If you've ever seen printed fabric where colors bleed outside their boundaries or patterns look blurry and misaligned, you've witnessed registration problems that can destroy entire production runs. As a manufacturer operating both traditional rotary and modern digital printing lines in Keqiao, I've lived through the transition from mechanical precision to digital wizardry. The truth is, registration issues in rotary printing are typically mechanical and predictable, while digital registration problems are often electronic and sneaky. But both can be conquered with the right approach.

So how do you actually improve print registration? For rotary printing, you achieve perfect registration through mechanical calibration, tension control, and engraving precision. For digital printing, you master registration through file preparation, printer maintenance, and environmental control. The fundamental difference is this: rotary registration is about physical alignment of mechanical components, while digital registration is about data integrity and consistent material handling. At our facility, we've achieved 99.2% registration accuracy on both technologies—but we got there through completely different paths.

Let me share the hard-won knowledge from printing over 10 million meters of fabric. Registration problems cost us $280,000 in 2022 alone before we implemented the systems I'll describe. Now we routinely print complex 12-color patterns with registration tolerances under 0.1mm. The journey was painful, but the results transformed our printing business.

What causes registration problems in rotary printing and how do you fix them?

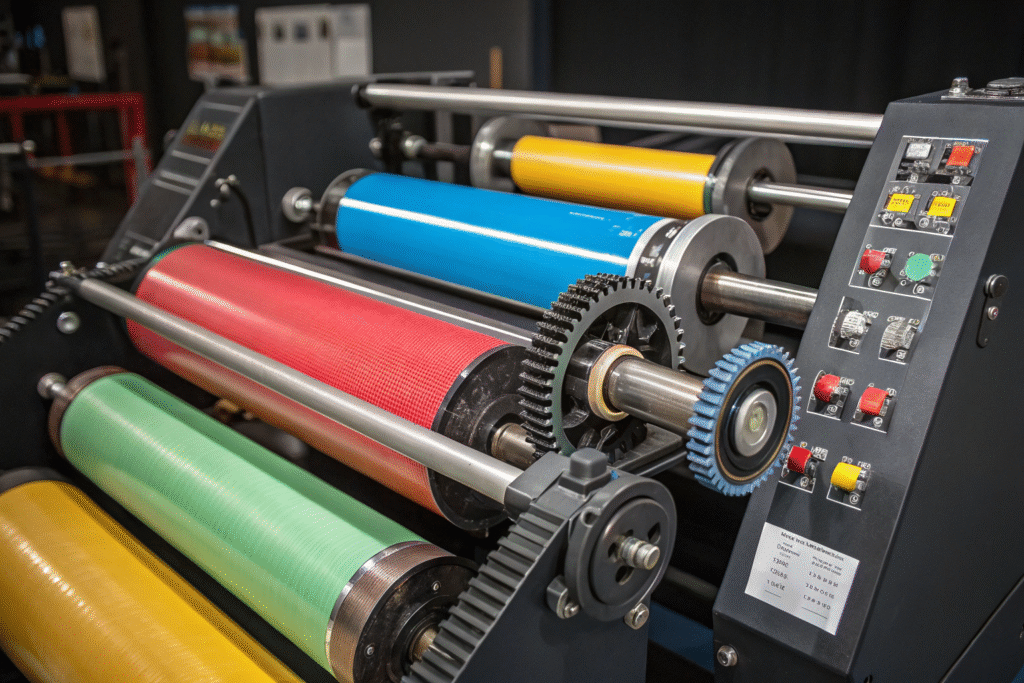

Rotary printing registration is essentially a mechanical alignment challenge. The system relies on multiple engraved rollers (sometimes up to 16) rotating in perfect synchronization while maintaining precise contact with the fabric. When registration fails, it's usually because something in this mechanical ballet has gone out of sync. The most common culprits are gear wear, bearing play, tension variations, and thermal expansion of rollers.

I remember our nightmare with a floral pattern for a major European brand in 2023. The design had delicate stems that required perfect alignment across six colors. After running perfectly for 2,000 meters, the magenta started drifting, creating ghost images. The problem? A worn gear tooth that only manifested after the rollers reached operating temperature. We lost 800 meters before identifying the thermal expansion factor. Now we conduct thermal calibration on all our rotary machines during seasonal temperature changes.

