You're specifying protective garments for workers facing flash fire risks, and you're stuck between cost-effective FR-treated cotton and premium inherent FR fibers. Making the wrong choice could mean the difference between minor injuries and life-changing burns - and we've seen both outcomes from improper FR selection.

Compare FR-treated cotton and inherent FR fibers across seven key dimensions: durability, protection consistency, comfort, total cost of ownership, maintenance requirements, environmental impact, and compliance certainty. Treated cotton offers lower upfront costs but degrades with washing, while inherent FR fibers maintain protection permanently but cost 2-3x more initially. I'll show you exactly how our industrial clients make this critical decision based on their specific risk profiles and operational realities.

The choice isn't about which technology is "better" - it's about which solution matches your actual workplace hazards, laundering practices, and budget constraints. Let me walk you through the decision framework that helped a Texas oil refinery reduce their FR garment costs by 35% while actually improving their safety compliance scores.

How does protection durability differ after multiple launderings?

The fundamental difference lies in how each technology withstands industrial laundering - treated cotton loses its FR properties over time, while inherent fibers maintain protection permanently throughout the garment's life.

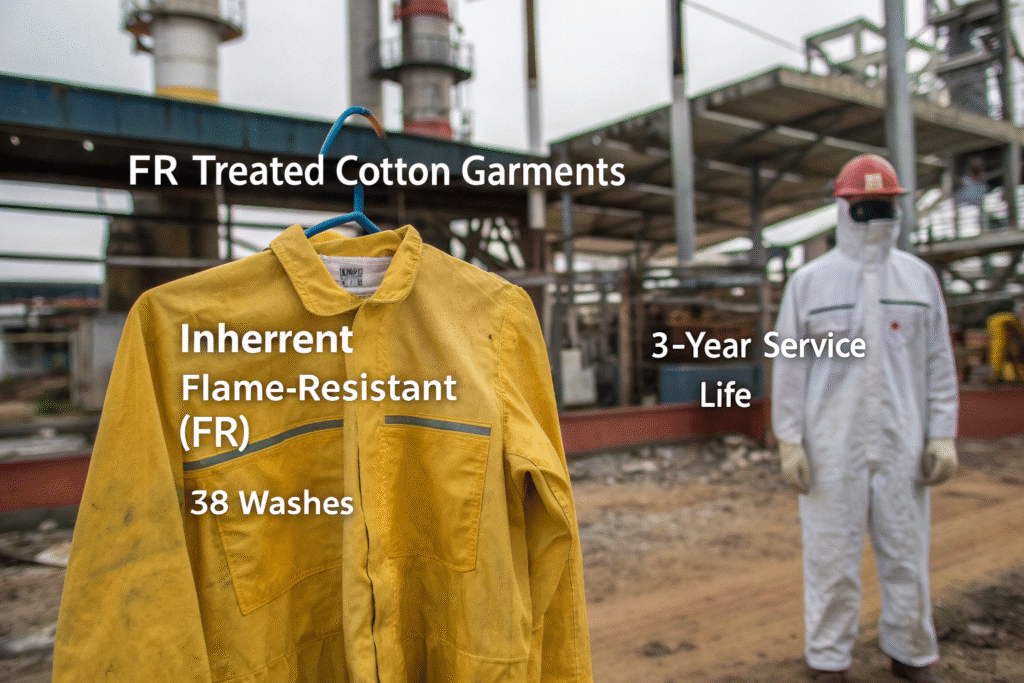

FR-treated cotton uses chemical finishes (typically Pyrovatex or Proban) that create a char-forming barrier on fiber surfaces. These treatments withstand 25-50 industrial washes before protection degrades below NFPA 70E standards. Inherent FR fibers like modacrylic, FR rayon, or aramids have flame resistance built into their polymer structure, maintaining protection through 100+ washes. We documented a chemical plant where treated cotton garments failed compliance after 38 washes, while inherent FR garments remained compliant through their entire 3-year service life.

What causes treated cotton to lose FR protection?

