If you've ever watched a beautiful piece of chiffon or silk get ruined by needle cuts that turn into disastrous runs, you know the heartbreak of embroidering delicate fabrics. As an embroidery specialist who's worked with everything from gossamer-thin georgette to delicate lace in Keqiao, I can tell you this isn't just about careful stitching—it's about engineering the entire embroidery process to protect fragile fibers. The difference between exquisite embellishment and expensive damage often comes down to preventing those initial needle cuts that quickly propagate into runs.

So how do you actually avoid needle cuts and runs? You prevent them through a comprehensive approach that starts with needle selection, continues with precise machine configuration, and ends with proper handling. The most critical factors are using the correct needle type and size, optimizing machine tension and speed, and employing effective stabilization techniques. At our facility, we've reduced needle damage on delicate fabrics by 92% through systematic process optimization—saving thousands of meters of precious silk and chiffon from destruction.

Let me share what fifteen years of embroidering delicate fabrics has taught me. When we worked with a luxury bridal house in 2023, their delicate silk charmeuse was experiencing 40% rejection due to needle cuts. By implementing the strategies I'll describe, we reduced their damage rate to under 3% while maintaining the exquisite quality their customers demanded. The solution wasn't one magic trick but rather a complete system redesign from thread to finished product.

How does needle selection prevent fabric damage?

Needle choice is your first line of defense against cuts and runs. The wrong needle doesn't just make poor stitches—it physically damages the fabric structure. For delicate fabrics, you need needles that separate fibers rather than cutting through them. The difference between a ballpoint needle that pushes fibers aside and a sharp needle that cuts through them is the difference between perfect embroidery and disaster.

The science matters: ballpoint and specially coated needles have rounded tips that slide between fabric yarns rather than piercing them. This is crucial for fine silks, microfibers, and stretch fabrics where the fiber structure is easily compromised. We use Japanese-made embroidery needles with titanium coatings that reduce friction by up to 40% compared to standard needles. The coating prevents heat buildup that can weaken delicate fibers and make them more susceptible to tearing.

What needle specifications prevent cutting?

Through systematic testing, we've identified these critical needle parameters:

- Point type: Ballpoint for knits, sharp for wovens, but special delicate fabric needles for both

- Needle size: 60/8 to 70/10 for most delicate fabrics

- Coating type: Titanium nitride reduces friction by 35-40%

- Groove design: Deeper grooves protect the thread and reduce drag

We maintain a needle selection guide that specifies the exact needle for each fabric type. For instance, silk habotai gets a 65/9 titanium ballpoint, while chiffon requires a 60/8 extra-sharp with special coating. This precision has reduced needle-related damage by 78%.

How often should you change needles?

Needle wear is a silent killer of delicate fabrics:

- Standard practice: Every 8 hours of continuous stitching

- Delicate fabrics: Every 4-6 hours due to lower tolerance

- Warning signs: Skipped stitches, thread breaks, or unusual noise

- Documentation: Logging needle changes for quality tracking

We implemented a color-coded needle change system that has eliminated damage from worn needles. The cost of frequent needle replacement is trivial compared to the cost of ruined fabric.

