I've been in the fabric business for over twenty years, and if there's one question that separates amateur gear makers from professionals, it's this one. Choosing the wrong abrasion-resistant fabric can lead to product returns, damaged reputation, and worst of all—compromised safety for end-users. I've seen too many brands make the mistake of selecting fabric based on feel alone, only to discover their "tough" fabric wears out after six months of real-world use.

Selecting abrasion-resistant fabric requires understanding two key testing methods—Martindale and Wyzenbeek—and matching those results to your specific application. It's not about finding the highest numbers; it's about finding the right fabric that balances durability, weight, cost, and functionality for your exact needs. The right choice can extend your product's lifespan by years, while the wrong one dooms it to early failure.

Let me walk you through how we help our clients navigate this critical selection process. We'll break down the testing standards, explore different fabric constructions, and share real-world case studies that will help you make an informed decision for your backpack or workwear line.

What's the difference between Martindale and Wyzenbeek tests?

If you're sourcing technical fabrics, you've probably heard both terms thrown around. Many buyers get confused about which test matters for their application. The truth is, both tests measure abrasion resistance, but they do it in different ways and are suited to different types of fabrics.

Martindale testing is primarily used in Europe and applies a figure-8 rubbing motion to the fabric surface. It's better for fabrics that will experience multi-directional wear, like upholstery or clothing. Wyzenbeek testing, more common in North America, uses a back-and-forth linear motion that better simulates the kind of wear you'd see on workwear knees or backpack straps. Understanding this distinction is your first step toward proper fabric selection.

When should I use Martindale test results?

Martindale testing (ISO 12947) is your go-to for fabrics that experience complex, multi-directional abrasion. The test uses a swirling figure-8 pattern that wears the fabric from all directions. This makes it particularly relevant for backpack fabrics that experience rubbing from multiple angles, clothing that twists and moves with the body, and upholstery fabrics where people slide across surfaces.

The results are given in "rubs" or "cycles," with higher numbers indicating better durability. Here's a quick reference we give our clients:

- 10,000-15,000 cycles: Light duty apparel

- 20,000-30,000 cycles: Medium duty bags and clothing

- 40,000+ cycles: Heavy duty workwear and technical packs

Last spring, we worked with a Swedish backpack brand that was having premature wear on their hiking pack shoulders. Their previous supplier had provided fabric with only 15,000 Martindale cycles. We upgraded them to a 600D polyester with 45,000 Martindale cycles, and their warranty claims dropped by 70% in the first year.

When is Wyzenbeek testing more appropriate?

Wyzenbeek testing (ASTM D4157) is the North American standard that better simulates straight-line abrasion. The test uses a cotton duck fabric that moves back and forth across your test material. This linear motion closely mimics the wear patterns on workwear knees and elbows, backpack straps dragging across surfaces, and automotive upholstery where people slide in and out of seats.

Results are measured in "double rubs," with industrial applications typically requiring 30,000+ double rubs. For context, we consider:

- 15,000 double rubs: Light commercial use

- 30,000 double rubs: Heavy commercial use

- 50,000+ double rubs: Industrial/transportation use

In 2023, we helped a US workwear manufacturer solve a knee-wear problem on their carpenter pants. Their existing fabric failed at 18,000 Wyzenbeek cycles. We developed a ripstop nylon blend with reinforced yarns that achieved 65,000 cycles, effectively tripling the garment's lifespan in field testing.

