You see the “OCS Certified” tag on a garment and think the hard work is done. As a supplier deep in the production trenches, I’m here to tell you that tag represents the outcome of hundreds of deliberate, documented steps. Many brands believe certification is something you “add on” at the end. That’s the fastest way to fail an audit. The truth is, OCS certification isn’t a final stamp—it’s a parallel process that must be woven into every single stage of production, from the cotton field to the carton box. Miss one link, and your entire chain of custody breaks.

The production of OCS-certified organic clothing follows a strictly defined, dual-track process: the physical manufacturing of the garment (cutting, sewing, etc.) and the meticulous documentation of the certified organic material’s journey. Every step, from sourcing GOTS-certified seed to issuing the final Transaction Certificate, must be verified and recorded. It’s a system built on transparency, where paperwork is as critical as stitch quality.

Let’s pull back the curtain. I’ll walk you through the complete journey, not as a theoretical flowchart, but as the practical, gritty, and absolutely essential sequence that we follow at Shanghai Fumao to guarantee your clothing is legitimately certified. This is how you move from claiming to be organic to proving it.

Stage 1: The Foundation - Sourcing & Verifying Raw Materials

This is where certification is won or lost. If the input isn’t right, nothing that follows can be certified. You can’t make a certified garment from uncertified fabric, and you can’t make certified fabric from uncertified fiber. This stage is all about vetting and locking down your supply chain’s very beginning. It’s the most critical control point.

For us at Shanghai Fumao, this stage starts long before a brand’s order. It’s about cultivating relationships with certified farms and spinners, and maintaining a buffer of OCS-certified yarn in our supply chain to ensure we can react to your timelines. We treat the raw material not as a commodity, but as a tracked asset with a documented history.

How is organic cotton fiber traced from the farm?

The traceability journey begins with the OCS 100 certificate at the farm or ginning level. This certificate, issued by an accredited body like Control Union or Ecocert, is the birth certificate for the organic fiber. It confirms the cotton was grown according to organic standards (no synthetic pesticides, GMOs, etc.).

The key document for movement is the Transaction Certificate (TC). When the certified cotton is sold from the gin to a spinner, a TC is issued. This TC has a unique number and specifies the weight and certification details. This process repeats at every transaction: spinner to weaver/knotter, weaver to dyer/finisher, finisher to garment factory. Each TC references the previous one, creating an unbroken paper trail. At Fumao, when we receive OCS-certified yarn, the first thing our QC team does is cross-reference the physical yarn lot numbers with the accompanying TC. We log it into our tracking system before a single meter is woven. This diligence in early 2024 prevented a major issue for a Scandinavian brand when we identified a TC-batch mismatch from a spinner, averting the use of non-certified material.

What certifications are needed before fabric production begins?

Before weaving or knitting can even start, you need verified inputs. The hierarchy is clear:

- OCS Certificate for the Fiber/Yarn: This is non-negotiable. It’s the proof of organic content origin.

- GOTS Certificate (Optional but Powerful): If you are producing GOTS-certified fabric (a higher standard), you need proof that the processing units (spinning, weaving, dyeing) are also GOTS certified. OCS alone does not cover processing chemicals.

- Chemical Input Certifications: For dyeing and finishing, the factory must use dyes and auxiliaries that meet certain environmental/toxicity criteria. While not part of OCS, using OEKO-TEX ECO PASSPORT or GOTS-approved chemicals is a best practice that we enforce to ensure the final fabric is safe and clean. This is crucial for brands targeting the European market. We guide our clients on the importance of low-impact dyes in organic textile production to meet their holistic sustainability goals.

Think of it like baking a cake: OCS certifies the organic flour. GOTS and chemical certifications ensure the sugar, eggs, and butter are also of a certain standard, and that your kitchen is clean.

Stage 2: Fabric Manufacturing with Chain-of-Custody Integrity

This is where the certified raw material is transformed into the fabric you’ll cut and sew. It’s a high-risk stage for contamination or mixing. A single mix-up on the factory floor—like running conventional yarn on a loom right after certified yarn without a proper clean-out—can invalidate an entire production lot. The physical process must be married to rigorous procedural controls.

Our advantage at Fumao is vertical control. With our own weaving factory, we manage this transformation directly. We don’t just order fabric from a mill and hope they followed the rules; we execute and document the rules ourselves.

What specific controls are in place during spinning and weaving?

The mantra is segregation and identification.