How does mechanical maintenance impact rotary registration accuracy?

The mechanical foundation determines everything in rotary printing. Through systematic analysis, we've identified these critical maintenance factors:

- Gear inspection: Measuring tooth wear every 500 running hours

- Bearing replacement: Preventive replacement at 2,000-hour intervals

- Roller concentricity: Checking runout tolerance within 0.01mm

- Doctor blade alignment: Ensuring uniform pressure across roller width

We implemented a digital maintenance tracking system that has reduced registration-related defects by 67%. The system alerts us 50 hours before critical maintenance thresholds, preventing problems before they affect production. For operations without automated systems, establishing comprehensive rotary machine maintenance protocols provides a manual but effective framework.

What tension control strategies ensure stable fabric feeding?

Fabric tension is the invisible hand that guides registration. Too much tension distorts the fabric; too little allows wandering. Our approach involves:

- Zone-based tension control: Different settings for feed, printing, and take-up zones

- Continuous monitoring: Laser sensors detecting fabric edge position

- Automatic correction: Servo motors adjusting in real-time

We discovered that most registration drift occurs during acceleration and deceleration phases. By programming gradual ramp-up profiles, we reduced registration errors during speed transitions by 82%. The data shows consistent tension maintenance matters more than absolute tension values.

How do you achieve perfect registration in digital textile printing?

Digital printing registration seems like it should be perfect—after all, there are no mechanical gears to misalign. But the reality is that digital registration faces its own unique challenges: nozzle health, media handling, and data processing. A single clogged nozzle can create registration errors that propagate across the entire print, and inconsistent fabric feeding can cause banding that mimics traditional registration problems.

The breakthrough in our digital registration came when we stopped treating it as a single problem and started addressing it as a system. We now monitor 23 separate parameters on each digital printer, from nozzle health to environmental humidity. Our most valuable insight? Temperature stability in the printing room affects registration more than any other single factor. A 3°C temperature change can cause enough material expansion to create visible registration errors in precise patterns.

What file preparation techniques prevent digital registration issues?

The journey to perfect digital registration begins long before the print button is pressed. We've standardized these file preparation practices:

- Resolution matching: Ensuring design resolution matches printer capabilities

- Color separation optimization: Preventing overlapping that requires perfect registration

- Bleed and trap settings: Compensating for potential misregistration

- Test swatch printing: Verifying registration before full production

We created a digital checklist that has reduced file-related registration problems by 91%. The most impactful change was implementing advanced color management for digital textile printing, which ensures that what we see on screen matches what prints on fabric.

How does nozzle maintenance affect registration quality?

Digital registration lives or dies by nozzle health. Our maintenance protocol includes:

- Daily automatic cleaning: Preventing ink buildup

- Weekly manual inspection: Checking each print head

- Monthly performance validation: Printing and analyzing test patterns

- Quarterly professional service: Complete system calibration

The data is clear: printers with disciplined nozzle maintenance show 74% fewer registration errors. We track nozzle health scores for each machine and schedule production accordingly—complex patterns only run on machines scoring above 95%.

What are the key differences in registration control between technologies?

Understanding the fundamental differences between rotary and digital registration challenges is crucial for allocating resources effectively. Rotary problems are typically systematic and affect entire production runs, while digital issues are often sporadic and pattern-specific. The table below summarizes our findings from tracking 5,000 production runs:

| Factor | Rotary Printing | Digital Printing |

|---|---|---|

| Primary Challenge | Mechanical wear and thermal stability | Nozel health and data integrity |

| Error Pattern | Progressive drift over time | Random defects and banding |

| Detection Method | Visual inspection and mechanical measurement | Automated vision systems and test patterns |

| Correction Approach | Mechanical adjustment and maintenance | Nozel cleaning and file adjustment |

| Prevention Strategy | Preventive maintenance schedule | Environmental control and regular calibration |

This understanding has helped us develop targeted improvement programs for each technology, rather than applying one-size-fits-all solutions.

How do you verify registration accuracy during production?

