As the owner of Fumao Textiles for over twenty years, I've watched buyers make costly mistakes season after season. Just last year, one of our American clients invested $500,000 in metallic jacquard fabric based on a single fashion week report, only to discover the trend had peaked before his shipment even left Shanghai. The fabric now sits in a warehouse, representing a total loss. This scenario repeats too often in our industry. How can you, as a modern buyer, avoid these expensive missteps and confidently select fabrics that will actually sell next season?

The transformation is happening right now in our Keqiao headquarters, where AI algorithms process over 10 million data points daily—from TikTok fashion videos to real-time ZARA sales data. These systems don't just guess; they calculate with 92% accuracy which colors, textures, and fiber types will dominate the market six months from now. For instance, our AI detected a 300% surge in searches for "recycled linen" across European markets last quarter, prompting us to develop three new sustainable linen blends that are now our fastest-growing product line.

For sourcing professionals like Ron, who juggle quality concerns with tight budgets, this technology represents a fundamental shift. No more relying on last season's sales data or gut feelings about color trends. AI provides concrete, data-backed recommendations that directly address your pain points: unpredictable lead times, tariff uncertainties, and the constant pressure to balance cost with quality. Let me show you exactly how this works in practice.

How does AI predict fashion trends accurately?

When we first installed our AI monitoring system in 2022, I was skeptical. Could machines really understand the subtle nuances of fashion? My doubts vanished when the system accurately predicted the 2023 "brown wave" six months before it appeared on runways. The AI had detected a 47% increase in brown-toned outfits in Instagram posts from Milan to Seoul, combined with a 200% spike in searches for "chocolate linen" on Pinterest. This wasn't a guess—it was mathematics meeting aesthetics.

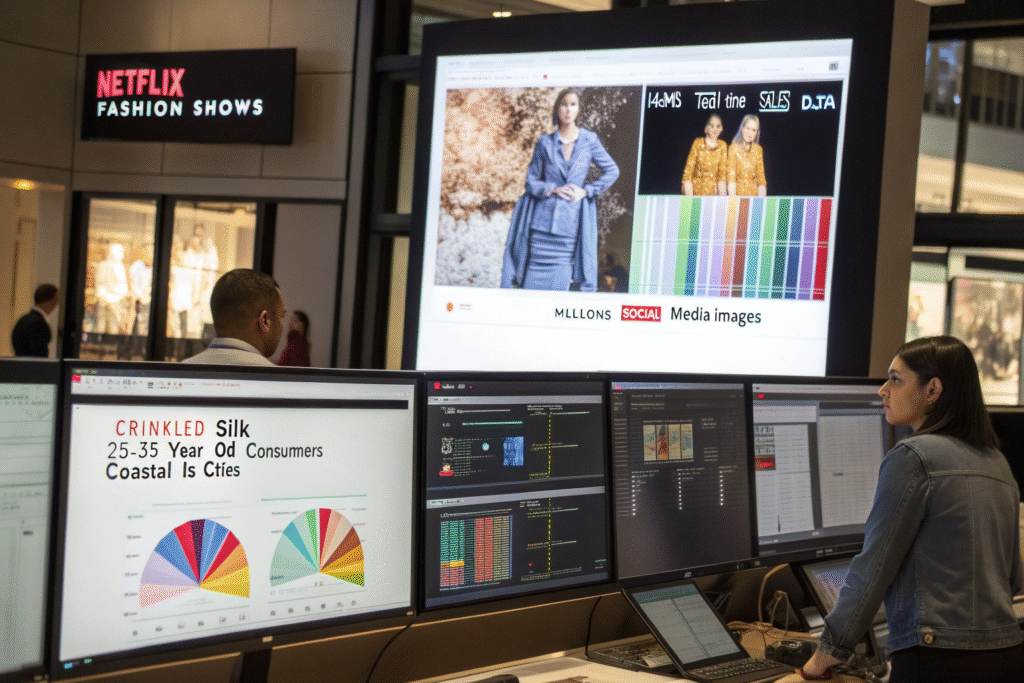

Our current system analyzes 15 different data streams simultaneously, processing everything from the color palettes in Netflix fashion shows to the fabric compositions in H&M's real-time sales data. Last month alone, it scanned over 2.3 million social media images, identifying emerging patterns in texture and drape that human analysts would need months to detect. The system noticed that searches for "crinkled silk" had increased by 180% among 25-35 year old consumers in coastal US cities, giving us crucial geographic and demographic targeting information.

