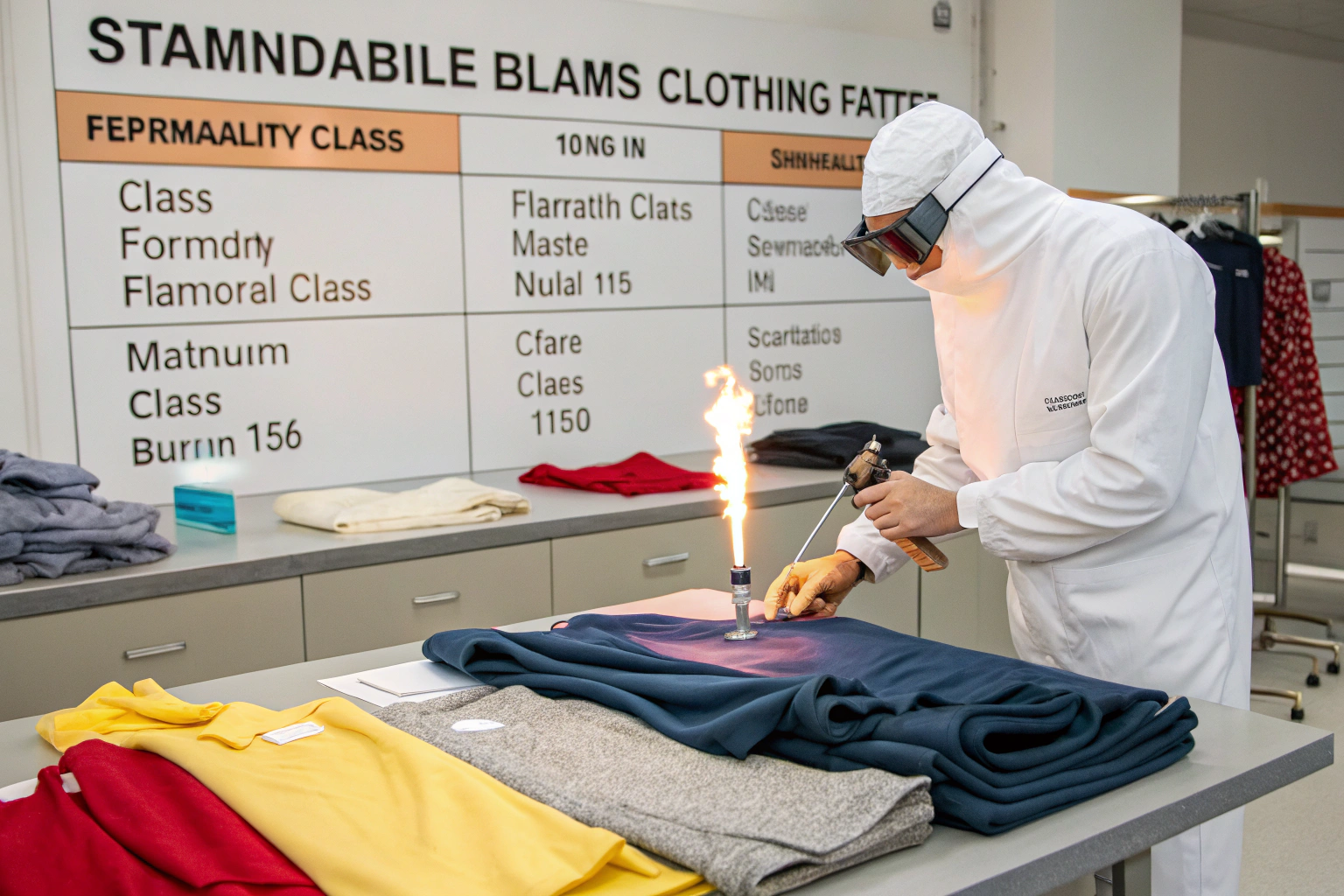

As someone who's been in the textile industry for over 20 years, I understand the growing demand for chemical-free solutions. Many brands today want to avoid flame retardant chemicals while still meeting safety standards. The good news? It's absolutely possible to pass 16 CFR 1610 without relying on chemical treatments.

16 CFR 1610 is the Standard for the Flammability of Clothing Textiles, and it classifies fabrics into three categories based on their burn rate. Class 1 is normal flammability and is acceptable for most clothing. The key to passing without FR chemicals lies in selecting the right inherent fiber properties and fabric constructions that naturally resist ignition or slow down burning.

Let me share some proven strategies that have worked for our clients worldwide.

Which fabric constructions naturally meet Class 1 requirements?

The construction of your fabric plays a crucial role in how it responds to fire. Tight weaves and heavy weights generally perform better because they have less air permeability and more mass to absorb heat. This isn't just theory—we've tested thousands of fabric samples in our CNAS-certified lab and found consistent patterns.

