As a fabric supplier deeply embedded in the global safety and functional textiles market, I get this question all the time from American brands. You're not just buying fabric; you're sourcing a critical safety system. Getting the reflective tape specification and bonding process wrong can lead to tape peeling off, reduced visibility, and ultimately, product failure that puts end-users at risk.

Specifying reflective tape and its bonding is a technical dance between material science, manufacturing precision, and compliance standards. It involves selecting the right tape grade and adhesive system, then engineering a bonding process that creates an indestructible union with the high-visibility base fabric.

What are the key properties of reflective tape for safety wear?

The first step is choosing the right tape. Not all reflective tapes are created equal. Think of it as the "brain" of your hi-vis system; its properties determine the final performance. A common mistake is focusing solely on initial cost, which can lead to premature failure and non-compliance.

The key properties boil down to three areas: photometric performance (how well it reflects light), physical durability, and the adhesive system. Photometric performance is measured by its coefficient of retroreflection (RA), a scientific term for how efficiently it bounces light back to the source.

How does tape brightness and color impact visibility?

Brightness, or photometric performance, is non-negotiable. It's governed by standards like EN ISO 20471 and ANSI/ISEA 107. The tape's construction—typically a prismatic microsphere or microprismatic structure—dictates its reflective efficiency.

For instance, a European client in 2023 required certified hi-vis fabric for construction PPE that met EN ISO 20471 Class 2. We recommended a certified microprismatic tape with a minimum RA value of 330 for light grey (x=0.310, y=0.483), ensuring their vests were visible at the required distances.

What makes a reflective tape durable and washable?

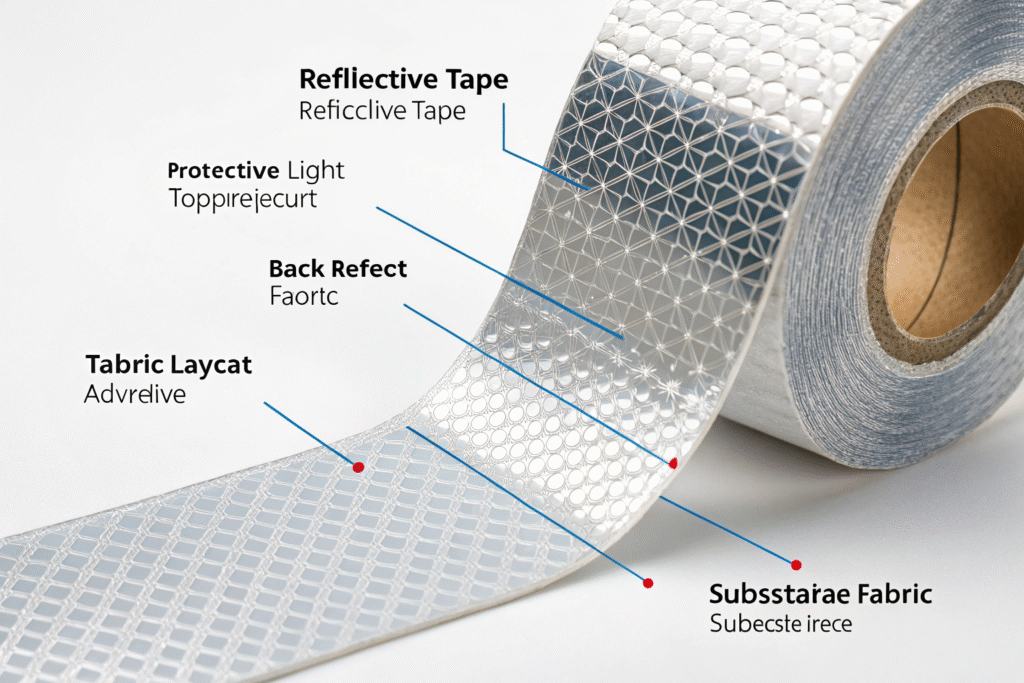

Durability is where cheap tapes fail. You need to assess the tape's construction: the protective topcoat, the strength of the carrier material (often a robust PVC or PU film), and the quality of the adhesive layer.

For workwear that requires frequent laundering, the tape must withstand industrial washing cycles. A key test is checking its performance after 25 or 50 washes, as per standard methods. We learned this the hard way years ago with a batch of tapes that delaminated after just five washes.

Now, our CNAS lab pre-tests every tape lot for abrasion resistance and washing fastness. For a major US utility company's uniforms, we specified a tape with a polyurethane topcoat and a high-tack hot melt adhesive, which survived 50 industrial washes at 75°C with no significant drop in reflectivity.

How is reflective tape permanently bonded to fabric?

Selecting the perfect tape is only half the battle. The bonding process is what makes it permanent. A poor bond is the single biggest cause of failure. This is where your fabric supplier's manufacturing expertise becomes paramount.

The two primary industrial methods are heat-seal bonding and sew-on applications. Heat-seal is the gold standard for most hi-vis applications because it creates a seamless, waterproof bond that doesn't compromise the fabric's integrity with needle holes.