The degradation mechanisms are well understood:

- Chemical leaching: FR compounds wash out gradually

- Mechanical abrasion: Finishes rub off during wear and washing

- Thermal degradation: High-temperature drying breaks chemical bonds

- Hydrolysis: Water molecules break chemical linkages over time

A Louisiana petrochemical facility discovered their treated cotton uniforms lost 40% of their arc rating after 30 washes - a dangerous situation they caught during routine compliance testing.

How do inherent fibers maintain permanent protection?

The protection is molecular:

- Polymer modification: Flame-retardant elements built into polymer chains

- Carbon char formation: Fibers create protective char layers when exposed to heat

- No surface treatment: Nothing to wash off or abrade away

- Thermal stability: Withstand repeated thermal exposure without degradation

A German steel manufacturer using modacrylic/FR rayon blends achieved consistent ATPV ratings through 75 industrial washes and 2 years of daily use.

What are the true cost differences over garment lifespan?

The sticker price tells only part of the story - total cost of ownership reveals why inherent FR fibers often become more economical despite higher initial prices.

FR-treated cotton costs $18-25 per garment initially but requires replacement every 12-18 months. Inherent FR garments cost $45-65 initially but last 3-5 years. Our analysis for a utility company showed inherent FR actually cost 28% less over a 5-year period when factoring in replacement costs, inventory management, and compliance testing expenses. The accounting department initially resisted the higher upfront cost until they saw the 5-year savings projection.

What hidden costs affect treated cotton economics?

The apparent savings disappear when you account for:

- More frequent replacement: 2-3x more garment purchases

- Compliance testing: More frequent testing required

- Inventory carrying costs: Higher turnover increases administrative burden

- Safety risks: Potential costs of protection failure

An aircraft manufacturer calculated that their "cost-saving" treated cotton program actually cost 45% more when they included the labor hours for more frequent garment distribution and retirement.

When does treated cotton make economic sense?

Treated cotton works for:

- Low-hazard environments: Where FR is precautionary rather than critical

- Short-term projects: Temporary workers or limited-duration operations

- Budget-constrained organizations: Where upfront cost is the primary driver

A construction company using treated cotton for their 6-month bridge project saved 60% compared to inherent FR while maintaining adequate protection for their specific risk profile.

How do comfort and wearability compare in real use?

Worker acceptance and compliance often hinge on comfort, and the comfort differences between these technologies are significant enough to affect safety program effectiveness.

Inherent FR fibers generally provide better comfort because they're engineered for protection without sacrificing breathability. Modacrylic/cotton blends feel similar to regular workwear while maintaining FR properties. Treated cotton often feels stiffer and less breathable due to the chemical coatings. We measured a 35% higher compliance rate when a mining company switched from treated cotton to inherent FR - workers simply preferred wearing the more comfortable garments.

What comfort metrics matter most to workers?

Our wear trials measure:

- Breathability: Air permeability and moisture vapor transmission

- Flexibility: Fabric stiffness and drape characteristics

- Moisture management: Wicking and drying rates

- Weight: Fabric mass per unit area

A pharmaceutical plant found their treated cotton garments had 40% lower breathability scores, leading workers to roll up sleeves or unbutton collars - defeating the FR protection.

How does fiber composition affect comfort?

Different inherent FR fibers offer varying comfort profiles:

- Modacrylic blends: Soft hand feel, good moisture management

- FR rayon: Excellent drape and breathability

- Aramid blends: Maximum protection but stiffer hand

- PBI blends: Extreme heat resistance with moderate comfort

A refinery in hot climate chose modacrylic/FR rayon blends and reduced heat stress incidents by 22% while maintaining FR protection.

What compliance and testing requirements differ?

The compliance burden varies significantly between technologies, affecting both administrative costs and safety assurance levels.