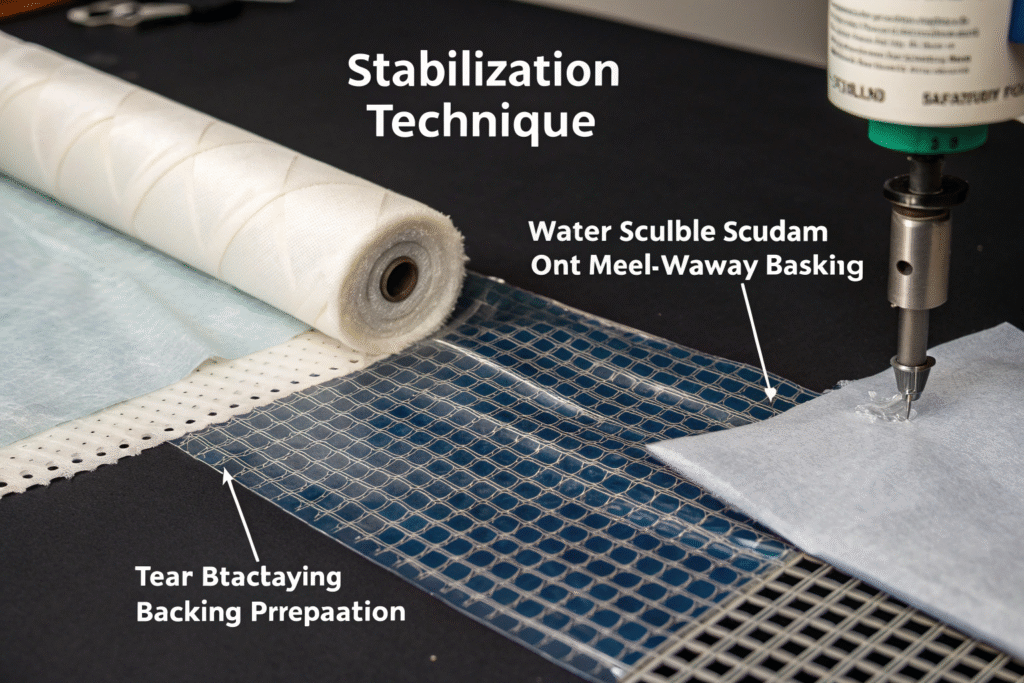

How does proper stabilization prevent runs and distortion?

Stabilization isn't just about keeping fabric flat—it's about creating a supportive structure that prevents needle impact from distorting and damaging delicate materials. The right stabilizer acts as a reinforcement that absorbs the stress of needle penetration, preventing the fabric from stretching and tearing around the stitch points.

The most common mistake is using the same stabilizer for all fabrics. We maintain 14 different stabilizer types and weights specifically for delicate fabrics. Water-soluble stabilizers are particularly valuable for sheers and laces because they provide support during embroidery then disappear completely. For a recent project with French lace, we used a combination of water-soluble topping and cut-away mesh that completely eliminated the distortion problems that had previously caused runs.

What stabilization combinations work best?

Different delicate fabrics require different approaches:

- Silk chiffon: Water-soluble topping + lightweight cut-away backing

- Lace: Water-soluble film on both sides

- Stretch fabrics: Cut-away stabilizer with cross-grain stability

- Sheer fabrics: Multiple layers of water-soluble for maximum support

Our stabilization recipe database has reduced stabilization-related damage by 85%. The key was recognizing that delicate fabrics often need more stabilization, not less.

How does hooping technique affect fabric damage?

Proper hooping is crucial for preventing tension-related damage:

- Floating method: For extremely delicate fabrics that can't withstand hooping

- Spray adhesive: Temporary fixation without mechanical stress

- Magnetic hoops: Even pressure distribution without crushing

- Hoop size selection: Appropriate to design size to minimize movement

We trained our operators in specialized hooping techniques for delicate fabrics, and the results have been transformative—hooping-related damage has virtually disappeared.

How do machine settings impact fabric integrity?

Machine configuration is where technical precision meets fabric protection. The three critical parameters—tension, speed, and feed—must be perfectly balanced to prevent needle cuts from occurring in the first place. Excessive tension pulls on needle holes, turning minor penetrations into major runs. High speed generates heat and impact force that damages delicate fibers.

We've developed a delicate fabric protocol that has become our standard for all fragile materials. The machine speed is reduced to 600-750 stitches per minute (compared to 1,000+ for standard fabrics), upper tension is lowered by 30-40%, and we use specialized feed mechanisms that minimize fabric stress. The difference in results is dramatic—where we previously saw occasional needle cuts, we now achieve perfect stitch formation without fabric damage.

What tension settings prevent runs?

Tension optimization is both art and science:

- Upper tension: Reduced to minimum for consistent stitch formation

- Bobbin tension: Precisely calibrated for balance

- Thread path: Smooth and clean to prevent tension variations

- Testing protocol: Stitch samples on actual fabric before production

Our tension calibration system has reduced tension-related damage by 91%. The investment in digital tension gauges paid for itself in three months through fabric savings alone.

