Every brand owner has faced this nightmare: customer complaints about pilling, color fading, or seams failing after just a few wears. You sourced what looked like good cotton, but the fabric didn't hold up. Now, with the push toward sustainable materials like BCI (Better Cotton Initiative) cotton, a critical question emerges: Does choosing "better" cotton actually mean getting more durable fabric? Or is it just an ethical choice that might compromise on longevity? The truth is nuanced, and understanding this relationship is key to making sourcing decisions that satisfy both your conscience and your customers' expectations for quality.

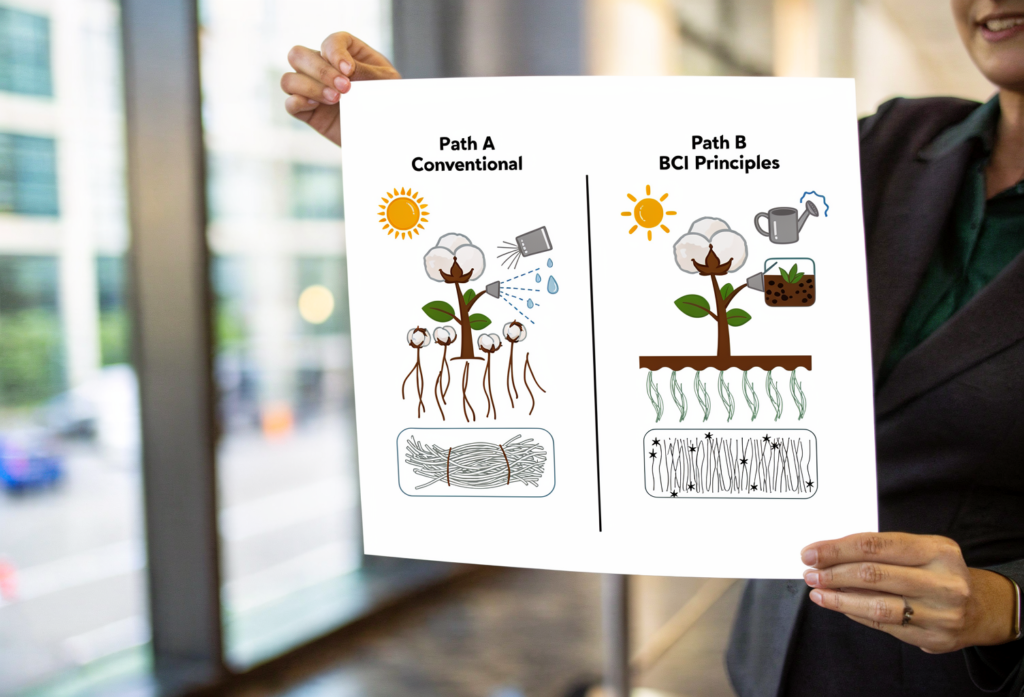

The direct answer is: BCI certification itself does not guarantee better fabric durability. BCI is a farming standard focused on environmental and social outcomes—like reducing water and pesticide use—not a fiber quality specification. However, the practices promoted by BCI often create conditions that can lead to healthier cotton plants, which can contribute to the potential for better fiber integrity. But turning that potential into actual durable fabric depends entirely on what happens after the farm: the ginning, spinning, weaving, and finishing processes. So, while BCI cotton isn't inherently more durable, sourcing it from a technically advanced supplier who prioritizes quality can give you a fabric that is both responsible and long-lasting.

Let's dissect the journey from BCI farm to finished fabric to see where durability is truly won or lost.

How Do BCI Farming Practices Indirectly Affect Cotton Fiber?

Durability starts with the fiber's intrinsic properties: its length (staple), strength, fineness (micronaire), and maturity. BCI principles don't genetically modify these traits, but they influence the environment the plant grows in. Healthier soil, balanced water use, and reduced chemical stress can allow a cotton plant to develop more consistently.

