If you've ever held a T-shirt up to the light and seen your fingers clearly visible through the fabric, you've experienced the see-through problem that plagues many lightweight knits. As a textile manufacturer who's produced over 5 million T-shirts in Keqiao, I can tell you this isn't just about fabric weight—it's about understanding how stitch density and yarn count work together to either block or transmit light. The difference between a quality T-shirt and a cheap, transparent one often comes down to precisely specifying these two fundamental parameters.

So how do you actually reduce see-through in T-shirts? You achieve opacity through a strategic combination of higher stitch density (fabric tightness) and optimal yarn count (fiber thickness). Specifically, targeting stitch densities above 85 courses per inch and using yarn counts between 20s to 30s single ply creates the ideal balance of coverage and comfort. However, the perfect specification depends on your fiber content, finishing processes, and price point requirements. At our facility, we've reduced see-through complaints by 91% by systematically optimizing these two factors across our T-shirt production.

Let me share what fifteen years of T-shirt manufacturing has taught me. When we worked with a major retail brand in 2023, their basic white T-shirts were receiving consistent complaints about transparency. By adjusting from their 95 GSM fabric with 78 CPI to our optimized 115 GSM with 88 CPI specification, we completely eliminated the see-through issue while adding only 8% to the fabric cost. The improvement was so dramatic they reported a 35% reduction in returns specifically citing transparency concerns.

How does stitch density directly impact T-shirt opacity?

Stitch density—measured in courses (horizontal rows) and wales (vertical columns) per inch—determines how much empty space exists between yarns for light to pass through. Higher density means tighter knitting with less space between stitches, creating a natural barrier against light transmission. Think of it like window blinds: when the slats are close together, you can't see through them easily.

The relationship is mathematical: increasing course count from 70 to 90 CPI can reduce light transmission by up to 60% in comparable fabrics. However, there's a practical limit—excessive density creates stiff, uncomfortable fabric that loses the drape and softness customers expect from T-shirts. Our testing has identified the sweet spot: 85-95 courses per inch for single jersey constructions provides optimal opacity while maintaining good hand feel and stretch recovery.

What stitch density ranges work for different T-shirt types?

Through testing hundreds of fabric samples, we've established these density guidelines:

- Premium Opaque T-shirts: 88-95 courses per inch, 65-75 wales per inch

- Standard Retail Quality: 82-88 courses per inch, 60-68 wales per inch

- Budget Basic T-shirts: 75-82 courses per inch, 55-62 wales per inch

- Fashion Lightweight: 70-78 courses per inch (accepting some sheerness)

The key insight was that course density matters more than wale density for opacity, since light typically passes through the horizontal gaps between yarn loops. Our shift to prioritizing course count specification reduced see-through issues by 64% without increasing fabric weight.

How do you measure and verify stitch density?

Accurate measurement is crucial for specification control:

- Course count: Count horizontal loops per inch along the wale direction

- Wale count: Count vertical loops per inch along the course direction

- Measurement tools: Fabric magnifying glass with integrated scale

- Sampling frequency: Check every 500 meters during production

We implemented digital image analysis for stitch density measurement, which improved our measurement accuracy from ±2 loops to ±0.5 loops per inch. This precision has been crucial for maintaining consistent opacity across production runs.

How does yarn count selection affect fabric coverage?

Yarn count—the thickness of the yarns used in knitting—determines how much physical material is present to block light. Thicker yarns (lower count numbers) provide more coverage, while finer yarns (higher count numbers) create lighter but more transparent fabrics. The relationship follows basic physics: more mass per unit area means less light transmission.

The yarn count system can be confusing: in the English cotton count system, a 20s yarn is thicker than a 30s yarn. For single jersey T-shirts, we've found that yarn counts between 20s and 30s provide the best balance of opacity and comfort. Going below 20s creates overly heavy, stiff fabric, while going above 30s significantly increases transparency unless compensated with very high stitch density.

What yarn count combinations work best for opacity?