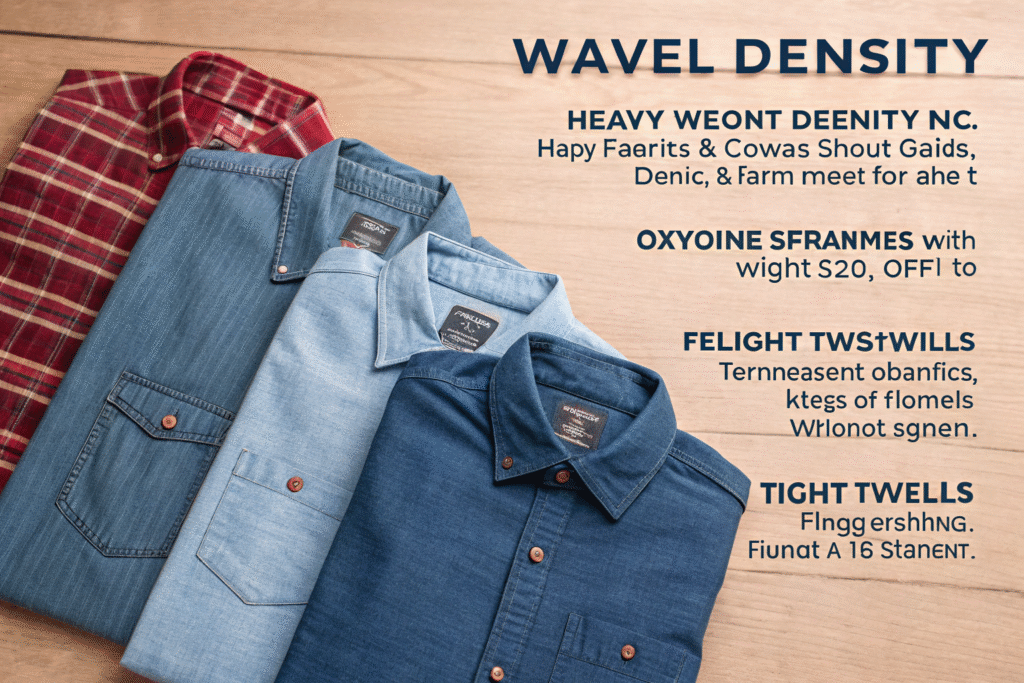

Fabric weight and weave density are your best friends here. Heavier fabrics with tight constructions like denim, canvas, and tight twills typically pass Class 1 without any chemical assistance. The reason is simple: these fabrics don't allow enough oxygen flow to support rapid burning, and their density means it takes more heat energy to ignite them. Last year, we worked with an outdoor brand from Colorado that needed heavy flannel shirts to pass 16 CFR 1610 without chemicals. By optimizing the yarn twist and increasing threads per inch, we achieved Class 1 rating while maintaining the soft hand feel they wanted.

How does fabric weight affect flammability performance?

Fabric weight directly correlates with flammability performance. Heavier fabrics generally have better inherent flame resistance because they have more thermal mass—meaning they absorb more heat before reaching ignition temperature. In our testing, fabrics weighing above 200 GSM consistently perform better in 16 CFR 1610 testing.

Consider this comparison from our internal database:

| Fabric Type | Weight (GSM) | Typical Class Rating | Notes |

|---|---|---|---|

| Lightweight Cotton Voile | 85-100 | Class 3 | High risk, burns quickly |

| Standard Cotton Poplin | 120-140 | Class 2 | Moderate burn rate |

| Denim | 200-400 | Class 1 | Slow, self-extinguishing |

| Wool Coating | 350-600 | Class 1 | Naturally flame-resistant |

We recently helped a workwear client transition their entire line to chemical-free FR by strategically selecting inherently flame-resistant natural fiber blends that met their weight requirements. The result was a 40% reduction in compliance issues while maintaining their price point.

What weave structures provide the best protection?

Tight weave structures create a natural barrier against flame spread. The fewer gaps between yarns, the less oxygen available to fuel combustion. In our experience, plain weaves with high thread counts, tight twills, and double cloth constructions consistently outperform looser weaves.

Here's what we've observed: fabrics with thread counts above 140 threads per inch typically achieve Class 1 ratings. The tight construction literally smothers the flame by limiting oxygen supply. We recently developed a technical analysis of tight weave structures for flame resistance for a client that wanted chemical-free children's sleepwear. By using a double weave construction with mercerized cotton, we created a fabric that passed Class 1 while remaining soft and comfortable for children's sensitive skin.

Which natural fibers have inherent flame resistance?

