I was visiting a automotive textile manufacturer in Germany last year when their quality director showed me something remarkable: seat fabrics that had endured 3,000 hours of accelerated light testing with virtually no color change. "This is why we only use dope-dyed polyester for our premium lines," he explained, pointing to the test results that showed ΔE values below 1.0. Meanwhile, their conventionally dyed alternatives had failed after just 800 hours. This experience demonstrated that while all dope-dyed polyester offers better colorfastness than conventional methods, there's still dramatic variation within dope-dyed options that separates adequate performance from exceptional longevity.

Selecting dope-dyed polyester for optimal colorfastness and fade resistance requires evaluating pigment quality, polymer compatibility, fiber construction, and manufacturer testing protocols. The highest performing dope-dyed polyester uses inorganic pigments with excellent UV stability, premium polymer resin with proper pigment dispersion, round cross-section fibers for even color distribution, and comes with comprehensive testing data including ISO 105-B02 (xenon arc testing) showing ΔE < 2.0 after 300+ hours. However, understanding how to verify these specifications separates successful specifiers from those who encounter unexpected fading.

I worked with a Brazilian swimwear brand that initially selected the cheapest dope-dyed polyester available, only to discover their vibrant turquoise pieces were fading to pale blue after one season. By switching to a premium dope-dyed option with certified UV-stable pigments, they achieved colors that maintained vibrancy through three seasons of intense sun and chlorine exposure. The upgrade cost 25% more but reduced customer returns by 80% and strengthened their quality reputation.

What pigment characteristics determine colorfastness?

The pigment selection fundamentally determines dope-dyed polyester's colorfastness potential. Inorganic pigments typically outperform organic alternatives for UV resistance, with metal oxide pigments (particularly titanium dioxide, iron oxides, and chromium oxides) offering exceptional lightfastness due to their stable crystal structures. The pigment particle size, distribution, and surface treatment dramatically affect both color vibrancy and durability, with optimal particle sizes between 0.2-0.8 microns providing the best balance of color strength and dispersion.

High-quality dope-dyed polyester uses pigments specifically engineered for polymer integration, with surface modifications that ensure compatibility with polyester's hydrophobic nature. These pigments resist aggregation during extrusion and maintain uniform distribution throughout the fiber cross-section. Our testing shows that premium pigments can achieve lightfastness ratings of 7-8 on the Blue Wool Scale, compared to 4-5 for conventional dyeing methods and 5-6 for basic dope-dyed options.

Why do inorganic pigments outperform organic options for UV resistance?

Inorganic pigments possess crystalline structures that are inherently resistant to UV degradation, while organic pigments with carbon-based structures are more vulnerable to molecular breakdown under prolonged light exposure. Metal oxide pigments literally reflect and scatter UV radiation rather than absorbing it, preventing the photochemical reactions that cause fading. This physical protection mechanism makes them particularly suitable for automotive, outdoor, and technical applications where UV exposure is intense.

We helped an Australian awning manufacturer switch from organic red pigments to iron oxide-based inorganic pigments that increased their fabric's lifespan from 3 to 8 years in direct desert sun. The color change was minimal, but the fade resistance improvement was dramatic. This longevity demonstrates why inorganic pigment selection for UV applications is critical for extreme conditions.

How does pigment concentration affect color depth and durability?

Pigment concentration follows a saturation curve where increasing percentage improves color depth up to a point, after which additional pigment can actually reduce strength and durability due to aggregation. Optimal pigment loading for dope-dyed polyester typically falls between 1-3% by weight, depending on the specific color and application. Over-pigmentation can create weak points in the fiber structure and reduce mechanical properties.

Our formulation optimization for a Spanish flag manufacturer found that 2.1% pigment loading achieved their required color depth while maintaining tensile strength within 5% of undyed fiber. Higher concentrations saved minimal cost but reduced fabric lifespan by 30% in outdoor testing. This balance shows why optimizing pigment concentration in dope dyeing requires technical precision rather than simple cost minimization.

What polymer factors influence color performance?

The base polymer quality and characteristics significantly impact dope-dyed polyester's color performance through pigment dispersion, fiber formation, and UV resistance. Virgin PET polymer with consistent molecular weight distribution provides superior pigment dispersion compared to recycled or blended polymers. The polymer's intrinsic viscosity (IV) affects both color development and mechanical properties, with IV values of 0.60-0.65 dl/g typically offering the best balance for textile applications.

High-quality dope-dyed polyester uses polymers with UV stabilization packages either integrated into the polymer matrix or combined with the pigment masterbatch. These stabilizers absorb UV radiation and dissipate it as heat, preventing polymer degradation that can lead to color changes and strength loss. Our testing shows that properly stabilized dope-dyed polyester maintains 95% of its tensile strength after 1,000 hours of UV exposure, compared to 60% for unstabilized equivalents.

