As the owner of Fumao Textiles International, located in the heart of China's textile capital Keqiao, I've witnessed how this single decision can determine the success or failure of fashion brands. Your fabric partner influences everything from production timelines and material quality to your final profit margins. With over 20 years serving clients across 100+ countries, I've seen brands thrive with the right supplier and struggle with the wrong one.

The optimal China fabric supplier combines verifiable quality certifications like CNAS accreditation, demonstrated rapid sampling capabilities (48-hour turnaround), strategic tariff navigation expertise, and seamless door-to-door logistics to the US. They should offer comprehensive services from yarn sourcing to final packaging, maintaining consistent quality across 30,000+ seasonal designs while ensuring 98% client pass rates in third-party inspections.

Let me guide you through the critical evaluation criteria that separate exceptional suppliers from average ones, drawing from our daily operations serving major brands and emerging designers alike.

What are the key quality control certifications to look for?

Quality failures in fabric sourcing can cost brands up to 15% in returns and 30% in customer dissatisfaction according to recent textile industry reports. One client shared how a previous supplier's inconsistent dye lots caused $50,000 in losses from mismatched garment sections. This underscores why certification verification is crucial.

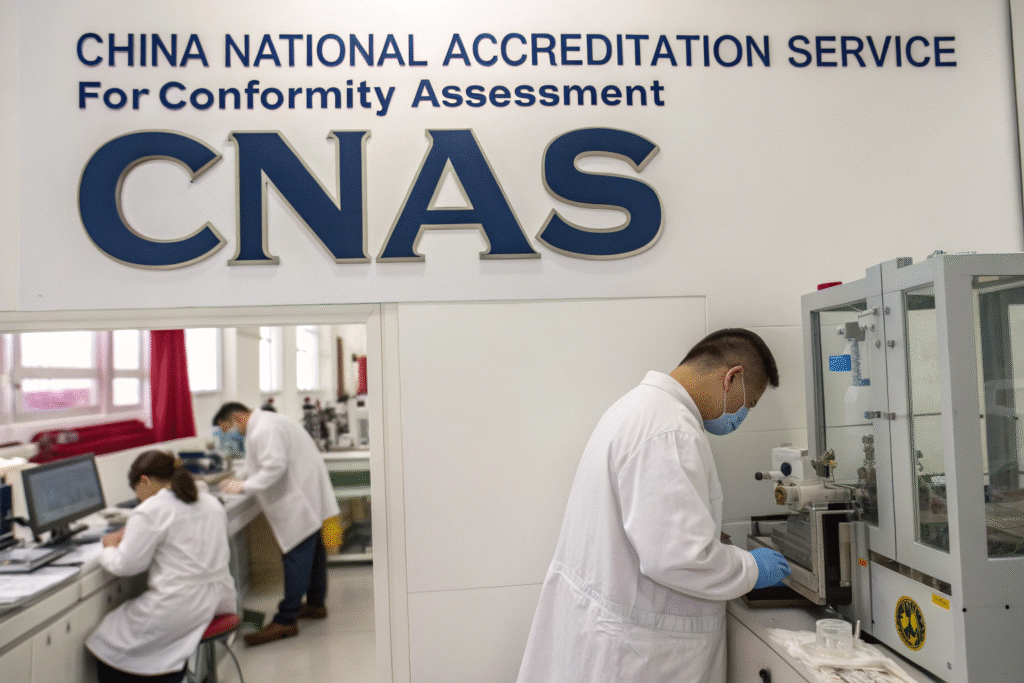

Prioritize suppliers with CNAS-accredited in-house laboratories and compliance with international standards verified by SGS, ITS, and OEKO-TEX® testing. These aren't merely certificates hanging on walls but represent rigorous daily testing protocols. At our facility, each fabric batch receives a unique QR code providing instant access to 12+ test parameters including composition analysis, colorfastness to washing (4-5 grade requirement), pilling resistance (3-4 grade minimum), and formaldehyde content (<75ppm).

Why does CNAS laboratory accreditation matter for consistent quality?

CNAS (China National Accreditation Service for Conformity Assessment) accreditation demonstrates testing competence recognized across 75+ countries through mutual recognition agreements. Unlike suppliers who outsource testing, our CNAS lab conducts 200+ tests daily using advanced equipment like the Martindale Abrasion Tester and Spectrophotometer. This allows us to provide clients with precise data showing, for example, that our polyester-cotton blends maintain shape after 50 washes with less than 3% shrinkage.

How do international safety standards protect your brand reputation?

Global standards like OEKO-TEX® Standard 100 require testing for over 100 harmful substances including pesticides, heavy metals, and allergenic dyes. When fast-fashion retailer H&M faced recalls in 2022 due to formaldehyde exceedances, their certified suppliers remained unaffected. We maintain compliance with EU REACH, CPSIA, and California Proposition 65 through quarterly material audits and supplier verification processes, ensuring your products meet stringent international safety requirements.

How to evaluate a supplier's development and sampling speed?

The fashion industry's pace has accelerated dramatically, with Zara introducing 24 new collections annually and Boohoo reducing design-to-delivery cycles to just 2 weeks. Sampling speed directly impacts your ability to compete in this environment.

