Let’s address the elephant in the atelier first. You're designing a beautiful, intricate women's wear collection—perhaps a delicate organic cotton lace trim blouse or a structured blazer with complex seaming. You ask a potential factory, "Is this OCS certified?" and they say "Yes." That "yes" is often a dangerous half-truth. The certification might cover their facility or a stock fabric, but does it cover your specific, custom garment with all its trims, linings, and embellishments? That's the multi-thousand-dollar question. OCS certification absolutely can cover custom women's wear production, but it’s not automatic. It’s a conditional coverage that depends entirely on how you and your factory manage the "chain of custody" for every single component that carries the organic claim.

OCS (Organic Content Standard) certification covers custom women's wear production if and only if the organic material content (like cotton, linen, wool) is tracked through the entire production process using the OCS chain-of-custody system, and the final product's composition label accurately reflects the percentage of certified content. The certification follows the material, not the garment style. This means your designer draping, custom dye lots, and unique constructions are all covered—provided the organic fibers within them are properly documented.

Navigating this for women's wear, with its diversity of fabrics, blends, and trims, requires a meticulous, proactive approach. Here's exactly how to ensure your custom designs are legitimately certified.

The Core Principle: Certification Follows the Fiber

This is the foundational rule every brand must internalize. OCS does not certify a "garment" as a whole; it certifies the organic fiber content within that garment. Think of it as a tracking system for a specific type of inventory—organic cotton, for example. The system must account for how much organic cotton entered the factory and where it ended up (in finished garments vs. waste).

For custom women's wear, this means you start with the Bill of Materials (BOM). Every component that contains or could contain organic fiber must be scrutinized. Is the main fabric 100% OCS organic cotton? Is the lining a blend? Is the lace trim synthetic or cotton? The certification coverage extends only to the components that are themselves OCS-certified.

How does OCS apply to complex blends (e.g., cotton-silk, linen-viscose)?

This is a critical and common scenario in women's wear. OCS can certify the organic portion of a blend.

- Scenario: You have a custom fabric that is 60% OCS organic linen and 40% conventional viscose.

- Process: Your fabric mill must have OCS certification and provide a Transaction Certificate (TC) for this specific fabric batch, stating the exact percentage of certified organic linen.

- Coverage: The OCS certification covers the 60% organic linen content. The viscose is not certified. Your final garment label must state the accurate blend, e.g., "60% Organic Linen, 40% Viscose."

- Verification: You need the TC from the mill and the mill's own OCS certificate. The garment factory then uses this fabric TC as an input for their own OCS mass balance.

If you cannot get a TC for the blended fabric, you cannot claim any part of it as OCS certified, even if the mill says they used organic linen. The TC is the proof.

What about fabric treatments and custom dyeing?

Custom dyeing, printing, and finishing (like wrinkle-resistant or water-repellent treatments) do not void OCS certification, but they introduce critical control points.

- The Dyehouse/Facility Must Be in the Chain: The facility applying the treatment must be included in the OCS scope of your supplier's certification or hold its own OCS certificate. If they don't, the organic material's chain of custody is broken the moment it leaves the certified factory.

- Chemical Compliance: While OCS itself doesn't restrict chemicals (unlike GOTS), using low-impact, OEKO-TEX certified dyes is a best practice to maintain the ecological integrity of the organic fiber. Your factory should be able to provide documentation for the dyes used.

- Mass Balance Continues: The weight of the fabric going into dyeing and coming out must be tracked to account for any weight gain/loss.

A US brand learned this the hard way in 2023. They sourced beautiful OCS organic cotton twill but sent it to a local printer in Los Angeles for custom patterns. Because the printer was not OCS-certified or linked to the chain, the final garments could not be sold as OCS certified, destroying the value of the organic fabric.

