You’re ready to source, and you’ve found a supplier who claims their fabrics meet safety standards. They send over a “CMIA Certificate.” It looks official, filled with technical jargon and stamps. But here’s the hard truth: in the garment sourcing world, not all certificates are created equal. I’ve seen buyers lose thousands because they trusted a document that turned out to be worth less than the paper it was printed on. The risk isn’t just financial—it’s about your brand’s reputation. Sending non-compliant products to market can lead to recalls, legal action, and broken consumer trust.

So, how do you separate genuine compliance from clever paperwork? You learn to verify. A CMIA Certificate—specifically for textiles—is a China-issued document that verifies a product meets certain national safety and quality standards, often related to formaldehyde content, pH value, colorfastness, and banned aromatic amines from azo dyes. It’s a key document for importing into many markets. But the certificate itself is only as trustworthy as the issuing body and the product batch it represents.

This guide will walk you through the exact steps to verify a CMIA Certificate, not as a passive recipient, but as an informed partner. We’ll move beyond simply checking for a stamp and dive into cross-referencing databases, understanding testing protocols, and asking the right questions. My goal is to equip you with the knowledge to ensure that the “certified” fabrics you’re buying are truly safe and compliant, protecting your business from the ground up.

What Exactly is a CMIA Certificate in Textile Sourcing?

Let’s clear up the confusion first. CMIA stands for “China Metrology and Inspection Association,” but in practice, the certificate you receive is typically issued by a third-party testing agency authorized by the Chinese government. It’s not a generic company registration; it’s a product-specific test report that certifies a textile product conforms to Chinese national standards (GB standards), which often align with international safety norms. Think of it not as a company license, but as a product’s “health report card” for specific hazardous substances.

For global buyers, this document is crucial because it provides a standardized, (theoretically) verifiable proof of compliance. It’s your first line of defense against importing fabrics with harmful levels of chemicals. Major retailers and brands often require it as part of their due diligence checklist for sourcing garments from Asia. However, the system’s integrity hinges on the competence and honesty of the testing lab and the supplier’s practice of batch testing.

What standards does a legitimate textile CMIA certificate test against?

A credible certificate must reference specific, current Chinese National Standards (GB). The most fundamental is GB 18401-2010 (National General Safety Technical Code for Textile Products). This is the core standard that covers:

- Formaldehyde Content: Classified into A (infants), B (direct skin contact), and C (non-direct skin contact).

- pH Value: Ensuring the fabric is not too acidic or alkaline.

- Colorfastness: To perspiration, water, rubbing, and saliva (for infants).

- Banned Azo Dyes: Which can release carcinogenic amines.

Other common standards might include GB 31701-2015 for infant and children’s textile products (a more stringent version of 18401) or GB/T 18885-2020 for eco-textiles. The certificate must clearly list the standard, the specific test items performed, and the results. In 2022, we assisted a French children’s wear brand in auditing a potential sweater supplier. The supplier provided a CMIA cert referencing GB 18401, but our check showed the sweater’s composition (wool blend) required additional testing for detecting allergenic disperse dyes in synthetic-natural fiber blends, which wasn’t on the report. We insisted on re-testing at an ITS lab, and the batch failed for a specific dye. That missing detail in the original cert could have caused a major skin allergy incident.

How does a CMIA differ from an SGS, ITS, or BV report?

This is a critical distinction. SGS, Intertek (ITS), and Bureau Veritas (BV) are international, privately-owned testing giants with global reputations. A CMIA certificate is typically issued by a Chinese domestic lab, though many are also CNAS (China National Accreditation Service) accredited, which adds a layer of oversight.

- Scope & Recognition: International brands often prefer SGS/ITS reports for global acceptance. A CMIA is highly respected and often sufficient, but some buyers’ manuals explicitly require an international lab’s report.

- Verification Path: Verifying an SGS report usually involves logging into the client portal of that company with a unique report number. Verifying a CMIA requires checking the issuing lab’s credentials and often using a Chinese-language verification system.

- The Risk: The main risk with a CMIA isn’t the standard itself—it’s the potential for a less scrupulous supplier to use a “cooperative” lab that might take shortcuts or, in worst cases, issue a certificate without proper testing. This is why verification is non-negotiable.

