Every promotional buyer and brand manager faces the same dilemma: you need to order 5,000 custom polo shirts or hoodies, but your stakeholders are now asking about sustainability. The budget is tight, lead times are tighter, and you can't risk quality issues on garments that literally carry your company's logo. Is BCI cotton just a feel-good add-on that complicates everything, or does it actually deliver tangible benefits for corporate apparel and promotional wear?

For custom logo wearables, BCI (Better Cotton Initiative) cotton offers substantial benefits beyond sustainability messaging. The key advantages include consistent fabric quality that ensures better embroidery and print results, enhanced supply chain transparency that mitigates reputational risk for brands, and a credible, scalable sustainability story that resonates with employees and end-users. Importantly, the structured BCI supply chain often leads to more predictable production timelines and reduced quality variances compared to conventional cotton sourcing.

I've supplied fabric for everything from Fortune 500 company uniforms to university sportswear. The shift toward BCI in this sector isn't just about "going green"—it's a calculated business decision. When your logo is on the garment, every stitch and fiber reflects your brand's values and attention to detail. Let me break down how BCI directly impacts the crucial aspects of custom wearable production: quality, risk management, storytelling, and cost-effectiveness.

How Does BCI Improve Embroidery and Print Quality on Logos?

The success of a custom wearable lives or dies by the clarity and durability of its logo application. Poor fabric quality leads to puckering under embroidery, blurred print edges, and overall unprofessional results. BCI cotton's production standards directly contribute to superior application surfaces.

Why is Fabric Consistency Crucial for Multi-Location Orders?

Custom wearables are often produced in large batches, sometimes split across multiple garment decorators in different regions. Fabric inconsistency is a nightmare. If Shipment A of polos has a slightly different knit tension or fiber content than Shipment B, the same embroidery file and thread will produce visually different results. BCI's certified supply chain enforces stricter quality controls at the yarn level. For a global tech company's 2023 conference swag, we supplied 8,000 meters of BCI pique fabric. The order was split between two embroidery shops in the US and one in Canada. Because the BCI fabric was uniform in weight, shrinkage, and surface texture, the client received consistent logo application across all units, which their brand team specifically praised. This level of consistency is harder to guarantee with uncertified commodity cotton.

Does BCI Cotton Accept Dyes and Inks Better?

In short, yes. More consistent fiber quality and fewer impurities (like seed coat fragments) mean the fabric prepares more evenly for dyeing and printing. This results in a cleaner, brighter base color for garment dyeing and a more uniform surface for direct-to-garment (DTG) or screen printing. A vibrant, opaque print is a must for logo visibility. Our partner printing factory reports that BCI cotton jersey requires less ink adjustment and has fewer "drop-outs" (faint spots in prints) compared to lower-grade conventional cotton. This translates to fewer rejected printed garments and a more reliable production run for your decorator.

Does BCI Mitigate Brand Risk for Corporate Apparel?

When you put your company name on a product, you implicitly vouch for its entire production journey. In the age of supply chain scrutiny, BCI provides a critical layer of due diligence.

How Does It Provide a "Story" for Employees and Clients?

Custom wearables are a physical touchpoint. Giving an employee a BCI cotton hoodie isn't just giving them a hoodie; it's an opportunity to communicate your company's values. You can tag the garment with a simple message: "Made with Better Cotton, supporting more sustainable farming." This turns a standard piece of apparel into a conversation starter and a tangible demonstration of corporate social responsibility. A Midwestern financial services firm we worked with included a hangtag with their BCI polos explaining their choice. They reported higher internal satisfaction with the uniforms and received positive comments from clients during off-site events. The value is in the authentic, explainable story.

Can It Protect Against Supply Chain Scandals?

While no system is impervious, sourcing BCI cotton significantly de-risks the raw material origin. The BCI audit trail means your fabric supplier is working with licensed spinners who source from BCI-engaged farms. This removes the risk of your company logos ending up on garments linked to the most egregious environmental or social issues in cotton farming. For procurement officers, this is not about marketing—it's about fiduciary duty and risk mitigation. It's a documented step toward responsible sourcing that can be presented to leadership and shareholders. For more on building a resilient supply chain, resources on managing ethical risk in apparel sourcing are invaluable.

Is BCI Cost-Effective for Promotional Quantities?

The perception is that "sustainable" equals "expensive." For custom wearables, the total cost equation includes factors beyond just the price per garment, and BCI can be competitive, especially at scale.

How Do MOQs and Bulk Discounts Work with BCI?

Because BCI cotton is now a high-volume commodity, the minimum order quantities (MOQs) and pricing tiers are often comparable to conventional cotton, especially for standard fabrics like jersey, pique, and fleece. The key is working with a fabric supplier who stocks or regularly produces BCI fabrics. At Shanghai Fumao, we keep popular BCI fabrics in our 30,000+ design stock for this reason. This means a buyer needing 500-1,000 meters for a promotional run can access BCI without the lead time and high MOQ of a custom mill order. For true bulk orders (10,000+ garments), the price differential shrinks to a few percentage points, which is often offset by the factors below.

Where Are the Hidden Cost Savings?

