Let's dismantle the industry's most persistent and damaging myth: that you must choose between quality and certification. This is a false dichotomy propagated by mediocre suppliers who can't deliver either. I've seen buyers accept brittle, inconsistent "organic" jersey because they believed the certification was the only thing that mattered. Conversely, I've seen brands reject superb, certified fabrics because they assumed "organic" meant "inferior." The truth is, the disciplines required to produce genuinely top-quality fabric—precision engineering, rigorous testing, obsessive consistency—are the exact same disciplines required to maintain impeccable OCS certification. They are not trade-offs; they are two sides of the same coin. Sourcing them together isn't just possible; it's the only way to build a product that is both premium and provable.

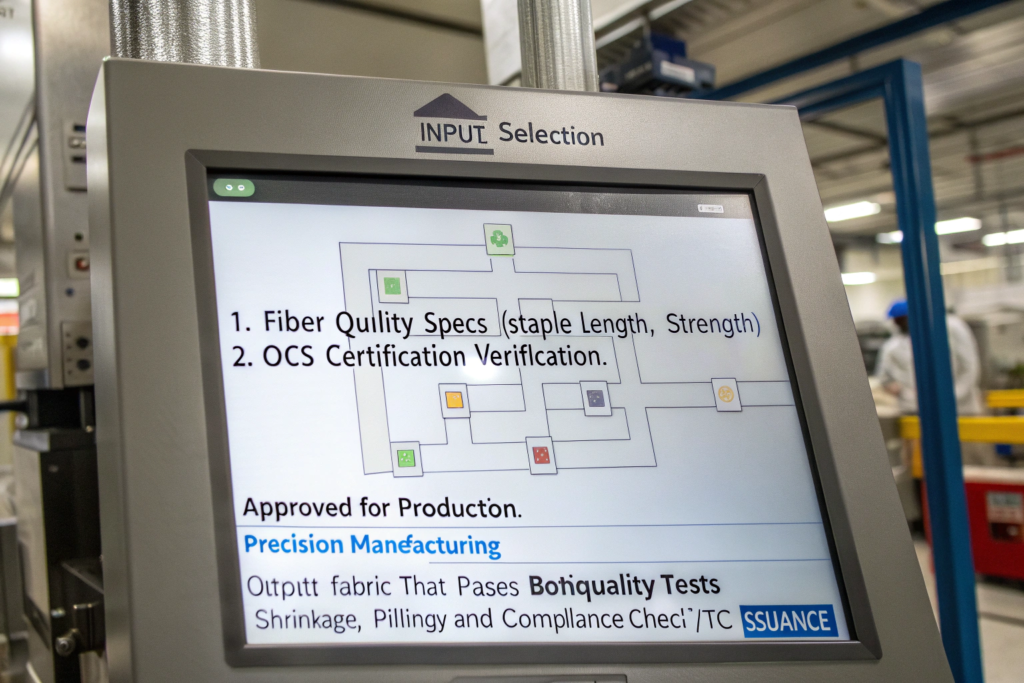

Yes, you can absolutely source top quality and OCS certified fabric together, but it requires targeting a specific tier of manufacturer: one that views certification not as a marketing cost, but as an integral part of a quality management system (QMS). This manufacturer invests in superior raw materials (like long-staple organic cotton), state-of-the-art machinery, and rigorous laboratory testing, and then uses the OCS framework to document and guarantee the purity and traceability of that high-performance output. The certification becomes the quality seal's data-rich backbone.

The quest is not for a supplier who has both, but for one whose business is built on the synergy of both. Let's map the route.

The Synergy: How Quality and Certification Reinforce Each Other

Think of OCS certification as a forensic tracking system for your raw material. A factory that operates such a system is, by necessity, process-oriented, data-driven, and audit-ready. These are the hallmarks of a quality-focused operation. The systems that prevent OCS yarn from mixing with conventional yarn are the same systems that prevent navy blue fabric from contaminating black fabric. The discipline is transferable.

Conversely, a factory focused on premium quality starts with superior inputs. They seek out the best long-staple organic cotton because it spins into stronger, smoother yarn. Their pursuit of quality leads them to certified premium fiber, and the certification then provides the proof of that premium choice.

How does OCS traceability prevent quality variability?

Inconsistent quality often stems from inconsistent inputs. If a factory uses yarn from three different spinners in one production run because they're chasing the cheapest spot price, the resulting fabric will have uneven strength, shrinkage, and dye uptake.

An OCS-certified factory committed to quality will:

- Source Strategically: They have long-term contracts with one or two certified spinners who can provide consistent, high-spec yarn.

- Track Religiously: The OCS lot tracking ensures that each fabric roll can be traced to a single yarn batch. If a quality issue arises (e.g., higher pilling), it can be isolated to a specific lot, and that lot can be held back.

- Enforce Consistency: The need to maintain mass balance records discourages the blending of different material batches, which is a primary cause of hidden quality defects.

This systematic approach inherently reduces variability, which is the enemy of top quality. A German sportswear brand we work with chose us precisely for this reason. Our OCS-controlled, single-origin organic cotton yarn resulted in jersey with a shrinkage tolerance of ±1.5%, compared to the ±4-5% they experienced with multi-source "organic" suppliers.

What quality benchmarks define "top quality" fabric?