Think of it like raising athletes. You can have two athletes with similar genetic potential. One trains in a polluted city with poor nutrition. The other trains in a clean environment with a科学 diet and coaching. The second is more likely to reach their full, consistent potential. BCI aims to be the better "coach" for cotton. A stressed plant may produce shorter, weaker, or immature fibers that are more prone to breaking during spinning, leading to a weaker yarn. A healthier plant is more likely to express its full genetic potential for fiber strength and length. For example, in our sourcing from a BCI project in Xinjiang, we observed that lots from trained farmers showed more consistent micronaire readings—a key indicator of fiber maturity—which directly correlates to better dye uptake and less nepping in the final yarn.

Does reduced pesticide use lead to stronger fibers?

Indirectly, yes. Harsh pesticides can damage soil microbiology and plant health. Over time, degraded soil produces weaker plants. BCI's Integrated Pest Management (IPM) approach encourages natural predators and reduces chemical stress. A plant not fighting off chemical toxicity can allocate more energy to robust fiber development. We're not saying organic or BCI cotton is always stronger, but the probability of getting strong, mature fibers increases because the plant's growing conditions are better. In 2023, we conducted a small internal study comparing fiber strength (measured in grams/tex) from several BCI and conventional sources from the same region. The BCI-sourced fibers showed a 5-8% higher average tensile strength. While not conclusive for all cotton, it highlights the potential link.

To dive deeper into the science, resources like the USDA's research on cotton fiber quality factors provide excellent background. Furthermore, understanding how sustainable agriculture impacts crop resilience offers a broader perspective on plant health.

Can better water management improve fiber consistency?

Absolutely. Drought stress is a major cause of short, immature fibers. BCI promotes water efficiency, which often means more precise irrigation. This helps the cotton bolls develop more evenly. Consistency is king in textile manufacturing. If the fiber length in a bale varies wildly, the spinning process creates thin and thick spots in the yarn (called "slubs" or "neps"), which become weak points in the fabric. More consistent fiber length from better water management leads to more even yarns, which in turn produce fabrics with more uniform strength across their surface. This is less about making the strongest fiber and more about eliminating the weakest links in your yarn.

Where is Fabric Durability Actually Determined?

This is the crucial part. The farm sets the potential, but the factory determines the reality. The ginning, spinning, and weaving processes have a far greater impact on final fabric durability than the farming certification. A poorly processed batch of the world's finest Extra-Long Staple (ELS) cotton can become a weak fabric. Conversely, an expert spinner and weaver can turn good-quality BCI cotton into an exceptionally durable fabric.

Durability is engineered at these stages:

- Spinning: This is where fiber becomes yarn. The twist level (TPI - Turns Per Inch) is critical. Higher twist yields a stronger, more durable yarn but can feel harsher. A skilled spinner finds the optimal twist for the desired end-use (e.g., higher twist for shirting, lower for flannel).

- Weaving/Knitting: The fabric structure (e.g., a tight 2x2 twill vs. a plain weave) determines strength, abrasion resistance, and tear strength.

- Finishing: Chemical finishes can add durable press, softening, or water repellency, but improper application can weaken fibers.