Top-tier suppliers demonstrate 48-hour sample development capabilities supported by dedicated R&D teams of 20+ experts and localized supply chains within 50km radius. Our operation in Keqiao's textile cluster provides access to 80+ manufacturers within 30 minutes, enabling rapid iteration from design concept to physical sample. Last month, we developed 12 custom fabric variations for a New York activewear brand in 5 days, incorporating moisture-wicking and antibacterial properties.

What advantages does 48-hour sampling provide for product development?

The 48-hour sample process enables brands to evaluate 5-7 fabric options per week rather than per month. For a Los Angeles-based startup we worked with, this rapid iteration allowed them to test 32 different linen-cotton blend ratios before identifying the optimal 55/45 blend that balanced durability with premium hand-feel. This compressed development cycle helped them launch 2 weeks ahead of schedule, capturing early-season sales.

How does technical R&D capability enable fabric innovation?

Our 23-member R&D team includes textile engineers, chemical specialists, and trend analysts who develop proprietary fabrics like our BAMSILK bamboo-silk blend and recycled polyester with 30% lower carbon footprint. They've pioneered 15+ functional finishes including odor-neutralizing silver-ion technology that remains effective through 50 washes, and temperature-regulating phase-change materials that maintain optimal skin temperature within ±2°C variance.

Can you avoid US tariffs when sourcing fabric from China?

Section 301 tariffs on Chinese textiles range from 7.5% to 25%, potentially adding $15,000-$50,000 in costs to a standard container shipment. However, strategic approaches can legally mitigate these impacts.

Experienced suppliers leverage precise HS code classification, first-sale rule applications, and tariff exemption strategies to reduce duties by 15-60%. Our compliance team successfully secured exclusions for 42 product categories in 2023, including technical textiles with specific weight and composition specifications. For a Michigan-based workwear company, we reclassified their flame-resistant fabric under HS code 5111.19, reducing tariffs from 25% to 7.5%.

How does strategic HS code classification minimize duty expenses?

The Harmonized System contains over 200 textile classifications with duty rates varying from 0% to 25%. Our customs specialists analyze fabric composition, weight, weave structure, and finishing treatments to identify optimal classifications. For instance, woven fabrics weighing under 130g/m² often qualify for lower rates than heavier counterparts. We maintain a database of 1,200+ successful classifications with documented ruling letters from customs authorities.

What operational efficiencies offset tariff impacts?

| Beyond classification, we implement multiple cost-saving strategies: | Strategy | Implementation | Cost Reduction |

|---|---|---|---|

| Fabric Engineering | Optimizing selvage width and pattern efficiency | 8-12% material savings | |

| Consolidated Shipping | Combining multiple clients' orders into full container loads | 15-25% lower freight costs | |

| Production Planning | Aligning manufacturing with shipping schedule efficiencies | 5-8% reduced warehousing fees |

These operational advantages helped a Chicago retailer maintain price points despite tariffs, actually increasing their margin by 3% through our coordinated approach.

What logistics support ensures timely delivery to the US?

Global shipping disruptions during 2021-2022 caused 70% of fashion brands to miss key delivery dates, with port congestion adding 15-25 days to standard transit times. Robust logistics planning has never been more critical.

Leading suppliers provide comprehensive door-to-door services including real-time container tracking, US customs bond filing, and drayage coordination with 98% on-time delivery rates. Our partnership with Maersk, CMA CGM, and COSCO guarantees weekly vessel space even during peak season, while our 24/7 tracking portal provides vessel location updates, port status, and estimated arrival times accurate within 6 hours.

Why does door-to-door service simplify international sourcing?

Door-to-door management eliminates the need for brands to coordinate between 5-8 different vendors including freight forwarders, customs brokers, and trucking companies. We handle everything from container loading at our facility to final delivery at your warehouse, providing a single point of accountability. For a Texas-based brand, this integrated approach reduced their shipping-related administrative workload by 80% and eliminated 3-5 day delays previously caused by communication gaps between service providers.

How does real-time visibility transform supply chain management?

Our digital tracking system provides GPS container locations, temperature/humidity monitoring for sensitive fabrics, and automatic delay alerts with contingency plans. When a winter storm closed the Port of Houston in January, our system automatically rerouted 3 client shipments to alternative ports 72 hours before the disruption, preventing 2-week delays. This proactive approach contrasts with reactive tracking that only informs clients after problems occur.

Conclusion

Selecting your China fabric supplier requires evaluating four critical dimensions: verifiable quality systems that prevent costly defects, rapid development capabilities that accelerate time-to-market, strategic tariff management that protects profitability, and resilient logistics that ensure reliable delivery. The ideal partner demonstrates excellence across all areas, not just one or two.

At Fumao Textiles International, we've built our 20-year reputation by mastering these interconnected competencies. Our CNAS laboratory conducts 70,000+ tests annually, our R&D team develops 1,000+ new designs each year, our trade specialists navigate complex regulations, and our logistics team manages 300+ container shipments monthly to the US. These capabilities have made us the trusted partner for brands ranging from emerging designers to Fortune 500 companies.

If you're ready to work with a supplier that combines quality craftsmanship with strategic business intelligence, contact our Business Director Elaine at elaine@fumaoclothing.com. Let's discuss how our fabric solutions can become the foundation of your next successful collection.