- Physical Segregation: Certified and conventional materials must be stored separately. Dedicated production runs are scheduled. The machinery must be thoroughly cleaned to remove residue from previous non-organic runs. We document these clean-outs with checklists.

- Lot Identification: Every batch of certified yarn and resulting fabric is given a unique lot number. This number follows the material physically (on tags, rolls) and in all documentation.

- Mass Balance Tracking: This is the core of OCS. We must account for all certified material input (e.g., 1000kg of OCS yarn) and match it with the output (e.g., 950kg of OCS fabric + 50kg waste). The waste must be recorded. This system ensures that the amount of certified product claimed cannot exceed the amount of certified material purchased. Our software system tracks this in real-time, a step beyond many basic operators.

How is dyeing and finishing managed for certified fabrics?

Dyeing is a potential breaking point. You can have perfectly certified greige (un-dyed) fabric, but if the dye house is not managed properly, you lose control.

- Partner Audits: We only use dyeing partners that understand and can demonstrate compliance with chain-of-custody procedures. They are audited by us and by certification bodies.

- Chemical Compliance: As mentioned, we mandate the use of approved, low-impact chemicals. We review their MSDS (Material Safety Data Sheets) and certificates.

- Continuous Documentation: The fabric’s lot number travels with it to the dye house. The dye house must provide documentation confirming they processed only that certified lot, and they must return a new TC to us showing the finished fabric output. This handoff is critical. A Swiss brand’s order in Q3 2023 was delayed by a week because we rejected the first dye house documentation for being incomplete. We switched to a backup partner with flawless records. The delay protected the brand’s certification integrity—a trade-off they fully supported.

Stage 3: Garment Construction & Decoration Compliance

Now you have certified fabric rolls. The risk shifts to the cutting and sewing factory. Here, the certified fabric can be mixed with conventional trims, threads, or even other fabrics, destroying the certification. This stage requires extreme attention to detail and clear communication from the brand regarding all components.

Many brands underestimate this stage. They think, “The fabric is certified, so the garment is certified.” Not true. Every component that contributes to the final product’s weight and claim must be assessed.

How are cutting and sewing processes audited for OCS?

The garment factory must be included in the OCS scope, either under the brand’s certificate or the manufacturer’s. They must have procedures to:

- Receive and Verify: Check incoming fabric rolls against the provided TCs and lot lists.

- Store Segregated: Keep certified fabric separate from other fabrics.

- Manage Cut-and-Sew Waste: Just like in weaving, they must track the weight of certified fabric input vs. the output of cut panels and final garments. Fabric waste (off-cuts) must be recorded and its disposal method noted (e.g., sent for recycling). This is part of the mass balance.

- Control Non-Fabric Components: This is crucial. Buttons, zippers, threads, and interlinings are not covered by OCS unless they are also made from certified organic content (which is rare). However, their use does not invalidate the OCS claim for the fabric content. The claim must accurately state the percentage of certified organic material in the final product. For example, “Made with 95% OCS-certified organic cotton, 5% other materials.”

What about labels, threads, and other trims?

This is a key decision point for brands.

- Thread: While 100% organic cotton thread exists, it is less strong. Most brands use polyester or cotton-covered polyester core thread. This thread is not organic, but its small percentage (usually 1-3% of total product weight) is factored into the final content calculation. The thread should, however, be OEKO-TEX Standard 100 certified for safety.

- Labels (Care & Brand): These are often made of polyester or conventional cotton. Like thread, they are part of the “other materials.” Some brands pursue GOTS certification which has stricter rules on accessories.

- Decoration (Embroidery/Print): Embroidery thread is typically polyester. Print inks and plastisols are chemical compounds. Their use is permitted under OCS, but again, they contribute to the “other materials” portion. Their chemical safety (OEKO-TEX) is a separate concern for product safety. We help clients source compliant trims and decoration materials for sustainable apparel to align with broader goals.

The rule of thumb: Communicate all trim specs to your supplier early so they can accurately calculate the final organic content percentage and ensure nothing introduces a banned substance.