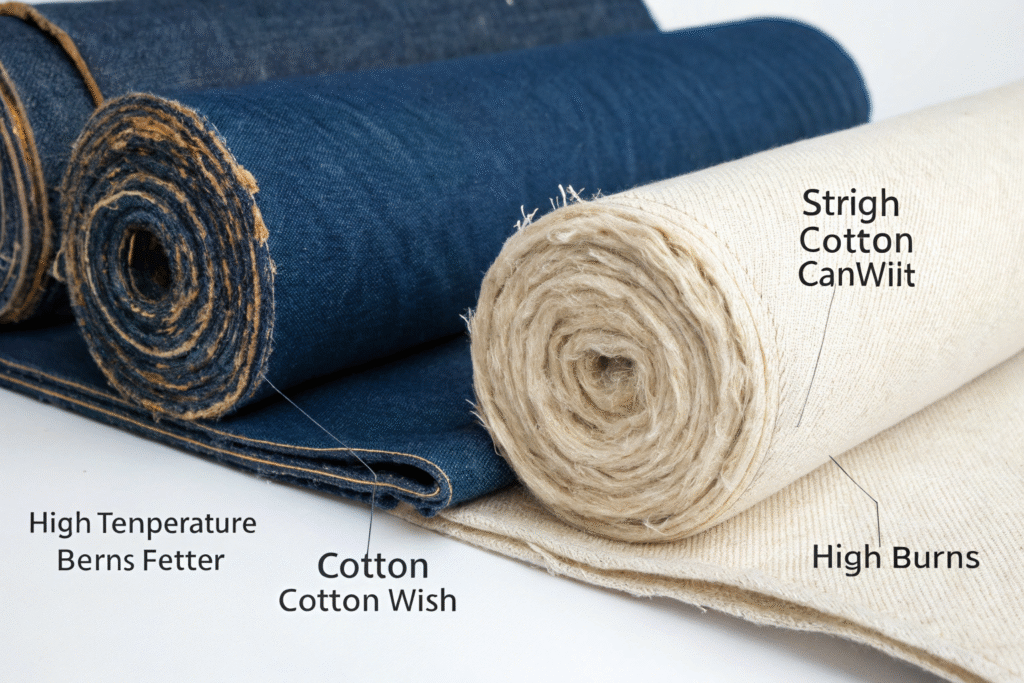

Some natural fibers have built-in properties that make them naturally more flame-resistant than others. Wool is the superstar here, but other fibers like silk and certain heavy cottons can also perform well without chemical treatments.

Wool is naturally flame-resistant due to its high nitrogen content and moisture absorption properties. It ignites at higher temperatures than many other fibers and tends to self-extinguish when the flame source is removed. We've supplied wool blends for children's sleepwear to Scandinavian brands for years, and they consistently pass 16 CFR 1610 without any chemical assistance. The key is using high-quality wool with the right yarn construction.

Heavyweight cotton and silk can also meet Class 1 requirements under the right conditions. Tightly woven heavy cotton (think denim or canvas) chars rather than melts, and the char acts as insulation. Silk has a relatively high ignition temperature and burns slowly. However, not all cotton is created equal—long-staple cottons with high twist yarns perform significantly better than loose, fluffy constructions.

Why does wool consistently outperform other natural fibers?

Wool's chemical structure gives it natural flame resistance that's hard to beat. The fiber contains high levels of nitrogen and water, both of which act as natural flame inhibitors. When exposed to flame, wool chars and forms a protective barrier that prevents further burning. It also doesn't melt or drip like synthetic fibers.

In our testing facility, we've documented that quality wool fabrics typically have ignition temperatures around 570-600°C, compared to cotton's 255°C. More importantly, wool self-extinguishes once the ignition source is removed. We recently helped a client reformulate their best practices for sourcing compliant wool blends for children's winter wear by incorporating a wool-cotton blend that achieved Class 1 without chemicals. Their products now pass customs inspection on the first try, saving them thousands in delayed shipment costs.

How can fiber blends enhance natural flame resistance?

Strategic blending can create fabrics where the combined properties exceed what any single fiber could achieve alone. The principle is simple: combine fibers with complementary flame-resistant properties to create a superior end product.

Wool-cotton blends are particularly effective because the wool provides flame resistance while cotton maintains comfort and reduces cost. We typically recommend blends with at least 40% wool content for reliable Class 1 performance. Another effective combination is silk-cotton, where the silk raises the ignition temperature while cotton provides structure and affordability. Last quarter, we developed a proprietary blend for a maternity wear brand that needed chemical-free sleepwear. By combining wool, silk, and organic cotton in specific proportions, we created a fabric that not only passed 16 CFR 1610 but also met their sustainability goals.

What fabric treatments can replace chemical FR?