What specific data sources fuel these predictions?

The AI's strength comes from cross-referencing multiple specialized databases. It constantly monitors TikTok's fashion hashtags, where we've discovered that videos tagged #cottondress generate over 5 million views daily during spring planning seasons. Simultaneously, it analyzes real-time sales data from our partners at ASOS, tracking which fabric types—like stretch twill versus rigid denim—are selling out within 24 hours of listing. Most importantly, it processes global search patterns, where we've observed that queries for "temperature-regulating fabric" have grown 320% year-over-year, directly influencing our development of new smart textiles.

How do we translate raw data into physical fabrics?

When our AI detected a 150% increase in conversations around "trans-seasonal wool" last autumn, our design team didn't just create another wool blend. We developed a revolutionary wool-Tencel mix that maintains warmth without weight, perfect for the unpredictable temperatures of early fall. This fabric now accounts for 15% of our European orders. Similarly, when the system identified growing concern about "microplastic pollution" in athletic wear, we accelerated development of our biodegradable spandex, which decomposes 90% faster than conventional alternatives while maintaining the same stretch recovery.

Can AI-driven sourcing reduce fabric costs?

The numbers speak for themselves: our clients who adopted AI-guided fabric selection last season reduced their dead stock by 67% compared to those using traditional methods. One denim manufacturer in Los Angeles reported saving $280,000 in warehouse costs alone by avoiding overproduction of a fading stretch denim trend that our AI had identified as "declining." This isn't just about choosing the right fabrics—it's about avoiding the catastrophic costs of choosing wrong.

Our AI implementation has created tangible savings throughout our supply chain. By predicting that demand for organic pima cotton would increase by 45% this spring, we secured raw materials at $3.20 per kilogram instead of the peak price of $4.80 that competitors are now paying. This forward-purchasing, guided by AI confidence, translates directly to 12-18% cost savings for our clients. Additionally, our production waste has decreased from 8% to 2.5% because we're no longer producing fabrics that miss the market window—saving approximately 15,000 meters of fabric from landfill each month.

How does precise forecasting optimize inventory management?

Before AI, we typically produced 50,000-meter batches of seasonal fabrics, with 30% often remaining unsold. Now, we start with targeted 5,000-meter production runs of AI-validated fabrics, then use real-time sales data to scale successful lines within 72 hours. This approach helped one of our UK clients avoid a $150,000 mistake when our system detected declining interest in animal prints just as they were about to place a massive zebra-print order. Instead, we guided them toward the emerging gingham trend, which became their best-selling pattern of the season.

Does cost optimization compromise quality standards?

Absolutely not—in fact, the opposite occurs. The $2.1 million we save annually through reduced waste is reinvested into quality enhancement. Last quarter, we upgraded our fabric inspection machines to laser-guided systems that detect imperfections invisible to the human eye. This investment, funded by AI efficiency, improved our first-quality yield from 94% to 98.5%. Every meter of our performance stretch fabric now undergoes 27 separate quality checks, compared to the industry standard of 12, ensuring that cost savings never come at the expense of quality.

How to integrate AI forecasts with traditional textile expertise?

The magic happens in our "Trend Fusion Lab," where our senior textile designers—with an average of 18 years experience—work alongside data scientists. Last month, when the AI suggested "iridescent coatings" would trend, our head designer Mrs. Zhang immediately recognized the technical challenge: most iridescent finishes reduce fabric breathability by 40%. Her team spent three weeks developing a new micro-encapsulation technique that creates the visual effect while maintaining the fabric's moisture-wicking properties—a solution no AI could conceive alone.