"Top quality" must be quantified. When evaluating an OCS supplier, you must demand test reports for these key performance indicators (KPIs):

| Quality Parameter | Test Standard | "Top Quality" Benchmark (e.g., for 200gsm Jersey) |

|---|---|---|

| Dimensional Stability (Shrinkage) | AATCC 135 / ISO 5077 | ≤ 3% after 5 home washes. Premium target: ≤ 2%. |

| Pilling Resistance | ASTM D4970 / ISO 12945-2 | Rating ≥ 4 (on 1-5 scale) after 12,000+ Martindale rubs. |

| Colorfastness to Washing | AATCC 61 / ISO 105-C06 | Rating ≥ 4 (1-5 scale). No staining of adjacent fabrics. |

| Tensile & Tear Strength | ASTM D5034 / D5587 | Meets or exceeds industry norms for the fabric weight and type. |

| Fiber Composition | ISO 1833 | 100% as declared (verifies no blending or adulteration). |

An OCS-certified supplier that is also quality-focused will have these reports on hand, often from an in-house CNAS-accredited lab or a partner like SGS. They will discuss these numbers with you. If they only want to talk about the certificate and the price, walk away.

The Supplier Profile: Identifying the Unicorn

The supplier that masters both is not a generic fabric mill. It is a vertically integrated, technologically advanced, and strategically sourced operation. Your sourcing must become a forensic investigation of their capabilities, not just their certificate.

What questions separate the contenders from the pretenders?

During supplier evaluation, ask these tandem questions:

- On Quality: "What is the staple length and micronaire of the OCS cotton you typically use? Can you share a recent fiber test report from your spinner?"

- On Certification: "Can you walk me through how your ERP system tracks OCS yarn lot #A123 from receipt through weaving and into the finished fabric roll #F456?"

- On Testing: "Do you conduct pre-emptive pilling and shrinkage tests on every fabric lot before shipping? Can I see a sample report?"

- On Problem-Solving: "If a lab test shows shrinkage at 4% against a 3% spec, what is your corrective action process? How does this interact with your OCS non-conformance procedures?"

A pretender will give vague answers. A contender will have detailed, confident responses and will offer to show you evidence in real-time. They will welcome these questions because it showcases their competitive advantage.

Why is vertical integration (like Fumao's) a key indicator?

A trading company cannot guarantee quality or certification integrity because they don't control production. A vertically integrated manufacturer that weaves its own fabric has direct command over the two most critical stages: yarn selection and weaving process control.

- Yarn Selection: They can insist their spinning partners provide both OCS certification and specific fiber quality parameters (e.g., 32mm staple length, Uster statistics on evenness).

- Process Control: In their own weaving facility, they can fine-tune machine settings (tension, speed) to optimize the fabric hand-feel and performance for that specific high-quality yarn. They can ensure flawless dyeing and finishing.

This control is why brands seeking the pinnacle of performance—like those in the athleisure or premium bedding sectors—increasingly seek out vertical OCS partners. The certification ensures the organic integrity; the vertical control ensures that integrity is expressed through superior fabric.

The Commercial Reality: Cost, Value, and Strategic Sourcing

Sourcing top-quality OCS fabric costs more. Period. But the value equation completely changes. You are not buying a commodity; you are buying a performance-guaranteed, risk-mitigated raw material asset. The total cost of ownership (TCO) for your brand is often lower.

How to justify the premium to internal stakeholders?

Build a business case around TCO and Risk Reduction:

- Reduced Waste & Higher Yield: Predictable shrinkage and consistent quality mean your garment factory has less cutting waste and fewer seconds. A 2% improvement in fabric utilization can pay for the entire fabric premium on a large order.

- Fewer Returns & Higher Customer Satisfaction: Garments that hold their shape, don't pill, and keep their color generate fewer returns and foster brand loyalty.

- Supply Chain Resilience: A partner with this level of systemization is less likely to cause production delays due to quality or certification failures.

- Marketing & ESG Value: The ability to market a verifiably premium, organic product supports higher price points and meets stakeholder ESG demands.

Presenting this holistic view shifts the conversation from "Why does it cost more?" to "What value does it protect and create?"

What does the sourcing process look like in practice?

It's a phased, evidence-based partnership:

- Benchmarking: Share your quality specs (e.g., "Jersey, 220gsm, shrinkage <3%, pilling 4+") and request fabric swatches and corresponding test reports.

- Documentation Review: Request the OCS certificate of the mill and a sample TC. Cross-check the company name and scope.

- Pilot Order: Place a small order (e.g., 1000 meters). Subject it to your own third-party testing for both quality (shrinkage, etc.) and certification integrity (composition analysis). This is your proof-of-concept.

- Strategic Agreement: If the pilot passes, negotiate a longer-term agreement that may include reserved capacity, program pricing, and joint quality targets.

This process filters out 95% of suppliers quickly, leaving you with a true partner. In 2023, a UK luxury homewares brand followed this exact process with us. Their pilot order passed their stringent 1% shrinkage test and a PCR test for GMOs. We are now their sole OCS linen supplier.

Conclusion

Sourcing top quality and OCS certified fabric together is not only possible—it is the defining sourcing strategy for brands that refuse to compromise between product excellence and ethical integrity. This combination is found not by searching for a certificate alone, but by identifying manufacturers whose operational DNA is built on precision, transparency, and systemic control. These partners treat certification as a quality checkpoint, not a sales brochure.

For brands aiming for the premium, conscious market, this dual-sourced fabric is the raw material of trust. It allows you to build products that perform flawlessly for the consumer and hold up impeccably under the scrutiny of the most demanding auditor.

If you are ready to source fabric that meets your highest standards of both feel and fact, you need a partner engineered for this dual mandate. At Shanghai Fumao, our vertical integration and obsessive quality systems are designed to deliver certified fabric that consistently passes the most rigorous performance tests. Contact our Business Director, Elaine, to start a partnership defined by uncompromising quality: elaine@fumaoclothing.com. Let's weave a new standard, together.