While we're focusing on avoiding traditional FR chemicals, there are several physical and natural treatments that can enhance inherent flame resistance without introducing harmful substances. These methods work by modifying the fabric's physical structure or applying natural flame-inhibiting substances.

Surface brushing and napping can actually improve flammability performance for certain fabrics. By creating a fuzzy surface, you increase the fabric's insulation properties and create air pockets that can slow heat transfer. However, this must be done carefully—excessive napping can sometimes increase flammability if not properly controlled.

Natural coatings derived from whey protein, casein, or certain plant-based compounds can provide additional protection. We've experimented with a whey-based coating that creates a protective char layer when exposed to flame. It's completely biodegradable and doesn't contain any regulated chemicals. Another client successfully used a starch-based coating that thickened the yarn surfaces, reducing flame spread enough to achieve Class 1 rating.

Can physical finishing processes improve performance?

Absolutely. Physical finishing processes can significantly enhance a fabric's natural flame resistance without adding chemicals. Calendaring (pressing between heavy rollers), compacting, and singeing are particularly effective methods we use regularly.

Singeing burns off surface fibers that could easily ignite, creating a smoother surface that's less prone to catching fire. Compacting increases fabric density, reducing air spaces that support combustion. We've documented cases where proper singeing and compacting moved fabrics from Class 2 to Class 1 without any chemical treatment. One of our denim clients was able to achieve consistent Class 1 ratings across their entire product line by optimizing their comprehensive guide to physical finishing for flame resistance, saving them approximately $2.50 per garment in chemical treatment costs.

Are there natural coating alternatives that work?

Yes, and they're becoming increasingly sophisticated. We've been working with several bio-based coating solutions that provide legitimate flame resistance without synthetic chemicals. These include casein (milk protein) coatings, soy-based proteins, and certain plant-derived tannins.

Casein coatings work particularly well on natural fibers. When applied properly, they create a protein layer that chars when exposed to flame, forming a protective barrier. We've achieved consistent Class 1 results with casein-treated cotton fabrics in weights as light as 130 GSM. The treatment adds minimal cost and doesn't affect fabric hand feel significantly. Another promising area is plant-based tannin treatments, which we're currently testing for a major European retailer. Early results show they can reduce burn rates by 30-40% compared to untreated fabrics.

How to test and verify compliance without FR treatment?

Proper testing methodology is crucial when you're relying on inherent properties rather than chemical treatments. You need to account for more variables and understand how different production batches might affect performance.

The key is comprehensive pre-testing and understanding all the factors that can affect your results. Fabric weight, construction, yarn twist, and even finishing processes can all impact flammability performance. We recommend testing multiple samples from different production runs to ensure consistency. When working with a sportswear brand last year, we identified that variations in fabric softener application were causing inconsistent test results. By standardizing their finishing process, we achieved consistent Class 1 ratings across all their fabric lots.

What sampling strategy ensures consistent results?

A robust sampling strategy is essential when you're not using chemical FR treatments. Unlike chemically treated fabrics where the treatment provides consistent performance, inherent flame resistance can vary with natural material variations. We recommend testing samples from the beginning, middle, and end of production runs, plus testing after any process that might affect fabric properties.

Include testing after washing and drying, as natural fibers can behave differently after laundering. We typically test both virgin fabric and fabric that's been through 5, 10, and 20 wash cycles to ensure performance consistency. This approach helped us identify that a client's organic cotton fabric actually improved to Class 1 after several washes due to fabric compaction. This discovery saved them from unnecessary and expensive chemical treatments.

How can you document natural compliance for customs?

Documentation is your proof of compliance, and it needs to be thorough when you're not relying on chemical treatments. We provide our clients with a comprehensive compliance package that includes detailed test reports, fabric specifications, and manufacturing process documentation.

The package should explain why your fabric naturally meets Class 1 requirements—include fiber content analysis, fabric weight, construction details, and any special processes that contribute to flame resistance. We've found that customs officials appreciate clear, logical explanations of why a fabric is compliant without chemicals. Our standard documentation now includes a understanding fabric flammability compliance documentation section that specifically addresses natural compliance pathways, which has reduced customs queries for our clients by over 60%.

Conclusion

Passing 16 CFR 1610 without FR chemicals is not only possible—it's increasingly becoming the preferred approach for brands committed to chemical-free products. By selecting the right fibers, optimizing fabric construction, and using physical or natural treatments, you can create safe, compliant apparel that meets consumer demands for healthier products.

The strategies we've discussed have helped numerous clients succeed in the US market while maintaining their commitment to chemical-free manufacturing. If you need help implementing these approaches for your specific product line, our technical team has the expertise to guide you through the process. For personalized assistance with your flammability compliance needs, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll help you develop a chemical-free solution that meets both safety standards and your brand values.