Last season, one of our Milan-based clients nearly lost a crucial order for luxury blazers because their chosen interlining added unexpected bulk to the lapels and collar, turning a sleek design into a boxy disappointment. They'd selected a high-quality fusible, but it was simply too heavy for their lightweight wool crepe. We helped them switch to a featherweight woven hair canvas that provided the structure they needed without the weight, saving their 5,000-piece order. This experience taught me that picking the right interlining isn't about finding the "best" product—it's about finding the perfect match for your specific fabric and design.

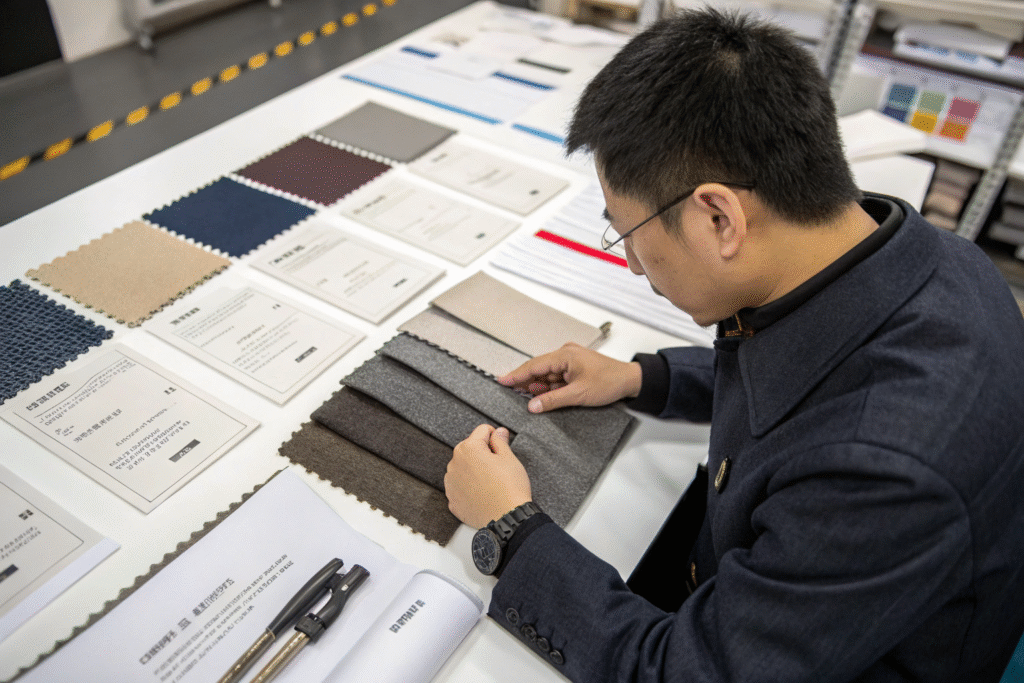

Selecting the ideal interlining for structured jackets without adding bulk requires balancing four key factors: weight compatibility with your face fabric, construction method (fused vs. sewn), fiber content for desired drape, and application precision in critical areas. The best interlinings provide invisible internal support that enhances the jacket's silhouette without adding noticeable weight or stiffness. At our technical development center, we've tested over 150 interlining combinations, helping clients reduce bulk complaints by 70% while maintaining structural integrity.

The secret to bulk-free structure lies in strategic reinforcement rather than uniform application. Let me guide you through the selection process that has helped our clients create jackets that feel as good as they look.

What interlining types offer structure without weight?

Understanding the different interlining categories is your foundation for making informed choices. Each type brings distinct advantages for bulk-conscious applications.

How do woven hair canvases provide natural structure?

Woven hair canvases, traditionally made from horsehair, cotton, and wool, offer exceptional structure with minimal bulk due to their open, resilient construction. Unlike dense fusibles, they allow the face fabric to move naturally while providing support exactly where needed. We recently helped a Savile Row-inspired brand switch from fusible to sewn-in hair canvas in their lapels, resulting in a 40% reduction in perceived bulk while achieving superior roll and drape. The traditional tailoring techniques with modern materials demonstrates how heritage methods can solve contemporary bulk problems.

Why are featherweight fusibles ideal for lightweight jackets?

