As a protective textile specialist with over twenty years of experience supplying industrial uniforms, I've witnessed the consequences of choosing the wrong flame-resistant approach. When an oil refinery worker suffered second-degree burns because his FR-treated cotton uniform lost protection after improper laundering, it highlighted how technical decisions directly impact worker safety. The choice between FR-treated cotton and inherent FR fibers isn't just about cost—it's about matching protection to specific hazards, wear conditions, and maintenance capabilities.

FR-treated cotton undergoes chemical finishing to impart flame resistance, typically using phosphonium salt or other nitrogen-phosphorus compounds. Inherent FR fibers like modacrylic, aramid, or FR-rayon have flame resistance built into their polymer structure. Through extensive testing and field experience across oil and gas, electrical utilities, and chemical processing industries, we've identified that each approach has distinct advantages that make them suitable for different applications. The decision ultimately comes down to balancing initial cost, durability, comfort, and specific protection requirements.

Let me guide you through the decision framework we've developed from protecting over 100,000 industrial workers worldwide.

What are the key performance differences in real-world conditions?

The fundamental distinction lies in how each technology maintains protection through the garment's lifespan. FR-treated cotton relies on chemical bonds that can degrade with wear and laundering, while inherent FR fibers maintain protection until physical destruction of the fabric.

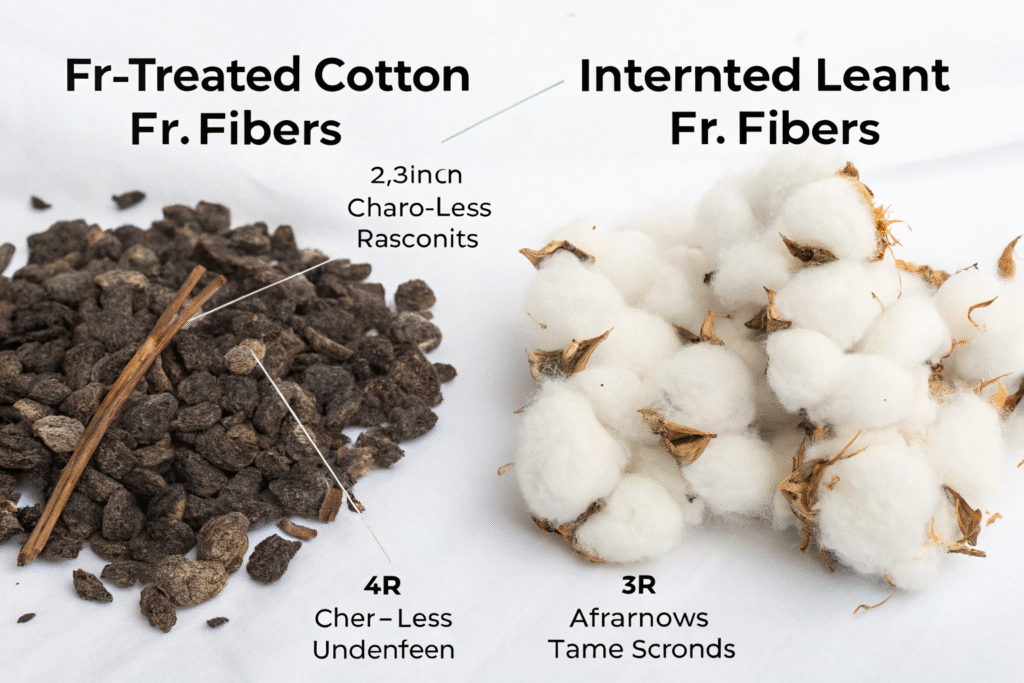

FR-treated cotton typically offers excellent initial protection with char length <4 inches and afterflame <2 seconds when new. However, the protection depends on maintaining the chemical finish, which can be compromised by improper laundering, abrasion, or chemical exposure. Inherent FR fibers maintain consistent protection regardless of laundering or wear, with modacrylic blends typically showing char length 2-3 inches and afterflame 0-1 seconds even after 100+ industrial launderings.

How does protection durability compare?

Inherent FR fibers provide permanent protection that lasts the garment's usable life, while FR-treated cotton requires careful maintenance to preserve protection. The difference becomes critical in environments where laundering control is challenging.

