You have a vision: a custom-designed hoodie for your streetwear line, or a signature organic cotton dress for your boutique. You've sourced beautiful sketches and specs. But when you ask, "Can this be OCS certified?" you often get a hesitant "maybe" or a confusing quote that doubles the price. The uncertainty is frustrating. As a brand owner or designer, you need a clear, actionable path—not vague promises. The direct answer is yes, your custom clothing order absolutely can be OCS certified, but only if every link in its production chain is certified and managed under the OCS protocol. The real question isn't about possibility; it's about process.

At Shanghai Fumao, we handle custom OCS orders not as exceptions, but as a core part of our business. The certification doesn't apply to a design; it applies to the physical organic material and its documented journey from fiber to finished garment. So, your custom tee can be certified if the organic cotton jersey it's made from is tracked through an OCS-certified mill (like us), and the garment is assembled in an OCS-certified factory that preserves that chain of custody. It's a matter of aligning your custom project with a certified supply chain from the start.

Think of it like baking a cake with a certified organic ingredient. You can make any cake design you want (custom), but for the final cake to be labeled "made with organic sugar," you must: 1) Source certified organic sugar, and 2) Ensure that in your kitchen, it's kept separate from conventional sugar and used in a traceable way. OCS certification for custom clothing follows the same logical, but stringent, rules.

The Three Non-Negotiable Pillars of Custom OCS Certification.

For your custom order to leave the factory with a valid OCS Transaction Certificate (TC), three pillars must be firmly in place. Missing any one collapses the entire claim.

Pillar 1: OCS-Certified Materials. The organic fibers in your custom design must originate from OCS-certified sources. This typically starts with the fabric. If you want an organic cotton twill, that twill must be produced in an OCS-certified mill. The mill (like us) will have a TC from its certified yarn supplier, and will issue a TC for the fabric it sends to the garment factory. This is the foundation. Important: All components that contribute to the organic content claim (e.g., organic cotton ribbing) must also be certified.

Pillar 2: OCS-Certified Garment Manufacturing. This is the most common point of failure. The factory that cuts, sews, and finishes your garment must be OCS-certified for garment manufacturing. Why? Because they are the final custodian of the organic material. They must have systems to:

- Verify the incoming fabric TC.

- Physically store the certified fabric separately.

- Track the fabric through cutting and sewing (mass balance).

- Use approved, documented trims (e.g., thread can be conventional, but must be accounted for).

- Issue the final, legally valid TC for the finished garments.

A non-certified factory, no matter how skilled, cannot issue an OCS TC. They break the chain.

Pillar 3: Documented Chain of Custody. This is the paperwork spine that connects Pillar 1 and 2. For your custom order, you should receive a TC from the fabric mill and a final TC from the garment factory. The final TC will reference the fabric TC, creating an unbroken audit trail. This dossier is your proof.

What are the biggest misconceptions about custom OCS orders?

- "My small MOQ can't be certified." False. Certification is about process, not volume. We've run OCS orders for as few as 500 custom garments. The cost is in the system setup and dedicated production run, which may incur a minimum charge, but the certification itself is scalable.

- "If the fabric is OCS, the final garment automatically is." False and dangerous. The garment factory's role is critical. We had a client in 2023 who sourced OCS fabric from us but used a non-certified printer for custom graphics. The printer used non-compliant inks and mixed batches, voiding the traceability. The order could not be certified.

- "OCS certification will limit my design choices." Partially true, but in manageable ways. It limits your material choices to those available from certified sources. You can still customize color, cut, fit, styling, and graphics, but you must use OCS-certified base fabrics and approved decoration methods.

For a real-world example, a New Zealand-based wellness brand came to us with a custom design for a waffle-knit robe. They needed OCS 100 certification. Step 1: We developed the custom waffle knit using OCS-certified organic cotton yarn (Pillar 1). Step 2: We connected them with a vetted, OCS-certified garment factory we partner with (Pillar 2). Step 3: The factory produced the robes, maintained the chain, and issued the final TC (Pillar 3). The brand received their fully certified custom product. The entire process is detailed in guides on managing custom product development with sustainability certifications.

How do I verify each pillar with my suppliers?

- For Fabric (Pillar 1): Ask for the mill's OCS scope certificate and a sample TC. Confirm the specific fabric you need can be supplied under that certification.

- For Garment Factory (Pillar 2): Ask for their OCS scope certificate—it must include "garment manufacturing." Ask about their trim management and how they handle small, custom batches.

- For Documentation (Pillar 3): Agree upfront that the delivery of the correct TCs is a condition of final payment. Specify this in your purchase order.

Navigating Design & Production Complexities.

Custom orders come with unique specs—special dyes, prints, embroidery, or fabric blends. Each of these touches the organic material and must be managed within the OCS framework. Understanding these constraints early prevents costly mid-production changes.

