Let me ask you a sharper question: When a Chinese manufacturer "guarantees" OCS organic cotton supply, what exactly are they guaranteeing? Are they guaranteeing the physical availability of the fabric, or the legal and traceable integrity of the organic claim? In my 20 years in Keqiao, I've seen factories guarantee the first and fail catastrophically on the second, leaving brands with warehouses full of "organic" clothes they can't legally sell. A true guarantee isn't a promise of delivery; it's a system-backed warranty of authenticity that covers the entire chain from farm to fabric. Without that system, the guarantee is just marketing words that vanish at the first audit.

Yes, a Chinese manufacturer can guarantee OCS organic cotton supply, but only if they operate with vertical control, transparent sourcing, and embedded certification protocols that allow them to assume and manage the entire risk of the supply chain. The guarantee is not about having organic cotton—it's about having an unbreakable, documented system to prove it's organic, consistently, batch after batch, and being financially liable if that proof fails.

This isn't about hope. It's about engineering a supply chain with multiple fallbacks and verifiable checkpoints. Let's dissect what a real guarantee looks like in practice.

The Anatomy of a Real Guarantee: Beyond the Sales Pitch

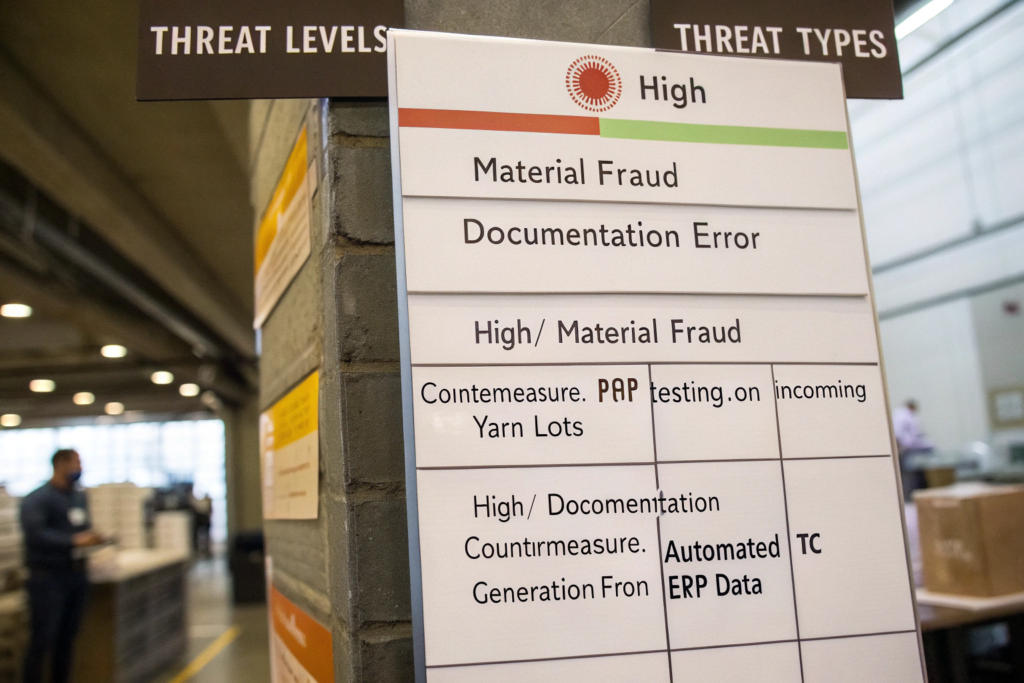

A sales manager's verbal promise is worthless. A real guarantee is a multi-layered operational and contractual framework. It must address the three core risks of organic sourcing: Material Fraud, Chain-of-Custody Breakage, and Supply Volatility. If a manufacturer's "guarantee" doesn't explicitly cover these, it's not a guarantee.

You must look for evidence of systemized control, not just confidence. The factory should be able to walk you through their risk-mitigation protocols for each layer, not just say "we have good relationships."

What does a contractual OCS supply guarantee include?

The guarantee must be in writing, as part of your purchase order or master supply agreement. Key clauses should state:

- Warranty of Conformity: "Supplier warrants that all goods supplied under this PO conform to the OCS 100 standard and are eligible for an OCS Transaction Certificate."

- Documentation Obligation: "Supplier shall provide, at no extra cost, a valid OCS Transaction Certificate for each shipment, traceable to certified upstream inputs."

