Last month, one of our Los Angeles-based clients received a $45,000 silk shipment that looked like someone had played football with it. The fabric was packed in loose rolls without proper wrapping, resulting in deep creases that couldn't be removed, water stains from exposure, and crushed selvedges. The entire shipment was rejected, causing a three-week production delay during their peak season. That disaster could have been prevented with the right packing method chosen for the specific fabric type and journey.

Selecting between rolling, boarding, or carton packing depends on three critical factors: fabric composition, transportation duration, and handling intensity. Each method offers distinct advantages for different scenarios, and the choice directly impacts whether your fabric arrives pristine or requires expensive rework. Getting this decision wrong doesn't just risk damage—it can compromise fabric performance and appearance permanently.

The packing decision matrix has evolved significantly with new materials and technologies. Where traditional methods focused mainly on basic protection, modern approaches combine structural engineering with material science to address specific vulnerabilities like moisture, compression, and abrasion. Understanding these options transforms packing from a simple cost center to a strategic quality preservation investment.

How does roll packing protect different fabric types?

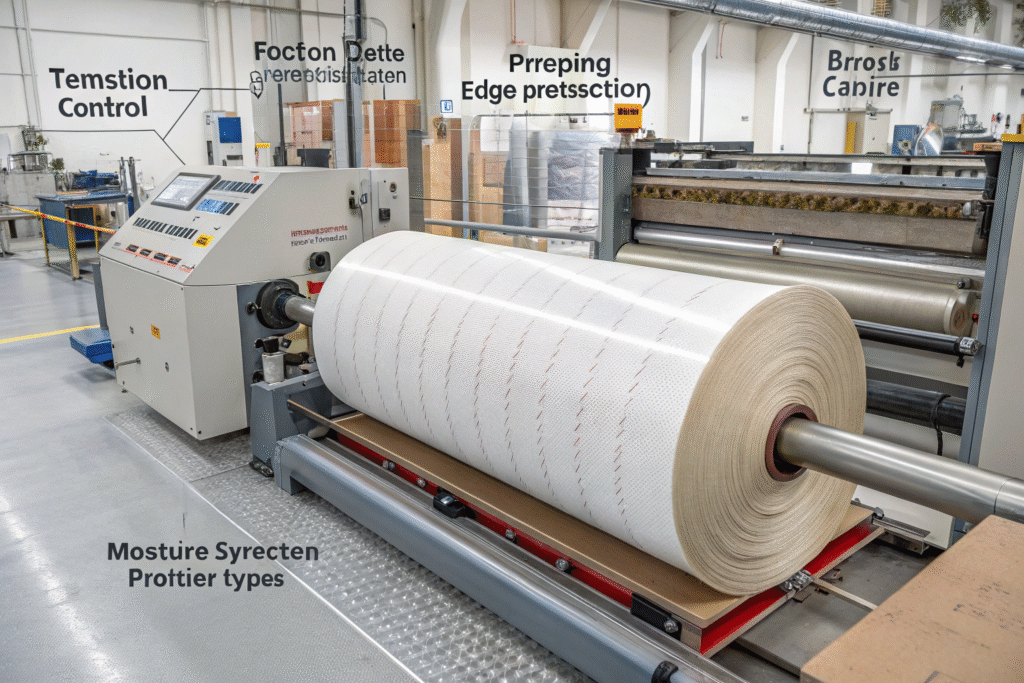

Roll packing remains the most common method for continuous yardage, but its effectiveness varies dramatically based on execution quality. Proper roll packing involves more than just winding fabric onto a tube—it requires precise tension control, diameter management, and protective wrapping tailored to fabric characteristics. Our quality audits show that correctly implemented roll packing reduces transit damage by up to 80% compared to poorly executed rolling.

The science behind roll packing centers on managing three destructive forces: compression creasing, edge damage, and internal friction. Each fabric type has an optimal roll diameter—heavy denims and upholstery fabrics perform best on larger cores (6-8 inches), while delicate silks and knits require smaller cores (2-3 inches) to minimize bending stress. Getting this wrong creates permanent creases or stretched areas that can't be removed during finishing.

What core materials and diameters work best?

The core material selection significantly impacts fabric protection, with cardboard, plastic, and steel each serving different purposes. We recommend heavy-duty plastic cores for international shipments because they resist crushing during rough handling, while breathable cardboard suits domestic shipments of natural fibers. The diameter calculation follows a simple rule: heavier fabrics need larger cores to prevent center condensation and compression marks.