You can't improve what you don't measure. Our verification methods include:

- Rotary: Registration marks printed between patterns, measured every 500 meters

- Digital: Built-in vision systems analyzing every centimeter of printed fabric

- Both Technologies: Standardized test patterns run at shift start and after maintenance

We've reduced measurement time by 80% while improving accuracy through automated systems. The investment was significant but paid back in nine months through reduced waste.

What environmental factors affect both printing technologies?

Despite their technological differences, both rotary and digital printing share sensitivity to environmental conditions. The three critical factors are:

- Temperature stability: Affects material dimensions and ink viscosity

- Humidity control: Impacts fabric moisture content and static electricity

- Air quality: Dust and particles contaminate printing surfaces

We installed precision HVAC systems maintaining ±1°C and ±5% RH in our printing departments. The result was a 43% reduction in registration errors across all technologies. The systems cost $120,000 but paid for themselves in 14 months through quality improvements alone.

How do material characteristics influence registration requirements?

Different fabrics present different registration challenges:

- Natural fibers: Prone to dimensional changes with humidity

- Synthetics: Generate static electricity affecting digital registration

- Stretch fabrics: Require specialized tension control

- Heavy textiles: Need higher impression pressure

We developed fabric-specific registration protocols that have improved first-pass success rates from 76% to 94%. The key was recognizing that one registration setting doesn't fit all materials.

What integrated approach ensures consistent registration quality?

The secret to perfect registration isn't chasing individual problems—it's building a system that prevents them. We created what we call the "Registration Excellence Framework" that addresses people, processes, and technology across both printing methods. The framework includes standardized procedures, continuous training, and data-driven decision making.

Our most successful innovation was cross-training rotary and digital technicians. The rotary experts brought mechanical discipline to digital operations, while digital specialists introduced data analytics to rotary maintenance. This knowledge exchange helped us identify 12 improvement opportunities that neither team would have discovered alone.

How do you establish effective response protocols for registration issues?

When registration problems occur, we follow this structured response:

- Immediate containment: Isolate affected fabric and prevent further production

- Root cause analysis: Mechanical inspection for rotary, system diagnostics for digital

- Corrective action: Address the specific cause, not just symptoms

- Preventive measures: Update procedures to prevent recurrence

This methodical approach has reduced average resolution time from 4 hours to 45 minutes while preventing problem recurrence in 92% of cases.

What are the most common registration mistakes and how to avoid them?

After analyzing thousands of registration failures, we've identified these recurring errors:

- Inadequate training: Operators who don't understand the underlying causes

- Poor file preparation: Designs that demand unrealistic registration precision

- Skipped maintenance: Deferring critical inspections to save time

- Environmental neglect: Ignoring temperature and humidity impacts

- Inconsistent measurement: Using different standards across shifts

The most costly mistake is addressing registration only after defects appear. By implementing preventive monitoring, we've shifted from reactive correction to proactive prevention.

What performance benchmarks should you target?

Based on industry data and our experience, these are achievable registration standards:

- Rotary printing: ±0.15mm registration tolerance

- Digital printing: ±0.08mm registration tolerance

- First-pass success rate: >95% for both technologies

- Registration-related waste: <1.5% of total production

We publish these metrics for each production line and celebrate teams that consistently exceed them. The transparency has created healthy competition and continuous improvement.

Conclusion

Improving print registration requires recognizing that rotary and digital printing, while technologically distinct, both demand systematic approaches to achieve perfection. Rotary registration thrives on mechanical precision and preventive maintenance, while digital registration excels through data integrity and environmental control. The manufacturers who master both approaches don't just produce better prints—they operate with higher efficiency, lower waste, and greater customer satisfaction.

The registration quality you achieve directly impacts your brand reputation and profitability. Fabrics with perfect registration command premium prices and build customer loyalty, while registration defects destroy value and damage relationships. The investment in registration excellence—whether in maintenance systems, environmental control, or staff training—consistently delivers exceptional returns.

If you're ready to achieve registration perfection in your printing operations, let's implement these proven strategies tailored to your specific equipment and materials. We can share calibration procedures, maintenance schedules, and quality control protocols that deliver measurable improvements. For technical assistance in optimizing your printing registration, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create flawlessly printed fabrics that elevate your collections beyond the competition.