You need to stock your shelves or fulfill a large order for your brand. The pressure is on to find the lowest cost per unit to protect your margins. But you also can't afford a customer lawsuit or a recall because of harmful chemicals in the clothing. The market tells you to choose: cheap or safe. This feels like an impossible dilemma. Is it?

Yes, a knowledgeable and efficient wholesaler can absolutely provide both competitive pricing and top safety. The key lies not in cutting corners on materials, but in leveraging economies of scale, vertical integration, and strategic partnerships with certified factories like Shanghai Fumao to eliminate waste, streamline logistics, and source certified materials at volume—passing the savings on to you while guaranteeing safety through standards like OEKO-TEX®.

The myth that safety must be expensive is often perpetuated by inefficient supply chains. Let's break down how a professional wholesaler structures their operations to deliver value without compromising on the non-negotiable element of product safety.

How Does Volume Sourcing Reduce Cost Without Sacrificing Safety?

The most direct path to a lower price is higher volume. But buying 10,000 units from an uncertified factory to get a low price is a high-risk gamble. The intelligent approach is to use that volume as leverage to secure better rates from certified, ethical suppliers.

Volume sourcing reduces cost through economies of scale. When a wholesaler like Shanghai Fumao commits to large fabric orders from OEKO-TEX® certified mills or large production runs, the per-unit cost of both the certified material and the manufacturing labor drops significantly. This allows us to offer you a competitive wholesale price while the safety certification—a fixed cost of testing and system management—is amortized across thousands of units, making its impact on the final price minimal.

This isn't just theory. It's a daily calculation in professional wholesale. The cost benefits come from several specific areas unlocked by volume.

What are the tangible cost savings from bulk material purchasing?

Purchasing fabric in bulk rolls of 10,000 meters instead of 1,000 meters typically reduces the cost per meter by 15-25%. When this fabric is pre-certified, the savings are direct. For instance, by consolidating the orders of three mid-sized activewear brands with similar fabric needs, we were able to place a single order for 50,000 meters of OEKO-TEX® certified polyester jersey. This secured a tier-1 price from the mill, and the savings were shared with all three clients, allowing each to access safer materials at a cost comparable to non-certified options from smaller suppliers.

How does production efficiency lower the price for safe garments?

Longer production runs mean less factory downtime for machine changes and operator re-training. This maximizes labor efficiency. A factory producing 20,000 units of a single style can achieve a higher productivity rate than one producing 2,000 units of ten different styles. This efficiency gain reduces the labor cost embedded in each garment. We apply this principle by offering clients "collection-based" production, where different styles share common certified fabrics and construction techniques, allowing for longer, more efficient runs without sacrificing design diversity or safety standards.

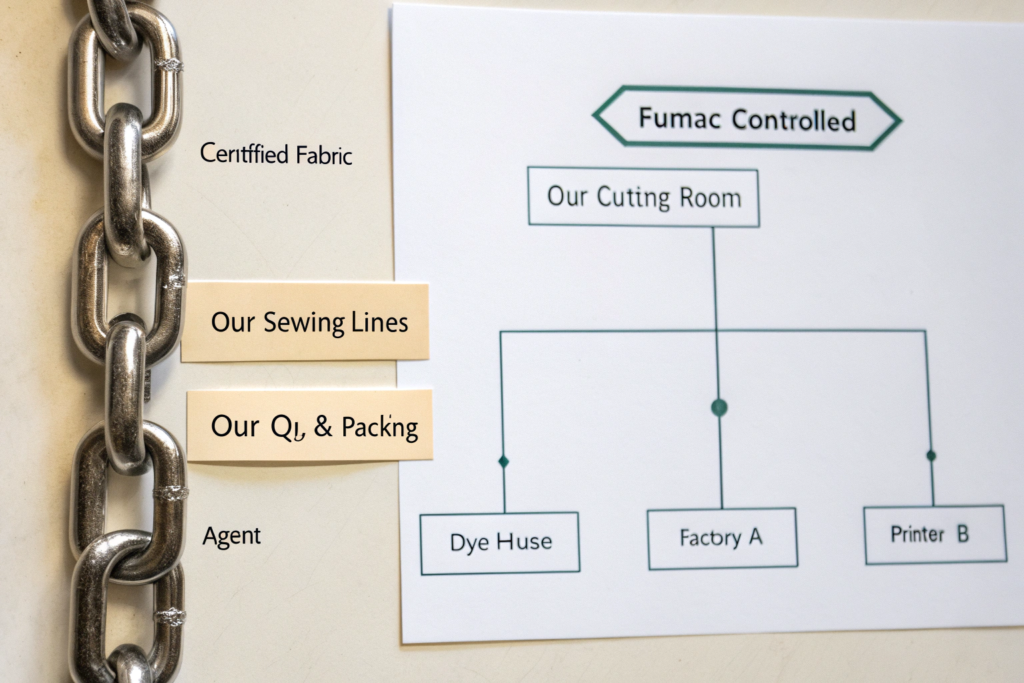

What Role Does Vertical Integration Play in Cost Control?

In a fragmented supply chain, every middleman adds cost and opacity. A fabric supplier, a dye house, a trim supplier, a factory, and an exporter all need their margin. This lengthens the journey and multiplies the points where cost—or safety—can be compromised.

Vertical integration, where a wholesaler controls multiple stages of production (e.g., sourcing, cutting, sewing, finishing), plays a crucial role in cost control for safe garments. It eliminates intermediary markups, reduces handling and logistics costs between separate facilities, and ensures seamless communication. Most importantly, it allows for strict, centralized oversight of material safety and production standards from start to finish.

