Let's be brutally honest: searching for an "OCS Organic Cotton Factory" on Alibaba is like panning for gold in a river filled with fool's gold. You'll see thousands of shiny listings, but 95% are traders, bait-and-switch artists, or factories with a certificate they don't understand how to use. I've seen brands waste six months and lose tens of thousands of dollars because they trusted an Alibaba profile with a photoshopped certificate. The platform is a powerful starting point, but it's a minefield of misinformation. Your goal isn't just to find a supplier who claims OCS—it's to find one who can prove it and execute with it.

Finding a reliable OCS organic cotton factory on Alibaba requires a forensic verification process that treats every claim as guilty until proven innocent. Success hinges on moving beyond profile keywords to demanding and validating specific documentation, conducting technical interviews, and performing on-site or virtual audits before a single dollar is committed. You must become an investigator, not just a buyer.

I'll guide you through the exact step-by-step process we would use to vet our own partners. This is how you separate the real manufacturers from the certification charlatans.

Phase 1: The Forensic Search & Initial Filtering

Don't just type "OCS organic cotton factory" and click the first sponsored result. You must refine your search with industrial precision. The goal is to filter out the obvious traders and find entities that have the physical infrastructure and language of a real manufacturer. Remember, a trading company can also be a reliable partner if they are transparent and have strong, audited factory partnerships, but you need to know which one you're dealing with.

Use specific, long-tail search terms that real factories would use, not just generic marketing buzzwords. Think like a manufacturer, not a marketer.

What are the most effective search keywords to use?

Avoid broad terms. Combine certification with specific processes, products, or machinery:

"OCS 100 certificate" "spinning mill"(if looking for yarn)"OCS certified" "weaving factory" "organic cotton poplin""organic cotton" "knitting mill" "GOTS"(factories with GOTS often have OCS)"OCS" "dyeing unit" "control union"(specifying the certifying body)"organic cotton fabric manufacturer" "Keqiao"(targeting the industrial cluster)

Including a specific industrial cluster like Keqiao, Zhangjiagang, or Guangzhou in your search can yield more specialized results. Factories in these hubs are more likely to be authentic manufacturers. A client of ours found us not by searching "OCS factory," but by searching "organic cotton twill" "Keqiao manufacturer", which led them directly to our product listing and our deep local footprint.

How to instantly identify red flags in an Alibaba profile?

Within 30 seconds of opening a supplier's page, you should spot these deal-breakers:

- Product Chaos: The supplier sells OCS organic cotton, polyester lace, sequin fabric, and metal zippers all on one page. This is a classic trader profile.

- Vague Location: The location is just "China" or "Zhejiang." A real factory lists a specific city and district (e.g., "Shaoxing, Keqiao District").

- Stock Imagery Only: Every product image is a generic studio shot or blatantly stolen from other websites. No photos of the factory, machinery, or raw materials.

- Inconsistent Certification Claims: The profile mentions "OCS," "GOTS," "OEKO-TEX," "ISO 9001" all in one line with no evidence. They are keyword-stuffing.

- Extremely Low MOQs for Custom Work: "OCS custom fabric, MOQ 100 meters." For woven fabric, this is almost always false. Real vertical factories have higher minimums due to yarn and weaving setup costs.

If you see these, close the tab. Do not waste time on a "maybe."

