Let me ask you a hard question: when you pay a 20-30% premium for an "organic cotton" garment, what are you actually buying? Is it just a softer hand-feel, or is it the promise of environmental integrity and ethical production? Now, here's the uncomfortable truth: without a system like OCS (Organic Content Standard) traceability, that promise is just marketing words. You're buying hope, not proof. In today's market, where greenwashing lawsuits are rising and consumers are savvier than ever, traceability isn't just "nice-to-have"—it's your only defense against fraud and your only path to genuine sustainability.

At Shanghai Fumao, we see OCS traceability as the backbone of trust in organic textiles. It's the technical system that answers the simple question: "How do I know this is really organic?" This isn't theoretical. In 2023, a major European retailer tested random "organic" garments from various brands. 40% showed traces of prohibited pesticides or synthetic fiber blends not on the label. The brands with broken supply chains faced millions in returns and permanent reputation damage. The ones with OCS traceability? They provided their Transaction Certificates and were cleared immediately. That's the power of traceability—it turns a crisis into a paperwork drill.

Think of the supply chain as a river. Organic cotton is a pure water source at the mountain top. But as it flows downstream through ginning, spinning, weaving, dyeing, and sewing, it can be contaminated by conventional cotton, synthetic fibers, or unethical practices. OCS traceability is the protective pipeline that keeps the pure water pure until it reaches the consumer. Without it, you're drinking from a river that anyone could have polluted.

The Broken Chain Problem: Why "Certified at Origin" Isn't Enough.

Many brands operate under a dangerous assumption: "If we buy certified organic cotton yarn, our final garment is certified." This is the most common and costly mistake in sustainable sourcing. Certification at the farm or yarn level only guarantees the starting point. The chain of custody—the documented journey from that certified raw material to your finished product—is what OCS traceability provides. Without it, you have no idea what happens in the middle.

Here’s what can (and does) go wrong in an untraced supply chain:

- Dilution/Blending: A spinner or weaver mixes premium organic yarn with cheaper conventional yarn to boost margins. Without mass balance tracking, this is invisible.

- Contamination: In a factory producing both organic and conventional goods, fibers mix in the air, on machinery, or through human error. Your "100% organic" fabric now contains 5% polyester from the adjacent production line.

- Document Fraud: Unscrupulous middlemen sell fake certificates or reuse old ones. We’ve been asked to "provide a certificate for a similar fabric" for clients who bought elsewhere—a major red flag.

- Lost Provenance: Even with honest players, without a system, batches get mixed. When a quality issue arises, you can't pinpoint which farm, which dye lot, or which production run was affected. Your entire inventory becomes suspect.

How does OCS traceability physically prevent these issues?

OCS isn't just paperwork; it enforces physical and procedural discipline. At our facilities, traceability means:

- Segregated Storage: OCS yarn and fabric are stored in labeled, separate areas. You can't accidentally grab the wrong roll.

- Dedicated Production Runs: We schedule OCS orders together and clean equipment thoroughly before and after. (Here's a real cost: we lose 4-8 hours of production time per machine for cleaning, but it's non-negotiable.)

- Mass Balance Accounting: We must account for every kilogram. If we input 1,000 kg of OCS yarn, we must output ~980-990 kg of OCS fabric (allowing for moisture loss). Any significant discrepancy fails the audit. This makes large-scale blending a mathematical impossibility.

- Serialized Documentation: Every batch gets a unique Transaction Certificate (TC) number. This number is referenced on the roll label, the packing list, and the shipping documents. It's a single source of truth.

A client story underscores this: In mid-2023, an American boutique brand received a shipment of organic cotton pants that inexplicably triggered skin allergies in some customers. They had no traceability system. It took weeks and thousands of dollars in testing to trace the problem to a specific dye lot from a sub-sub-contractor that used a non-compliant chemical. Had they used an OCS-traced supply chain with Shanghai Fumao, they could have isolated the batch in 24 hours using the TC number, limiting the recall to 200 units instead of 2,000.

What's the difference between traceability and transparency?

This is a key distinction. Transparency is the willingness to share information. Traceability is the hard, technical ability to provide that information accurately and verifiably. A brand can be transparent ("We source from India") but lack traceability ("We can't tell you which farm or which batch"). OCS provides the technical infrastructure for meaningful transparency. It allows you to move from vague stories to specific, verifiable data—a shift increasingly demanded by regulators studying extended producer responsibility (EPR) laws for textiles.

From Compliance Shield to Consumer Trust Engine.