Custom Dyeing and Finishing: Any wet-processing (dyeing, softening, washing) must be done in facilities that are included in the OCS scope of either the fabric mill or the garment factory. If you want a unique custom color, the dye house must be certified or part of a certified partner network. At Shanghai Fumao, our cooperative dyeing facilities are under our OCS certification, so custom colors are possible without breaking the chain.

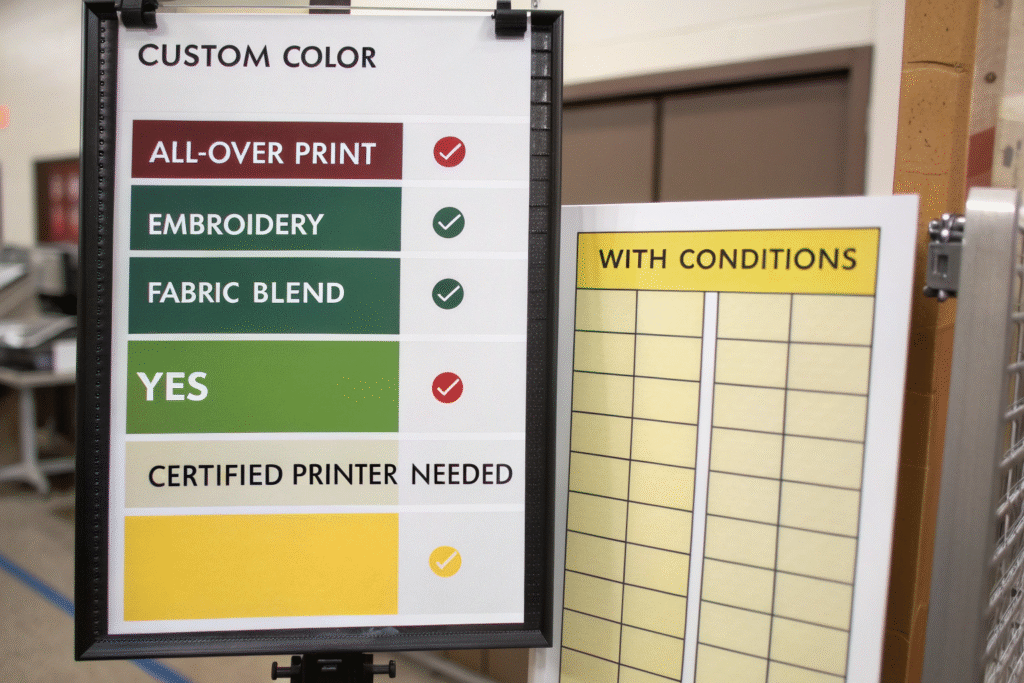

Prints and Embellishments: This is a critical area.

- Printed Fabrics: If you want a custom print on OCS fabric, the printing facility must be OCS-certified. They receive the certified fabric, print it (using inks that do not need to be organic, but their process must be tracked), and issue a new TC for the printed fabric.

- Garment Decoration (Post-Sewing): If you are screen printing or embroidering on finished garments, the decoration unit does NOT need OCS certification, as they are not transforming the organic material. However, the certified garment factory must manage this outsourcing carefully to ensure no mixing of certified and non-certified goods occurs and that the decorated garments can be traced back to their original certified batch.

Blended Fabrics (OCS Blended vs. OCS 100): Is your design a blend? For example, 70% organic cotton, 30% Tencel™ for drape. This is possible under OCS Blended. The system will track only the 70% organic portion. You must decide this at the fabric development stage. The fabric mill (us) will need to source certified organic cotton and pair it with the Tencel, maintaining mass balance for the organic part only.

Can I get a small custom run of OCS fabric developed?

Yes. This is a key service we provide. The MOQ for custom OCS fabric development depends on the complexity. For a simple knit or weave from existing organic yarn, MOQ can be as low as 500kg. For a completely new development, it's higher. The process is:

- You request a development sample.

- We use OCS-certified yarn from our inventory to create the sample.

- Upon approval, we schedule a production run in our certified facility, dedicating a specific batch of yarn to your order.

- We issue a TC for the exact quantity of fabric produced for you.

In late 2023, we developed a custom, heavy-weight OCS organic cotton canvas for a US workwear brand. The MOQ was 800kg (approx. 2000 yards). They received their exclusive fabric with full certification, which then went to their certified garment factory. This is the essence of co-developing exclusive sustainable fabrics with a mill.

| Custom Design Element | OCS Certification Impact | Key Requirement |

|---|---|---|

| Custom Color Dyeing | Possible. | Dyeing must occur at an OCS-certified facility (or within the mill's certified scope). |

| Fabric Print (e.g., digital print) | Possible. | Printing facility must be OCS-certified to handle and re-issue TCs for printed fabric. |

| Garment Embroidery/Screen Print | Does not break certification. | Must be coordinated by the OCS-certified garment factory to maintain batch traceability. |

| Blended Fabric (e.g., Cotton/Tencel) | Possible under OCS Blended. | Mill must track organic portion; final label must state accurate percentage (e.g., 70% organic cotton). |

| Special Washes (Garment Wash) | Complex. | Wash house must be under the garment factory's OCS control or certified itself to handle certified goods. |

The Practical Roadmap: From Sketch to Certified Shipment.

