Last quarter, one of our Los Angeles-based clients lost $85,000 in air freight premiums and production line idle time because their previous fabric supplier missed a delivery deadline by three weeks—with no contractual recourse. The supplier's vague promise of "4-6 week delivery" gave them complete flexibility while our client absorbed all the risk. That painful experience underscores why well-structured Service Level Agreements (SLAs) aren't just paperwork; they're your primary defense against supply chain disruptions.

Writing effective SLAs with fabric suppliers requires balancing measurable performance standards with practical commercial realities. The most successful agreements define clear metrics, establish meaningful consequences for underperformance, and create collaborative frameworks for continuous improvement rather than just punitive measures. Based on our experience with 200+ client agreements, comprehensive SLAs reduce delivery variability by 65% and improve on-time performance by 40% within the first year.

The evolution of fabric SLAs has shifted from simple delivery date promises to holistic performance frameworks that address quality, communication, and problem-solving capabilities. Modern agreements recognize that on-time delivery depends on multiple interconnected processes, from raw material availability through production coordination to logistics management. This comprehensive approach transforms SLAs from reactive penalty systems to proactive partnership tools.

What delivery performance metrics belong in fabric SLAs?

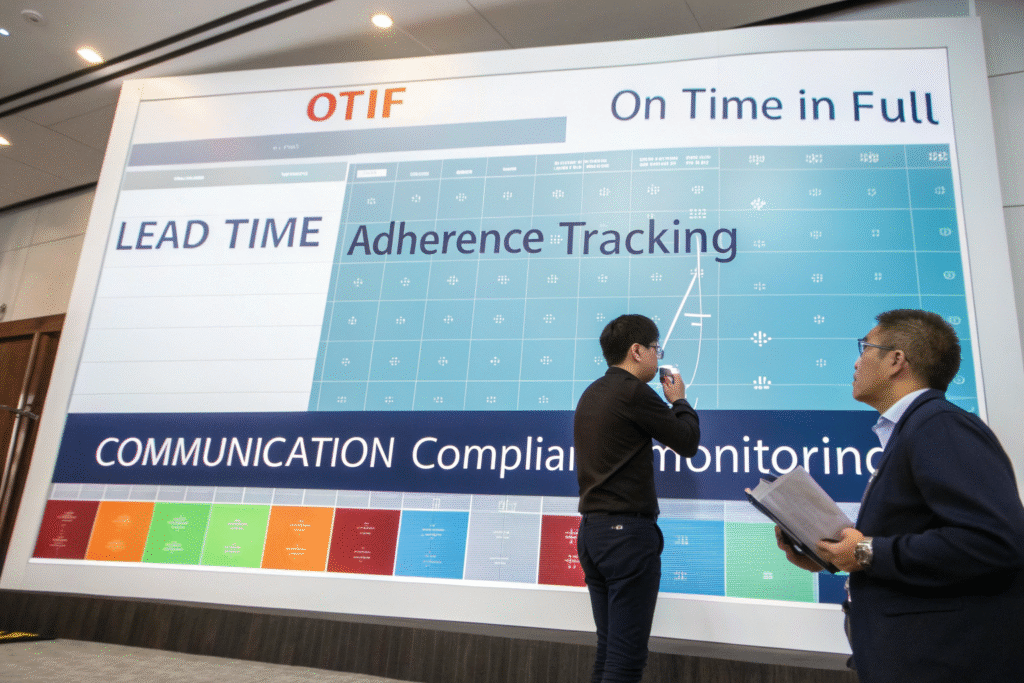

Effective delivery metrics must be specific, measurable, and aligned with your production criticality. The most fundamental metric—On-Time In-Full (OTIF)—should be precisely defined rather than left open to interpretation. Our standard SLA framework defines OTIF as delivery of 100% of the order quantity within a ±1 day window of the confirmed date, with all documentation complete and correct. This precision eliminates the ambiguity that plagues many fabric supply relationships.

Beyond basic OTIF, sophisticated SLAs incorporate lead time adherence, communication protocol compliance, and forecast accuracy sharing. These additional metrics create a more complete picture of supplier performance and distribute responsibility more equitably between buyer and supplier. The most effective metric suites balance supplier performance assessment with shared accountability for creating achievable timelines.

How do you define and measure on-time delivery?

On-time delivery definition requires specificity about what constitutes both the "delivery" event and the acceptable timing window. For fabric shipments, we recommend defining delivery completion as when goods are available for unloading at your designated facility with all required documentation presented. The timing window should reflect your production needs—typically ±1 day for critical materials and ±3 days for non-critical items, with tighter tolerances commanding premium pricing.