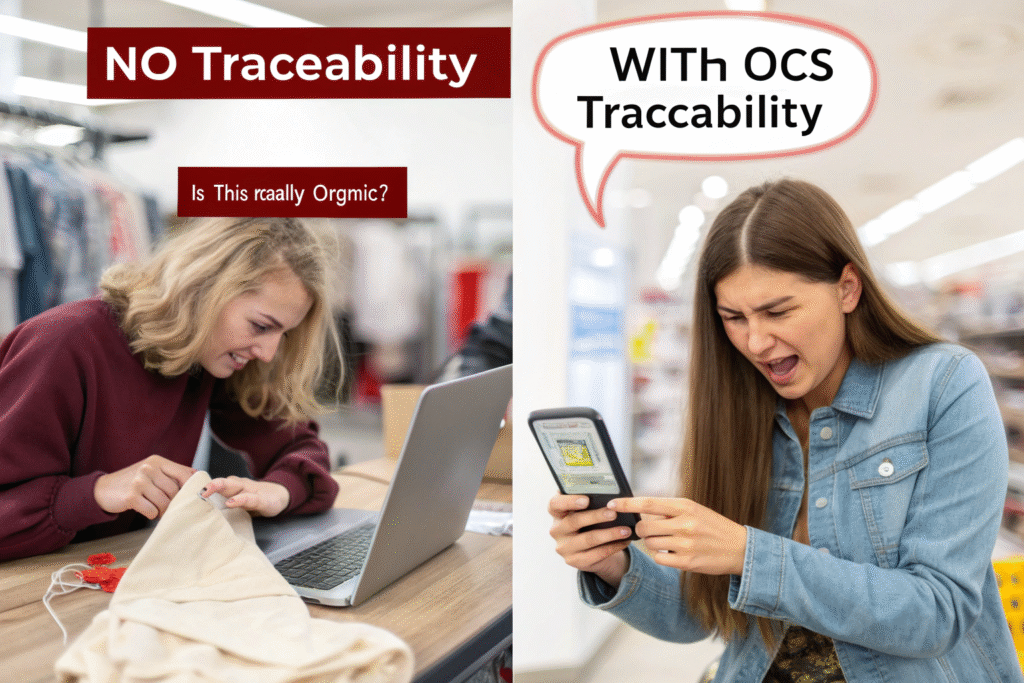

For years, traceability was seen as a back-office compliance function. Today, it's a frontline marketing asset and a direct driver of consumer trust. In an age of skepticism, consumers don't just want to hear your story; they want to see your proof. OCS traceability provides the proof you can actually show.

Building Trust Through Verification: Imagine a product page on your website that does more than say "100% Organic Cotton." Imagine it has a "Trace This Garment" button. A customer clicks it, enters the unique batch code from their care label, and sees a simplified map: "Organic Cotton Grown at [Farm Cooperative, India] > Spun at [X Mill] > Woven at Shanghai Fumao, China > Dyed at [Partner Facility] > Sewn at [Certified Factory]." This isn't science fiction; it's the logical endpoint of OCS data. This level of detail transforms passive buyers into active believers in your brand mission.

The Data-Backed Story: Traceability turns abstract sustainability claims into concrete narratives. Instead of "we save water," you can say, "This batch of fabric, tracked under OCS TC #CU-2024-087654, used organic cotton that required 91% less water than conventional cotton, based on farm-level data from our certified supplier." Specificity beats generality every time. This approach aligns with what leading consumer studies show about demand for product origin stories.

How can a small or medium brand leverage OCS traceability?

You don't need a massive tech budget. Start simple:

- Feature the TC on Your "Our Materials" Page: Post an anonymized sample Transaction Certificate. Explain what each part means. This educates and builds credibility.

- Include Traceability in Your Unboxing: Add a small card that says, "Your garment's organic journey is verified. Learn more at [URL]."

- Train Your Customer Service Team: Arm them with the knowledge of what OCS is, so they can confidently answer questions.

The ROI isn't just in risk avoidance; it's in customer loyalty and conversion. A 2024 survey by an industry group found that products with verifiable traceability data had a 17% higher conversion rate and a 23% lower return rate in the "sustainable" category. People trust—and keep—what they understand.

What happens when trust is broken?

The opposite scenario is a cautionary tale. Without traceability, a single social media allegation from a watchdog group—"Brand X's 'organic' clothes are made in a polluting factory!"—can spiral uncontrollably. You have no evidence to refute it. Your PR team can only issue weak statements. With OCS traceability, you can immediately respond with documented evidence of your certified supply chain partners, their environmental audits, and the clean chain of custody. You turn a potential scandal into a demonstration of integrity. This is why traceability is now a core component of crisis management for sustainable brands.

