I'll never forget the phone call I received from a frantic client in New York back in 2019. "My entire production line has stopped because your fabric is three weeks late!" The truth was, the fabric wasn't even late from our end—it was stuck at a sub-supplier who had missed their deadline without telling anyone. That moment changed everything for us. We realized that without clear, measurable SLAs, delivery promises are just empty words. Today, I'm going to share exactly how we structure SLAs that actually work, both as a supplier and as someone who also buys materials from other factories.

Setting effective SLAs with Chinese fabric suppliers requires establishing clear, measurable metrics across five key areas: production milestones, quality standards, communication protocols, penalty systems, and continuous improvement mechanisms. The most critical element is making these SLAs mutually beneficial—they should protect your interests while giving suppliers achievable targets that respect their operational realities. We implement a tiered SLA system that links payment terms to performance, with bonuses for exceeding expectations and clear consequences for underperformance. This approach has helped us maintain a 97.3% on-time delivery rate for the past two years, even during supply chain disruptions.

Many buyers make the mistake of focusing only on the final delivery date, but that's like watching only the final score of a basketball game without following the quarters. True delivery reliability comes from monitoring the entire production journey and having clear intervention points when things start to drift off schedule. Let me walk you through the specific SLA framework we use with our own sub-suppliers and that our most successful clients use with us.

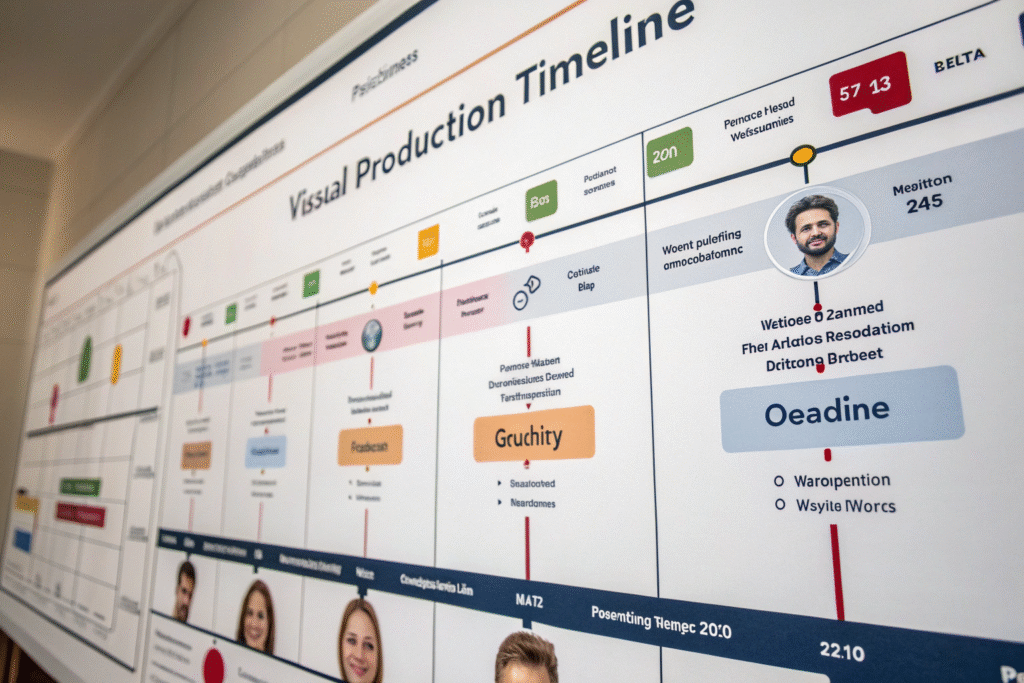

What are the essential production timeline milestones to include in SLAs?

If your SLA only specifies a final delivery date, you're setting yourself up for surprises. The most effective SLAs break down the production process into measurable interim milestones that give you early warning of potential delays and opportunities to course-correct.