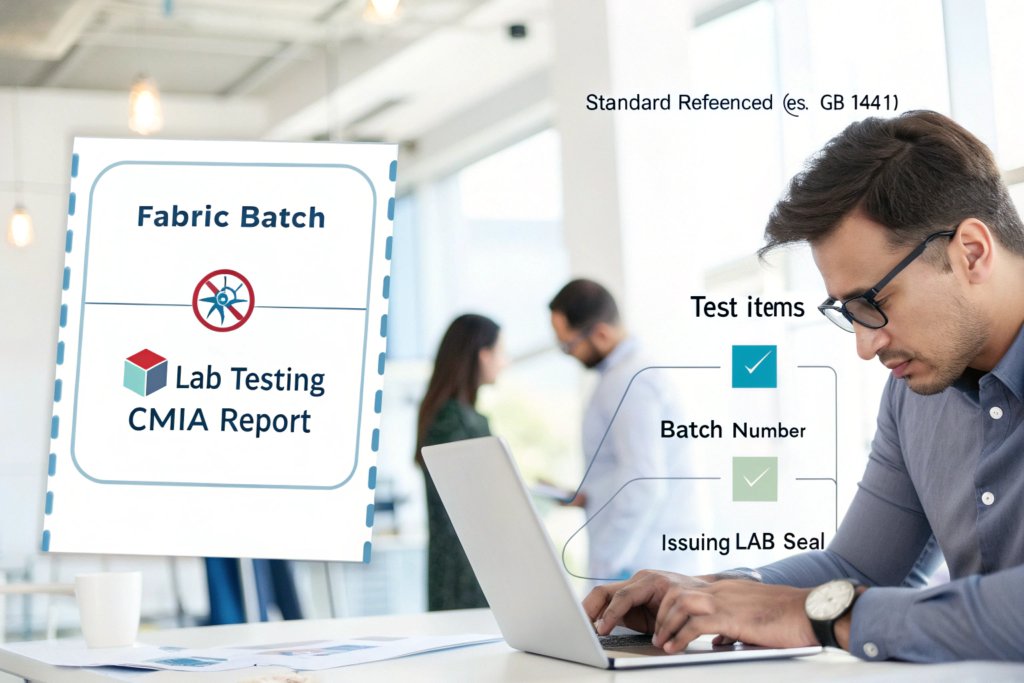

What are the 5 key elements to check on the certificate itself?

Before you even go online to verify, the document itself should pass a visual audit. A genuine certificate is a detailed technical document, not a vague letter of commendation. Here’s your five-point physical checklist:

- Issuing Laboratory Information: Full, legal name, official address, contact details, and most importantly, a CNAS accreditation logo and number (e.g., CNAS LXXXX). This is your first sign of legitimacy.

- Product and Sample Description: This must be exhaustively detailed. It should include the precise product name, fabric composition (e.g., “100% Cotton Single Jersey”), color, batch/lot number, and even the applicant’s (factory’s) name. Vague descriptions like “knitted fabric” are a red flag.

- Test Standard and Specific Items: As discussed, it must list the exact GB standard (e.g., GB 18401-2010) and every single test item performed under that standard, with the limiting values and the actual test results clearly stated.

- Test Result Page and Conclusion: There should be a clear, unambiguous statement like “The sample complies with the requirements of GB 18401-2010, Class B.” Look for the signature of the authorized signatory and the date of issue.

- Unique Identification: A unique report/certificate number, and increasingly, a QR code. This code is your direct gateway to online verification.

How to decode the CNAS accreditation number on the report?

The CNAS (China National Accreditation Service) accreditation is the gold stamp for testing labs in China. It means the lab’s equipment, procedures, and personnel meet international standards (ISO/IEC 17025). The number (format: CNAS LXXXX) is not just a logo; it’s a verifiable credential.

- Go to the CNAS official website: Use the English portal if available.

- Navigate to “Accredited Organizations” or “Search.”

- Enter the full CNAS number from the certificate.

The search should return the exact name of the laboratory as it appears on your certificate, along with its scope of accreditation. Crucially, check if the “Scope of Accreditation” includes the specific GB standards your product was tested against (e.g., GB 18401). If the lab isn’t accredited for that standard, the certificate’s validity is severely compromised. We perform this check for every new mill partner at Shanghai Fumao. Last year, a mill’s certificate had a valid CNAS number, but the scope only covered “Textiles - Physical Properties,” not “Safety and Chemical” tests. The certificate was, therefore, technically invalid for the chemical safety claims it made.

Why is the product batch/lot number the most critical detail?

The batch or lot number is the tether that connects the certificate to the physical goods you will receive. A major red flag is a “generic” certificate that has no batch number or one that is years old. A valid certificate is batch-specific. Here’s why:

- Traceability: It allows you to confirm that the exact batch of fabric rolls you are buying was the one tested.