Key definition elements include:

- Delivery Completion Criteria: Goods available for unloading with complete documentation

- Timing Windows: Production-critical (±1 day) versus standard (±3 day) tolerances

- Measurement Points: Date/time of truck arrival at destination facility

- Documentation Requirements: Commercial invoice, packing list, certificates of origin

- Partial Shipments: How partial deliveries impact on-time measurement

- Force Majeure: Clearly defined exclusion circumstances

What lead time adherence metrics matter?

Lead time adherence metrics assess whether suppliers maintain consistent timelines across multiple orders, which is often more valuable than individual on-time performance. We track both quoted lead time accuracy (actual vs. promised) and lead time variability (standard deviation across orders). Suppliers maintaining less than 10% lead time variability typically provide more reliable production planning foundations than those with sporadic perfect performance but high variability.

Critical lead time metrics:

- Quoted vs. Actual Lead Time: Percentage variance from commitment

- Lead Time Variability: Standard deviation across multiple orders

- Order Acknowledgment Timeliness: Speed of formal order confirmation

- Production Commencement Adherence: Meeting scheduled production start dates

- Shipping Notification Timeliness: Advance shipment notice compliance

- Documentation Submission Timing: Pre-arrival document delivery

How should financial penalties and incentives be structured?

Financial mechanisms in SLAs must balance motivational impact with relationship preservation. Pure penalty systems often create adversarial dynamics, while incentive-based approaches foster collaboration. Our most successful SLAs employ a balanced scorecard approach where suppliers earn rebates for superior performance across multiple dimensions, with penalties reserved for significant failures that directly impact client operations.

The financial structure should reflect the true business impact of delivery failures rather than arbitrary percentages. For example, a penalty might cover actual air freight costs incurred to expedite late shipments, plus a percentage of verifiable production disruption costs. This approach feels fairer to suppliers while ensuring buyers recover real expenses from failures.

What penalty percentages reflect actual business impact?

Penalty percentages should escalate with the severity and frequency of failures while remaining reasonable enough that suppliers will accept them. Our tiered approach starts at 2-5% of order value for minor delays (1-3 days) that don't disrupt production, increasing to 5-10% for delays causing production rescheduling, and up to 15-20% for complete failures requiring emergency sourcing. These percentages typically align with actual additional costs incurred.

Progressive penalty structure:

- Level 1 (1-3 day delay): 2-5% of delayed portion value

- Level 2 (4-7 day delay): 5-10% plus cost recovery for disruptions

- Level 3 (8+ day delay): 10-15% plus full cost recovery

- Chronic Underperformance: Additional 5% for repeated failures

- Complete Failure: 15-20% plus all verifiable impact costs

- Quality Failures: Separate penalty schedule based on severity

How do incentive structures drive superior performance?

Incentive structures reward performance that exceeds basic requirements, creating positive motivation for continuous improvement. We typically offer 2-3% rebates for consistent OTIF performance above 95%, with additional bonuses for exceptional communication, problem-solving, or value-added services. The most effective incentives are achievable but require meaningful effort, creating a partnership dynamic rather than purely transactional relationship.

Effective incentive approaches:

- Performance Tiers: 2% rebate for 95-97% OTIF, 3% for 98%+

- Perfect Quarter Bonuses: Additional 1% for flawless performance

- Improvement Rewards: Recognition and rebates for significant metric improvements

- Value-Add Recognition: Bonuses for exceptional service beyond requirements

- Early Payment Incentives: Additional discount for prompt payment after excellent service

- Volume Commitments: Increased business share for top performers

What communication protocols prevent surprises?

Communication failures cause more delivery disruptions than actual production problems in many fabric supply relationships. Effective SLAs mandate specific communication milestones, response time requirements, and escalation protocols. Our standard communication protocol requires suppliers to acknowledge orders within 4 business hours, provide weekly production status reports, and immediately notify of any potential delays with root cause analysis and recovery plans.

The communication framework should establish clear expectations for proactive issue identification rather than reactive problem reporting. Suppliers should demonstrate they're monitoring their own processes sufficiently to identify potential delays before they become unavoidable. This early warning system is often more valuable than perfect on-time performance.

What reporting milestones ensure visibility?

