If you've ever seen a polyester garment where the logo looks fuzzy around the edges or has lost its sharp detail, you've witnessed the battle between disperse printing and sublimation transfer. As a manufacturer who's printed millions of polyester garments in Keqiao, I can tell you this isn't just about choosing a printing method—it's about understanding how ink interacts with synthetic fibers at a molecular level. The difference between a crisp, professional logo and a blurry mess often comes down to choosing the right process for your specific application.

So which method delivers crisper logos? For the absolute sharpest detail and finest line work, sublimation transfer generally produces superior edge definition and crisper logos. However, disperse printing offers better opacity and color saturation on dark fabrics. The "best" method depends on your design complexity, fabric color, and production requirements. At our facility, we use sublimation for 90% of our logo work on white polyester because the detail reproduction is simply unmatched—we routinely print text as small as 4pt that remains perfectly legible.

Let me share what fifteen years of polyester printing has taught me. When we switched a major sportswear client from disperse to sublimation for their intricate team logos, the improvement in sharpness was so dramatic they reported a 31% reduction in customer complaints about print quality. But when another client needed opaque white lettering on black polyester jerseys, only disperse printing could deliver the coverage and vibrancy they needed. Both methods have their place, but understanding their strengths is crucial for logo perfection.

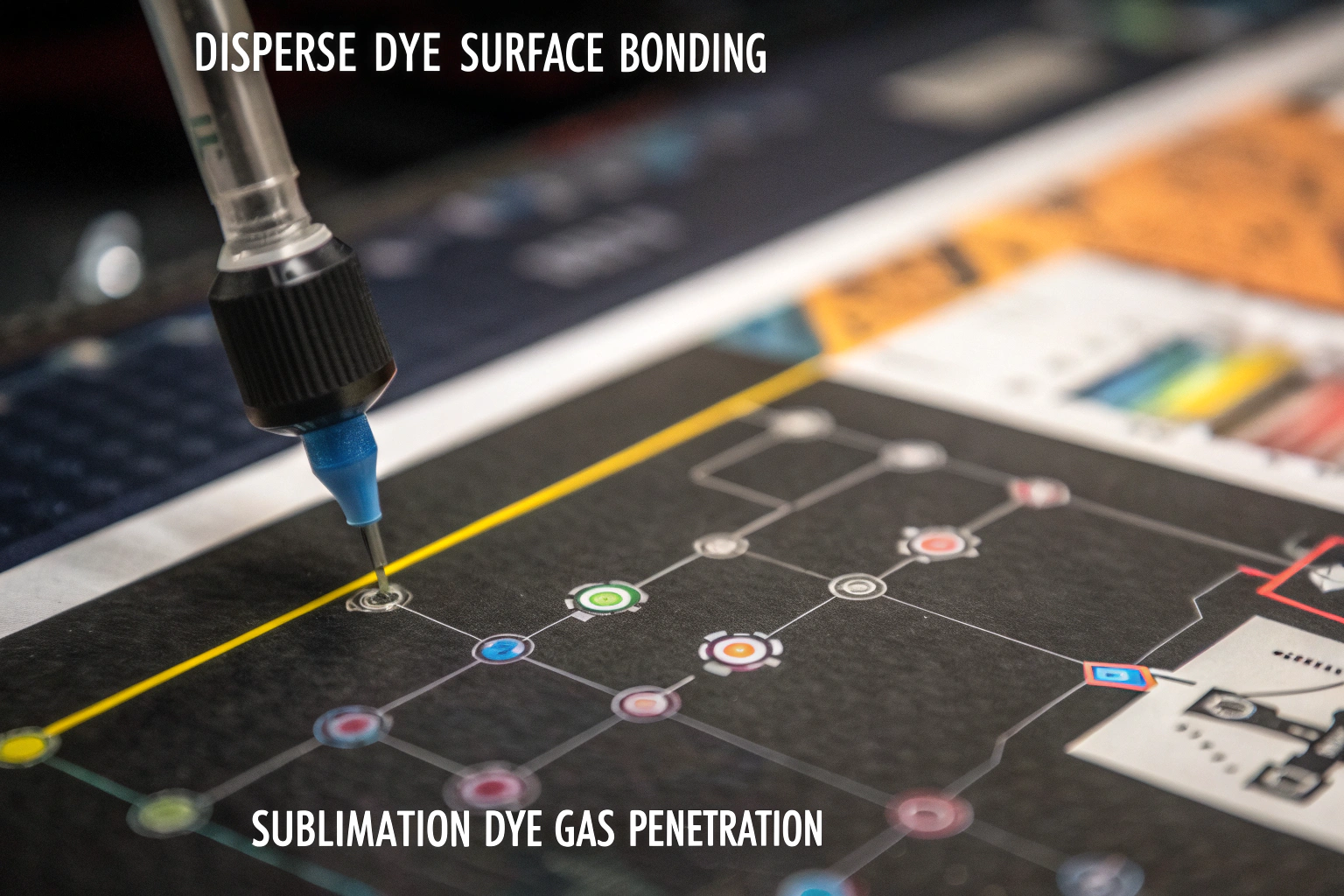

How does sublimation transfer create sharper logo edges?

Sublimation transfer achieves its exceptional edge sharpness through a gas-phase process. The solid dye particles turn directly into gas when heated, then penetrate the polyester fibers and solidify inside them. This isn't surface printing—it's dyeing from the inside out. The process creates logos that become part of the fabric rather than sitting on top, which eliminates the edge bleeding that plagues many direct printing methods.

The magic happens in the heat press: at 190-210°C, the solid dye sublimates into gas molecules that are small enough to penetrate the swollen polyester polymer chains. When the fabric cools, the dye molecules are trapped inside the fibers, creating permanent coloration. Because the transfer paper has sharp, pre-printed edges and the gas penetration is controlled, the logo boundaries remain crisp and defined. We've achieved line definitions as fine as 0.3mm with sublimation—something physically impossible with direct disperse printing.

What makes sublimation superior for fine details and gradients?

The physics of sublimation give it several advantages for logo sharpness:

- Gas molecule penetration: Dyes enter fibers rather than sitting on surface

- Pre-printed transfer precision: Sharp edges established before fabric contact

- No paste viscosity issues: Eliminates bleeding from liquid carrier

