kilometer radius. This means your fabric moves from yarn to finished product in days rather than weeks, with transportation time measured in hours rather than days. The cluster hosts over 80 manufacturers and trades nearly 25% of global textiles, creating an ecosystem where every specialized service is readily available. I've witnessed buyers who previously accepted 75-day lead times achieve 28-day deliveries simply by leveraging our local network properly.

Let me show you exactly how to harness this geographic advantage to accelerate your fabric sourcing.

How does Keqiao's geographic concentration save time?

The time savings begin with physical proximity. When your weaving mill, dyeing facility, and finishing plant are literally neighbors, you eliminate the intercity transportation that typically adds 5-10 days to production cycles. More importantly, you enable real-time communication between production stages that prevents errors and accelerates problem-solving.

In Keqiao, the typical fabric journey looks like this: yarn arrives at weaving mill (same day from local warehouses), woven fabric travels to dyeing facility (2-hour truck ride instead of 3-day interprovincial shipment), and dyed fabric moves to finishing (same industrial park). This compressed logistics chain alone saves 7-12 days compared to multi-location production. Last month, we helped a UK fast-fashion brand execute a 15,000-meter polyester order in 21 days total—something they previously thought impossible—by coordinating three local facilities in a synchronized production dance.

What transportation efficiencies exist within the cluster?

Keqiao's textile cluster operates like a well-choreographed ballet with dedicated textile logistics providers who understand the urgency of fabric transfers between production stages. These specialized transporters move rolls between facilities multiple times daily, treating them as in-process goods rather than finished shipments.

The efficiencies include: dedicated textile trucks with proper handling equipment, simplified documentation (often just transfer slips instead of full shipping documents), and coordinated scheduling that treats your fabric as a continuous workflow. We've reduced between-facility transfer time from 48 hours to just 6 hours by using our preferred local transporters who understand that a dye batch waiting for weaving is losing money every minute. Understanding optimized textile logistics within industrial clusters can dramatically improve your timeline planning.

How does proximity improve communication and problem-solving?

When production managers from different facilities can meet face-to-face within hours—or even minutes—issues get resolved immediately rather than festering through days of email exchanges. This proximity transforms quality control from a reactive to proactive process.

We recently had a situation where a jacquard weave was creating tension issues in dyeing. Instead of waiting for sample shipments and days of communication, our weaving technician visited the dyeing facility that afternoon, observed the process firsthand, and adjusted the loom settings by the next morning. The problem was solved in 24 hours instead of what would typically take two weeks of back-and-forth. This hands-on collaboration is something you simply can't achieve with facilities scattered across different provinces.

How to coordinate dyeing and weaving for maximum efficiency?

The traditional sequential approach—complete weaving, then send for dyeing—creates natural bottlenecks. The advanced method involves coordinating these stages to overlap, with dyeing facilities preparing for your order even as weaving is underway. This parallel processing can save 5-8 days on typical orders.

We implement a "production wave" approach where dyeing facilities receive weaving capacity schedules and prepare their dye formulas and machine time in advance. As woven grey fabric rolls off the loom, it moves directly to dyeing facilities that are already primed for its arrival. For a recent 8,000-meter cotton twill order, this approach reduced the weaving-to-dyed-fabric timeline from 14 days to just 6 days. The key is having a central coordinator who understands both processes and maintains constant communication between facilities.

What technical alignment prevents quality issues?

Coordinating dyeing and weaving requires technical alignment on fabric construction parameters that affect dye absorption and finishing results. When facilities work in isolation, they optimize for their own process without considering downstream implications.

We maintain a shared technical specification that includes: yarn twist levels, weave density, and loom settings that we know work well with local dyeing processes. This prevents common issues like uneven dyeing from tension variations or shrinkage mismatches between warp and weft. Our database contains over 500 validated fabric-dyeing combinations that we've refined through years of local collaboration. A client recently avoided what would have been a 10-day rework when our system flagged that their chosen weave structure typically causes barré effects with local dyeing methods—we adjusted the construction before production began.

How does real-time capacity sharing work?

Keqiao's network operates on a remarkable level of transparency regarding production capacity. Through our established relationships, we know which dyeing vats and loom time become available days in advance, allowing us to slot orders into upcoming openings.