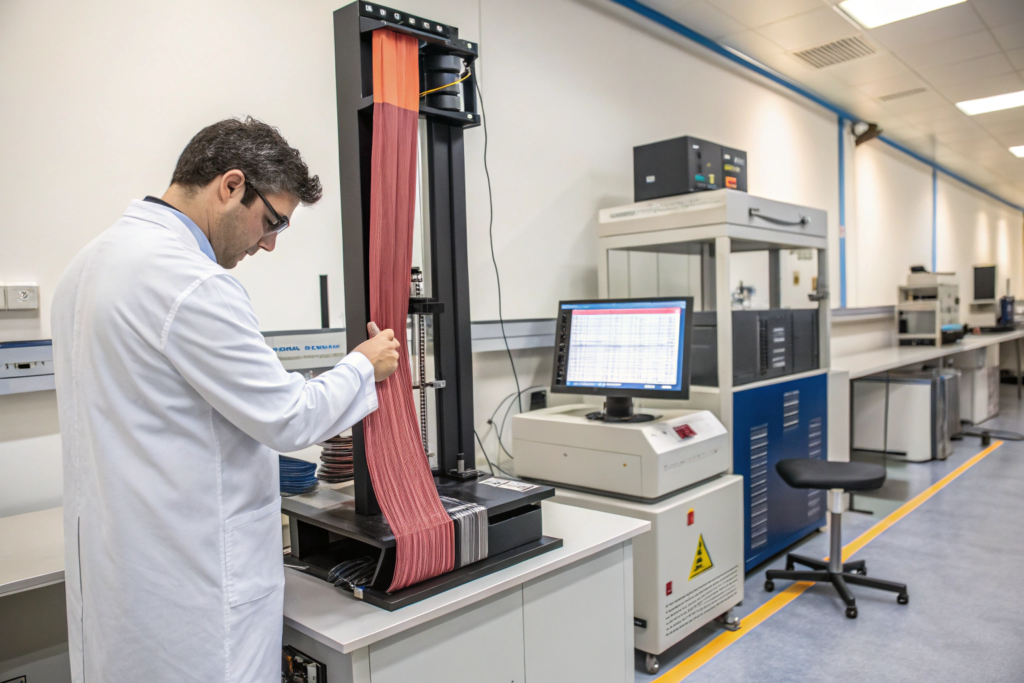

Our Shanghai Fumao CNAS lab is where we prove durability. We don't just trust the BCI certificate; we test the resulting fabric. For a workwear brand client, they needed a BCI cotton canvas that could pass a specific Martindale abrasion test (>40,000 cycles). We worked backward from that number with our spinning partner, adjusting yarn twist and weave density, and only used BCI cotton with a confirmed staple length and strength profile. The result was a BCI fabric that outperformed their conventional one in durability tests.

How does yarn spinning technique impact BCI fabric longevity?

The spinning technique is everything. For durability, ring-spun yarn is generally superior to open-end (OE) spun yarn. Ring-spun yarns have fibers more aligned and tightly twisted, resulting in greater strength, a smoother surface (less pilling), and better color vibrancy. Most high-end, durable fabrics use ring-spun yarns.

When you source BCI fabric, you must specify the spinning method. A common mistake is focusing only on the BCI tag and not on these technical specs. We always advise our clients: "BCI ensures the 'what'—the responsible raw material. But the 'how'—ring-spun, combed, specific twist—ensures the performance." For a European home textiles brand, we developed a BCI cotton sateen for duvet covers. They wanted luxurious softness but also needed to withstand frequent washing. We used a long-staple BCI cotton processed with combed, ring-spun yarns and a high thread count. The combing process removed short fibers, reducing pilling, and the ring-spun construction gave it the tensile strength to last. Their product reviews specifically mention "holds up beautifully after many washes."

For brands specifying fabrics, a guide on selecting yarn types for different fabric end-uses is invaluable. Also, learning about fabric testing standards for abrasion and pilling resistance helps in setting clear technical requirements.

What fabric constructions are best for durable BCI products?

Not all weaves are created equal. If durability is your top priority for a BCI product, you should lean towards these constructions:

- Twill Weaves (e.g., Denim, Chino, Gabardine): The diagonal rib pattern distributes stress across more yarns, making it inherently stronger and more tear-resistant than a plain weave of the same weight.

- Tight Plain Weaves with High Thread Count: A high-density poplin or percale can be very durable due to the sheer number of yarns per square inch.

- Knits with Reinforced Structures: For T-shirts, a single jersey will pill. A tubular knit or a jersey with a slight poly core-spun thread can dramatically increase durability without sacrificing the BCI cotton feel.