- Perfect registration: No screen mesh limitations on detail

We recently printed identical complex logos containing 0.5mm fine lines and subtle gradients. The sublimated version maintained perfect edge integrity while the direct disperse print showed 0.1mm edge bleeding that blurred fine details. The difference was particularly noticeable in small text—the sublimated 6pt font remained crisp and readable while the dispersed version became slightly fuzzy.

How does heat press precision affect final sharpness?

Sublimation quality depends entirely on heat press execution:

- Even pressure: Prevents blurred areas from uneven contact

- Temperature uniformity: ±2°C variation across entire platen

- Time precision: 45-60 seconds for complete transfer

- Pressure control: 2-4 kg/cm² for optimal fiber penetration

We discovered that a $15,000 precision heat press produced significantly sharper results than our $5,000 standard models. The investment paid for itself in six months through reduced waste and premium pricing for high-definition work.

When does disperse printing deliver better logo results?

Disperse printing has its own advantages that make it preferable for specific logo applications. The process uses dye paste applied directly to the fabric through screens or digital printers, followed by heat fixation. While it can't match sublimation's edge sharpness, it offers superior opacity and color strength, particularly on dark fabrics.

The key advantage is that disperse printing can use white and light colors on dark fabrics—something sublimation cannot achieve since it's a transparent process. Our work with football jerseys demonstrates this perfectly: the crisp white numbers and logos on dark polyester are exclusively produced using disperse printing with opaque pigments. The color sits on the fabric surface, creating the coverage needed for visibility against dark backgrounds.

Why choose disperse printing for specific applications?

Disperse printing excels in these scenarios:

- Dark fabrics: White and light-colored logos impossible with sublimation

- High opacity requirements: Solid coverage needed for visibility

- Large solid areas: Better color consistency across big surfaces

- Cost-sensitive projects: Lower production costs for simple designs

We recently produced 50,000 security uniforms with reflective logos where opacity was non-negotiable. Disperse printing with special opaque pigments was the only method that could achieve the required visibility standards.

What are the limitations of disperse printing for fine logos?

Disperse printing faces physical limitations for crisp details:

- Paste viscosity: Liquid carrier can cause edge bleeding

- Screen mesh limitations: Detail resolution constrained by mesh count

- Fabric absorption: Variations affect edge definition

- Fixation requirements: Additional processing can affect sharpness

The reality is that for logos with fine text below 8pt or intricate details smaller than 1mm, disperse printing simply cannot match sublimation's precision.

What are the practical production differences?