This capacity visibility lets us: secure dyeing time before weaving completes, arrange finishing line time while dyeing is underway, and minimize queue times at each stage. We typically know 3-5 days in advance when a dyeing machine will free up, allowing us to time weaving completion to match that availability. This system helped a client jump the queue during peak season by identifying an unexpected capacity opening, saving them 12 days on a rush order.

What finishing advantages does Keqiao offer?

Finishing often becomes the bottleneck in dispersed production models, but in Keqiao, it's integrated as the final step in a continuous flow. The district hosts specialized finishing facilities for every conceivable treatment—from simple calendaring to advanced functional coatings—all available within the same compact geographic area.

The finishing advantage includes: immediate processing after dyeing (no storage or reshipment), specialized facilities for different fabric types, and technical expertise accumulated through generations of textile finishing. We recently coordinated a complex multi-stage finishing process involving softening, anti-pilling, and water repellency that was completed in 4 days instead of the typical 14—because each specialized facility was within 15 kilometers of the previous stage.

How does local expertise accelerate finishing development?

Keqiao's finishing technicians have seen virtually every fabric type and requirement, giving them unparalleled problem-solving speed. Where a remote facility might need days to develop finishing parameters for a new fabric, local experts often have reference formulas they can adapt immediately.

This collective knowledge means: faster recipe development for special effects, immediate troubleshooting when issues arise, and innovation through cross-pollination between facilities. We leveraged this when a client needed a specific peach-skin hand feel on a new recycled polyester—three finishing houses had existing similar formulas, and we had perfect samples within 48 hours instead of the typical 2-week development cycle.

What sustainable finishing options are locally available?

Keqiao's "Silk Road Keqiao" initiative has driven significant investment in eco-friendly finishing technologies, many available through local specialized facilities. These include water-free dyeing, digital printing, and green chemical applications that meet international sustainability standards.

The available sustainable options include: Oeko-Tex certified chemical finishes, GRS-compliant processing, water-saving dyeing technologies, and digital printing that reduces chemical usage by 70%. We recently helped a European brand achieve their sustainability targets by routing their organic cotton through local facilities using biodegradable softeners and energy-efficient curing processes—all while maintaining their aggressive 30-day timeline.

How to implement just-in-time production in Keqiao?

Just-in-time production in Keqiao means leveraging the tight geographic network to minimize inventory at every stage while maintaining continuous flow. This approach reduces working capital requirements while accelerating overall lead times through elimination of queue times.

We implement JIT by: synchronizing production schedules across facilities, maintaining buffer stock of common greige goods, and using digital tracking to monitor real-time progress. The system functions like a well-conducted orchestra where each section knows exactly when to begin their part. A sportswear client achieved 22-day total lead time for their seasonal collection using this approach, compared to 55 days with their previous multi-region supply chain.

What digital tools monitor production flow?

We employ a combination of WeChat groups for immediate communication, shared spreadsheets for schedule tracking, and occasionally custom tracking systems that provide real-time visibility into each production stage. This digital layer over the physical proximity creates unprecedented transparency.

Our standard tracking includes: daily photo updates from each facility, digital approval of intermediate stages, and real-time capacity tracking. This system recently helped a client avoid a potential delay when we identified a weaving slowdown early and immediately shifted part of the order to another local facility with available capacity.

How does local sourcing of materials support speed?

Keqiao's textile market provides immediate access to virtually any material, eliminating weeks of waiting for cross-country shipments. Our established relationships with local yarn suppliers, chemical distributors, and accessory providers mean most materials are available within 24 hours.

The local sourcing advantage includes: immediate availability of common yarns and chemicals, sample approval within hours instead of days, and rapid problem-solving when material issues arise. This comprehensive local ecosystem is why we can confidently promise lead times that seem impossible to buyers accustomed to fragmented supply chains.

Conclusion

Leveraging Keqiao's integrated dyeing-weaving-finishing ecosystem can transform your fabric sourcing from a sequential marathon into a synchronized sprint. By coordinating geographically proximate facilities, implementing parallel processing, and utilizing local expertise, you can achieve lead times 40-60% shorter than conventional multi-location production. The key is working with a partner who understands how to orchestrate this complex local network to your advantage.

The speed advantage isn't just about faster production—it's about increased responsiveness to market trends, reduced inventory costs, and competitive agility. If you're ready to explore how Keqiao's unique textile ecosystem can accelerate your fabric sourcing, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll show you how to turn geographic concentration into your most powerful competitive advantage.