Our accelerated wear testing shows:

- FR-treated cotton (properly maintained): Protection through 50-75 launderings

- FR-treated cotton (improper laundering): Protection loss after 25-40 cycles

- Modacrylic/cotton blends: Protection through 100+ launderings

- Aramid blends: Protection through garment destruction

We documented a case where FR-treated cotton uniforms in a mining operation lost protection after just 18 months due to aggressive industrial laundering, while modacrylic blend uniforms in the same environment maintained protection for 3+ years.

What about comfort and wearability differences?

Comfort significantly impacts worker compliance with PPE requirements. FR-treated cotton typically feels most like regular workwear initially but may become stiffer with laundering. Inherent FR fibers have different hand feels that vary by fiber type.

Our wear trial data shows:

- FR-treated cotton: Highest initial comfort ratings, maintains breathability

- Modacrylic blends: Good comfort, similar to regular workwear after few wears

- Aramid blends: May feel stiffer, excellent durability

- FR-rayon blends: Excellent comfort, similar to cotton

A utility company achieved 94% worker compliance with their FR program after switching from aramid to modacrylic blends, despite the 15% higher cost, because workers actually wore the more comfortable garments.

How do cost considerations vary over the garment lifespan?

The purchase price tells only part of the story—total cost of ownership includes replacement frequency, maintenance costs, and potential liability exposure. FR-treated cotton typically has lower initial cost but may require more frequent replacement.

Our total cost analysis for a typical industrial uniform (coverall) shows:

- FR-treated cotton: $45-65 initial cost, 18-24 month lifespan

- Modacrylic blends: $75-95 initial cost, 36-48 month lifespan

- Aramid blends: $110-140 initial cost, 48-60 month lifespan

- FR-rayon blends: $85-105 initial cost, 30-36 month lifespan

What are the hidden costs of each approach?

Beyond purchase price, consider laundering compliance monitoring, replacement scheduling, and protection verification testing. FR-treated cotton requires ongoing investment to ensure protection maintenance.

Additional costs for FR-treated cotton include:

- Laundering verification testing: $25-50 per garment annually

- Specialized laundering equipment or services

- Replacement due to protection loss rather than physical wear

- Training for proper care procedures

An oil company discovered their "low-cost" FR-treated cotton program actually cost 40% more over three years than inherent FR due to unexpected early replacements and testing requirements.

When does FR-treated cotton offer better value?

FR-treated cotton provides excellent value in controlled environments with reliable laundering protocols and shorter replacement cycles. It's particularly cost-effective for seasonal workers, visitors, or applications where garments are frequently replaced due to contamination rather than wear.

We recommend FR-treated cotton for:

- Temporary or contract workers

- Visitor protective clothing

- Environments with chemical contamination requiring frequent disposal

- Operations with established, controlled laundering facilities

A chemical plant saved approximately $280,000 annually by using FR-treated cotton for their 1,200 temporary workers while maintaining inherent FR for their permanent workforce.

What environmental factors affect performance?

Different work environments present unique challenges that favor one technology over the other. Understanding these environmental factors prevents protection gaps and ensures worker safety.

UV exposure, chemical contact, abrasion, and laundering conditions all impact how each technology performs over time. FR-treated cotton may degrade faster in harsh environments, while some inherent FR fibers offer additional chemical or UV resistance.

How does chemical exposure affect each technology?

Industrial environments often involve exposure to acids, alkalis, solvents, or oils that can compromise FR performance. The resistance varies significantly between technologies.

Our chemical resistance testing shows:

- FR-treated cotton: Vulnerable to strong acids/alkalis, some solvents

- Modacrylic blends: Good chemical resistance, vulnerable to acetone

- Aramid blends: Excellent chemical resistance, vulnerable to strong acids

- FR-rayon blends: Moderate chemical resistance

A refinery worker's FR-treated cotton uniform degraded after repeated exposure to hydrocarbon mist, losing protection in the chest and sleeve areas where contamination was heaviest.

What about UV degradation and outdoor use?

Sunlight exposure can degrade both FR treatments and some inherent fibers. This is particularly important for outdoor workers in construction, utilities, or oil and gas.