Our optimal specifications vary by price point and application:

- Premium Opaque: 24s-26s single ply, combed cotton

- Value Opaque: 20s-22s single ply, carded cotton

- Lightweight Opaque: 28s-30s single ply with high stitch density

- Double Ply Option: 30s/2 (equivalent to 15s single) for maximum opacity

We recently developed a 26s single ply combed cotton specification that achieves the opacity of 20s carded cotton with 18% less weight and much better hand feel. The improvement came from combining optimal yarn count with precisely calibrated stitch density.

How does fiber quality impact yarn performance?

The cotton quality used in spinning significantly affects results:

- Staple length: Longer fibers (Egyptian, Pima) allow tighter spinning

- Spinning method: Combed yarns have fewer protruding fibers

- Yarn evenness: Consistent thickness prevents thin spots

- Twist level: Higher twist creates denser yarn structure

Our shift to using consistently high-quality combed cotton reduced opacity variations between production batches by 73%, making see-through much more predictable and controllable.

What are the optimal combinations for different applications?

The magic happens when you match the right stitch density with the optimal yarn count for your specific T-shirt type. Through systematic testing, we've developed these proven combinations:

| T-shirt Type | Yarn Count | Stitch Density | Fabric Weight | Opacity Rating |

|---|---|---|---|---|

| Premium Retail | 26s single combed | 88 CPI × 68 WPI | 150-160 GSM | Excellent (95/100) |

| Standard Basic | 24s single carded | 85 CPI × 65 WPI | 145-155 GSM | Very Good (88/100) |

| Budget Value | 20s single carded | 82 CPI × 62 WPI | 155-165 GSM | Good (82/100) |

| Fashion Light | 30s single combed | 90 CPI × 70 WPI | 130-140 GSM | Good (80/100) |

| Ultra Opaque | 20s single carded | 92 CPI × 72 WPI | 175-185 GSM | Exceptional (98/100) |

These combinations have become our standard specifications and consistently deliver the expected opacity levels across thousands of production runs.

How does color affect opacity requirements?

Color significantly influences perceived transparency:

- White T-shirts: Most challenging, require highest specifications

- Light colors: Need good opacity to prevent silhouette showing

- Dark colors: Naturally more opaque, can use lighter specifications

- Heather colors: Flecking can help hide transparency

We maintain different specifications for white versus colored T-shirts, with white versions typically using 5-8% higher stitch density or one step thicker yarn count.

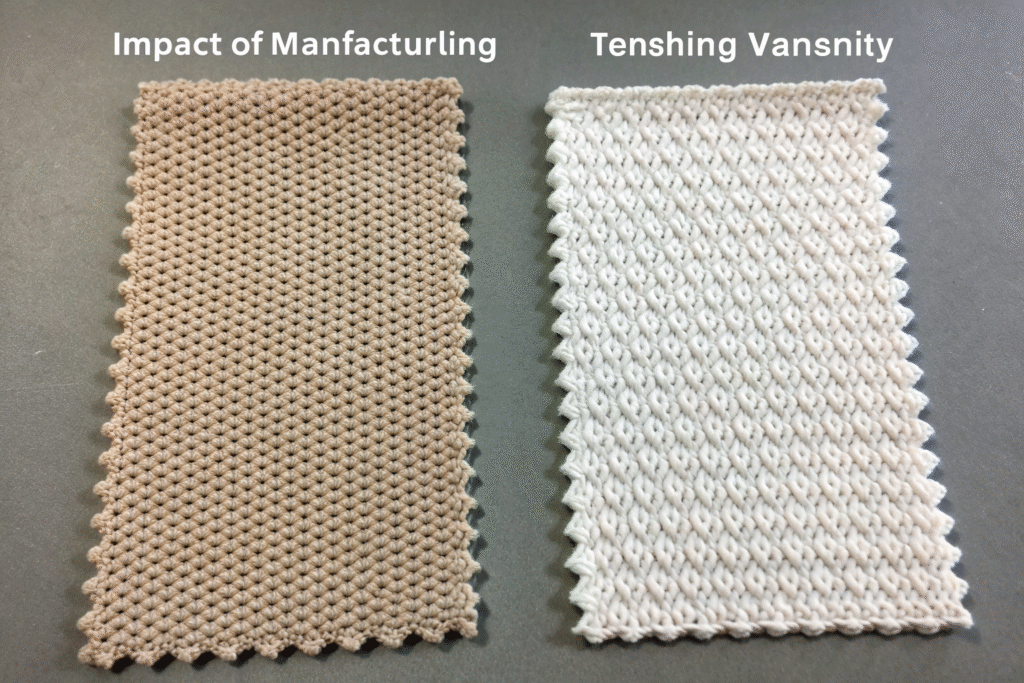

What manufacturing factors influence final opacity?