For you, the buyer, this integration means a single point of accountability and a leaner cost structure. The savings from cutting out middlemen can be redirected into better materials or simply lower prices.

How does in-house fabric sourcing and QC cut costs?

By operating our own fabric sourcing department with direct relationships with major mills, we bypass trading companies. This saves 5-10% immediately. More critically, our in-house lab can perform preliminary tests on incoming certified fabrics, catching issues before they enter production. This prevents costly rework or batch rejection later. Last quarter, this system allowed us to identify a slight color variance in a certified cotton lot before cutting, enabling a minor adjustment that saved a client's entire 8,000-piece order from a potential quality failure.

Does controlling the finishing process impact safety and cost?

Absolutely. Processes like garment washing, dyeing, and applying water-resistant finishes are where chemicals are often introduced. By managing these in our own controlled facilities or with vetted partners under our direct supervision, we ensure only approved, certified chemicals are used. This control prevents contamination and eliminates the cost of outsourcing these steps to subcontractors who might use cheaper, non-compliant chemicals. For a client's line of stone-washed denim, our controlled washing facility used OEKO-TEX® compliant softeners and enzymes, ensuring the final product was safe and achieving the desired look at a 15% lower processing cost than if they had sourced it separately.

Why is OEKO-TEX® Certification a Cost-Saver in the Long Run?

Viewing safety certification as a pure cost is a short-term accounting error. While there is an upfront testing and system investment, its real function is as a powerful risk mitigation tool that prevents catastrophic losses, making it a net cost-saver over the lifecycle of your business.

OEKO-TEX® certification is a long-term cost-saver because it virtually eliminates the monumental expenses associated with product recalls, rejected shipments, legal liability, and brand reputation damage. The relatively small premium for certified production is a fixed, predictable cost. The potential financial impact of a single safety scandal is variable and unlimited. A certified supply chain is a stable, low-risk asset.

This is about total cost of ownership (TCO). A cheaper, uncertified product has a high risk of hidden future costs.

How does certification prevent financially devastating shipment rejections?

If a shipment is held by customs or fails a retailer's lab test for substances like formaldehyde or azo dyes, the costs are immediate: storage fees, testing fees, return freight, and often the total loss of the goods. In 2022, a brand came to us after a $120,000 shipment of children's sweaters was rejected at the EU border. The non-certified supplier had used a banned dye. By switching to our OEKO-TEX® certified production, they have since shipped over 500,000 units without a single chemical-related rejection. The certification premium paid has been a fraction of that one loss.

Can certified products reduce insurance and liability costs?

Yes. Demonstrating due diligence by sourcing certified products strengthens your legal defense and can be viewed favorably by business liability insurers. It shows you have taken reasonable steps to ensure product safety. While not a guaranteed discount, it contributes to a lower risk profile for your company. More directly, it can be the deciding factor in securing a contract with a large retailer whose vendor agreement includes stringent indemnity clauses for product harm.

How to Vet a Wholesaler on Both Price and Safety?

The marketplace is full of claims. To find a partner who genuinely delivers on both price and safety, you need a vetting process that goes beyond the initial quote and looks for evidence of systemic efficiency and verifiable standards.

Vet a wholesaler by demanding transparency on both their costing structure and their safety documentation. Ask for a breakdown of costs (fabric, labor, overhead) and compare it against their valid OEKO-TEX® certificates (factory and product-specific). A legitimate wholesaler will explain how their scale and integration allow for competitive pricing while proudly providing verifiable proof of safety compliance.

The willingness to provide this information is the first filter. The quality of the information is the second.

What specific questions about cost structure should I ask?

- "Can you provide a price tier based on my order quantity, showing where the cost savings come from?"

- "Do you own your production facilities, or are you an agent? If an agent, what is your fee?"

- "Is the cost of OEKO-TEX® certification included in the FOB price, or is it separate?"

Their answers will reveal their business model. At Shanghai Fumao, we provide transparent cost models that show how the price decreases at 3,000, 5,000, and 10,000 piece intervals, directly linked to our bulk fabric procurement and production scheduling.

How do I verify their safety claims are not just marketing?

- Ask for the certificate number and verify it in the OEKO-TEX® database.

- Request a recent test report summary for a product similar to what you want to order.

- Inquire about their factory's audit history (e.g., STeP by OEKO-TEX®, SMETA).

- Ask for references from other U.S. or EU brands they supply.

A credible wholesaler will provide these within 24 hours. We maintain a digital portal for our clients where all compliance documents for their orders are stored and accessible in real-time.

Conclusion

The choice between competitive price and top safety is a false dilemma created by inefficient or opaque supply chains. A professional, vertically-integrated wholesaler leverages scale, operational efficiency, and strategic sourcing to deliver both. They understand that true cost savings come from eliminating waste and risk, not from compromising on the fundamental safety of the product.

OEKO-TEX® certification is not a cost driver; it is the cornerstone of a low-risk, sustainable business model that protects your bottom line from catastrophic failures. By partnering with a wholesaler who has built their system around these principles, you secure a strategic advantage: market-competitive pricing backed by ironclad safety assurance.

If you are looking for a wholesale partner who refuses to make you choose between your margin and your conscience, your cost sheet and your compliance file, let's talk. At Shanghai Fumao, our integrated model is designed to deliver exactly that: exceptional value through safe, certified production. Contact our Business Director, Elaine, to request a transparent quote and our certification portfolio. Email: elaine@fumaoclothing.com.