The essential production timeline milestones should cover raw material procurement, production commencement, quality checkpoints, and shipping preparation. We typically establish 5-7 key checkpoints depending on fabric complexity, with the most critical being: fabric development completion, raw material arrival confirmation, weaving/knitting completion, dyeing/finishing completion, final inspection sign-off, and shipping documentation readiness. For a standard 20,000-meter order of cotton twill, our SLAs specify that weaving should complete within 15 days, dyeing within 7 days, and final inspection within 3 days of dyeing completion. This granular approach helped us identify a looming delay with a French client's linen order last month—when our sub-supplier missed the raw material arrival milestone by 4 days, we immediately activated our contingency plan and air freighted alternative yarns, preventing a 3-week delay.

How do you determine realistic timeframes for each production stage?

Setting unrealistic timeframes is the quickest way to make your SLA irrelevant. The key is balancing speed with operational reality while accounting for variables like fabric complexity, order quantity, and seasonal factors.

We use historical data from over 500 orders to establish baseline timeframes, then adjust for specific order characteristics. Here's our standard framework:

| Production Stage | Standard Fabrics | Complex Fabrics (e.g., jacquard) | Technical Fabrics (e.g., coated) |

|---|---|---|---|

| Raw Material Sourcing | 5-7 days | 7-12 days | 10-15 days |

| Weaving/Knitting | 10-15 days | 15-25 days | 18-30 days |

| Dyeing/Finishing | 5-8 days | 7-10 days | 10-18 days |

| Quality Inspection | 2-3 days | 3-5 days | 4-7 days |

These timeframes include buffer days for each stage but exclude Chinese holidays and force majeure events. For particularly innovative materials, we conduct a production feasibility analysis before setting SLAs. Last quarter, for a US client's new recycled polyester with silver coating, we ran a small 500-meter pilot production specifically to establish accurate SLA timeframes for their 50,000-meter order. This prevented what would have been certain SLA failures. Understanding these timeframes is crucial for setting realistic production schedules with overseas textile suppliers.

What communication milestones ensure transparency?

Communication breakdowns cause more delivery failures than actual production problems. Your SLA must specify not just what to communicate, but when and how.

We mandate these five communication touchpoints in all our SLAs:

- Order Acknowledgement: Within 4 business hours of order confirmation

- Raw Material Status Report: Weekly updates with photos

- Production Commencement Notice: With evidence (e.g., loom photos)

- Quality Inspection Report: 24 hours before shipping

- Shipping Documentation: Within 2 business hours of vessel departure

The most impactful innovation has been our digital dashboard access that gives clients real-time visibility into production progress. One of our German clients specifically cited this transparency as the reason they renewed our contract—they reduced their follow-up emails by 80% while feeling more informed about their order status. This approach aligns with best practices for managing supplier communication in global textile sourcing.