- Prevents “Certificate Recycling”: Unethical suppliers may test one small batch of high-quality fabric, get a certificate, and then use it for months or years for all subsequent (and potentially sub-standard) production.

- Your Action: When you receive the certificate, immediately compare the batch number on it with the batch number marked on the commercial invoice, packing list, and ideally, on the physical fabric roll tags. They must match. If your supplier says, “Oh, this certificate covers our whole production for this fabric,” be very, very skeptical.

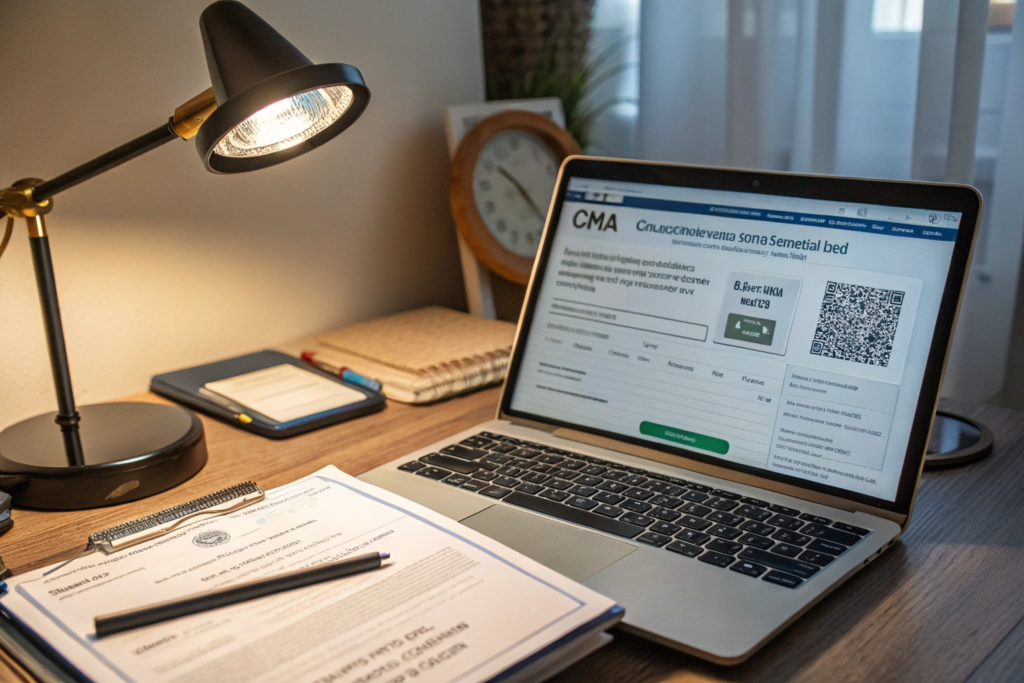

How to perform online verification of a CMIA certificate?

The physical check is step one. Step two is digital verification to ensure the document exists in the issuer’s database and hasn’t been altered. This is where many fake certificates fall apart.

Most legitimate labs now provide online verification, typically via:

- QR Code: Scan it with your phone. It should lead directly to the lab’s verification page, displaying the certificate details.

- Lab’s Official Website: Navigate to the “Report Verification” or “Certificate Inquiry” section.

- Enter the Details: Input the unique certificate number and sometimes the company name (applicant).

A valid verification will show a digital copy of the certificate that matches your paper version exactly—dates, results, product details. If the QR code is broken, the link goes to a non-official site, or the details don’t match, stop immediately.

What should you do if the QR code or online check fails?

Don’t panic, but do not proceed with the order. This is a serious warning sign. Your action steps are:

- Contact the Supplier Immediately: Provide a screenshot of the failed verification. Ask for an explanation and a new, verifiable certificate from the same batch.

- Contact the Lab Directly: Use the contact information from the CNAS website, not from the potentially fake certificate. Inquire if they issued a report with that number for that company.

- Consider Independent Testing: If the order is large or critical, the safest course is to instruct the supplier to send a new sample from the production batch to an internationally recognized lab of your choosing (e.g., SGS, ITS) for a retest. You bear the cost, but it buys certainty. Make this a condition of the purchase order.

- Walk Away: If the supplier becomes evasive or defensive, consider it a major red flag about their overall integrity. The cost of a failed shipment is far greater than the cost of finding a new, transparent supplier.