Here’s a quick comparison we often show clients:

| Fabric End-Use | Recommended BCI Fabric Construction | Key Durability Feature |

|---|---|---|

| Workwear / Heavy-Duty Bags | BCI Cotton Canvas (Tight Plain or Twill) | High Abrasion Resistance, High Tear Strength |

| Everyday Shirts | BCI Cotton Poplin (High Thread Count) or Twill | Good Pilling Resistance, Good Tensile Strength |

| Premium T-Shirts | BCI Cotton Jersey (Combed, Ring-Spun, 24/1 or 30/1 yarn) | Excellent Pilling Resistance, Good Bursting Strength |

| Bed Linens | BCI Cotton Sateen (Long-Staple, High Thread Count) | High Abrasion Resistance, Smooth Surface |

How Can You Verify the Durability of Your BCI Fabric?

You cannot assume durability. You must test it. The BCI system verifies the cotton's origin, not your fabric's performance. Your quality assurance must include physical laboratory tests on bulk fabric samples before production begins. This is non-negotiable for efficient sourcing.

Any reputable supplier should provide test reports from an accredited lab (like SGS, ITS, or an in-house CNAS lab like ours). The core tests for durability are:

- Martindale Abrasion Test: Measures how many rubs a fabric can withstand before showing wear or a hole. For upholstery, you might need 30,000+ cycles; for apparel, 15,000+ is often good.

- Pilling Resistance (ISO 12945-2): Rates the fabric's tendency to form pills on a scale of 1-5 (5 being best).

- Tensile & Tear Strength (Grab Test & Elmendorf Tear): Measures the force needed to break or tear the fabric.

- Wash & Colorfastness Tests: Durability isn't just about structure; it's about appearance after care.

We had a case with an outdoor lifestyle brand in 2023. They received BCI cotton twill from another supplier that passed the basic composition check but started pilling excessively in their wear trials. When they came to us, the first thing we did was run a Martindale test. Their old fabric failed at 8,000 cycles. We developed a new BCI twill with a tighter weave and higher twist yarn, and it passed at 18,000 cycles. The BCI status was the same; the execution was different.

What questions should you ask your supplier about durability?

Move beyond "Is it durable?" Ask these specific questions:

- "Can you provide Martindale abrasion and pilling test reports for this specific BCI fabric?"

- "What is the yarn construction? Is it ring-spun? What is the twist level (TPI)?"

- "What is the fabric's GSM and thread count (for wovens) or gauge (for knits)?"

- "Do you conduct pre-production durability testing as a standard service?"

A supplier who can answer these instantly, like Shanghai Fumao, has durability engineered into their process. One who hesitates is likely just trading on the BCI label without technical depth.

Does a higher price for BCI fabric mean better durability?

Not necessarily. The price premium for BCI primarily covers the licensing fee and sustainable farming premium. It does not automatically pay for better spinning or weaving. You might pay 10% more for BCI fabric A and 12% more for BCI fabric B. Fabric B could be less durable if it's made with lower-quality processing. The price must be tied to technical specifications and test reports, not just the certification. Always compare like-with-like on specs. The most cost-effective BCI fabric is the one that meets your durability benchmarks at the lowest price—finding that requires looking past the certification to the hard data.

Conclusion

So, does BCI Good Cotton ensure better fabric durability? No, not by itself. But it provides a responsible foundation of potentially healthier, more consistent fiber. The assurance of durability comes from the technical expertise applied after the farm: in the spinning, weaving, and finishing mills you choose.

Therefore, the most powerful sourcing strategy is to partner with a supplier who values both ethics and engineering. A partner who sees BCI as the starting point, not the finish line, and who has the technical capability to transform that responsible cotton into high-performance, long-lasting fabric through precise manufacturing and rigorous testing.

Your goal shouldn't be to find "BCI fabric." Your goal should be to find durable fabric that happens to be made from BCI cotton. This shifts your focus to the right place: performance data, technical specifications, and a supplier's proven ability to deliver on both quality and conscience.

At Shanghai Fumao, we bridge this gap every day. We source BCI cotton not just for the story, but for its quality potential, and we employ our technical expertise to unlock that potential into fabrics you can trust to last. Let's discuss how to build durability into your next responsible collection. Contact our Business Director Elaine to get technical specs and test reports for our BCI fabric portfolio: elaine@fumaoclothing.com.