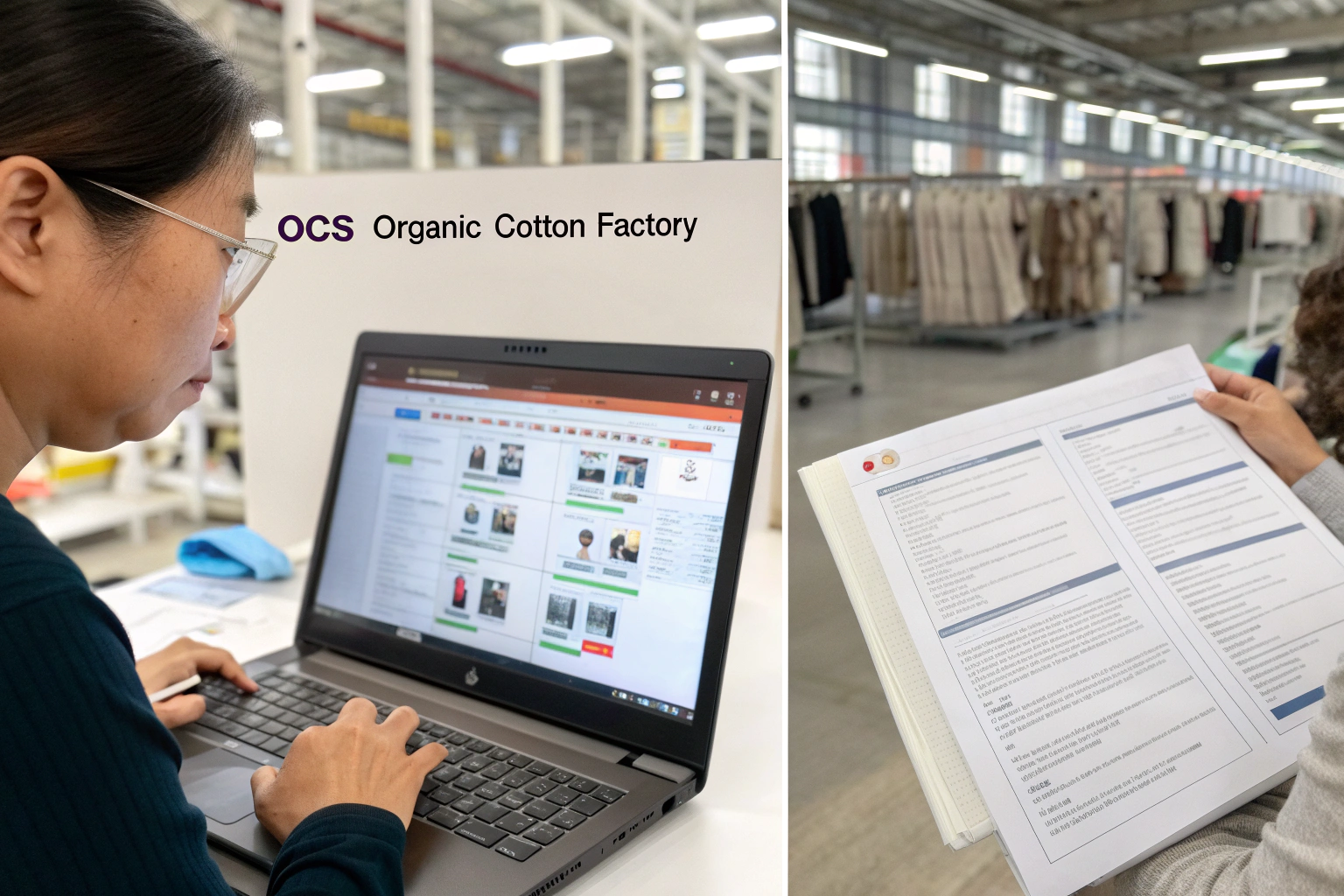

Phase 2: The Document Interrogation

This is the core of the process. Any legitimate factory will have, and be willing to share, current certification documents. Your job is to not just receive them, but to scrutinize them like a bank teller checks for counterfeit money. The document request is your first test of their transparency and competence.

What specific documents must you request, and how do you verify them?

Request 1: Their Business License (Chinese: 营业执照).

- Why: Confirms legal entity name and registered address. Cross-check this with the Alibaba "Company Name" and location.

- Verification: The name on the license should match the Alibaba store name closely. You can (with the Chinese name) do a basic check on Chinese business registry sites, though this can be complex for foreigners.

Request 2: Valid OCS Certificate.

- Why: This is the heart of the matter.

- Verification Steps:

- Issuing Body: Is it from an accredited certifier like Control Union, Ecocert, SGS, or ICEA?

- Certificate Number: Note it down.

- Scope: The scope must include "Processing" and "Trading" for a factory that weaves/dyes and sells fabric. If it only says "Trading," they are not a manufacturer.