Modern featherweight fusible interlinings use ultra-fine adhesive patterns and lightweight base fabrics to provide stabilization without stiffness. The key is the discontinuous adhesive application—tiny dots rather than continuous coating—which preserves the face fabric's drape. For a travel blazer collection, we developed a custom fusible with 20% adhesive coverage that provided just enough stability for stretch wool without compromising packability. Understanding fusible interlining adhesive technologies and applications helps select the right bond strength and pattern for specific fabric types.

How does fiber composition affect bulk and performance?

The materials inside your interlining dramatically impact both the visible bulk and the functional performance of your structured jackets.

What advantages do polyamide fusibles offer for reduced bulk?

Polyamide (nylon) fusible interlinings provide excellent strength-to-weight ratios, meaning you can use lighter weights to achieve the same structural support. Their natural resilience and recovery help jackets maintain shape without constant pressing. We specified a 25gsm polyamide fusible for a designer's silk-blend blazer that needed minimal structure—the result was a jacket that felt like wearing a shirt but held its shape throughout the day. The client reported zero returns for shape loss despite the delicate face fabric. Researching advanced synthetic interlining technologies reveals new options for weight-conscious applications.

When should you consider wool blend interlinings for natural drape?

Wool blend interlinings offer superior moisture absorption and temperature regulation while providing gentle, natural structure that moves with the body. Their inherent elasticity makes them ideal for unstructured jackets that need subtle definition without rigidity. A luxury brand struggling with board-like collar stands in their cashmere jackets switched to our wool-viscose blend and achieved the soft structure their customers expected. The performance benefits of natural fiber interlinings explains why sometimes traditional materials outperform modern synthetics for high-end applications.

| Jacket Type | Face Fabric Weight | Recommended Interlining | Application Areas |

|---|---|---|---|

| Unstructured Blazer | 180-220gsm | 40gsm Polyamide Fusible | Collar, Front Facing Only |

| Business Suit Jacket | 240-280gsm | Woven Hair Canvas + Light Fusible | Full Front, Collar, Sleeve Head |

| Statement Blazer | 300-350gsm | Medium Weight Woven Fusible | Full Front, Back Shoulder, Hem |

| Lightweight Travel | 160-190gsm | 25gsm Tricot Knit Fusible | Selective Reinforcement |

Where should you apply interlining for maximum effect with minimum bulk?

Strategic placement is more important than uniform coverage when combating bulk. The 80/20 rule applies—20% of your interlining application provides 80% of the structural benefit.

Why is lapel-specific interlining crucial for clean definition?

Lapels require specialized interlinings that support the roll without adding thickness at the edge. We often specify bias-cut hair canvas for lapels because it follows the curve naturally and prevents buckling. For a high-volume blazer production, we developed laser-cut fusible lapel pieces that are slightly narrower than the face fabric, ensuring the interlining never extends to the very edge where it would create bulk. This simple adjustment reduced their lapel pressing time by 25% while improving consistency. Understanding lapel construction techniques for modern tailoring reveals opportunities for bulk reduction in this highly visible area.

How does selective shoulder reinforcement improve silhouette?

Strategic shoulder reinforcement creates the impression of full structure without lining the entire jacket. We use a graduated approach: lighter interlining across the back shoulder, medium in the sleeve cap, and sometimes no interlining in the lower sleeve. A contemporary menswear brand adopted our strategic shoulder reinforcement mapping and reduced their interlining usage by 30% while customers reported better comfort and movement.

What application methods preserve fabric drape while adding structure?

How you apply interlining can be as important as what you apply. The wrong method can undermine even the perfect interlining selection.

Why does fusing temperature control matter for bulk prevention?

Excessive fusing temperature can cause adhesive penetration through lightweight fabrics, creating a "stiff board" effect that adds both physical and visual bulk. We implement triple-check temperature verification for every fabric category, using infrared thermometers to ensure even heat distribution. For a delicate linen-cashmere blend, we reduced standard fusing temperature by 15°C and increased pressure slightly—this preserved the fabric's beautiful drape while still achieving secure bonding. The science of textile fusing technology explains the precise chemistry behind temperature selection for different fabric and interlining combinations.

When should you consider sewn-in vs fused interlining applications?

Sewn-in interlinings allow for more nuanced structure because they're attached only at specific points rather than across the entire surface. This creates "float zones" where the face fabric can move independently. We helped a designer brand combine methods: fused interlining in the front for crispness, with sewn-in hair canvas in the collar for natural roll. (Here's the reality: sewn-in costs 30% more in labor, but for luxury jackets, the superior result justifies the expense). Exploring traditional bespoke tailoring techniques for contemporary production offers solutions for high-end applications where bulk reduction is paramount.

