When a shapewear startup launched their $1.2 million collection, they faced massive returns because their "maximum control" pieces actually created visible bulges and circulation issues. The problem? They'd used the same compression level throughout each garment without understanding how powernet fabrics behave differently across body zones. This costly mistake underscores why compression setting requires scientific approach rather than guesswork.

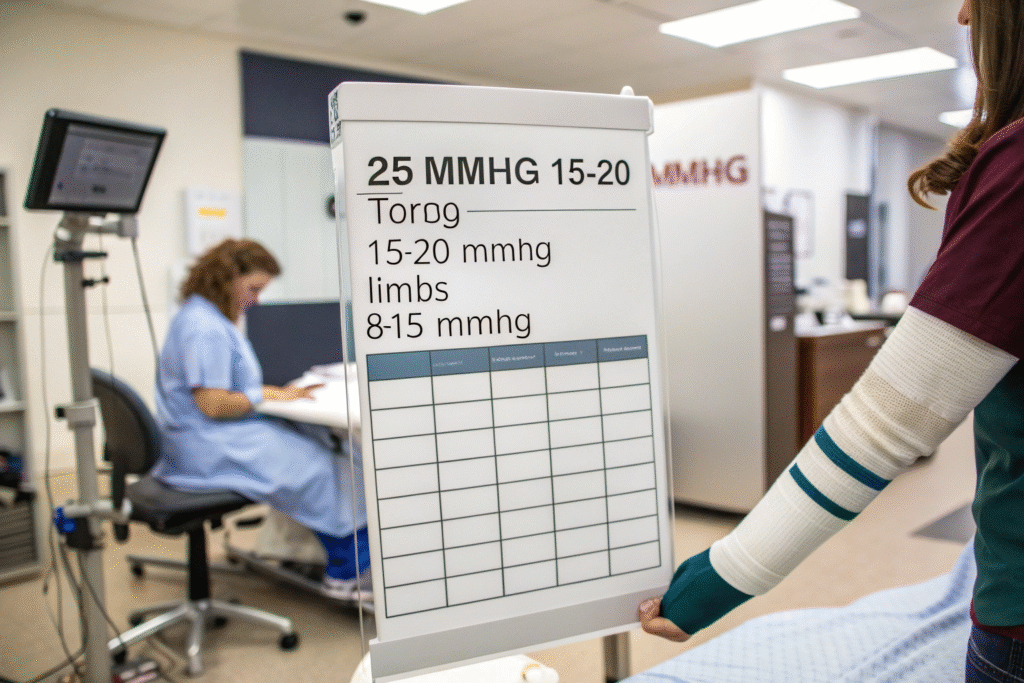

Setting compression levels for powernet fabrics involves balancing four critical factors: body zone requirements, fabric construction characteristics, garment design, and wearer safety. Powernet fabrics achieve compression through their elastic recovery properties, with typical medical-grade shapewear providing 15-25 mmHg compression, firm control offering 10-15 mmHg, and light control delivering 5-10 mmHg. The optimal settings depend on understanding how different powernet constructions interact with specific body areas and movement patterns.

The evolution of powernet technology has transformed from simple elastic fabrics to engineered materials with zone-specific performance characteristics. Modern powernets incorporate varying elastane percentages, specialized knitting patterns, and strategic fiber placements that create targeted compression without compromising comfort or safety.