- Expiry Date: Must be valid.

- Company Name & Address: Must match the Business License.

- Action: Ask them to hold the original certificate next to their face in a video call. Then, ask them to take you on a live video walk to the location on the certificate. If they refuse or make excuses, it's a major red flag.

Request 3: A Sample Transaction Certificate (TC) from a previous order.

- Why: This proves they understand how to use the certification in commerce. Anyone can buy a certificate; issuing a valid TC requires a functioning chain-of-custody system.

- Verification: The TC should be detailed, with product description, quantities, and reference to the OCS certificate number. Ask them to explain one line on the TC to you. If they can't explain the "mass balance" or "input/output" concept, they are not operating the system.

Request 4: Test Reports for Their Key Fabrics.

- Why: Shows commitment to quality. Ask for a recent SGS, ITS, or CNAS lab report for shrinkage, colorfastness, and composition.

- Verification: Check the date, the testing standard, and that the client name on the report matches their company.

A factory that cannot provide these four documents within 48 hours is not a serious OCS partner.

Phase 3: The Technical & Operational Deep Dive

Once documents check out, you must assess their operational capability. This is where you transition from a compliance officer to a production manager. You need to understand if they can actually produce the quality and quantity you need, on time. This is done through a structured interview and a visual audit.

What questions to ask during a supplier interview?

Move beyond price and MOQ. Ask process-focused questions:

- On OCS Process: "Can you walk me through your procedure from receiving OCS-certified yarn to shipping certified fabric? How do you maintain segregation?"

- On Capacity & Lead Time: "For an order of 5,000 meters of OCS organic cotton twill, what is your realistic lead time from yarn sourcing to finished fabric, broken down by week?"

- On Quality Control: "What is your in-process QC procedure? Can you share your AQL inspection checklist? Who is your third-party lab for testing?"

- On Problem-Solving: "What was your biggest production challenge in the last year on an OCS order, and how did you resolve it?"

- On Communication: "Who will be my single point of contact? What systems do you use for order tracking (ERP, WhatsApp, email)?"

Their answers reveal depth. Vague answers like "we have good quality" are useless. Specific answers like "we use a separate warehouse zone for OCS yarn, and our lead time is 35 days including 7 days for Oeko-Tex testing at our partner lab" indicate real expertise.

How to conduct a meaningful virtual factory audit?

A live video call is non-negotiable. Schedule it in their working hours (China time).

- Demand a Live Walkthrough: No pre-recorded videos. Ask to see specific areas: the warehouse (look for labeled OCS zones), the production floor (weaving/knitting machines), the dyeing/finishing area (if applicable), the QC lab, and the packing area.

- Ask to See Specific Things: "Please show me the lot number tag on that yarn cone." "Can you walk over to that loom and show me the fabric being produced?" "Please show me your fabric inspection machine."

- Talk to Staff: Ask the guide to ask a machine operator a simple question (with translation), like "What are you making right now?" Engaged, trained staff are a good sign.

- Check for Consistency: Does the factory you see match the scale and capability described in their profile and documents?

In Q1 2024, a US brand conducted a virtual audit with us and a competing factory. The competitor had a clean, empty showroom but hesitated to show the weaving floor, claiming it was "too noisy." Our guide walked directly into the active production area, showing real-time production of an OCS order. The brand chose us based on that transparency.