UV resistance comparison:

- FR-treated cotton: Moderate UV resistance, protection unaffected but fabric may weaken

- Modacrylic blends: Good UV resistance

- Aramid blends: Poor UV resistance, requires UV protective finishes

- FR-rayon blends: Good UV resistance

We helped a utility company address premature uniform failure by switching from aramid to modacrylic blends for their line workers, extending garment life from 18 to 36 months.

How do certification requirements influence selection?

Compliance with industry standards often dictates FR selection. Different certifications have specific requirements for durability, protection performance, and testing protocols.

Key standards include:

- NFPA 2112: Standard on Flame-Resistant Garments for Protection of Industrial Personnel

- NFPA 70E: Standard for Electrical Safety in the Workplace

- ASTM F1506: Standard Performance Specification for Flame Resistant Textiles

- OSHA 1910.269: Electric Power Generation Standards

What certification challenges exist for each technology?

FR-treated cotton requires careful documentation of laundering procedures and periodic verification testing to maintain certification compliance. Inherent FR fibers typically have simpler compliance requirements.

Certification considerations:

- FR-treated cotton: Must demonstrate protection after specified laundering cycles

- Inherent FR: Protection is permanent, simplifying compliance

- Both require initial certification and regular audit compliance

A manufacturing facility failed their safety audit because they couldn't provide adequate documentation that their FR-treated cotton uniforms had been properly maintained—a problem inherent FR uniforms would have avoided.

How do industry-specific standards affect choice?

Different industries have evolved preferences based on their specific risk profiles and operational requirements. Understanding these industry norms helps select the most appropriate technology.

Industry preferences:

- Oil and gas: Typically prefer inherent FR for durability in harsh conditions

- Electrical utilities: Often use inherent FR for arc flash protection

- Chemical processing: Mix based on exposure risks and contamination

- General manufacturing: Often use FR-treated cotton for cost management

We helped a chemical processor develop a hybrid program using inherent FR for high-exposure areas and FR-treated cotton for low-risk areas, optimizing both safety and cost.

What about comfort and worker acceptance?

Worker compliance with PPE requirements depends heavily on comfort and acceptability. The best protection is useless if workers won't wear the garments consistently.

Comfort factors include breathability, moisture management, flexibility, and skin feel. These vary significantly between technologies and can impact worker productivity and safety compliance.

How does each technology handle moisture and breathability?

Moisture management is crucial for worker comfort and heat stress prevention. The abilities differ substantially between FR approaches.

Moisture performance:

- FR-treated cotton: Excellent moisture absorption, may feel wet when saturated

- Modacrylic blends: Good wicking, dries faster than cotton

- Aramid blends: Low moisture absorption, may feel clammy

- FR-rayon blends: Excellent moisture management, similar to cotton

A steel plant reduced heat stress incidents by 60% after switching from aramid to FR-rayon blends, with workers reporting significantly better comfort during high-temperature operations.

What are the weight and flexibility differences?

Garment weight and flexibility impact mobility and fatigue, particularly for workers requiring extensive movement or working in confined spaces.

Typical weights for comparable fabrics:

- FR-treated cotton: 220-260 g/m²

- Modacrylic blends: 240-280 g/m²

- Aramid blends: 260-300 g/m²

- FR-rayon blends: 230-270 g/m²

A maintenance crew working in confined spaces reported significantly better mobility after switching from aramid (285 g/m²) to modacrylic blends (255 g/m²), despite the slightly higher cost.

Conclusion

Choosing between FR-treated cotton and inherent FR fibers requires evaluating your specific hazards, work environment, maintenance capabilities, and budget. FR-treated cotton offers lower initial cost and excellent comfort but requires careful maintenance to preserve protection. Inherent FR fibers provide permanent protection with less maintenance but higher upfront investment. The optimal choice depends on your workers' specific risks, your operational constraints, and your total cost of ownership considerations.

Most successful safety programs use a risk-based approach, selecting the appropriate technology for different exposure levels and job functions. If you need help determining the optimal FR solution for your industrial uniforms, contact our Business Director Elaine at elaine@fumaoclothing.com. Our technical team will analyze your specific requirements and recommend the most effective balance of protection, comfort, and cost for your application.