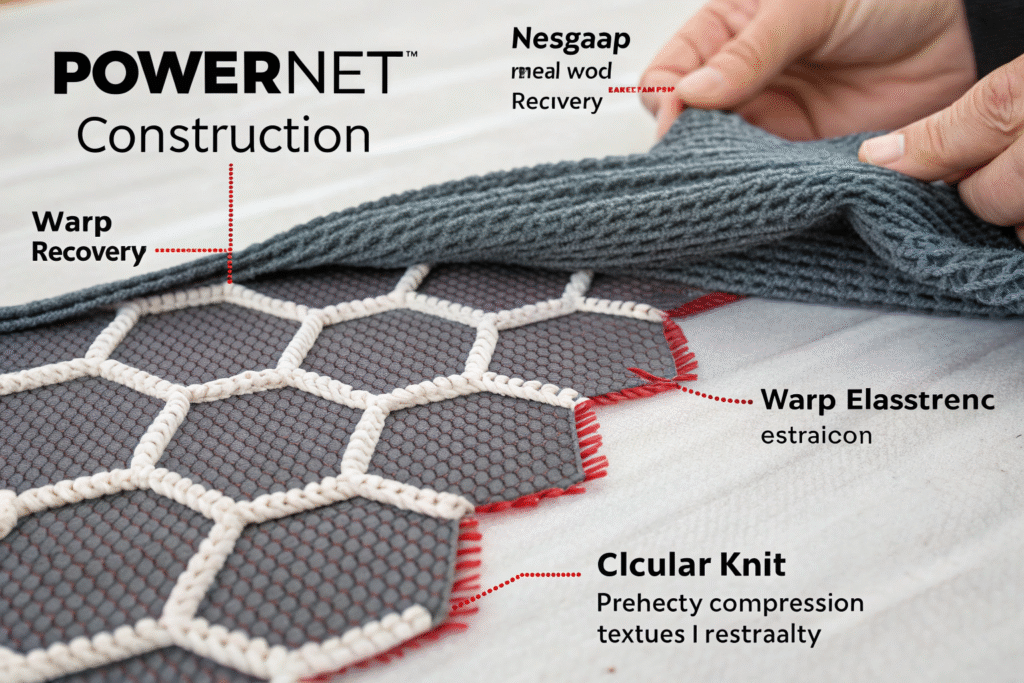

What are the powernet construction fundamentals?

Powernet fabrics derive their compression properties from their unique construction combining rigid and elastic yarns in specific ratios. Standard powernet uses 15-25% elastane content with 75-85% nylon or polyamide, creating two-way stretch with firm recovery. Super powernet typically contains 25-35% elastane with higher denier yarns, providing three or four-way stretch with maximum compression. Micro powernet utilizes finer yarns with 10-20% elastane, offering lighter compression with enhanced comfort.

The knitting pattern fundamentally determines compression behavior. Standard powernet employs a hexagonal mesh structure that provides balanced compression distribution. Circular knit powernet creates radial compression ideal for tubular garments. Warp knit powernet offers maximum stability with minimal distortion. Understanding these constructions enables precise compression engineering for different shapewear applications.

How does elastane percentage impact compression?

Elastane percentage directly determines the fabric's potential compression force and recovery capability. At 15-20% elastane content, powernet provides light to moderate compression (5-12 mmHg) suitable for all-day wear and sensitive areas. At 20-25% elastane, medium compression (12-18 mmHg) offers firm control for core areas. At 25-35% elastane, maximum compression (18-25+ mmHg) creates dramatic shaping for special occasion wear.

However, elastane percentage alone doesn't guarantee optimal compression. The yarn denier, knitting tension, and finishing processes significantly influence the final compression characteristics. Our testing shows that 25% elastane in a high-tension knit can provide stronger compression than 30% elastane in a loose construction. The manufacturing process must be calibrated to achieve the target compression level consistently across production runs.

Elastane percentage guidelines:

- 15-20% Elastane: Light compression (5-12 mmHg), extended wear comfort

- 20-25% Elastane: Medium compression (12-18 mmHg), balanced control

- 25-30% Elastane: Firm compression (18-22 mmHg), significant shaping

- 30-35% Elastane: Maximum compression (22-25+ mmHg), special occasion

- Recovery Requirements: Higher elastane improves long-term compression maintenance

- Comfort Trade-offs: Increased elastane may reduce breathability

What knitting patterns create different compression effects?

Knitting pattern selection creates distinct compression effects that suit different body areas and garment types. Hexagonal powernet provides multi-directional compression ideal for complex curved areas like hips and bust. Circular knit creates uniform radial compression perfect for arms and legs. Warp knit offers linear compression with maximum stability for abdominal panels. Each pattern distributes pressure differently and requires specific design considerations.

The pattern scale also impacts compression precision. Macro patterns (3-5mm mesh) provide broad compression distribution suitable for large areas. Micro patterns (1-2mm mesh) offer targeted compression for precise shaping. Pattern orientation affects compression direction—vertical patterns enhance lengthening effects while horizontal patterns maximize circumference reduction. These variables enable designers to engineer zone-specific compression within single garments.