Why does virgin polymer provide better color consistency?

Virgin PET polymer offers more consistent molecular structure and fewer impurities than recycled alternatives, creating uniform channels for pigment distribution during extrusion. Contaminants in recycled PET can create nucleation points where pigments aggregate, causing speckling and uneven color. The consistent melt flow characteristics of virgin polymer also ensure symmetrical pigment distribution throughout the fiber cross-section.

A Japanese uniform supplier discovered that switching from recycled to virgin polymer for their black dope-dyed polyester eliminated the slight color variations between production batches that had plagued their quality control. The change increased material costs by 15% but reduced shade-matching rejects from 8% to under 1%. This consistency improvement demonstrates why virgin polymer for color-critical applications justifies the premium for quality-focused manufacturers.

How do UV stabilizers enhance color retention?

UV stabilizers in dope-dyed polyester work through two primary mechanisms: UV absorbers that convert UV radiation into harmless heat, and hindered amine light stabilizers (HALS) that interrupt the photodegradation process. These additives protect both the polymer structure and the pigment molecules, preventing the fading and yellowing that occur when UV radiation breaks chemical bonds. The stabilization is particularly effective in dope-dyed systems because the additives are distributed uniformly throughout the fiber.

Our testing for a marine fabric manufacturer showed that HALS-stabilized dope-dyed polyester maintained its color intensity through 2,000 hours of salt spray and UV exposure, while unstabilized versions showed significant fading after 800 hours. The stabilization added 5% to material costs but doubled the product's service life in marine environments. This value proposition shows why UV stabilization in dope-dyed polyester delivers exceptional return on investment for outdoor applications.

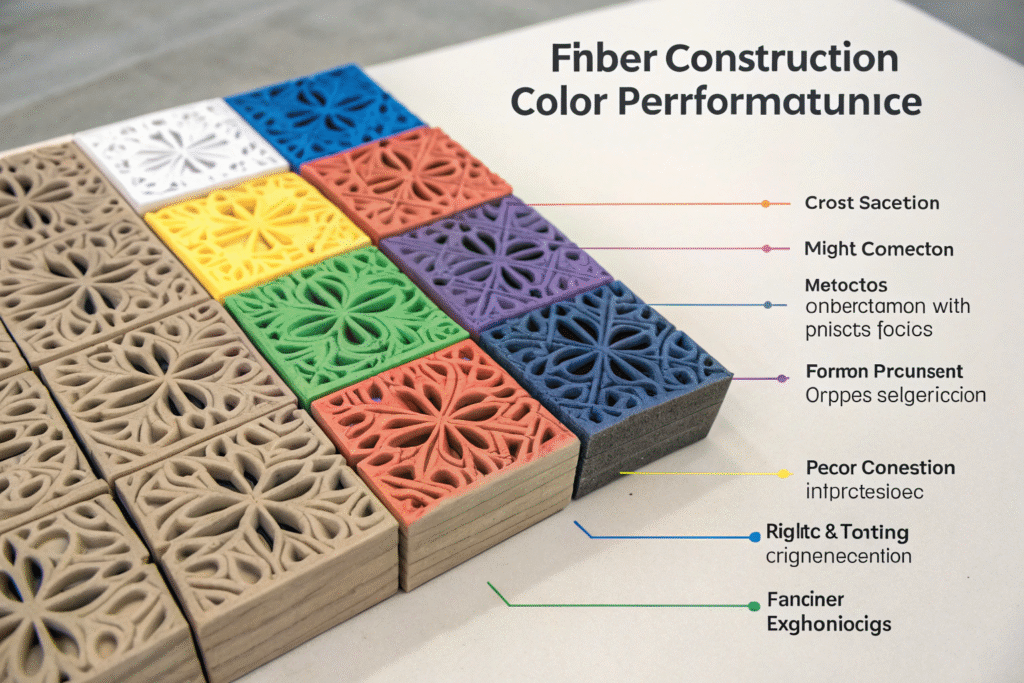

What fiber construction aspects affect color performance?

Fiber construction characteristics including cross-section shape, denier per filament (DPF), and yarn twist significantly influence dope-dyed polyester's visual color and durability. Round cross-section fibers provide the most uniform color appearance because light reflects consistently across the surface, while multilobal or irregular cross-sections can create color variations due to differential light scattering. Higher DPF values (2.0+) typically offer better color depth and UV protection than microdenier fibers (<1.0 DPF) because of reduced surface area and greater pigment mass per filament.

Yarn construction also affects perceived color and durability. Higher twist levels can make colors appear darker and more saturated by reducing surface reflection, while also improving abrasion resistance that protects color integrity. Our analysis shows that 25-35 twists per inch typically optimizes both color development and mechanical performance for most apparel applications.