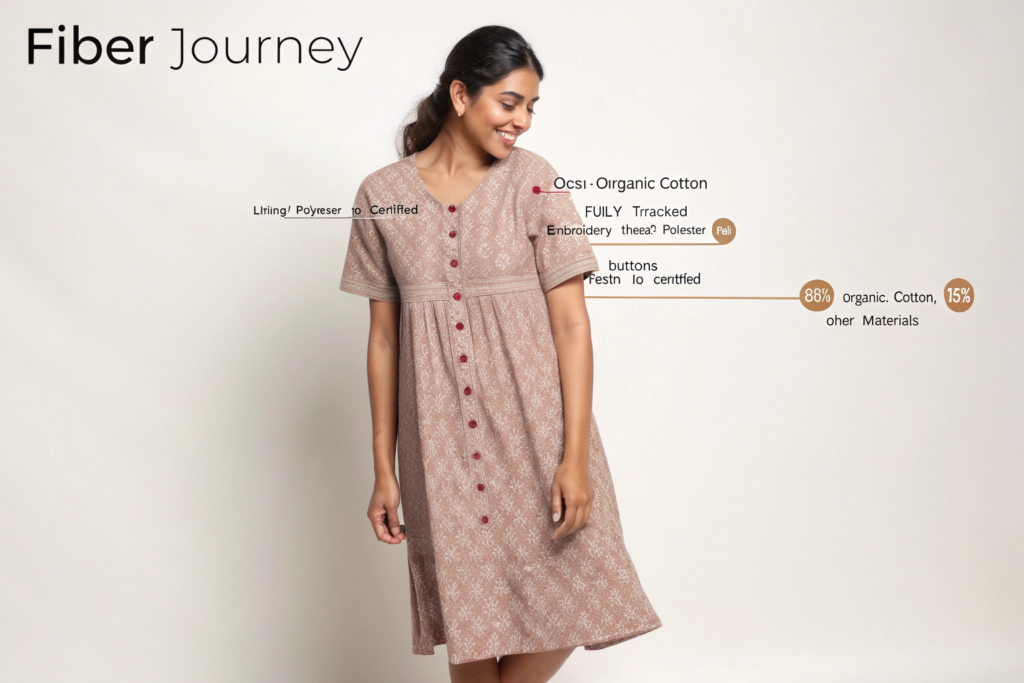

Navigating Trims, Embellishments, and the "Other Materials" Category

Women's wear often lives in the details: delicate lace, satin ribbons, specific buttons, embroidered motifs. This is where OCS coverage gets precise, and where many factories' knowledge falls short. You must have a clear, documented strategy for every non-fabric component.

The golden rule: If a component is not made from OCS-certified material, it does not contribute to the certified content. It is tracked as part of the "other materials" percentage in the final composition.

Which common women's wear trims can be OCS certified?

Very few off-the-shelf trims are OCS-certified. To have a certified trim, it must be specially made from certified organic fiber and tracked through its own production chain. This is rare and expensive. Examples might include:

- 100% organic cotton bias binding or twill tape.

- Organic cotton lace (extremely rare and often not durable).

- Labels made from 100% organic cotton.

In 99% of cases, you will work with non-certified trims. This is acceptable under OCS, as long as they are accurately declared. The key is to document and weigh. Your factory should have a standard weight for the buttons, zippers, and threads you use to calculate the final "other materials" percentage.

How to manage embroidery, prints, and appliqués?

These decorative elements are almost always made from non-organic materials (polyester thread, plastic-based sequins, synthetic appliqué fabric).

- Embroidery: The thread is non-organic. The embroidery process does not affect the certification of the base fabric it's stitched onto. However, the weight of the thread used should be estimated and included in the "other materials" calculation.

- Prints: Ink is not an organic material. Printing does not break the chain for the fabric. Use of pigments vs. plastisols and their safety (OEKO-TEX) is a separate concern.

- Appliqués: If an appliqué is made from a different fabric, and that fabric is not OCS-certified, then the appliqué is part of the "other materials." If you want an organic appliqué, it must be cut from the same OCS-certified fabric as the garment.

The certification covers the organic canvas; the art on the canvas can be anything, but it doesn't become organic itself.

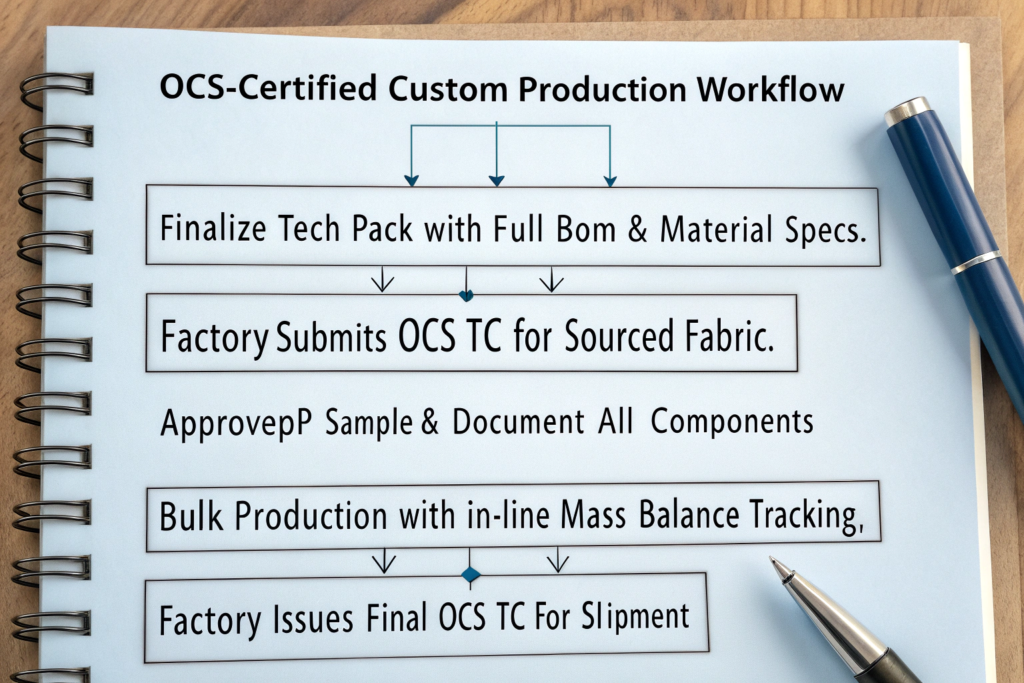

The Production Workflow: From Tech Pack to Transaction Certificate

To successfully produce certified custom women's wear, your tech pack and communication with the factory must be upgraded. Precision is no longer just about fit and style; it's about material accountability. Every decision must be documented because it will be audited.