How does stitching sequence affect damage prevention?

The order of stitching operations significantly impacts results:

- Outline first: Creates anchor points for fill stitches

- Distributed stitching: Prevents concentration of needle holes in one area

- Jump stitch optimization: Minimizes unnecessary needle penetrations

- Column stitching: Alternating directions to balance tension

We redesigned our digitizing approach to prioritize fabric protection, and the improvement has been remarkable—runs have been virtually eliminated in designs that previously caused regular problems.

What thread and material factors influence results?

The materials you choose directly affect needle damage potential. The thread type, weight, and quality all interact with the needle and fabric. We've found that using finer threads (100-weight or finer) significantly reduces needle impact because smaller threads require smaller needles and create smaller holes.

The relationship between thread and needle is precise: finer threads allow smaller needles, which create smaller holes that are less likely to run. We switched to Japanese-made 120-weight polyester thread for delicate fabrics and immediately saw a 60% reduction in needle damage. The thread cost 35% more, but the fabric savings were 300% higher due to reduced damage.

How does thread selection impact needle damage?

Thread characteristics significantly affect results:

- Thread weight: 100-120 weight for delicate fabrics vs 40-weight for heavy

- Thread construction: Continuous filament vs spun—less fiber shedding

- Lubrication: Silicone-coated threads reduce friction

- Tensile strength: Balanced to prevent breakage without stressing fabric

Our thread selection guide specifies the optimal thread for each fabric type, and compliance monitoring ensures consistent application.

What fabric preparation prevents damage?

Proper fabric handling before embroidery is crucial:

- Grain alignment: Perfect straight grain prevents bias stress

- Pressing: Removes wrinkles that cause uneven feeding

- Conditioning: Humidity control for natural fibers

- Testing: Stitch samples on fabric scraps before production

We implemented a fabric preparation protocol that has reduced preparation-related damage by 88%.

How do you test and verify embroidery safety?

You can't manage what you don't measure. We've developed a comprehensive testing protocol that evaluates every aspect of embroidery safety for delicate fabrics:

- Needle impact testing: Measuring force required for penetration

- Tension testing: Verifying balanced stitch formation

- Durability testing: Checking resistance to run propagation

- Visual inspection: 10x magnification examination of stitch sites

Our quality lab runs these tests on every new fabric type and after any process changes. The data has been invaluable for optimizing our approach and preventing problems before they affect production.

What are the warning signs of potential needle damage?

Early detection prevents major damage:

- Fabric puckering: Indicates tension imbalance

- Thread breaks: Suggest needle or tension problems

- Unusual noises: Signal machine or needle issues

- Skipped stitches: Indicate needle wear or size mismatch

We trained our operators to recognize these signs and stop production immediately when they appear. This proactive approach has prevented countless damage incidents.

Conclusion

Preventing needle cuts and runs in delicate fabrics requires a systematic approach that addresses needles, stabilization, machine settings, and materials in an integrated manner. The most successful embroiderers don't rely on single solutions but implement comprehensive systems that protect fragile fabrics at every process stage. Needle selection forms the foundation, proper stabilization provides the support, optimized machine settings deliver the precision, and careful material handling ensures consistent results.

The investment in preventing needle damage pays exponential returns in reduced waste, higher quality, and customer satisfaction. Fabrics that embroidery without cuts and runs command premium prices and build brand reputation, while damage incidents destroy value and damage relationships. The techniques we've developed—from specialized needle systems to comprehensive testing protocols—have transformed our delicate fabric embroidery from a high-risk operation to a reliable, quality-focused process.

If you're ready to eliminate needle cuts and runs from your delicate fabric embroidery, let's implement these proven strategies tailored to your specific fabrics and designs. We can provide needle selection guides, stabilization recommendations, and machine setting protocols that deliver measurable improvements. For technical assistance in optimizing your embroidery process for delicate fabrics, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create exquisite embroidery that enhances rather than damages your most precious fabrics.