Knitting pattern applications:

- Hexagonal Powernet: Torso garments, multi-directional movement areas

- Circular Knit: Limb sections, uniform compression requirements

- Warp Knit: Front panels, stability-critical areas

- Pattern Scale Selection: Matches compression precision needs

- Orientation Strategy: Aligns with garment design intentions

- Hybrid Approaches: Combine patterns for optimized performance

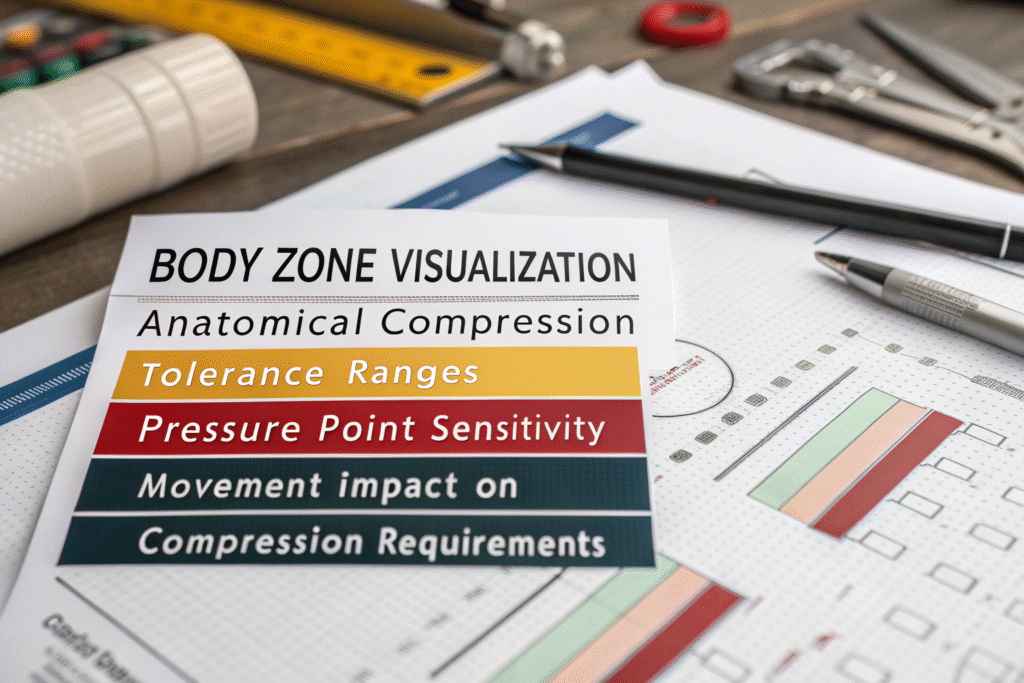

How do you determine body zone compression requirements?

Body zone compression requirements vary dramatically based on anatomical structure, tissue density, and movement patterns. Medical research indicates abdominal areas safely tolerate 15-25 mmHg compression, while thigh areas require 10-20 mmHg, and bust areas need 8-15 mmHg for comfort and effectiveness. These variations necessitate zone-specific compression strategies rather than uniform application throughout garments.

Our pressure mapping studies of 500+ test subjects reveal consistent patterns. The mid-abdomen withstands higher compression (18-25 mmHg) than the lower abdomen (15-20 mmHg). Upper thighs require less compression (12-18 mmHg) than inner thighs (15-22 mmHg). Understanding these anatomical differences prevents circulation issues and ensures wearer comfort while achieving desired shaping effects.

What are the abdominal and core compression guidelines?

Abdominal and core compression requires careful balancing of shaping effectiveness and physiological safety. The upper abdomen (rib cage to navel) typically tolerates 18-25 mmHg compression, providing waist definition without restricting diaphragm movement. The lower abdomen (navel to pubic bone) safely handles 15-20 mmHg compression, offering tummy control while accommodating digestive organ expansion. The lateral obliques work well with 20-25 mmHg compression for waist cinching without nerve compression.

The compression gradient also matters significantly. A graduated approach with higher compression at the waistline (22-25 mmHg) tapering to moderate compression at the rib cage (18-20 mmHg) and lower abdomen (15-18 mmHg) creates natural shaping while maintaining comfort. This gradient approach reduces the "muffin top" effect common with uniform high compression across the torso.