The workflow must integrate certification checkpoints at every stage, with the factory's QC team acting as both quality inspectors and data auditors.

What must be included in the tech pack for OCS compliance?

Your tech pack becomes a legal document. Beyond the usual specs, it must include:

- Detailed Bill of Materials (BOM): List every component: main fabric, lining, interlining, thread, buttons, zippers, labels, elastic. For each, specify:

- Material Composition: (e.g., 100% OCS organic cotton, 100% polyester).

- Certification Status: (e.g., OCS-certified, non-certified).

- Supplier/Reference: If known.

- Labeling Instructions: Specify the exact composition you want on the care label, based on the BOM. E.g., "92% Organic Cotton, 8% Other Materials." Include the OCS license number if required by your certifier.

- Approval Protocols: State that the Pre-Production (PP) sample must be made with all correct, specified materials and that its approval is conditional on material compliance.

Sending this level of detail prevents the factory from making unilateral substitutions that could break certification. A UK contemporary brand we work with provides a "Compliance Annex" with every tech pack, which has reduced pre-production queries by 70%.

What are the critical checkpoints during production?

The factory should provide evidence at these points:

- Checkpoint 1: Fabric Sourcing. Receive and approve the OCS TC for the bulk fabric.

- Checkpoint 2: Trim Sourcing. Receive documentation (spec sheets, non-certification declarations) for all major trims.

- Checkpoint 3: PP Sample Approval. The physical sample is the binding reference for quality and material compliance. Do not approve it until you have verified every component matches the BOM.

- Checkpoint 4: In-Production Mass Balance. The factory should be able to report that the certified fabric input is being tracked against cut panels and waste.

- Checkpoint 5: Final Audit & TC Issuance. Before shipment, you must review the draft final OCS TC and confirm its accuracy against the actual shipment.

Missing any of these checkpoints introduces risk. The most common failure is at the PP sample stage, where a factory might use a similar-looking but non-certified fabric or trim to save time or cost.

The Business Case: Cost, Communication, and Choosing the Right Partner

Producing OCS-certified custom women's wear has cost implications beyond the fabric premium. It requires more time for sourcing, more rigorous sampling, and potentially higher minimum order quantities (MOQs) for custom-dyed or woven certified fabrics. However, this investment unlocks premium pricing, market access, and brand integrity.

Your choice of factory is the single most important factor. They must be a true partner, not just a contractor.

How does OCS impact MOQs and lead times for custom women's wear?

- MOQs: They are typically higher than for conventional fabrics. A spinning mill may have a 1-ton MOQ for OCS yarn, and a weaving mill a 3,000-meter MOQ for a specific construction. This translates to higher garment MOQs. Vertical factories (like ours at Shanghai Fumao) that control spinning/weaving can sometimes offer more flexibility by grouping smaller orders. For a truly custom OCS fabric (unique weave/dye), expect MOQs of 1,000-3,000 meters.

- Lead Times: Add 2-4 weeks for sourcing certified raw materials and for the extra sampling/approval loops. The entire process is less flexible because you cannot easily substitute materials.

Planning is paramount. You must engage your OCS factory during the design development phase, not after designs are finalized.

What questions to ask a potential factory to gauge their OCS expertise?

Go beyond "Are you OCS certified?" Ask these operational questions:

- "Can you show me a recent OCS TC for a custom order similar to mine?"

- "Walk me through how you track organic and non-organic components in cutting and sewing."

- "What is your procedure if a non-certified trim arrives and needs to be substituted?" (The answer should involve your approval).

- "Who in your organization is responsible for OCS documentation and TC issuance? Can I meet them?"

- "What is your policy on fabric and trim testing for OCS orders?"

Their answers will reveal if OCS is an integrated management system or just a framed certificate on the wall. A factory that specializes in this will have clear, confident answers and will appreciate your detailed questions.

Conclusion

OCS certification does cover custom women's wear production, but this coverage is not blanket or automatic. It is a conditional coverage earned through meticulous material tracking, precise documentation, and a deeply collaborative partnership with a knowledgeable factory. The process demands that designers and product developers think like supply chain managers, accounting for the provenance of every fiber that carries the organic claim.

For brands willing to master this discipline, the reward is a product that carries not just beauty and style, but also the uncompromising integrity that the modern consumer values and verifies. It transforms a custom garment from a simple article of clothing into a documented statement of values.

If you are developing a custom women's wear collection where authenticity is as important as aesthetics, you need a factory partner that speaks both languages fluently. At Shanghai Fumao, our vertical integration and OCS expertise allow us to guide brands through this complex process, ensuring their creative visions are realized without compromising certification integrity. Contact our Business Director, Elaine, to begin the conversation: elaine@fumaoclothing.com. Let's craft a collection that is truly, verifiably, exceptional.