Optimal core specifications include:

- Cardboard Cores: 3-inch diameter for lightweight fabrics, 6-inch for heavy materials

- Plastic Cores: 2-4 inch diameter with ventilation holes for moisture control

- Steel Cores: Reserved for extremely heavy industrial fabrics exceeding 800 GSM

- Length Management: 2-4 inches wider than fabric to protect edges

- End Cap Protection: Plastic or cardboard caps to prevent core indentation

- Load Distribution: Calculating rolls per pallet based on weight limits

How does wrapping configuration prevent damage?

The wrapping sequence creates layered protection against different hazards, with each layer serving a specific purpose. Our standard protocol involves: first layer (anti-abrasion tissue), second layer (moisture-resistant plastic), third layer (edge protectors), and final layer (heavy-duty outer wrap). This system reduced water damage claims by 95% for a Seattle-based outdoor brand shipping technical fabrics through humid climates.

Critical wrapping elements include:

- Inner Layer: Acid-free tissue for delicate surfaces

- Moisture Barrier: Perforated polyethylene for breathable protection

- Edge Reinforcement: Cardboard or foam selvedge guards

- Compression Protection: Corrugated inserts for heavy stacking

- Outer Layer: Reinforced waterproof paper or woven plastic

- Identification: Waterproof labeling with handling instructions

When is board packing the superior choice?

Board packing transforms flat packing from a budget option to a premium solution for sensitive fabrics when executed with precision. This method involves sandwiching fabric between rigid boards, creating a protected environment that eliminates rolling stresses entirely. The investment in proper board packing typically adds 15-25% to packing costs but can prevent 100% loss for fabrics that can't tolerate any creasing.

The economics of board packing shift dramatically based on fabric value and damage sensitivity. For fabrics exceeding $50/yard or those with sensitive surfaces like laminated coatings, the additional packing cost becomes insignificant compared to potential rejection losses. Our cost-benefit analysis shows board packing becomes economically justified when fabric value exceeds $25/yard or when rejection costs would exceed $5,000 per shipment.

What board materials and layering prevent creases?

The board selection critically impacts protection level, with corrugated plastic, foam-core, and specialty boards each offering different benefits. We developed a fabric-specific boarding matrix that matches board type to fabric characteristics: corrugated plastic for most wovens, foam-core for delicate surfaces, and acid-free conservation board for museum-quality textiles. The layering sequence includes cushioning tissue, the fabric itself, and top boarding with even pressure distribution.

Advanced boarding configurations include:

- Standard Protection: Single-layer corrugated plastic boards

- Premium Protection: Double-layer with foam insulation core

- Maximum Protection: Triple-layer with vibration damping material

- Moisture Control: Waterproof board with silica gel packets

- Static Prevention: Anti-static boards for synthetic fabrics

- Custom Sizing: Board dimensions matching fabric widths exactly

How do you optimize board packing for different fabrics?

The folding technique within board packing requires as much precision as the board selection itself. For fabrics that tolerate folding, we employ the "concertina fold" method with generous curvature radii that prevent sharp creases. The fold frequency depends on fabric weight—every 2-3 yards for heavy fabrics, 1-yard intervals for medium weights, and continuous laying for extremely delicate pieces. This approach eliminated crease-related rejections for a New York luxury brand shipping cashmere blends.

Fabric-specific boarding protocols include:

- Heavy Fabrics: Minimal folding with reinforced corner protection

- Delicate Fabrics: Tissue interleaving between layers

- Sensitive Surfaces: Non-contact suspended boarding systems

- Large Pieces: Sectional boarding with overlap protection

- Mixed Shipments: Color-coded board systems for identification

- High-Value Items: Serial-numbered security seals on boards

When should you use carton packing systems?

Carton packing provides the highest level of protection for high-value, small-quantity, or mixed fabric shipments where organization and security are priorities. The method involves placing rolled or boarded fabrics into reinforced cartons, creating a container-within-a-container protection system. While adding 30-50% to packing costs, carton packing reduces handling damage by creating uniform, stackable units that withstand warehouse automation systems.

The decision framework for carton packing considers shipment value, handling intensity, and destination infrastructure. For air freight shipments under 500kg or destinations with limited unloading equipment, carton packing often delivers the best total cost by eliminating specialized handling requirements. Our data shows carton-packed shipments experience 70% fewer claims than non-carton equivalents for complex logistics routes.

What carton specifications ensure protection?

