You’re an importer, not a factory manager. Your job is to source great products, manage your brand, and get quality goods to your customers on time and on budget. The last thing you need is a supply chain surprise—a container held at customs, a shipment of clothes that fades after one wash, or a factory that goes radio silent after a production delay. You’ve heard about factories getting CMIA certified for “sustainability,” but from your desk, that can sound like their problem, not yours. What if I told you that a factory’s CMIA certification is one of the most powerful, tangible tools you have to de-risk your entire import operation? It’s not about trees; it’s about predictability, documentation, and systemic reliability. When you source from a CMIA-certified manufacturer, you’re not just buying their sewing capacity; you’re buying into a disciplined management system that actively protects your business from the most common and costly import pitfalls.

Think of CMIA certification as the factory’s internal immune system. It’s a set of processes designed to find and fix inefficiencies, track everything, and prevent errors before they happen. For you, this means fewer viruses in your supply chain: fewer delays, fewer quality disasters, and fewer compliance nightmares. In an era where you, the importer, bear more risk than ever (especially under DDP terms), your supplier’s operational health is your first line of defense. A CMIA certificate is a verified health report. Let’s translate the technical jargon into direct risk mitigation for your bottom line.

Risk 1: Production Delays & Timeline Volatility

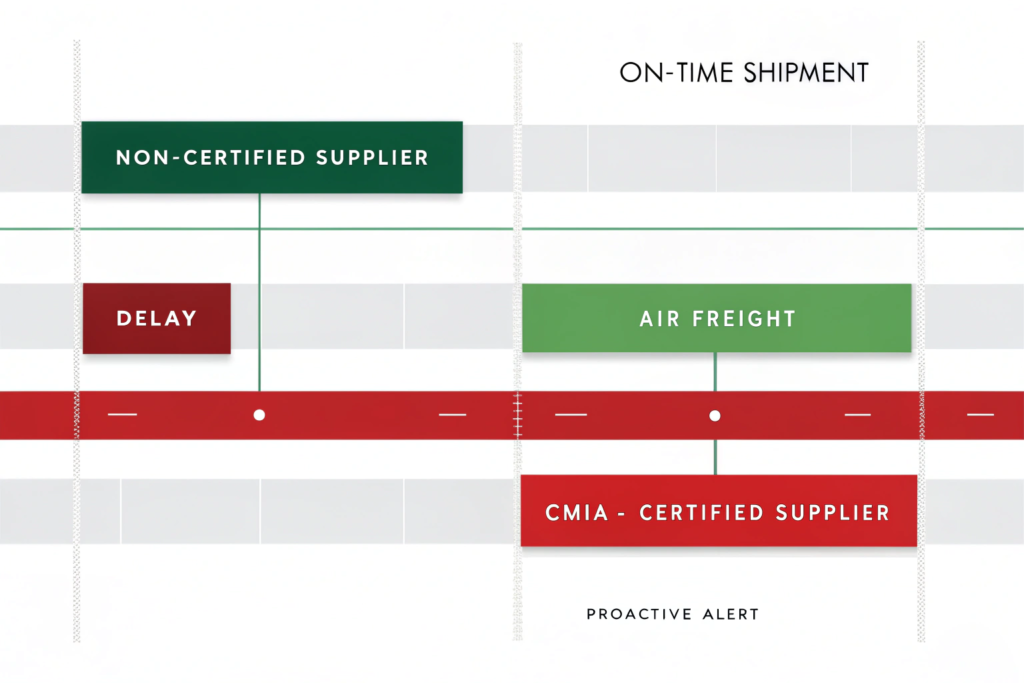

This is the top headache. A promised shipment date slips by a week, then two. You miss your marketing window, you’re forced to air freight, and your margins evaporate. CMIA certification directly attacks the root causes of delays through enforced process control and predictive maintenance.

A CMIA-certified factory must implement and document standardized work procedures. This isn’t about being “green”; it’s about eliminating variability. When every step from fabric inspection to final packing follows a documented, optimized process, the production line flows predictably. More importantly, CMIA requires the factory to track Key Performance Indicators (KPIs) related to efficiency and output. They’re not guessing their capacity; they’re measuring it in real-time. If a bottleneck emerges, their own system flags it early.