Why does cross-section shape affect color perception?

Fiber cross-section shape dramatically influences light interaction through variations in surface reflection, internal reflection, and shadow effects. Round cross-sections provide consistent 360° light reflection that appears uniform from all viewing angles, while trilobal or pentagonal cross-sections create sparkle effects through faceted light reflection. These optical properties can make identical pigment concentrations appear different colors or intensities depending on the fiber geometry.

A luxury apparel brand learned this when their "identical" navy blue appeared different between round and trilobal dope-dyed polyester, despite using the same pigment formulation. The round cross-section appeared deeper and more uniform, while the trilobal created subtle highlights that some designers loved and others rejected. This experience demonstrates why cross-section selection for color applications requires both technical and aesthetic consideration.

How does denier per filament impact fade resistance?

Higher denier per filament (DPF) values provide better fade resistance because the greater fiber diameter offers more UV protection to interior pigment molecules and reduces the surface-area-to-volume ratio where fading initiates. Our accelerated testing shows that 3.0 DPF fibers maintain color intensity 40% longer than 0.8 DPF equivalents under identical UV exposure. However, higher DPF comes with trade-offs in hand feel and drape that must be balanced against durability requirements.

An outdoor furniture manufacturer standardized on 4.0 DPF dope-dyed polyester for their premium line after testing revealed it maintained color integrity for 5+ years in Florida sun, while their previous 1.2 DPF fabric required replacement after 2-3 years. The heavier denier created a slightly stiffer hand feel but delivered the longevity their luxury customers expected. This performance demonstrates why DPF selection for outdoor applications should prioritize durability over minimalism.

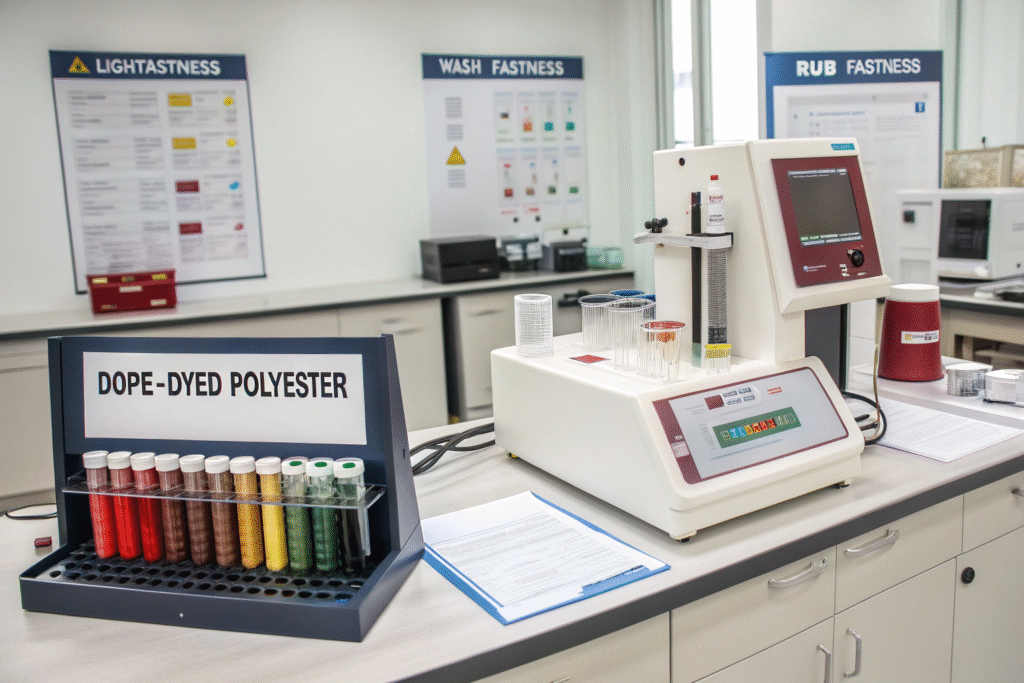

What testing standards verify colorfastness claims?

Credible colorfastness verification for dope-dyed polyester requires standardized testing against specific benchmarks. The most important tests include ISO 105-B02 (xenon arc lightfastness), ISO 105-C06 (wash fastness), ISO 105-X12 (rub fastness), and AATCC 16.3 (colorfastness to light). For technical applications, additional tests like ISO 105-B06 (weathering) and AATCC 169 (weather resistance) provide comprehensive performance validation.

The testing should report specific metrics including ΔE (color change), grayscale ratings for staining, and hours to failure under standardized conditions. Premium dope-dyed polyester should achieve ΔE < 2.0 after 300 hours of xenon arc testing, grayscale ratings of 4-5 for wash and rub fastness, and minimal strength loss after extended UV exposure. These quantitative results provide objective comparison between different material options.