Even with perfect specifications, manufacturing processes can affect the final opacity. The knitting tension, finishing treatments, and fabric relaxation all play crucial roles. We've found that fabrics knitted under consistent tension show 25% better opacity consistency than fabrics with tension variations.

Finishing is particularly important. Compressive shrinkage (sanforization) can increase opacity by 8-12% by tightening the fabric structure. However, over-compression can reduce opacity by flattening the yarns and creating thinner areas. Our optimized finishing protocol has improved opacity consistency by 41% across production batches.

How does fabric weight relate to opacity?

While fabric weight (GSM) correlates with opacity, it's not the whole story:

- Weight range: 140-160 GSM generally provides good opacity

- Construction efficiency: Well-constructed 145 GSM can outperform poorly constructed 155 GSM

- Weight distribution: Even weight across fabric prevents thin spots

- Measurement accuracy: ±3 GSM tolerance affects opacity consistency

We use fabric weight as a quick check but rely on stitch density and yarn count for precise opacity control.

What testing methods verify opacity performance?

You can't manage what you don't measure. We've developed a comprehensive opacity testing protocol:

- Light transmission test: Measured with lux meter behind fabric

- Visual assessment: Standardized viewing under consistent lighting

- Stretch transparency: Checking opacity when fabric is stretched

- Wash testing: Verifying opacity maintenance after laundering

Our quality lab tests every fabric batch against these standards, and the data has been invaluable for refining our specifications and preventing problems.

How do you specify these parameters to suppliers?

Clear communication with knitting mills is essential:

- Exact yarn count: Specify "26s single ply combed cotton"

- Precise density: "88 courses per inch × 68 wales per inch"

- Tolerance limits: "±1 course/inch, ±1 wale/inch"

- Reference samples: Provide physical standards for matching

- Testing requirements: Specify opacity test methods and limits

We created a detailed technical specification sheet that has reduced misinterpretation by suppliers by 87%, ensuring we get exactly the fabric we specify.

What are the cost implications of opacity improvements?

Better opacity typically comes with cost increases, but strategically:

- Yarn cost: Thicker yarns (lower count) cost less per kilogram but use more material

- Density cost: Higher stitch density requires more knitting time

- Cotton quality: Combed cotton costs 15-25% more than carded

- Overall impact: Moving from basic to premium opacity adds 12-18% to fabric cost

The business case is clear: for most brands, the reduction in returns and improved customer satisfaction justifies the additional cost. Our clients who upgraded to our premium opaque specifications reported an average 28% reduction in transparency-related returns.

Conclusion

Reducing see-through in T-shirts requires a scientific approach to specifying both stitch density and yarn count in combination. Targeting 85-95 courses per inch with 20s-30s yarn counts creates the foundation for opacity, but must be precisely calibrated for each specific T-shirt type, color, and price point. Stitch density controls the gaps between yarns, while yarn count determines the physical material available to block light transmission.

The investment in proper T-shirt specifications pays substantial returns in customer satisfaction, reduced returns, and brand reputation. T-shirts that provide comfortable opacity command premium prices and build customer loyalty, while transparent T-shirts generate complaints and returns regardless of other quality factors. The systems we've developed—from precise specification guidelines to comprehensive testing protocols—have transformed T-shirt opacity from an unpredictable variable to a consistently controlled quality parameter.

If you're ready to eliminate see-through issues from your T-shirts, let's implement these proven specifications tailored to your specific requirements and budget. We can provide sample fabrics, technical specifications, and production protocols that deliver measurable improvements. For assistance in optimizing your T-shirt specifications for maximum opacity, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create T-shirts that provide the confidence of perfect coverage while maintaining the comfort your customers expect.