The Business Imperative: Risk Management and Market Access.

Beyond ethics and marketing, OCS traceability is a cold, hard business tool for risk management and revenue growth. It directly addresses two of the biggest challenges for apparel businesses today: supply chain fragility and stringent retailer requirements.

Supply Chain Risk Mitigation: The modern supply chain is opaque and fragmented. A problem at one invisible sub-contractor can torpedo your entire season. OCS traceability acts as a diagnostic map. Because every input and output is recorded and linked, you can instantly isolate issues. If a fabric fails a quality test, you can trace it back to the exact dye lot and yarn batch. This allows for surgical recalls, targeted negotiations with responsible suppliers, and continuous improvement. It turns your supply chain from a black box into a manageable system.

Unlocking Key Retail Channels: Major retailers and e-commerce platforms are your gatekeepers to mass markets. They are terrified of greenwashing scandals in their stores. Therefore, they are shifting from voluntary sustainability programs to mandatory verification requirements. Amazon's Climate Pledge Friendly, Target's Forward Sustainable, and Zalando's do.MORE explicitly require proof of claims like "organic cotton." An OCS Transaction Certificate is the pre-approved, standardized proof they accept. Without it, you are simply barred from these channels or face immediate delisting upon audit. For wholesalers and brands alike, this isn't a future possibility—it's today's reality. Understanding these evolving retailer compliance mandates is essential for growth.

How does traceability impact my bottom line beyond premiums?

Consider these tangible financial impacts:

- Reduced Testing Costs: With a trusted traced supply chain, you can move from 100% batch testing to risk-based auditing, cutting QC costs.

- Faster Problem Resolution: Isolating a problem to a single TC-batched lot minimizes disruption and financial exposure.

- Enhanced Negotiating Power: When you have data proving exactly which supplier caused an issue, you have leverage for compensation or price negotiations.

- Access to Financing: Banks and investors increasingly use Environmental, Social, and Governance (ESG) criteria. A verifiable, traced supply chain is strong evidence of good governance and operational control, making you a more attractive investment.

A concrete example: One of our brand partners reduced their quality-related chargebacks from retailers by 65% in one year after moving their organic line to a fully OCS-traced pipeline with us. The clarity and proof provided by the system resolved disputes before they became financial penalties.

Implementing Traceability: A Practical Guide for Brands.

Implementing OCS traceability is a project, but a manageable one. The key is to start upstream with your material source and work downstream.

Step 1: Secure Your Certified Source. This is the foundation. Partner with a fabric manufacturer like Shanghai Fumao that has robust OCS systems. Verify their certification, audit their processes, and ensure they can provide TCs and support your traceability story.

Step 2: Map and Certify Your Manufacturing. Work with your garment factory to achieve OCS certification or partner with one that already has it. They are the final custodian.

Step 3: Integrate Data Flow. Ensure the TC from your fabric supplier is seamlessly passed to your garment factory, and that the final product TC is delivered to you and logged in your system.

Step 4: Communicate the Story. Use the data you now have to build consumer-facing content.

What are the first steps if I'm starting from zero?

- Pick a Hero Product: Don't boil the ocean. Choose your best-selling organic item or a new launch to pilot traceability.

- Have the Conversation with Fumao: Tell us you want to build a traced product. We will guide you on fabric options, minimums, and connect you with certified manufacturing partners.

- Budget for the Process: Include the cost of certified materials and manufacturing in your cost-of-goods-sold (COGS). The premium is an investment, not an expense.

- Start Small, Learn, and Scale: Use the first order to understand the flow of materials and documents. Then, expand to other products.

Conclusion

OCS traceability is crucial for organic cotton garments because, in the end, it is the only mechanism that validates the premium price, protects the brand promise, and fulfills the ethical contract with the consumer. It replaces blind faith with verified fact. It transforms sustainability from a marketing department slogan into an operational reality documented at every step.

In the coming years, traceability will not be a differentiating factor for leaders; it will be the baseline requirement for participation in the responsible apparel market. Brands that build their supply chains on this verifiable foundation will survive retailer audits, navigate increasing regulation, and win the lasting trust of consumers. Those that don't will be exposed, often catastrophically.

The time to build traceability is now, before a crisis forces you to. It begins with choosing partners who have already built the systems.

Shanghai Fumao doesn't just sell OCS-certified fabric; we provide the traceable foundation and partnership to help you build a truly credible organic product. Let us help you turn your commitment into a verifiable chain of evidence.

Ready to make traceability the core of your organic offering? Contact our Business Director, Elaine, to map out your path to a fully traceable supply chain. Email elaine@fumaoclothing.com to start the process.