Are there official government databases for certificate verification?

For CMIA certificates specifically, there is no single, central “government database” like a business registry. Verification is decentralized through the individual accredited labs. However, the CNAS website is the official government-backed platform for verifying the accreditation status of the lab itself, which is the foundation of trust.

For broader supplier verification, you can cross-reference your supplier’s business license on official Chinese platforms like the National Enterprise Credit Information Publicity System. This can confirm their legal existence, registered capital, and any administrative penalties—providing a fuller picture of who you’re dealing with. Combining lab accreditation check with business license check is a powerful one-two punch for establishing a reliable supplier audit process for garment imports.

When should you insist on third-party lab testing instead?

Even a verified CMIA certificate might not be enough. Certain situations demand the heightened credibility and global recognition of an international third-party test.

Insist on SGS/ITS/BV testing when:

- Your Corporate Compliance Manual Requires It: Many large EU and US brands have this as a non-negotiable policy.

- The Product is for Infants or Children: The stakes are highest. Standards like OEKO-TEX® Standard 100 or CPSIA (USA) are often required alongside or instead of GB standards.

- The Fabric is High-Risk: Deep, dark colors (higher dye risk), synthetic leathers (phthalate risk), or fabrics with special functional coatings (chemical risk).

- It’s a New Supplier Relationship: The cost of the test is an investment in trust. We recommend it for all first-time bulk orders with new partners at Shanghai Fumao.

- The Order is for a Critical Launch: You cannot afford any compliance doubts for a flagship product.

In these cases, you specify the testing standard (e.g., GB 18401 + OEKO-TEX Standard 100, Class I) and the lab (e.g., “Testing must be performed by SGS and reports submitted prior to shipment release”). You then verify the report directly via that lab’s portal.

How to coordinate and verify a third-party test with your supplier?

Make this process collaborative but controlled.

- Specify in the Contract: The testing requirement, standard, and lab must be in the purchase order/contract.

- Sample Submission: Agree that the supplier will submit samples from the actual production batch to the lab. You can request photos of the sampling process with batch numbers visible.

- Report Access: Upon completion, the lab will issue the report to the applicant (the supplier). You must request a copy of the full, detailed test report (not just a summary certificate) and the invoice from the lab as proof it was done.

- Final Verification: Use the report number to log into the lab’s official verification website yourself. Confirm all details match the production batch.

This process closes all loopholes. In 2023, a Canadian retailer used this method with us for a large order of performance polyester. We submitted samples to ITS, they paid for the test directly, and we provided them with the report number and digital access. They verified it online in real-time, which built tremendous trust and streamlined the shipment release.

What are the cost and time implications for third-party testing?

Be prepared for this. International lab testing is more expensive and can add time.

- Cost: Can range from $200 to $800+ per fabric/color combination, depending on the number of test items. This is typically negotiated as part of the order cost—sometimes split, sometimes borne fully by the supplier or buyer.

- Time: Adds 5-10 working days to your timeline for sample shipping, testing, and report issuance. This must be factored into your critical path schedule. The trade-off is absolute peace of mind versus speed. For standard, repeat fabrics with a trusted partner like us, a verified CMIA may suffice. For new, complex, or high-risk items, the cost and delay are a wise investment.

Conclusion

Verifying a CMIA Certificate is not an administrative afterthought; it’s a fundamental act of due diligence that protects your capital, your customers, and your brand. By moving from passive acceptance to active verification—scrutinizing the document, checking CNAS accreditation, matching batch numbers, and performing online checks—you transform a piece of paper into a powerful tool for risk management.

Remember, the goal isn’t to find faults for the sake of it, but to build a sourcing relationship on a foundation of transparency and proven compliance. When a supplier readily provides verifiable, batch-specific certificates and is open to third-party checks, you’ve found a partner, not just a vendor. This rigorous approach filters out unreliable players and aligns you with manufacturers who value quality and integrity as much as you do.

If navigating the complexities of certification feels daunting, you don’t have to do it alone. At Shanghai Fumao, our integrated control from weaving to finishing means every batch is produced with compliance in mind. We don’t just provide CMIA certificates; we facilitate the entire verification process, from guiding you through our CNAS-accredited lab reports to coordinating third-party testing with SGS or ITS upon request. Let us be your transparent partner in securing not just great fabrics, but unquestionable peace of mind. Contact our Business Director, Elaine, to discuss how we can build a compliant and efficient sourcing channel for you: elaine@fumaoclothing.com.