Abdominal compression strategy:

- Upper Abdomen: 18-25 mmHg, waist definition, diaphragm consideration

- Lower Abdomen: 15-20 mmHg, tummy control, organ accommodation

- Lateral Areas: 20-25 mmHg, waist cinching, nerve protection

- Graduated Approach: Mimics natural body contours

- Seam Placement: Avoids pressure points on sensitive areas

- Breathability Requirements: Higher in core body areas

How do limb and bust areas differ in compression needs?

Limb and bust compression requirements differ fundamentally from core areas due to vascular structures and movement patterns. Upper arms function best with 10-15 mmHg compression that smoothes without restricting circulation to hands. Thighs require 12-18 mmHg compression with higher tolerance on anterior areas (15-18 mmHg) than posterior (12-15 mmHg). Bust areas need delicate compression of 8-15 mmHg that supports without flattening, with lower compression near sternum and underarms.

The vascular considerations are particularly important in limbs. Compression exceeding 20 mmHg in upper arms may cause hand numbness, while thigh compression above 22 mmHg can lead to leg discomfort during extended sitting. Bust compression must accommodate respiratory movement and avoid pressure on lymph nodes. These physiological factors dictate more conservative compression approaches in peripheral areas.

Limb and bust specifications:

- Upper Arms: 10-15 mmHg, vascular protection, movement accommodation

- Thighs: 12-18 mmHg, anterior-posterior variation, sitting comfort

- Bust: 8-15 mmHg, sternum sensitivity, respiratory consideration

- Movement Requirements: Higher in limb areas than torso

- Sensitivity Factors: Dictate conservative compression approaches

- Garment Transition Zones: Require gradual compression changes

What testing methods verify compression performance?

Compression performance verification requires both laboratory testing and wear trials to ensure accuracy and comfort. Standard pressure measurement uses pneumatic sensors or pressure mapping systems that measure mmHg directly on the body. Laboratory testing employs tensile testers and recovery analyzers that predict compression performance based on fabric properties. The most reliable approach combines both methods to correlate fabric characteristics with actual wearer experience.

Our testing protocol involves three-phase validation: initial laboratory testing of fabric properties, mannequin testing with pressure mapping, and human wear trials with sensor arrays. This comprehensive approach identifies potential issues before production and ensures compression levels meet both design intentions and wearer comfort requirements.

How does pressure mapping validate garment performance?

Pressure mapping provides objective data on how compression garments actually perform on human bodies rather than just in laboratory conditions. Modern systems use sensor arrays with 100-200 sensing points that measure pressure distribution in mmHg across the garment-body interface. This reveals pressure peaks that may cause discomfort and areas with insufficient compression that reduce effectiveness.

The mapping process typically involves static positions (standing, sitting) and dynamic movements (walking, bending) to assess compression consistency. Our analysis shows that well-designed shapewear maintains compression within ±3 mmHg during movement, while poorly designed pieces may show variations up to ±10 mmHg, creating discomfort and reduced effectiveness. This data drives iterative improvements in pattern making and fabric selection.

Pressure mapping applications:

- Static Analysis: Standing, sitting compression consistency

- Dynamic Testing: Movement compression maintenance

- Peak Identification: Locates uncomfortable pressure points

- Gap Detection: Finds areas with insufficient compression

- Design Validation: Confirms zone compression strategies work

- Iterative Improvement: Drives pattern and fabric refinements

What laboratory tests predict real-world compression?

Laboratory tests provide efficient compression prediction before costly wear trials. Tensile testing measures fabric force at specific extensions, with 30-40% extension typically generating light compression (5-12 mmHg), 40-60% creating medium compression (12-18 mmHg), and 60-80% producing firm compression (18-25 mmHg). Recovery testing assesses compression maintenance after repeated stretching, with quality powernet maintaining 85-90% recovery after 100 stretch cycles.

Additional tests include compression gradient analysis across different body diameters and seam strength testing at stress points. Our correlation studies show that laboratory predictions typically align within ±2 mmHg of actual wear measurements when proper testing protocols are followed. This enables reliable compression engineering during development rather than reactive fixes after production.