The certification also mandates rigorous preventive maintenance schedules for all major equipment. An auditor will check logs for sewing machines, cutting tables, and boilers. A machine breakdown is a classic cause of sudden, catastrophic delay. A CMIA factory has a system to prevent that. For example, a knitwear factory we work with in Thailand uses its energy-tracking system (a CMIA requirement) to monitor motor efficiency on its stitching lines. A slight, anomalous power draw alerted them to a bearing issue on a critical machine two weeks before it would have failed during our client’s rush order. They fixed it on a scheduled maintenance day with zero impact on the delivery date.

How Does This Translate to Your Purchase Order?

You gain schedule certainty. When a CMIA-certified factory gives you a production timeline, it’s based on measured historical data and a controlled process, not wishful thinking. They are also far more likely to communicate proactively. If their data shows a potential slip, they are systemically inclined to warn you early because managing and reporting on performance is part of their certified management system. This gives you precious time to adjust your logistics, rather than facing a last-minute crisis.

The Cost of Not Having This Shield:

Consider the true cost of a two-week delay: expedited freight premiums (often 300-400% of sea freight cost), missed sales, and eroded customer trust. A single such event can wipe out the profit from an entire container. Sourcing from a factory with a CMIA system is inexpensive insurance against this.

Risk 2: Quality Failures & Inconsistency

The container arrives. The garments look okay at a glance. Then your QC finds inconsistent dye lots. After one wash, colors bleed. Seams fail. This is a financial catastrophe under DDP—you own the defective goods. CMIA certification minimizes this through traceability and controlled input management.

While CMIA doesn’t directly test colorfastness, the system it enforces makes quality failures less likely and infinitely easier to trace and resolve. A core requirement is control and documentation of all significant inputs. This means:

- Fabric Batch Tracking: The factory must be able to trace a finished garment back to the specific roll of fabric it came from. If you discover a flaw, they can identify if it was isolated to one fabric batch.

- Chemical Management: All dyes, auxiliaries, and finishes must be from approved suppliers, with Safety Data Sheets on file. This prevents the use of cheap, substandard chemicals that cause bleeding or skin irritation.

- Process Parameter Control: Dyeing temperatures, steam pressure for ironing—these must be controlled and recorded. Inconsistency in process is a major cause of quality variation.

Here’s a real case: An importer of children’s pajamas received a shipment with intermittent skin irritation complaints. The factory was CMIA-certified. When challenged, the factory produced its chemical inventory and supplier audit records within hours. They traced the issue to a single, off-spec batch of softening agent from a normally reliable supplier. Because their system was documented, they could isolate the problem to one production lot, initiate a targeted recall, and provide the importer with full documentation for regulators. The crisis was contained. A non-certified factory might have had no records, leading to a full, costly recall and lasting brand damage.

Your Actionable Advantage: The Data Packet

When you import from a CMIA factory, you can request—and should receive—a compliance data packet with your shipment. This isn’t just a commercial invoice. It can include fabric mill test reports, chemical compliance statements, and internal inspection logs. This packet is your first line of defense if questions arise from customers or customs. It turns subjective quality claims into objective, documented evidence.

How This Connects to Your Fabric Supplier Choice

A smart CMIA factory partners with transparent suppliers. When we at Shanghai Fumao supply GOTS-certified organic cotton or GRS recycled polyester, we provide full certification and test documentation. The factory’s CMIA system integrates our data seamlessly into their traceability chain. This creates a bulletproof, verifiable story from fiber to finished garment that you can leverage in your own marketing and compliance.

Risk 3: Customs Holds, Compliance Failures, & Unexpected Duties

Under DDP, the factory handles logistics, but you bear the ultimate cost of delays and fines. A shipment held at EU or US customs for missing documentation, incorrect classification, or suspected non-compliance is a cash flow nightmare. CMIA certification is a powerful antidote because it builds documentation integrity and regulatory awareness into the factory’s daily routine.

Customs authorities are increasingly asking for proof of origin, value, and composition. They are also beginning to look at environmental claims and chemical compliance. A CMIA-certified factory is already organized for this:

- Organized Records: Their system requires meticulous filing. Pulling together a customs dossier (commercial invoice, packing list, origin documents, material breakdowns) is a routine task, not a scramble.