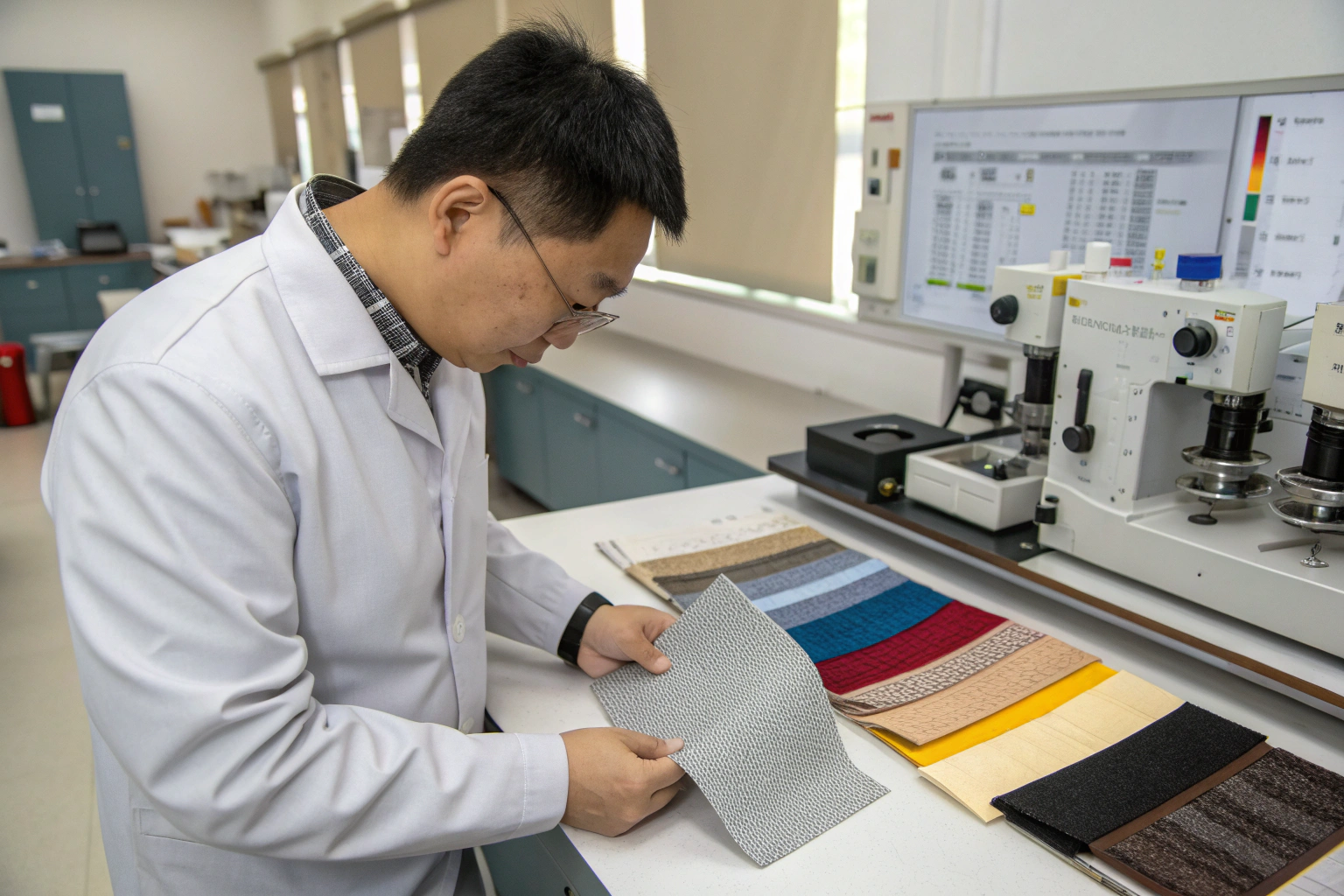

How does fabric construction affect abrasion resistance?

The testing numbers only tell part of the story. The real magic happens in how the fabric is constructed. I always tell clients: "The construction method can make or break your durability, regardless of the fiber type." Understanding construction gives you the power to predict performance beyond the test numbers.

There are three main construction methods we work with—woven, knit, and technical weaves—each with distinct advantages for different applications. Woven fabrics generally offer the best abrasion resistance due to their tight interlacing, while knits provide superior stretch and comfort. Technical weaves like ripstop and canvas offer specialized durability for high-stress areas.

What woven constructions work best for high-wear areas?

Woven fabrics create durability through the tight interlacing of warp and weft yarns. The density of this interlacing directly impacts abrasion resistance. For backpack straps and workwear knees, you want tightly woven constructions that prevent yarns from shifting under friction.

The most effective woven constructions we recommend include:

- Canvas: Dense plain weave that distributes abrasion across multiple yarns

- Twill: Diagonal rib pattern that resists abrasion while maintaining flexibility

- Dobby weaves: Complex patterns that create additional surface strength

Last quarter, we developed a custom ballistic nylon fabric for tactical gear that combined a 1000D nylon base with a 2x1 twill weave. This construction achieved 80,000+ Wyzenbeek cycles while maintaining the flexibility needed for tactical movements. The client reported zero abrasion failures after six months of military field testing.