Stage 4: Final Verification, Certification & Logistics

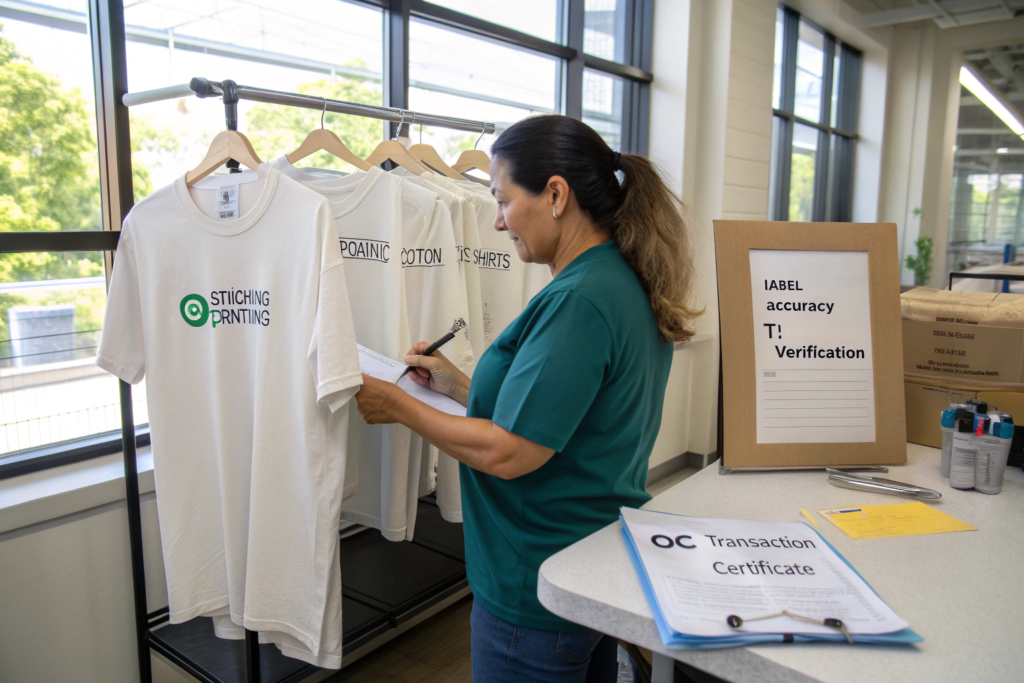

The garments are sewn, but they are not yet certified for shipment. This final stage is about collating all the evidence, performing the final quality and compliance check, and generating the legal document that allows you to sell the product as OCS certified. This is where the parallel tracks of production and documentation converge.

Skipping or rushing this stage renders all previous efforts useless. It’s the moment of truth before the goods leave the factory.

What is the final audit and Transaction Certificate (TC) process?

Before shipment, the certification body’s auditor (or an internal auditor for certified entities) will review the entire dossier for that production lot. This includes:

- All incoming TCs for fabric and materials.

- Mass balance calculations from the garment factory.

- Production records, inventory logs, and cleaning records.

- The final product’s specification sheet and lab test reports (e.g., for colorfastness).

If everything is in order, the supplier (or the brand, if they hold the certificate) can apply for the final Transaction Certificate. This TC is the definitive legal document. It states the final product description, quantity, and the exact percentage of certified organic content. You need this TC to sell the goods as OCS certified. At Fumao, we manage this application process for our clients as part of our service, ensuring no last-minute paperwork gaps delay their shipment.

How does packaging and shipping protect certification status?

Even packaging has a role. The shipping cartons should be marked to indicate they contain certified goods, which can help prevent accidental mixing in warehouses. More importantly, all certification documentation (the final TC, test reports) must travel with the commercial invoice or be readily available for customs authorities.

For the European market, this is especially critical. Having the TC easily accessible can prevent delays at EU borders where officials may check environmental claims. We create a “Compliance Packet” for each shipment—a digital folder containing all certificates, TCs, and test reports—that we email directly to the client’s logistics team for smooth clearance. This proactive step saved a UK client from a potential 10-day hold at Felixstowe port in late 2023 when a random inspection was triggered.

Conclusion

Producing OCS-certified organic clothing is a meticulously choreographed sequence where material flow and data flow must move in perfect lockstep. It’s a process that demands expertise at every stage—from agricultural verification to final logistics documentation. There are no shortcuts. The “certification” is not an additive; it is the integrity of the entire system.

For brands, understanding these steps is empowering. It allows you to ask the right questions, choose the right partners, and build a supply chain you can truly trust. At Shanghai Fumao, we’ve embedded this dual-track process into our DNA. Our vertical control and obsessive documentation turn the complexity of OCS production into a reliable, transparent service for our clients.

If you are looking to launch or scale a line of certified organic clothing and want a partner who handles the intricate compliance burden while delivering premium quality, let’s connect. Reach out to our Business Director, Elaine, to discuss how we can streamline this entire journey for your brand: elaine@fumaoclothing.com. Let’s produce not just clothing, but confidence.