- Right to Verify: "Buyer has the right to conduct or appoint a third party to conduct unannounced audits of Supplier's facilities and its upstream yarn/fabric suppliers to verify compliance."

- Liability for Breach: "In the event of a breach of the OCS warranty, Supplier shall be liable for all direct damages, including but not limited to the full cost of the non-conforming goods, recall costs, and statutory damages for misleading labeling."

A manufacturer unwilling to put these terms in writing is not standing behind their guarantee. We include these as standard in our contracts because our systems are built to support them.

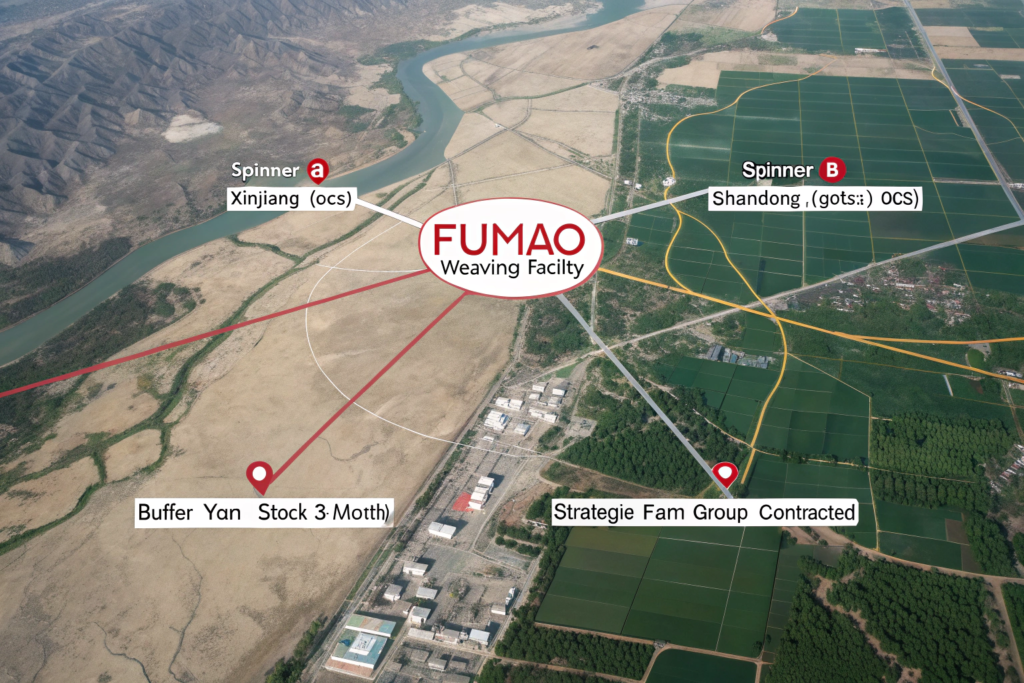

How does vertical control enable a genuine guarantee?

A trader or simple garment factory cannot guarantee the OCS integrity of their fabric because they don't control its production. A vertically integrated manufacturer—one that controls or has equity in the weaving (and ideally has strategic partnerships with spinning)—can.

- Control Point 1: Weaving. When the manufacturer owns the looms (like Shanghai Fumao does), they control the transformation of certified yarn into certified fabric. They enforce segregation, track mass balance in real-time, and prevent commingling.

- Control Point 2: Sourcing. They have long-term contracts with certified spinners, not just spot purchases. They can commit to buying forward, securing future organic yarn capacity.

- Control Point 3: Testing. They can implement batch testing at the yarn stage before it's even woven, catching fraud or contamination early.

This control allows them to know, not just believe, the provenance of the material. It turns a guarantee from a promise into a predictable outcome of their operating model. A client from France switched to us after their previous supplier's "guaranteed" organic yarn failed a mid-season. That supplier was a trader who ran out of allocated stock. Because we control weaving and have annual yarn contracts, we had buffer stock and fulfilled the order without delay.

Mitigating the Invisible Risks: Fraud and Documentation Gaps

The biggest threats to an organic supply are invisible: a spinner blending in 20% conventional cotton, a dyehouse breaking the chain, or a paperwork error that invalidates the TC. A manufacturer's guarantee must have active countermeasures for these.

This is where "guarantee" shifts from procurement to cybersecurity-style thinking. You're building defenses against deception and error.

What proactive testing validates the guarantee?

Relying solely on the spinner's certificate is naive. A guaranteeing manufacturer will conduct their own defensive testing.