Carton selection requires balancing strength, weight, and cost factors, with double-wall corrugated providing the best overall protection for most fabric shipments. The box compression test standards determine carton strength, with 32 ECT (edge crush test) double-wall being our minimum for international shipments. Internal dimensions should provide 2-3 inches of clearance around the fabric to allow for protective cushioning and prevent compression against carton walls.

Critical carton specifications include:

- Wall Construction: Double-wall 200# test for shipments under 30kg

- Size Optimization: Custom dimensions to minimize empty space

- Moisture Resistance: Wax-impregnated or polyethylene-coated options

- Stacking Strength: Designed for specific pallet configurations

- Handling Features: Integrated hand holes for manual movement

- Identification: Waterproof labeling on multiple sides

How does internal bracing prevent movement damage?

Internal bracing transforms a simple container into a protective cocoon by immobilizing the contents against transit vibrations and impacts. Our standard system uses foam corner braces, air cushion systems, and partition walls that create separate compartments for different fabric pieces. This approach proved crucial for a Chicago designer shipping mixed fabric collections, reducing damage from 12% to under 1% despite complex multi-stop logistics.

Advanced bracing systems include:

- Foam End Caps: Custom-cut to fit fabric rolls precisely

- Air Pillow Systems: Inflatable cushions that adapt to contents

- Partition Kits: Cardboard grids creating separate compartments

- Suspension Systems: Elastic cords preventing contact with walls

- Vibration Dampers: Specialty materials absorbing shocks

- Temperature Buffers: Insulating layers for climate control

What hybrid approaches address special requirements?

Many challenging fabrics require customized hybrid approaches that combine elements from multiple packing methods. These solutions typically emerge from specific damage incidents that reveal limitations in standard approaches. The development cost for hybrid packing is higher initially but becomes justified for recurring shipments of high-value or damage-prone fabrics.

The most innovative hybrid approaches often combine structural elements from different methods—such as rolled fabrics within boarded cartons or flat-packed pieces with rolled accent elements. These solutions typically cost 40-100% more than standard packing but can reduce damage from 15% to near zero for problematic fabrics.

How do you pack mixed fabric shipments effectively?

Mixed shipments containing different fabric types, weights, and sensitivities present the most complex packing challenges. The solution involves creating individual optimized packing for each fabric type, then integrating them into a unified external pack that protects all components equally. We developed a modular mixed fabric packing system using color-coded inner packs with fabric-specific protection, all contained within a reinforced master carton.

Mixed shipment strategies include:

- Individual Wrapping: Fabric-specific protection for each piece

- Separation Systems: Moisture and color-transfer barriers

- Compartmentalization: Divided cartons preventing compression

- Identification Systems: Clear labeling for unpacking sequence

- Weight Distribution: Heavy items at bottom, delicate on top

- Unpacking Instructions: Guided opening to prevent damage

What specialized solutions exist for extreme fabrics?

Extreme fabrics—those with unusual sensitivity, value, or dimensional characteristics—require completely custom packing approaches. These include vacuum packing for space efficiency, climate-controlled containers for temperature sensitivity, and custom crating for oversized pieces. The development process typically involves prototyping and testing to ensure protection throughout the planned logistics route.

Specialized solutions for challenging fabrics:

- Vacuum Packing: Compression-resistant systems for downproof fabrics

- Climate Control: Active temperature management for coated fabrics

- Custom Crating: Wooden frameworks for architectural textiles

- Humidity Control: Desiccant systems for moisture-sensitive natural fibers

- Light Protection: UV-resistant packaging for fade-prone colors

- Security Packaging: Tamper-evident systems for high-value textiles

Conclusion

Selecting the optimal fabric packing method requires analyzing fabric characteristics, transportation conditions, and handling intensity to match protection needs with practical constraints. Roll packing offers efficiency for standard fabrics, board packing provides superior crease protection for sensitive materials, and carton packing delivers maximum security for high-value or complex shipments. The most effective approach often involves customizing standard methods to address specific vulnerabilities identified through damage analysis and testing.

The packing decision shouldn't be based solely on cost minimization but rather on total cost optimization that includes potential damage, rejection expenses, and production delays. Investing in appropriate packing transforms from an expense to insurance against much larger potential losses. As logistics networks become more automated and complex, the importance of engineered packing solutions only increases.

If you're facing persistent fabric damage during transit, our packaging engineering team can analyze your specific challenges and recommend optimized packing protocols. We maintain a packaging laboratory that tests various methods against simulated transit conditions. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to schedule a packaging assessment for your next shipment.