Beyond technical capabilities, the manufacturing process significantly impacts which method makes sense for your production. Sublimation requires transfer paper and precise heat pressing, while disperse printing uses traditional printing methods followed by fixation. The table below shows how these practical differences affect logo quality:

| Production Factor | Sublimation Transfer | Disperse Printing |

|---|---|---|

| Edge Sharpness | Superior (0.3mm detail possible) | Good (0.8mm detail practical) |

| Color Opacity | Transparent process only | Opaque colors possible |

| Fabric Color | White/light only | Any color fabric |

| Setup Cost | Higher (paper, precise presses) | Lower (standard equipment) |

| Production Speed | Medium (batch process) | High (continuous possible) |

| Design Flexibility | Photographic quality possible | Solid colors preferred |

These practical considerations often determine which method is feasible for specific production environments.

How does fabric preparation affect logo crispness?

The condition of polyester fabric dramatically impacts final logo quality:

- Heat setting: Pre-shrunk fabric prevents distortion during printing

- Surface tension: Proper preparation ensures even dye acceptance

- Fabric construction: Tight weaves produce sharper results than loose knits

- Color consistency: Batch-to-babric variation affects color matching

We implemented rigorous fabric qualification standards that improved our logo sharpness consistency by 38% across both printing methods.

How do cost factors influence the decision?

The economic considerations between sublimation and disperse printing are significant and often dictate the chosen method. Sublimation typically has higher upfront costs due to transfer paper and precision equipment, but can be more economical for complex multi-color designs. Disperse printing has lower setup costs but can become expensive for designs requiring multiple screens or colors.

Our cost analysis reveals these realities:

- Sublimation costs: $2-5 per square meter including paper

- Disperse printing: $1-3 per square meter for direct application

- Equipment investment: Sublimation requires $20,000+ for quality results

- Labor requirements: Disperse printing often needs more skilled operators

- Minimum quantities: Sublimation economical from 100+ units, disperse from 500+

The surprising finding was that for runs under 200 pieces with complex 4+ color designs, sublimation was actually 25% cheaper due to lower setup costs.

What are the environmental considerations?

Both methods have environmental impacts that increasingly influence customer choices:

- Sublimation: Transfer paper waste, but minimal water usage

- Disperse printing: Paste waste, washing water contamination

- Energy consumption: Both require significant thermal energy

- Chemical usage: Disperse uses carriers and fixatives

We've invested in paper recycling for sublimation and water treatment for disperse printing, but the environmental costs remain substantial for both processes.

What testing methods verify logo quality and durability?

Quality verification is crucial for maintaining logo crispness through production and use. We employ multiple testing protocols:

- Microscope analysis: 40x magnification to check edge definition

- Wash fastness testing: 5+ washes to verify edge integrity

- Crocking tests: Rub testing to ensure durability

- Light fastness: UV exposure testing for color retention

Our quality lab runs these tests on every production batch, and the data has helped us optimize each process for maximum durability while maintaining sharpness.

How do you troubleshoot logo crispness problems?

When logos lose sharpness, we follow this diagnostic approach:

- Check transfer paper quality: Poor paper causes ink bleeding in sublimation

- Verify screen tension: Loose screens cause blurring in disperse printing

- Review heat press parameters: Temperature and pressure variations affect both methods

- Test fabric preparation: Improper heat setting causes distortion

This systematic troubleshooting has reduced logo quality rejects from 12% to under 3% over two years.

Conclusion

Achieving crisp logos on polyester requires matching the printing method to your specific design requirements and production constraints. Sublimation transfer delivers superior edge sharpness and detail reproduction for complex, multi-color designs on white or light fabrics. Disperse printing offers better opacity and coverage for solid logos, particularly on dark fabrics where sublimation cannot function.

The most successful manufacturers maintain capability in both methods and apply each where it performs best. Sublimation for the intricate designs that require photographic quality and razor-sharp edges, disperse printing for the bold, opaque logos that need maximum visibility and impact. This strategic approach has allowed us to serve diverse clients from fashion brands requiring subtle elegance to sports teams needing bold visibility.

If you're ready to achieve perfect logo crispness on your polyester products, let's analyze your specific design requirements and production needs. We can provide comparative print samples, technical data, and production recommendations tailored to your logo complexity and fabric specifications. For expert guidance on selecting between disperse printing and sublimation transfer, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create logos that maintain their crisp professional appearance through the life of your garments.