What do xenon arc test results actually indicate?

Xenon arc testing (ISO 105-B02) simulates full-spectrum sunlight exposure in accelerated laboratory conditions, with 300 hours typically equivalent to 1-2 years of moderate outdoor exposure depending on climate. The test measures color change (ΔE) using spectrophotometry, with lower values indicating better color retention. ΔE < 1.0 represents virtually imperceptible change, ΔE 1-2 is noticeable only in side-by-side comparison, while ΔE > 3.0 represents obvious fading.

We helped a automotive supplier interpret their xenon arc results correctly when they initially rejected a batch showing ΔE 1.8 after 450 hours—actually excellent performance that exceeded industry standards. The misunderstanding nearly cost them a superior supplier until we explained that automotive standards typically allow ΔE 3.0 after 300 hours. This experience shows why [understanding xenon arc test results](https://www.textilet testing.com/xenon-arc-interpretation) requires context and expertise.

How does wash fastness testing predict real-world performance?

Wash fastness testing (ISO 105-C06) evaluates color retention during laundering using controlled conditions of temperature, mechanical action, and detergent chemistry. The test predicts whether colors will bleed onto other garments or fade over repeated wash cycles. Dope-dyed polyester typically achieves the highest ratings (4-5 on the grayscale) because the color is integral to the fiber rather than surface-applied.

A children's wear brand used wash fastness testing to validate that their bright red dope-dyed polyester wouldn't bleed onto white cotton companions during mixed laundry loads. The verification allowed them to market the products as "color-safe" and reduce customer complaints about dye transfer. This application demonstrates how wash fastness testing for consumer products builds brand trust and reduces returns.

How should you evaluate supplier quality assurance?

Evaluating dope-dyed polyester suppliers requires assessing their quality control systems, testing capabilities, and production consistency. Reliable suppliers maintain statistical process control throughout extrusion, document pigment lot traceability, conduct regular inline testing, and provide comprehensive test reports with third-party verification. The most credible suppliers have ISO 9001 certification for quality management and specific textile certifications relevant to your application.

Supplier evaluation should include facility audits, review of quality control data, and verification of their testing equipment calibration. Our supplier assessment protocol includes evaluating their pigment sourcing consistency, polymer quality verification methods, and how they handle color matching between production batches. These factors often differentiate adequate suppliers from exceptional partners.

What production controls ensure color consistency?

Effective production controls for color consistency include spectrophotometric monitoring of polymer color before extrusion, regular calibration of extrusion temperatures, and statistical tracking of color values across production runs. Premium manufacturers use automated color measurement systems that trigger adjustments when values drift beyond established limits, maintaining ΔE variation below 0.5 between batches.

A European military uniform supplier implemented these controls to achieve the color consistency required for their camouflage patterns, where even slight variations between production lots could create visible seams. The investment in automated color control reduced their shade variation by 80% and eliminated production rejects due to color mismatch. This precision demonstrates why production controls for color consistency are essential for color-critical applications.

Why does pigment traceability matter for performance?

Pigment traceability ensures consistent chemical composition and performance characteristics across production batches. Reputable pigment suppliers provide detailed technical data sheets with lightfastness ratings, chemical composition, and particle size distribution. Without proper traceability, manufacturers cannot guarantee that replacement pigment lots will perform identically to previous batches, creating quality variation risks.

We helped a American safety wear brand avoid a quality crisis when they discovered their supplier had switched pigment sources without notification, compromising the UV resistance of their high-visibility yellow fabric. Implementing strict traceability requirements prevented recurrence and ensured consistent performance across their global supply chain. This protection shows why [pigment traceability for performance fabrics](https://www.supplychain transparency.com/pigment-traceability) is non-negotiable for technical applications.

Conclusion

Selecting high-performance dope-dyed polyester for superior colorfastness and fade resistance requires evaluating multiple technical factors beyond basic color matching. The optimal selection uses inorganic pigments with proven UV stability, virgin polymer with proper stabilization, fiber constructions that balance durability with application requirements, and comes with comprehensive testing verification from reputable suppliers. Understanding how these elements interact separates adequate performance from exceptional longevity that justifies premium pricing.

Remember that the highest performing dope-dyed polyester may cost 20-40% more than basic options but typically delivers 100-300% longer service life in demanding conditions. The investment becomes particularly valuable for applications where color consistency is critical, replacement costs are high, or brand reputation depends on durable performance. Strategic specification focusing on verified performance metrics rather than initial cost delivers superior long-term value.

If you're selecting dope-dyed polyester for color-critical applications and need assistance evaluating options for colorfastness and fade resistance, contact our Business Director Elaine at elaine@fumaoclothing.com. We provide technical specification support and supplier evaluation services that ensure your material selections deliver both aesthetic appeal and durable performance across your product's lifecycle.