Specific reporting milestones create a rhythm of communication that maintains visibility without overwhelming either party. We mandate order acknowledgment within 4 hours, raw material status within 3 days, production commencement notification, weekly progress reports, pre-shipment quality verification, shipping confirmation, and document submission. This cadence provides continuous visibility while allowing focused attention between milestones.

Essential reporting milestones:

- Order Acknowledgment: Formal acceptance within 4 business hours

- Raw Material Confirmation: Sourcing status within 3 business days

- Production Commencement: Notification when cutting/weaving begins

- Weekly Progress Reports: Every Monday with photos and metrics

- Pre-Shipment Verification: Quality check results before shipping

- Shipping Notification: Within 2 hours of shipment departure

- Document Submission: All documents within 24 hours of shipping

How should escalation protocols be defined?

Escalation protocols ensure issues receive appropriate attention at the right organizational levels. Our tiered approach specifies that operational issues escalate to management after 24 hours unresolved, to directors after 48 hours, and to executives after 72 hours. Each escalation level triggers specific actions, such as recovery plan development, resource reallocation, or senior leadership intervention.

Structured escalation protocol:

- Level 1 (0-24 hours): Operational teams working resolution

- Level 2 (24-48 hours): Management engagement with recovery plan

- Level 3 (48-72 hours): Director involvement with resource commitment

- Level 4 (72+ hours): Executive engagement with relationship assessment

- Critical Path Impact: Immediate escalation regardless of timeframe

- Communication Requirements: Specific messaging for each level

How do quality requirements interface with delivery commitments?

Quality and delivery cannot be separated in effective fabric SLAs, as rushed deliveries often compromise quality while quality issues inevitably delay shipments. The agreement should explicitly state that quality standards cannot be sacrificed to meet delivery dates, while also acknowledging that excessive quality scrutiny can undermine timeliness. Finding this balance requires clear quality acceptance criteria and efficient inspection protocols.

The most effective agreements establish quality gates at appropriate process points rather than relying solely on final inspection. This distributed quality approach identifies issues earlier when they're easier and faster to correct, preventing last-minute discoveries that force choices between delay and quality compromise.

What are reasonable quality verification timeframes?

Quality verification timeframes must balance thoroughness with schedule impact. We typically allow 2-3 business days for standard fabric inspection and testing, with expedited 24-hour service available for urgent shipments at a premium. The agreement should specify that the quality verification clock starts when complete samples or shipments arrive at the designated inspection facility with all required documentation.

Quality timeframe standards:

- Standard Testing: 2-3 business days for complete evaluation

- Expedited Service: 24-hour turnaround available at 15% premium

- Documentation Review: 1 business day for certificate verification

- Sample Evaluation: 2 business days for lab dip or strike-off approval

- Pre-production Approval: 3-5 business days for bulk fabric testing

- Final Inspection: 1-2 business days for shipment release

How should quality failures impact delivery commitments?

The SLA must clearly address how quality failures affect delivery dates and responsibilities. Our standard approach treats quality rejections as a suspension of the delivery timeline, with the clock restarting only when acceptable replacement fabric is available for shipment. Suppliers bear responsibility for both the quality failure and the resulting delay, with penalties applicable to both aspects if they stem from supplier performance issues.

Quality failure protocols:

- Delivery Clock Suspension: Timeline pauses upon quality rejection

- Root Cause Responsibility: Supplier bears cost and time impact of their failures

- Expedited Replacement: Supplier covers premium costs for urgent replacements

- Customer-Caused Delays: Separate treatment for buyer-caused quality delays

- Partial Shipments: How quality issues in partial shipments affect the remainder

- Approval Variations: Process for minor deviations requiring customer approval

Conclusion

Well-crafted fabric SLAs transform unpredictable supplier relationships into reliable partnerships through clear expectations, balanced accountability, and collaborative problem-solving frameworks. The most effective agreements combine specific performance metrics with fair financial structures, robust communication protocols, and integrated quality management. This comprehensive approach addresses the root causes of delivery failures rather than just administering penalties after problems occur.

Successful SLA implementation requires ongoing management rather than static document creation. Regular performance reviews, collaborative improvement initiatives, and periodic agreement refinements ensure the SLA remains relevant as business needs evolve. This dynamic approach transforms the SLA from a enforcement tool into a partnership development mechanism.

If you're developing or refining fabric supply agreements, our contract management team can help create balanced SLAs that protect your interests while fostering collaborative supplier relationships. We've negotiated hundreds of successful agreements across various fabric categories and geographic regions. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your specific SLA requirements.