Here is a step-by-step roadmap to turn your custom design into a certified reality. Following this sequence prevents 90% of the common pitfalls.

Phase 1: Strategic Planning (Before Design Freeze)

- Define Your Certification Goal: OCS 100 or OCS Blended? This decides your material options.

- Engage a Certified Fabric Source Early: Contact a mill like Shanghai Fumao during the design phase. Discuss your fabric vision, and get guidance on available OCS-certified base materials (jersey, twill, fleece, etc.) and development possibilities.

- Budget for Certification: Factor in the potential premium (typically 5-15% overall) for certified materials and manufacturing. It's an investment in claim integrity.

Phase 2: Development & Sourcing

- Develop Samples with Certified Materials: Ensure all development samples are made from actual OCS-certified yarn/fabric. This gives you a true feel.

- Select Your Garment Factory Concurrently: Don't finalize fabric before finding the maker. Vet garment factories for OCS certification at the same time. We can often recommend partners.

- Finalize Trim Specs: Work with the garment factory to source any threads, labels, or elastics. Document their composition.

Phase 3: Production & Documentation

- Place PO with Clear Terms: Your POs to the fabric mill and garment factory must state that OCS certification and provision of TCs are required.

- Pre-Production Meeting: Facilitate a call between us (the mill) and the garment factory to confirm TC transfer and material handling protocols.

- QC with Documentation Check: Your third-party QC inspection should include verifying that OCS labels/markings are correct and that the factory has the TC ready.

What are the typical lead time additions for custom OCS?

Add time for:

- Fabric Development/Sampling: +2-4 weeks.

- Certified Production Scheduling: Factories schedule dedicated OCS runs. This can add +1-2 weeks vs. a conventional slot.

- Documentation Flow: Ensure you build in time to receive and verify TCs before final payment. This is usually just days, but must be planned for.

A realistic timeline for a fully custom OCS order from scratch is 18-24 weeks, compared to 14-20 weeks for a similar non-certified custom order. The extra time is for system alignment and certified production scheduling.

How does Fumao support this process for custom orders?

We act as your certified source and guide. For custom orders, we provide:

- Feasibility Assessment: We'll tell you upfront if your design vision can be executed within OCS parameters.

- Integrated Sampling: We make samples from real OCS materials, so you see and feel the certified end-product.

- Supply Chain Introduction: We connect you with our network of OCS-certified garment manufacturing partners, ensuring a seamless handoff.

- Unbroken Documentation: We provide the critical first TC and work with the garment factory to ensure the chain is complete.

This turnkey support is why brands choose to partner with a vertically integrated fabric supplier for complex custom orders. It consolidates responsibility and expertise.

Cost Analysis: Is Custom OCS Certification Worth It?

The investment breaks down into two parts: the direct premium and the protected value.

Direct Costs:

- Fabric Premium: OCS-certified fabric may cost 3-8% more due to segregated production and auditing.

- Garment Manufacturing Premium: An OCS-certified factory may charge 5-10% more for their controlled processes.

- Testing & Documentation: Minimal, often included.

Protected Value (ROI):

- Brand Equity: Ability to market a verified, custom product. This can support a 15-30% retail price premium.

- Risk Avoidance: Eliminates risk of greenwashing fines, chargebacks, and lost retailer partnerships.

- Market Access: Unlocks wholesale channels that require proof.

Consider this case: A DTC brand invested an extra $2.50 per unit in OCS certification for their custom organic cotton sweatsuit. They marketed it as "Verified Custom Organic," sold it for $40 more than their conventional line, and sold out the 2000-unit run in 3 weeks. The certification cost was $5,000; the additional revenue generated was $80,000. The math speaks for itself.

Conclusion

Yes, your custom clothing order can be OCS organic certified. The path is clear but requires intentional planning, partnership with certified suppliers at every stage, and a commitment to following the documented chain of custody. It transforms your custom design from a mere style into a substantiated asset with protected market value.

The complexity is manageable when you work with partners who have the systems in place. Attempting to retrofit certification onto a completed supply chain is nearly impossible; building it in from the start is straightforward.

If you have a custom design that demands authentic organic credentials, start the conversation early. Shanghai Fumao specializes in guiding brands through this exact process—from custom OCS fabric development to connecting you with certified manufacturing.

Ready to bring your custom, certified vision to life? Contact our Business Director, Elaine, to discuss your project specifics and our custom OCS development capabilities. Email elaine@fumaoclothing.com to begin the journey from sketch to certified shipment.