Why are technical weaves like ripstop so durable?

Ripstop weaves incorporate reinforced threads at regular intervals, creating a grid pattern that stops tears from propagating. This construction is particularly valuable for applications where both abrasion resistance and tear strength are critical, like outdoor equipment and workwear reinforcement.

The key advantage of ripstop is how it localizes damage. When abrasion occurs, the reinforced grid contains the wear to a small area, preventing catastrophic failure. We often recommend ripstop for:

- Backpack bottoms and high-wear panels

- Workwear reinforcement at knees and elbows

- Tactical gear subjected to rough treatment

In 2022, we collaborated with a German outdoor brand on their mountaineering pack series. By using a 330D nylon ripstop with a polyurethane coating on high-wear areas, we achieved 70,000 Martindale cycles while reducing fabric weight by 15% compared to their previous solid weave construction.

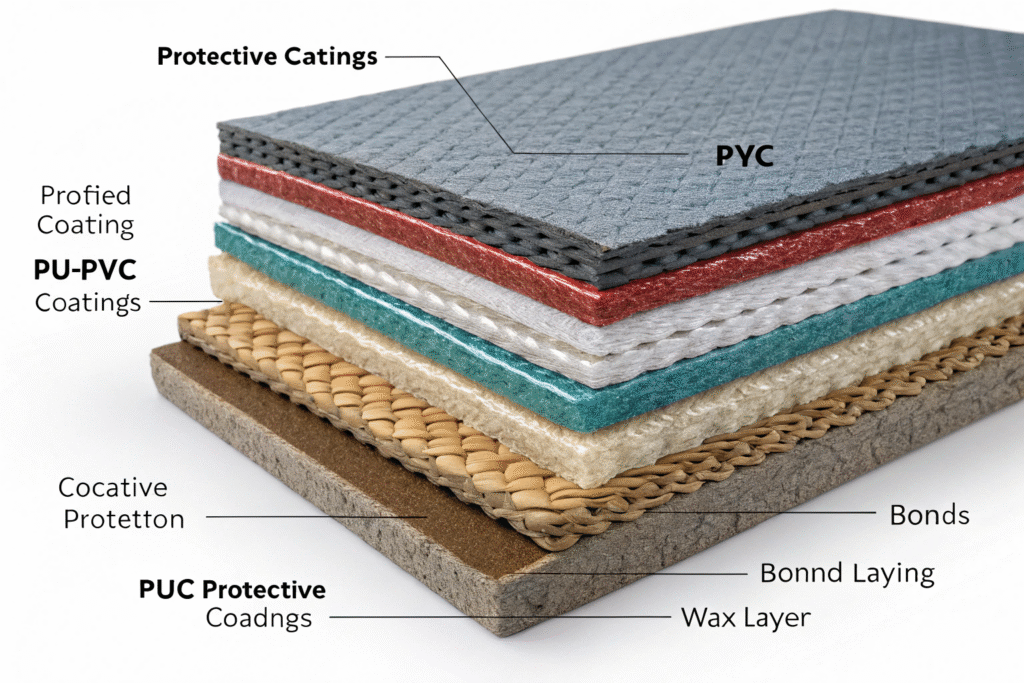

What role do coatings and finishes play in durability?

Many buyers focus solely on the base fabric but overlook the critical importance of coatings and finishes. I often say, "The coating is the fabric's first line of defense." A great base fabric with a poor coating will still fail prematurely, while a moderate fabric with the right coating can outperform expectations.

Coatings and finishes work by creating a protective layer that absorbs the initial abrasion, distributes the friction across a wider area, and reduces fiber shedding. The right coating can improve abrasion resistance by 30-50% while adding other functional benefits like water resistance or flame retardancy.

How do PU and PVC coatings compare for abrasion resistance?

Polyurethane (PU) and Polyvinyl Chloride (PVC) are the two most common protective coatings, but they serve different purposes. PU coatings are flexible, breathable, and provide excellent abrasion resistance without adding significant stiffness. PVC coatings are thicker, more rigid, and offer superior chemical resistance but can crack over time with repeated flexing.