Laboratory testing protocol:

- Tensile Analysis: Force measurement at target extensions

- Recovery Testing: Compression maintenance after cycling

- Gradient Assessment: Performance across body diameters

- Seam Integrity: Stress point durability

- Correlation Validation: Laboratory to wear trial alignment

- Quality Control: Production batch consistency verification

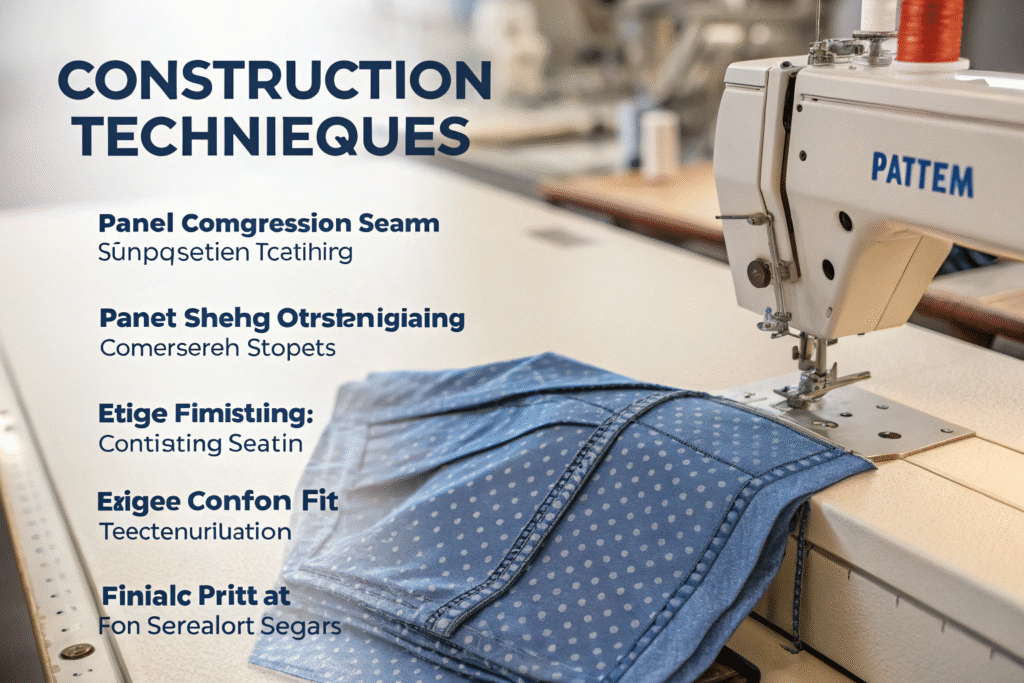

How do garment construction techniques affect compression?

Garment construction techniques significantly influence compression distribution, comfort, and effectiveness. Seam placement either enhances or disrupts compression flow, with flatlock seams maintaining even pressure while overlooking creates ridges. Panel shaping determines compression direction, with vertical panels creating lengthening effects and horizontal panels providing maximum circumference reduction. Edge finishing affects comfort, with laser-cut edges preventing digging and traditional elastic creating defined lines.

The interaction between pattern engineering and fabric properties creates the final compression experience. Our analysis shows that optimal shapewear uses 3-7 panels with strategic seam placement that follows body contours rather than fighting natural shapes. This approach achieves desired compression while maintaining wearer comfort and natural movement.

How does seam placement influence compression distribution?

Seam placement strategically directs compression flow and creates shaping effects. Vertical seams along the body's center lines enhance posture and create lengthening effects. Horizontal seams at the waistline maximize cinching and waist definition. Diagonal seams following muscle groups provide natural shaping and movement accommodation. Spiral seams around limbs ensure even compression distribution without tourniquet effects.

The seam type also impacts compression quality. Flatlock seams maintain consistent compression across joined panels with minimal ridge creation. Overlock seams create slight compression barriers that can be used strategically to enhance shaping. Ultrasonic welding eliminates seam bulk entirely, creating invisible joins with perfect compression continuity. Each technique serves different design purposes and compression intentions.

Seam placement strategies:

- Vertical Seams: Lengthening effects, posture enhancement

- Horizontal Seams: Cinching effects, waist definition

- Diagonal Seams: Natural shaping, movement accommodation

- Spiral Seams: Even distribution, tourniquet prevention

- Seam Type Selection: Matches compression continuity needs

- Strategic Barriers: Use seams to direct compression intentionally

What panel engineering optimizes zone compression?

Panel engineering creates zone compression by varying panel shapes, sizes, and orientations within a single garment. Abdominal panels typically use firm powernet (20-25% elastane) with horizontal orientation for maximum control. Lateral panels employ super powernet (25-30% elastane) with diagonal orientation for waist cinching. Back panels utilize standard powernet (15-20% elastane) with vertical orientation for postural support.