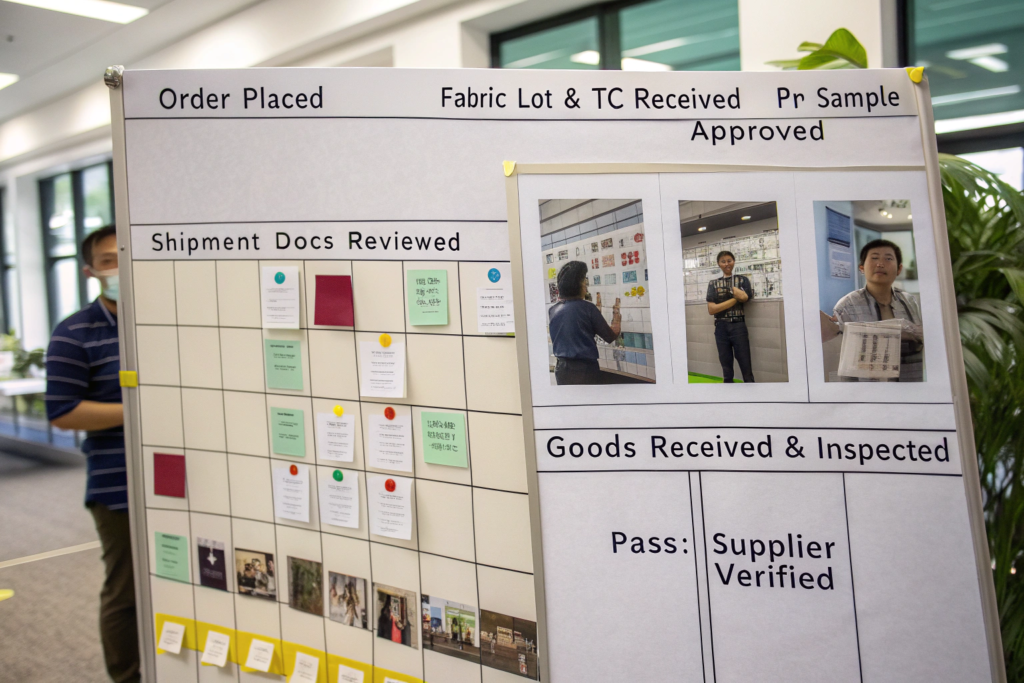

Phase 4: The Pilot Order Strategy

Never start with your full seasonal order. The final test is a small, paid pilot order. This is your ultimate due diligence. It tests everything: communication, documentation accuracy, quality, shipping, and their understanding of the OCS chain-of-custody for a real transaction.

What should a pilot order test?

Your pilot should be designed to stress-test their system:

- Order a Small Batch: Enough to make a meaningful assessment (e.g., 500-1000 meters of fabric, or 200-500 pieces of a simple garment).

- Request Full Documentation: Demand the complete pack: Commercial Invoice, Packing List, Bill of Lading, and the specific OCS Transaction Certificate (TC) for this shipment.

- Include a Custom Element: Ask for a specific color match or a small label change. This tests their flexibility and attention to detail within a certified framework.

- Conduct Rigorous Receiving Inspection: When the goods arrive, inspect them against the PP sample and the documents. Does the physical product match the description on the TC?

How to evaluate the pilot order results?

Create a scorecard:

- Communication & Responsiveness (Score 1-10): Were they proactive? Did they provide updates?

- Documentation Accuracy (Score 1-10): Was the TC correct and issued promptly? Were all docs consistent?

- Quality Compliance (Score 1-10): Did the product meet the agreed specs and quality standard?

- Timeline Adherence (Score 1-10): Did they ship within the promised window?

- Problem Resolution (Score 1-10): If any issues arose, how were they handled?

A supplier scoring below 8 on Documentation Accuracy or Quality Compliance should be disqualified, regardless of price. The pilot order cost is your most valuable market research spend.

Conclusion

Finding a reliable OCS organic cotton factory on Alibaba is a rigorous, multi-stage investigation that prioritizes proof over promises. It requires you to be part detective, part quality engineer, and part compliance officer. By mastering the forensic search, the document interrogation, the technical deep dive, and the pilot order strategy, you transform Alibaba from a risky bazaar into a powerful sourcing database for qualified partners.

The factories that pass this gauntlet are rare, but they are worth their weight in gold. They provide not just a product, but a bulletproof, scalable supply chain asset.

If this process seems daunting, know that there are partners who have already done this work on themselves. At Shanghai Fumao, we are the vertically integrated, OCS-certified factory that buyers find after wading through the Alibaba noise. We welcome the scrutiny because our systems are built for it. For a direct path to a verified partner, skip the search and contact our Business Director, Elaine: elaine@fumaoclothing.com. Let's build your certified line on a foundation of proven reliability.