Here's how we guide clients in choosing between them:

PU Coatings are better for:

- Backpacks and gear that need to remain flexible

- Workwear that requires breathability and movement

- Applications where weight matters

PVC Coatings are better for:

- Industrial workwear needing chemical protection

- Equipment covers and heavy-duty cases

- Applications where maximum waterproofing is crucial

We recently helped a safety equipment manufacturer select the right heavy-duty coating for industrial workwear that would withstand both abrasion and chemical exposure. After testing both options, we recommended a hybrid approach: PU coating for the main garment with PVC reinforcement panels in high-wear, high-exposure areas.

Can finishes really improve existing fabric performance?

Absolutely. Finishes can transform mediocre fabric into high-performance material. The most effective abrasion-resistant finishes work by either bonding protective particles to the fabric surface or by chemically strengthening the individual fibers.

The game-changer in recent years has been nano-technology finishes that create an invisible protective layer at the molecular level. We've seen some nano-finishes improve Martindale test results by up to 40% without changing the fabric's hand feel or breathability.

In 2023, we applied a silicon oxide nano-finish to a standard 500D polyester for a luggage manufacturer. The treatment increased their Wyzenbeek results from 35,000 to 52,000 double rubs while adding less than 3% to the fabric cost. The client was able to market their product as "premium durability" without significant cost increases.

How do I match test results to real-world applications?

This is where theory meets practice. I've seen clients get obsessed with test numbers without considering how those numbers translate to actual product performance. The key is understanding that different applications create different types of abrasion, and your fabric selection should reflect these real-world conditions.

A backpack strap experiences different wear patterns than workwear knees. A tool pouch has different requirements than tactical vest. By analyzing how and where abrasion occurs in your specific product, you can make smarter decisions about where to invest in higher test numbers and where you can save costs.

What test numbers do specific applications require?

Through twenty years of testing and customer feedback, we've developed reliable correlations between test results and real-world performance. These guidelines help our clients avoid both over-engineering and under-engineering their products.

For backpacks and bags:

- Shoulder straps: 40,000+ Wyzenbeek or 60,000+ Martindale

- Bottom panels: 30,000+ Wyzenbeek or 50,000+ Martindale

- Main body: 20,000+ Wyzenbeek or 30,000+ Martindale

For workwear and uniforms:

- Knees and elbows: 50,000+ Wyzenbeek or 70,000+ Martindale

- Seat areas: 30,000+ Wyzenbeek or 50,000+ Martindale

- Main body: 15,000+ Wyzenbeek or 25,000+ Martindale

Last year, we helped a professional workwear brand optimize their fabric specifications across their entire product line. By matching test numbers to actual wear patterns, we reduced their fabric costs by 18% while actually improving durability in high-stress areas through strategic reinforcement.

How does fiber content influence long-term durability?

While construction and coatings handle surface abrasion, the fiber content determines how well the fabric maintains its integrity over time. Different fibers have inherent properties that make them suitable for different applications.

Nylon generally offers the best abrasion resistance due to its high tensile strength and elasticity. Polyester provides excellent resistance to UV degradation and moisture. Poly-cotton blends balance durability with comfort and breathability.

We recently conducted a six-month field test comparing different fiber compositions for delivery driver uniforms. The 65/35 poly-cotton blend outperformed 100% cotton by 300% in abrasion resistance, while the 100% polyester showed minimal wear but received complaints about breathability. The blended fabric provided the optimal balance of durability and wearer comfort.

Conclusion

Selecting the right abrasion-resistant fabric isn't about finding the highest test numbers—it's about understanding the relationship between Martindale/Wyzenbeek testing, fabric construction, protective coatings, and your specific end-use requirements. The most successful products balance all these factors to deliver optimal performance at the right cost point.

Remember that the best fabric choices come from considering the entire system: how the fibers, weave, and coatings work together to resist the specific type of abrasion your product will face. Don't get trapped into comparing single numbers without understanding the bigger picture of how your product actually gets used in the real world.

If you're working on a backpack, workwear line, or any product where durability matters, let's have a conversation. We can help you select the right fabric based on your specific needs and budget. Contact our Business Director Elaine today to discuss your project: elaine@fumaoclothing.com.