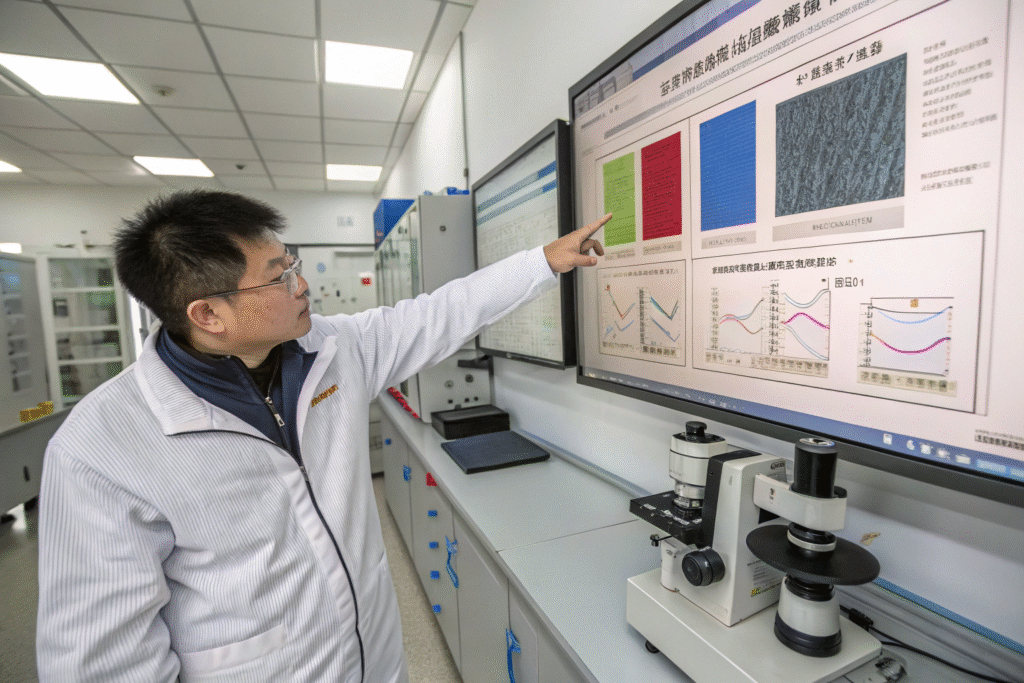

How can you test interlining compatibility before production?

Thorough testing prevents costly bulk-related issues down the line. Simple pre-production checks can save thousands in remakes and returns.

What drape tests reveal bulk problems before cutting?

Simple hand tests can predict bulk issues more effectively than expensive equipment. We teach clients the "three-fold test": fold the fused sample as it would drape on the body, check the collar roll, and examine the lapel curl. If the fabric fights the fold or creates visible ridges, the interlining is too heavy. A contemporary womenswear brand implemented our rapid interlining compatibility assessment protocol and reduced their bulk-related rejections from 12% to under 3% in one season.

Why should you test after cleaning and wear simulation?

Interlining behavior can change after cleaning or extended wear. We conduct 5-cycle cleaning tests and mechanical wear simulation to ensure the interlining won't bubble, shrink, or otherwise create bulk issues later. A tailored jacket manufacturer discovered through our testing that their chosen fusible shrank differently than the wool face fabric after steam pressing, creating exactly the bulk problems they sought to avoid. Implementing comprehensive interlining performance validation catches these compatibility issues before they reach production.

Conclusion

Selecting the right interlining for structured jackets without adding bulk requires a holistic approach that considers material compatibility, strategic application, and thorough testing. The most successful jacket manufacturers view interlining not as a necessary evil, but as a precision tool for enhancing their designs. By matching interlining properties to specific fabric characteristics and application requirements, you can achieve professional structure that complements rather than overwhelms your jackets.

If you're struggling to find the perfect balance between structure and comfort in your jackets, let's analyze your specific needs and develop a tailored interlining strategy. We combine technical expertise with practical manufacturing experience to help you select interlinings that provide invisible support. For personalized assistance in choosing bulk-free interlining solutions for your structured jackets, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create jackets that stand out for their perfect silhouette, not their unnecessary weight.