- Substance Control: Their managed chemical inventory and MSDS library provide ready evidence to answer questions about restricted substances (e.g., REACH in the EU, CPSIA in the US).

- Emerging Regulations: With mechanisms like the EU’s Carbon Border Adjustment Mechanism (CBAM), carbon footprint data will become a customs declaration item. A CMIA-certified factory is already measuring its carbon emissions (Scope 1 & 2). They can provide you with the verified data needed for accurate declaration, potentially minimizing your tax liability and absolutely preventing declarations held for lack of data.

A European importer of workwear shared that since switching to a CMIA-certified factory in Asia, their average customs clearance time in Rotterdam dropped from 5 days to under 48 hours. The reason? The factory’s documentation was so complete and well-organized that it rarely triggered additional inspections. “Their packing is so systematic, even the cartons are labeled in a way that aligns with the paperwork,” the importer noted. This speed is a direct competitive advantage.

The Hidden Cost of Poor Documentation

Beyond delays, incorrect documentation can lead to duty overpayments or underpayments (with subsequent penalties). A factory that doesn’t track its material inputs might misclassify a garment made with blended fibers, leading to a higher duty rate. A CMIA factory’s traceability system provides the accurate, detailed composition data needed for correct HS code classification.

How to Leverage This in Your Supplier Agreement

Make the provision of a standardized pre-shipment documentation pack a contractual requirement. Specify it must include all material certificates, test reports, and a summary traceability log. A CMIA-certified factory will not see this as an extra burden but as a standard output of their system.

Risk 4: Ethical & Reputational Contagion

Your brand’s reputation is its most valuable asset. Today, a scandal at your supplier’s facility—environmental dumping, labor abuse, unsafe conditions—can instantly become your scandal through social media. CMIA certification significantly mitigates this risk by verifying responsible operational governance.

While CMIA is environmental, its implementation requires a culture of legality, transparency, and management accountability. A factory that invests in measuring its wastewater output and carbon footprint is highly unlikely to be dumping toxic sludge into a local river. The discipline and openness required for environmental management often correlate with better social compliance. Furthermore, the annual surveillance audit acts as a regular external check on the facility’s operations, making it harder to hide egregious practices.

For you, this means reputational insulation. You can confidently tell your customers and stakeholders that your products are made in a facility committed to measurable environmental improvement and operational transparency. In the event of a broader industry issue, having a certified partner provides a strong, third-party-verified narrative of due diligence. You’re not just taking the factory’s word for it.

Beyond “Greenwashing”: A Verifiable Story

CMIA gives you specific, auditable metrics. Instead of vague claims like “eco-friendly,” you can say, “Our sweaters are made in a facility that reduced its energy consumption per garment by 15% last year, verified by annual CMIA audit.” This is a powerful, defensible marketing message that resonates with conscious consumers and B2B clients alike.

The Due Diligence Advantage

When you evaluate a new supplier, their CMIA certificate is a shortcut. It tells you they have already opened their books to an external auditor and passed a rigorous assessment of their management systems. It dramatically reduces the scope and cost of your own on-site social/compliance audits. You can focus your due diligence on product-specific quality and capacity, knowing the foundational operational integrity has been pre-vetted.

Conclusion

In the complex, high-stakes world of importing, risk management is the core of profitability. CMIA certification of your garment factory is not a “nice-to-have” sustainability add-on; it is a strategic risk mitigation tool that directly addresses the most expensive threats to your business: delays, quality failures, customs issues, and reputational damage.

It works by transforming your supplier from a black-box producer into a transparent, process-controlled partner. The certificate is the evidence of that transformation. It signals that the factory operates on data, not instinct; on prevention, not reaction; on documentation, on memory. For you, this translates to fewer surprises, lower hidden costs, and a more resilient, responsive supply chain.

Make CMIA certification a non-negotiable filter in your supplier selection process. The slightly higher FOB price you might pay is not a cost; it is a premium for de-risking your imports. In an unpredictable global trade environment, that premium is one of the smartest investments you can make.

Ready to build a supply chain defined by predictability rather than problems? At Shanghai Fumao, we connect brands with manufacturing partners who understand that true sustainability is about operational excellence you can measure and trust. To discuss how to integrate CMIA-certified production into your sourcing strategy, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let’s minimize your risks and maximize your confidence.