What are the pros and cons of heat sealing vs. sewing?

Let's compare these two methods head-to-head. Your choice depends on the application's demands.

| Feature | Heat-Seal Bonding | Sew-On Application |

|---|---|---|

| Bond Integrity | Superior, seamless, waterproof | Prone to failure at stitch holes |

| Production Speed | Very Fast (we can do it in-line) | Slower, labor-intensive |

| Durability | Excellent abrasion resistance | Stitches can abrade and break |

| Cost | Lower per unit at scale | Higher due to labor |

| Flexibility | Good, but can be stiff if over-pressed | Excellent, fabric moves independently |

For most modern hi-vis apparel, heat-sealing is the winner. However, for heavy-duty applications like firefighter turnout gear, a combined approach—sewing with a heat-sealed seam cover—is often used.

What factors affect heat seal bonding strength?

Achieving a perfect heat seal is a science. The main factors are temperature, pressure, and dwell time. Too low temperature, and the adhesive doesn't fully activate. Too high, and you risk damaging the tape's reflective layer or the base fabric.

A real-world example: In Q2 2024, a client from Seattle was having issues with tape peeling at the corners on their new line of waterproof and breathable hi-vis jackets. The problem was a combination of an uneven presser foot on their machine and a 5°C temperature variance across the heating plate.

We helped them recalibrate their equipment and switch to a tape with a more forgiving pressure-sensitive adhesive system, which completely eliminated the peeling and passed the peel-strength test with a result over 35 N/50mm.

What standards govern hi-vis fabric and tape compliance?

You can have the brightest, best-bonded tape in the world, but without the right certifications, it's worthless for professional use. Compliance is your legal and ethical license to operate.

The major standards are Europe's EN ISO 20471 for high-visibility clothing and North America's ANSI/ISEA 107. While they share the goal of enhancing visibility, their requirements for tape placement, color, and photometric performance have subtle but important differences.

How do EN ISO 20471 and ANSI/ISEA 107 differ?

Understanding the difference between these two is critical for exporting. EN ISO 20471 is a three-class system (Class 1 being the lowest risk, Class 3 the highest) based on the minimum area of background and reflective materials.

ANSI/ISEA 107, on the other hand, also uses a class system but includes Type classifications (e.g., Type O for Off-Road, Type R for Roadway) that dictate design and performance requirements. A key difference is in the reflective tape performance.

We always advise clients to source certified hi-vis fabric from China that is tested for the specific target market. Our CNAS lab, for example, can pre-test your materials against both standards, saving you the time and cost of third-party testing failures.

Why is base fabric color fastness critical for compliance?

The high-visibility of the garment starts with the fluorescent background fabric. If this fabric fades, the entire safety system fails. Standards require rigorous testing for color fastness to xenon-arc light (simulating sunlight), perspiration, and washing.

We had a case in late 2023 with a European client who sourced fabric from a less rigorous supplier. The fluorescent yellow fabric failed the xenon-arc test after just 80 hours, falling outside the EN ISO 20471 color box. The entire batch of 10,000 meters was rejected.

In contrast, our in-house flame resistant fabric dyeing process uses specific pigment chemistry and a proprietary fixing agent that ensures our fluorescent fabrics exceed 200 hours of xenon-arc exposure without significant color shift.

How to choose a supplier for hi-vis fabric and tape bonding?

This is the culmination of everything we've discussed. Your supplier isn't just a vendor; they are your partner in risk management. The right partner brings technical expertise, quality control, and supply chain reliability to the table.

Look for a supplier with vertical integration or strong partnerships with tape manufacturers and finishing houses. They must have a certified in-house lab for quality control. Ask for their QC data and whether they understand navigating customs and logistics for US fabric imports.

What quality control checks ensure bonding reliability?

A professional supplier will have a multi-layered QC system. First, there's incoming quality inspection of both the base fabric and the reflective tape. Then, in-process checks during bonding: we perform a manual peel test every hour on the production line.

We also use a simple but effective "cross-cut test": a lattice pattern is cut into the tape, pressed with adhesive tape, and then ripped off. The amount of tape removed indicates the bond strength. This rigorous process is why we maintain a 98.7% client pass rate.

Why does supplier expertise in logistics matter for the US market?

For our American clients, the journey doesn't end at our factory door. Your supplier must be an expert in getting the finished, certified goods to your warehouse efficiently and without hassle. This is a major pain point we solve daily.

Key considerations include tariff engineering, stable shipping partnerships for reliable sailing schedules, and proper documentation for US customs clearance. We've streamlined this to a 48-hour document turnaround for our US clients, avoiding costly demurrage charges.

Conclusion

Specifying reflective tape and bonding for hi-vis safety fabrics is a detailed, technical process, but it doesn't have to be a daunting one. By focusing on tape selection, bonding mastery, compliance, and supplier partnership, you transform a potential liability into a reliable, life-saving product.

If you're looking for a partner who can co-create value and navigate these complexities with you, let's talk. For a deeper discussion on your specific hi-vis apparel needs, please reach out to our Business Director, Elaine at elaine@fumaoclothing.com.