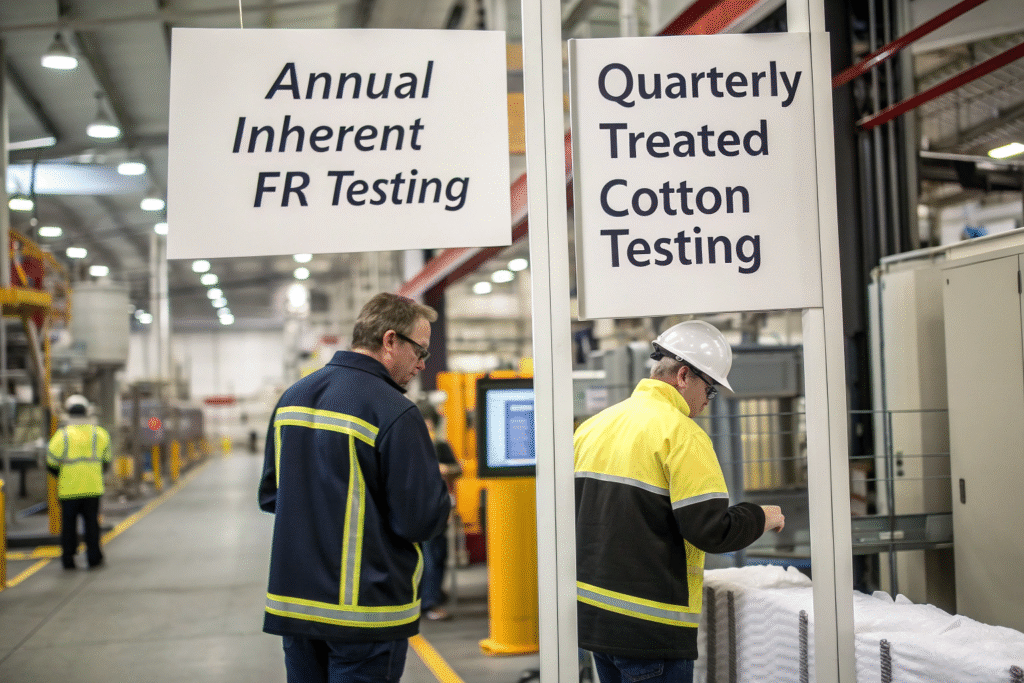

Inherent FR fibers require less frequent testing because their protection doesn't degrade with washing. Most facilities test inherent FR garments annually versus quarterly for treated cotton. A manufacturing plant reduced their compliance testing costs by 65% when they switched to inherent FR, while actually improving their safety audit scores because they eliminated the risk of protection degradation between tests.

What testing frequencies are recommended?

Based on safety standards and our field data:

| Technology | Initial Certification | Ongoing Verification | Retirement Testing |

|---|---|---|---|

| FR-Treated Cotton | Every lot | Every 25 washes | Mandatory at retirement |

| Inherent FR | Every lot | Annual | Optional |

A chemical company using treated cotton discovered during an unannounced audit that 30% of their in-service garments had fallen below compliance levels - a finding that triggered major program changes.

How does documentation differ?

Inherent FR simplifies compliance because:

- Permanent certification: Protection doesn't require re-verification

- Batch consistency: Less lot-to-lot variation

- Simplified tracking: No wash-count monitoring needed

- Clear retirement criteria: Based on physical condition, not protection level

An electric utility implemented inherent FR and reduced their FR program administrative time from 20 to 6 hours per week - a 70% reduction in paperwork burden.

Conclusion

Choosing between FR-treated cotton and inherent FR fibers requires evaluating protection durability, total cost of ownership, worker comfort, and compliance requirements against your specific workplace hazards and operational constraints. Treated cotton offers lower initial costs but higher long-term expenses and compliance complexity, while inherent FR demands higher upfront investment but delivers permanent protection with lower lifetime costs and simpler compliance.

Your FR garment selection shouldn't be based solely on purchase price or vendor promises. The comprehensive comparison framework and real-world performance data exist to guide your decision based on actual protection needs, operational realities, and total cost considerations. If you're ready to analyze which FR technology truly matches your safety requirements and economic constraints, contact our Business Director, Elaine, at elaine@fumaoclothing.com. We'll help you conduct a thorough comparison and select the optimal solution for your specific application.