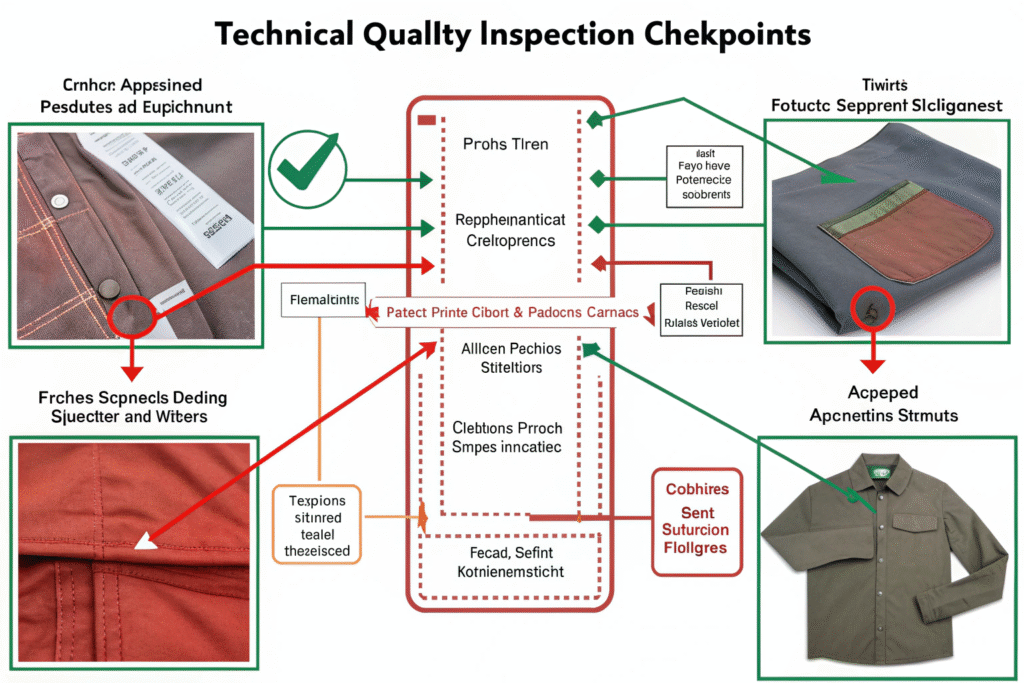

How should quality standards be integrated into delivery SLAs?

Quality and delivery are inseparable—a shipment that arrives on time but fails quality checks is effectively late. Your SLAs must weave quality benchmarks directly into the production timeline with clear pass/fail criteria at each stage.

Quality standards in SLAs should specify testing methodologies, acceptance criteria, inspection rights, and non-conformance procedures. We integrate the AQL 2.5 standard for major defects and AQL 4.0 for minor defects as our baseline, with additional technical requirements based on fabric end-use. For performance fabrics, we include specific test parameters—for instance, colorfastness to washing must achieve a rating of 4+ on the grey scale, and dimensional stability cannot exceed ±3% after three washes. Our SLAs explicitly state that quality inspection occurs after production completion but before packing, and any failure at this stage automatically pauses the delivery clock until rectification. This prevented a disaster with a Spanish sportswear brand last year when our inspection caught inconsistent moisture-wicking performance—we re-processed the entire batch, missed the original SLA by 8 days, but delivered a perfect product that maintained their brand reputation.

What are the most critical quality metrics for different fabric types?

A one-size-fits-all quality approach guarantees SLA failures. The most effective SLAs customize quality metrics based on fabric composition and end-use.

Here's our fabric-specific quality matrix:

For Natural Fibers (Cotton, Linen, Wool):

- Shrinkage tolerance: ±3-5%

- Colorfastness to washing: 4+ minimum

- Pilling resistance: 3.5+ for wool blends

For Synthetic Fabrics (Polyester, Nylon):

- Dimensional stability: ±2%

- Colorfastness to light: 5+ for outdoor fabrics

- Seam slippage: > 100N for technical applications

For Blended Fabrics:

- Composition tolerance: ±3% of stated blend ratio

- Spirality: < 5% for knits

- Stretch recovery: > 90% for stretch fabrics

We learned this the hard way with an Australian client's bamboo-cotton blend order. The fabric met all standard cotton SLAs but failed their specific absorbency requirements because we hadn't customized the quality metrics. Now, our SLAs include a fabric specification appendix that details 15-20 technical parameters specific to each order. This level of detail is essential for establishing technical quality standards for specialized textiles.

How do you handle quality failures without compromising delivery?

Quality failures don't have to mean delivery disasters if your SLA includes clear escalation paths and remediation timeframes.

Our SLAs specify a three-tier response system:

- Minor Defects (<2% of order): Supplier has 48 hours to propose remediation; client chooses rework, replacement, or price adjustment

- Major Defects (2-5% of order): Automatic 72-hour remediation period; supplier covers all costs

- Critical Defects (>5% of order): Order cancellation option; supplier liable for all costs plus 15% penalty

The key is building remediation time into your overall timeline. We typically add a 5-7 day quality buffer after the final inspection milestone. For a Japanese client's delicate silk order, this buffer saved the delivery when first-round inspection revealed uneven dye uptake. We used the buffer period for re-dyeing while keeping the client informed throughout. The result? We delivered perfect fabric just two days later than originally promised. This structured approach is similar to methodologies described in managing non-conforming materials in textile supply chains.