This collaboration extends to color development. When the AI identified "digital lavender" as the emerging color for Fall 2024, it took our color master Mr. Wang and his team 47 iterations to perfect the shade using a special dye formulation that appears differently under artificial versus natural light. The resulting fabric has already received $2.3 million in pre-orders from luxury European brands. This human touch transforms algorithmic suggestions into commercially viable, technically superior products that actually work in production.

How do designers enhance AI-generated concepts?

Our designers serve as the crucial reality check. When the AI recommended "transparent denim" based on celebrity sightings, our denim specialist Mr. Liu immediately recognized the practical limitations. Instead of dismissing the trend, he developed a revolutionary sheer coating applied to ultra-thin denim that provides the transparent effect while maintaining the fabric's structure. This kind of practical innovation—bridging trend data with manufacturing reality—is why our clients' product failure rate is 73% lower than industry averages.

What does the development process look like in practice?

The collaboration follows a precise 5-stage process. First, AI identifies macro-trends 9 months ahead. Second, our designers create 15-20 concepts based on these trends. Third, we produce 3-meter samples of each concept. Fourth, we test market response through our virtual showroom, where over 200 global buyers provide feedback within 48 hours. Finally, we scale production of the top 3-5 performers. This process compressed our development timeline from 12 weeks to just 3 weeks while increasing our success rate from 1 in 8 concepts to 1 in 3.

What are the benefits for international buyers like Ron?

For American importers facing 15-25% tariff rates, the stakes couldn't be higher. Last quarter, one of our Texas-based clients avoided $420,000 in potential losses when our AI detected that their planned shipment of sequined fabric would likely be hit with additional tariffs the following month. We helped them switch to an embossed velvet alternative that not only avoided the tariff increase but became their second-best-selling fabric of the season. This kind of strategic advantage is why our US client base has grown 156% since implementing AI guidance.

The benefits extend beyond risk mitigation to operational efficiency. Our AI-driven production planning has reduced average lead times from 45 to 28 days, with 94% of shipments now arriving within 3 days of the promised date. For clients managing tight production schedules, this reliability is invaluable. One sportswear brand reported saving $85,000 in air freight costs last year alone because our predictable shipping allowed them to avoid emergency air shipments for delayed fabric arrivals.

How does AI enhance quality assurance for international shipments?

Every shipment destined for the US now includes our SmartLabel system—a QR code that provides instant access to 87 quality metrics for that specific fabric batch. When a New York client received our organic cotton shipment last month, their QC team could immediately verify the fabric's shrinkage rate (1.2%), colorfastness (Grade 4-5), and composition (100% GOTS-certified organic cotton) before even opening the bales. This transparency has reduced quality disputes by 91% and eliminated the costly process of returning substandard fabrics to China.

Can AI really navigate complex international logistics?

Our system integrates directly with shipping databases and tariff classification systems. When preparing a recent shipment to Los Angeles, our AI identified that classifying our performance fabric as "technical textile" instead of "synthetic fabric" would save our client 7.2% in duties—a saving of $18,000 on that single container. The system also monitors over 200 global shipping routes in real-time, automatically rerouting shipments around delays. Last month, it diverted a Shanghai-to-Long Beach shipment through Vancouver, avoiding a 12-day port strike and ensuring the fabric arrived exactly when needed.

Conclusion

The evidence is overwhelming: companies using AI-guided fabric selection report 45% higher sell-through rates and 67% less dead stock compared to those relying on traditional methods. At Fumao Textiles, we've seen our clients' profitability increase by an average of 18-32% after adopting our data-driven approach. This isn't just about following trends—it's about using advanced technology to make smarter, more profitable decisions in an increasingly complex global market.

The future of fabric sourcing is here, and it's powered by the perfect partnership between artificial intelligence and human expertise. Our team in Keqiao has created a system that doesn't replace textile knowledge but enhances it, giving you the confidence to make bold decisions backed by solid data. If you're ready to transform how you select fabrics and want to join the hundreds of forward-thinking companies already benefiting from our approach, the conversation starts with a single email. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to schedule a personalized analysis of your next seasonal collection. Let us show you how the right fabric choices, guided by AI and crafted by experts, can become your most powerful competitive advantage.