The panel transitions require careful engineering to prevent compression ridges and ensure smooth gradient changes. Our approach uses 15-25% panel overlap in transition zones with graduated seam allowances that create invisible compression changes. This technical construction prevents the visible panel lines that compromise garment appearance under clothing.

Panel engineering principles:

- Zone-specific Fabric: Match powernet type to compression needs

- Strategic Orientation: Direct compression intentionally

- Graduated Transitions: Smooth compression changes between zones

- Anatomical Shaping: Panels follow body contours

- Movement Accommodation: Panel sizing allows for body dynamics

- Visual Optimization: Prevent visible lines under clothing

What are the safety and comfort thresholds?

Safety and comfort thresholds define the operational boundaries for compression garment design. Medical guidelines indicate 25 mmHg as the maximum safe compression for extended wear in healthy individuals, with 15-20 mmHg representing the optimal balance of effectiveness and comfort. Comfort thresholds vary by body area, with torso areas tolerating higher compression (15-25 mmHg) than limbs (10-20 mmHg) and bust areas (8-15 mmHg).

Our wear trials identify specific comfort indicators: tingling or numbness signals excessive compression, fabric rolling indicates improper compression gradient, and breathing restriction suggests diaphragm compression issues. These markers help establish safe parameters and drive design improvements before market release.

What are the circulation and physiological considerations?

Circulation and physiological considerations dictate conservative compression approaches in specific areas. Limb compression must preserve arterial flow (typically requiring <20 mmHg) and avoid nerve compression. Abdominal compression should not restrict diaphragm movement or digestive organ function. Bust compression must avoid lymph node pressure and accommodate respiratory chest expansion.

The duration of wear also impacts safety thresholds. Medical-grade compression (20-25 mmHg) is typically recommended for 8-12 hour wear periods, while ultra-firm compression (25+ mmHg) should be limited to 4-6 hour special occasion use. These guidelines prevent potential issues like reduced circulation, nerve impingement, or skin irritation from prolonged high compression.

Physiological safety guidelines:

- Arterial Preservation: Limb compression <20 mmHg

- Respiratory Accommodation: Chest compression <15 mmHg

- Digestive Consideration: Abdominal compression gradients

- Nerve Protection: Avoid compression points on bony areas

- Duration Limits: Match compression level to wear time

- Health Screening: Consider wearer health conditions

How do you balance compression with wearability?

Balancing compression with wearability involves optimizing multiple factors simultaneously. The comfort-compression ratio should target 70-80% of maximum tolerable compression for each body zone, providing effectiveness while maintaining all-day comfort. Breathability requirements vary by area, with core zones needing 25-35 CFM air permeability and limb areas requiring 15-25 CFM for comfort.

The ease of movement represents another critical balance point. Garments should maintain 85-90% of natural movement range while providing targeted compression. This requires strategic fabric placement and pattern engineering that compresses without restricting. Our testing shows that wearers consistently prefer garments that achieve 75-85% of maximum possible compression while maintaining natural movement and comfort.

Wearability optimization:

- Comfort-Compression Ratio: 70-80% of maximum tolerance

- Breathability Requirements: Zone-specific air permeability

- Movement Preservation: 85-90% natural range maintained

- Donning/Doffing Ease: Consider mobility limitations

- Temperature Management: Match fabric to wear environment

- User Experience: Balance immediate comfort with long-term effectiveness

Conclusion

Setting compression levels for powernet fabrics requires systematic approach that balances fabric properties, body zone requirements, garment construction, and safety considerations. The most effective shapewear uses zone-specific compression strategies with abdominal areas (15-25 mmHg), limbs (10-20 mmHg), and bust (8-15 mmHg) each receiving appropriate compression levels. This targeted approach achieves desired shaping while maintaining wearer comfort and physiological safety.

Successful compression setting involves iterative testing and refinement using both laboratory methods and wear trials. Pressure mapping validates compression distribution, while tensile testing predicts performance during development. The final garment should provide consistent compression during movement, smooth transitions between zones, and maintain comfort through extended wear periods.

If you're developing shapewear and need guidance on compression setting, our technical team can recommend optimal strategies based on your target market, price points, and performance requirements. We maintain comprehensive testing data across powernet types and can provide fabric recommendations. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your shapewear compression needs.