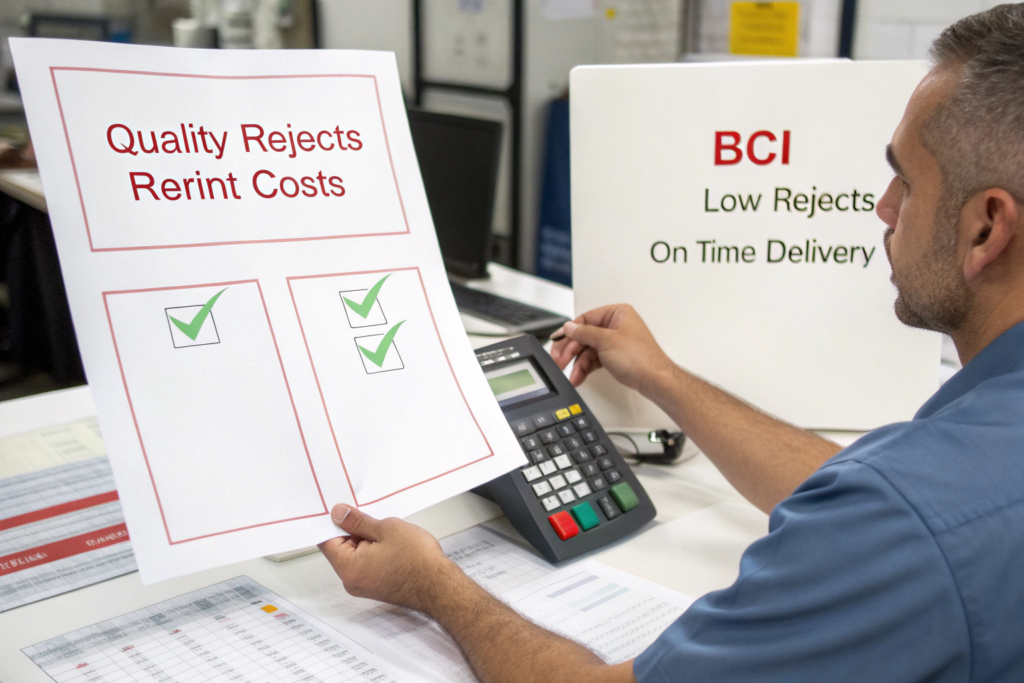

The real savings come from reduced defect rates and smoother production. Consistent fabric = fewer embroidery thread breaks, less printer downtime, and fewer garments rejected for subpar logo application. It also means more accurate forecasting—you're less likely to have to rush-order replacement fabric due to quality fails, avoiding expensive air freight. A European university ordering branded graduation hoodies found that using our BCI French terry reduced their embroidery defect rate from 5% to under 1.5%. That 3.5% reduction in waste on an order of 4,000 hoodies saved hundreds of garments and significant cost, effectively neutralizing the fabric premium. (Here's a pro tip: always ask your supplier for the fabric's "CV% of evenness" test report—lower is better for decoration).

What Should Buyers Specify When Ordering BCI Custom Fabrics?

To reap the benefits, you need to be specific in your sourcing request. "BCI cotton" is the starting point, not the complete specification.

Which Fabric Constructions Work Best for Decoration?

| Not all BCI fabrics are created equal for logo application. Here’s a quick guide: | Wearable Type | Recommended BCI Fabric | Why It Works |

|---|---|---|---|

| Polo Shirts | BCI Cotton Pique (Jersey or Lacoste) | Dense, textured knit provides stable base for embroidery, reduces puckering. | |

| T-Shirts | BCI Combed Cotton Jersey (180-220gsm) | Smooth surface for DTG & screen printing; higher weight prevents bleed-through. | |

| Hoodies/Sweatshirts | BCI Cotton Fleece or French Terry | Heavyweight, stable; holds embroidery well; brushing should be consistent. | |

| Performance Polos | BCI Cotton/Recycled Poly Blend | Wicks moisture; ensure blend is tested for print adhesion. |

Always request a biopolishing finish. It reduces pilling and creates a smoother surface for printing, making your logo look sharp for longer.

How Do You Ensure Certification is Legitimate and Delivered?

Your due diligence is simple but critical:

- Request the Supplier's BCI License Number. Any legitimate fabric supplier will provide this upfront.

- Specify "Transaction Certificate (TC) to be Provided." This must be in your PO terms. The TC is the legal document that traces the BCI cotton through the chain.

- Use a Supplier with In-House Quality Control. This ensures the BCI fabric is also tested for the physical properties that matter for decoration, like shrinkage and colorfastness. Our CNAS-accredited lab runs these tests as standard, so you get one report covering both sustainability and performance. For deeper insight, look at guides on verifying textile sustainability certifications.

Conclusion

The benefits of BCI for custom logo wearables are real, measurable, and extend far beyond a sustainability checkbox. It is a strategic choice that directly influences the perceived quality of your branded items, protects your company's reputation, provides a genuine story, and can be managed within a practical budget framework.

In a competitive market where custom apparel is a key tool for brand building and employee engagement, choosing a higher-quality, ethically sourced base material is a clear differentiator. It signals that your brand pays attention to detail and cares about its broader impact—from the farmer who grew the cotton to the employee who wears the final product.

Ready to explore how BCI cotton can elevate your next custom wearable program? We specialize in supplying high-performance, consistently quality BCI fabrics tailored for embroidery, printing, and brand excellence. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to request BCI fabric swatches and see the difference for yourself. Let's ensure your logo is showcased on the best possible canvas.