- PCR (Polymerase Chain Reaction) Testing: This is the gold standard. It detects genetic modification (GMO). While not required by OCS, it's the definitive test for organic cotton fraud. Manufacturers who guarantee supply should be willing to conduct random PCR tests on incoming yarn lots and share the results. The cost is minimal compared to the risk.

- Fourier-Transform Infrared Spectroscopy (FTIR): Can identify fiber composition and detect unexpected synthetic blends.

- Stable Isotope Analysis: Can sometimes help determine geographic origin, adding another layer of verification.

Offering to do this testing—or better, making it a standard procedure—is a strong signal of a real guarantee. It shows the manufacturer is investing to protect their own liability, not just yours.

How is documentation integrity guaranteed?

The guarantee extends to the paper trail. The system must be designed to prevent human error.

- Integrated Software: The best manufacturers use ERP/MES systems where the OCS data (yarn lot in, fabric lot out) is captured automatically from production scales and scanners. The TC is auto-generated from this data, minimizing typos.

- Digital Dossier Access: Instead of emailing PDFs that can get lost, they provide a client portal where all certificates, TCs, and test reports for your orders are permanently archived and accessible.

- Pre-Shipment Document Review: They institute a mandatory internal check where the sales, production, and compliance teams cross-verify the draft shipping documents (Invoice, Packing List, TC) before they are finalized.

This turns documentation from a clerical task into a quality-controlled output of the production process. It's how we ensure that the OCS TC you receive is flawless and ready for customs.

Ensuring Supply Continuity in a Volatile Market

Organic cotton is an agricultural product subject to weather, policy, and market speculation. A guarantee that only works in a perfect market is no guarantee at all. A manufacturer must demonstrate a strategy for supply continuity that smooths out volatility.

This means having a multi-pronged sourcing strategy and the financial strength to execute it. It's about risk distribution.

How do manufacturers secure long-term organic yarn supply?

They move beyond spot purchases to strategic partnerships:

- Annual Contracts with Spinners: They commit to purchasing a certain volume over a year, giving the spinner confidence to reserve capacity and pay premiums to farmers.

- Dual/Multi-Sourcing: They qualify at least two certified spinners for key yarn counts. If one has an issue, they can pivot without halting production.

- Buffer Stock Policy: They maintain a strategic inventory of key OCS yarns (e.g., 30s, 40s for knitting and weaving) to cover lead times and spot shortages.

- Participation in Farm Programs: The most advanced manufacturers may engage in or support farm-level programs to ensure quality and volume at the source.

This approach costs more in working capital, which is why only serious, financially stable manufacturers can do it. It's a direct investment in the guarantee. When droughts affected Xinjiang cotton yields in 2022, our dual-sourcing from Shandong and our buffer stock allowed us to fulfill all OCS orders without delay or quality change, while many traders faced allocation or substitution demands.

What happens during a global organic cotton shortage?

This is the ultimate test of a guarantee. A manufacturer with a real guarantee has a pre-defined escalation protocol:

- Transparent Communication: They notify committed clients immediately, providing data on the situation and their stock coverage.

- Allocation by Priority: They allocate secured yarn to clients based on long-term partnership and order history, not just who shouts loudest.

- Alternative Proposals: They present viable alternatives within the OCS framework, such as temporarily offering a different but available organic yarn count or blend, with full transparency.

A manufacturer that goes silent or suddenly says "cannot do" has no guarantee—they were just a passenger in the supply chain.

Conclusion

A Chinese manufacturer can absolutely guarantee OCS organic cotton supply, but the guarantee is a function of their operational depth, technical rigor, and financial commitment—not their sales pitch. It is manifested in vertical control that prevents fraud, defensive testing that validates content, robust documentation systems that ensure legal compliance, and a multi-sourced, buffered supply strategy that defies market volatility.

When evaluating a manufacturer, don't ask if they guarantee it. Ask how they guarantee it. Demand to see the systems, the contracts, the test protocols, and the contingency plans. A real guarantee is expensive to build, which is why it's rare. But it's the only kind that matters.

If your brand requires a supply chain where "organic" is a guaranteed fact, not a hopeful adjective, you need a partner built for that responsibility. At Shanghai Fumao, our vertical model and systematic protocols are our guarantee. Contact our Business Director, Elaine, to discuss a partnership where your organic supply is secured, not just sourced: elaine@fumaoclothing.com. Let's build on a foundation of certainty.