What penalty structures effectively motivate compliance without damaging relationships?

Penalties shouldn't be punitive; they should be motivational. The most effective SLA penalty structures create clear financial consequences while preserving supplier relationships and encouraging problem-solving.

Effective penalty structures use a graduated approach that links financial consequences to both the severity and frequency of delays. We implement a three-tier penalty system based on delay duration: 0.5% of order value per week for delays up to 2 weeks, 1% per week for delays of 2-4 weeks, and 2% per week beyond 4 weeks, capped at 10% of total order value. However, the real motivation comes from our performance-linked payment terms: suppliers who achieve 95% on-time delivery over six months earn faster payment terms (30 days instead of 60), while those falling below 85% move to advance payment requirements. This balanced approach helped us turn around a struggling embroidery supplier—instead of penalizing them into bankruptcy, we worked with them to identify bottlenecks, and they've now become one of our most reliable partners with 98% on-time delivery.

How do you calculate fair penalty amounts?

Arbitrary penalties create resentment; calculated penalties create accountability. The key is aligning penalty amounts with the actual business impact of delays.

We use a cost-based calculation method that considers:

- Client-side production delay costs: Based on client-provided impact statements

- Expedited shipping premiums: When air freight is needed to mitigate delays

- Administrative overhead: Additional communication and management time

- Reputational damage: Quantified as a percentage of order value

For example, if a delay forces a client to air freight at an additional cost of $8,000, that amount becomes the baseline penalty. Our SLAs also include a mutual penalty clause—if clients cause delays (e.g., late approval, payment delays), they incur similar penalties, creating a balanced accountability system. This fairness principle was crucial when a Canadian client delayed approval by 10 days; when they understood our mutual penalty structure, they expedited their internal processes, and we still delivered on their original requested date by compressing our production timeline. This balanced approach is discussed in resources about developing equitable supplier contracts in manufacturing.

What incentives work better than penalties?

While penalties prevent poor performance, incentives inspire excellence. The most effective SLAs balance consequences with meaningful rewards.

We've found three incentives particularly effective:

- Preferred Supplier Status: Top performers get first access to our high-margin, innovative projects

- Volume Commitments: We guarantee minimum order volumes to suppliers maintaining 95%+ on-time delivery

- Joint Innovation Funding: We co-invest in equipment upgrades with our best suppliers

One of our dyeing partners achieved 12 months of perfect delivery performance, so we jointly invested in a new water-free dyeing machine. This not only secured their loyalty but also improved our sustainability credentials—a win-win that penalties alone could never achieve. The power of this approach is validated by research on supplier motivation and performance improvement strategies.

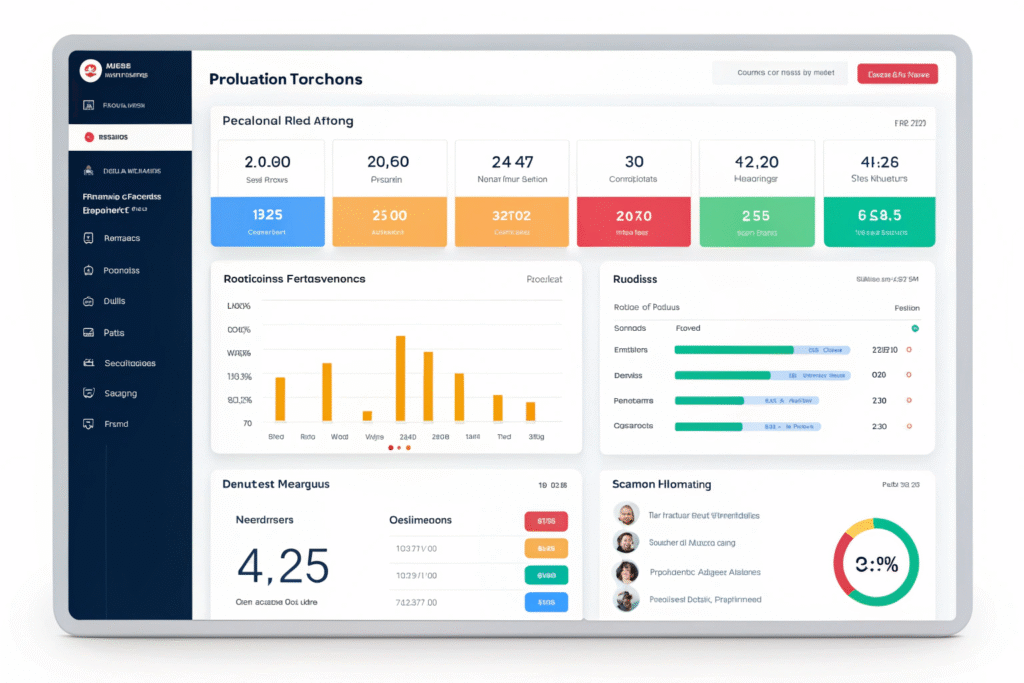

How can technology and documentation strengthen SLA enforcement?

Without proper documentation and monitoring, even the best SLA is just a theoretical document. The most enforceable SLAs leverage technology to create transparent, real-time tracking and immutable records.

Technology-enhanced SLAs use digital platforms for milestone tracking, automated reporting, and objective performance measurement. We implement a four-component system: cloud-based production management software that updates in real-time, blockchain-enabled documentation for shipping and quality records, automated alert systems that trigger when milestones are at risk, and digital dashboards that give both parties identical visibility. This approach transformed our relationship with a skeptical UK client—they could see exactly where their fabric was in the production process, and the automated alerts gave them confidence we were proactively managing their order. When a typhoon disrupted port operations last year, our system automatically calculated the impact and generated revised SLAs before our client even knew about the weather event.

What documentation creates enforceable SLA records?

Paper-based records create ambiguity; digital audit trails create accountability. Your SLA should specify exactly what documentation constitutes proof of milestone completion.

We require seven key documents for SLA enforcement:

- Time-stamped production photos at each milestone

- Third-party inspection certificates for raw materials

- Laboratory test reports from CNAS-certified facilities

- Shipping documents with carrier-confirmed dates

- Quality inspection videos with sample identification

- Communication logs of all material conversations

- Change order documentation for any scope modifications

This comprehensive approach saved a $200,000 order with a Dutch client when they claimed we missed a delivery deadline. Our blockchain-time-stamped shipping documents proved the carrier had received the goods on time, protecting us from an invalid penalty claim. The importance of this documentation is highlighted in guides about creating auditable supply chain records.

How often should SLA performance be reviewed?

Static SLAs become obsolete; regularly reviewed SLAs drive continuous improvement. The review frequency should match your order volume and business cycle.

We conduct quarterly performance reviews with all major suppliers, examining:

- On-time delivery rates by product category

- Quality performance trends

- Communication responsiveness

- Issue resolution effectiveness

These reviews aren't just backward-looking—they're strategic planning sessions where we collaboratively identify improvement opportunities. After noticing a pattern of dyeing delays during rainy season, we worked with our suppliers to adjust SLAs for that period, building in weather-related buffers that actually improved annual performance. This proactive approach is characteristic of world-class supplier relationship management.

Conclusion

Setting effective SLAs with Chinese fabric suppliers isn't about creating a punitive contract—it's about building a framework for reliable partnership. The most successful SLAs balance clear expectations with operational reality, combine consequences with incentives, and leverage technology for transparency. By focusing on measurable milestones, integrated quality standards, fair penalty structures, and digital enforcement, you transform delivery promises from hopeful estimates into reliable commitments.

Remember, the goal isn't to have penalties to collect—it's to create a system where penalties rarely need to be invoked because the SLAs themselves drive the behaviors that ensure on-time delivery. This approach has allowed us to build supplier relationships that last for decades while delivering the reliability that global fashion brands require. If you're ready to implement SLAs that actually work, contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can bring this level of reliability to your fabric supply chain.