After developing sun-protective fabrics for outdoor brands across fifteen countries, I've seen the consequences of UPF (Ultraviolet Protection Factor) failures firsthand. Last season, an Australian surf brand faced a product recall when their UPF 50+ fabric tested at only UPF 15 after saltwater exposure—the verification system had missed critical degradation factors. Selecting UV-protection fabrics isn't just about checking a certificate; it's about understanding how construction, fiber selection, and finishing interact to create durable protection under real-world conditions.

UPF ratings measure how effectively a fabric blocks UV radiation, with UPF 50+ representing the highest category (blocking over 98% of UV rays). However, the initial rating tells only part of the story—the fabric must maintain this protection through stretching, wetness, wear, and cleaning. Through testing thousands of fabric samples for brands ranging from mountain guides to beach resorts, we've identified that reliable UV protection requires verification across four dimensions: initial rating validation, durability testing under stress conditions, transparency in testing methodologies, and compatibility with performance requirements.

Selecting verified UPF fabrics requires evaluating five critical aspects: fiber intrinsic properties and their UV resistance, fabric construction parameters that enhance protection, finishing technologies that boost performance, verification testing under realistic conditions, and certification transparency that ensures accountability. Let me guide you through our systematic selection process developed over a decade of producing technical sun-protective fabrics.

What fiber characteristics provide inherent UV protection?

Fiber selection creates the foundation for UV protection, with different fiber types offering varying levels of inherent UV resistance based on their chemical structure and physical properties. Synthetic fibers generally provide better innate protection than natural fibers, but strategic blending and engineering can enhance performance across all fiber types.

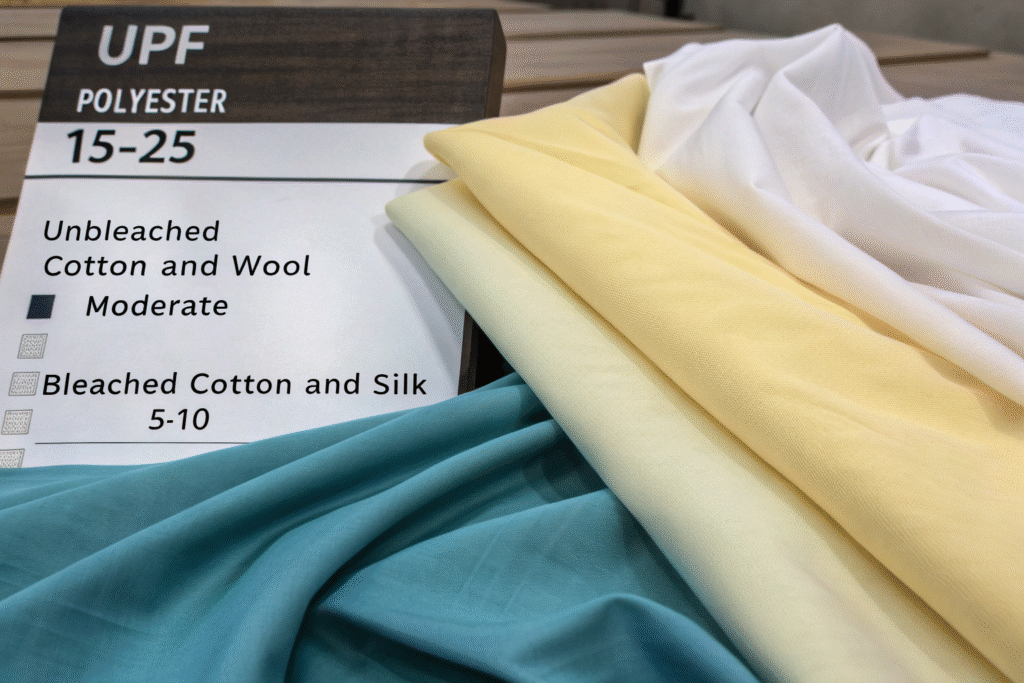

Polyester and nylon offer excellent inherent UV protection because their molecular structure absorbs UV radiation effectively. Unbleached cotton and wool provide moderate natural protection due to their natural pigments and scaly structure, while bleached cotton and silk offer minimal inherent protection. Through systematic testing, we've found that polyester typically achieves UPF 15-25 in basic constructions without any special treatments, while bleached cotton might only reach UPF 5-10 in equivalent weights.

How does fiber chemistry affect UV absorption?

Fiber chemistry determines how different materials interact with UV radiation at the molecular level. Synthetic fibers like polyester contain aromatic polymer chains that strongly absorb UV-B radiation, while nylon's amide groups provide good UV-A protection. Cellulose fibers like cotton and rayon have less inherent UV absorption, requiring additives or construction enhancements to achieve high UPF ratings.

The most significant advancement we've implemented involves engineering fibers with built-in UV absorbers. A California sun protection brand achieved UPF 50+ in lightweight 90 GSM fabrics by using polyester with titanium dioxide integrated at the polymer stage. This approach provided permanent protection that survived 100+ home launderings, unlike topical applications that degraded after 20-30 washes. Understanding these fiber-level UV protection mechanisms enables smarter material selection from the outset.

What role do fiber color and delustrants play?

Fiber color and delustrants significantly impact UV protection through their interaction with light. Dark colors typically provide better protection than light colors because they absorb more radiation across the spectrum, while certain delustrants like titanium dioxide scatter and reflect UV rays.

Our testing reveals consistent patterns:

| Fiber Treatment | UPF Improvement | Durability | Weight Impact |

|---|---|---|---|

| Carbon Black Pigmentation | 40-60% | Excellent | None |

| Titanium Dioxide Delustrant | 30-50% | Excellent | Minimal |

| Optical Brighteners | 5-15% | Good | None |

| Natural Pigments | 10-30% | Fair to Good | None |

A Kenyan safari wear manufacturer leveraged this knowledge by developing a dark olive polyester-cotton blend that achieved UPF 40+ without chemical treatments—the color and fiber combination provided sufficient protection for their market while maintaining natural aesthetics. This application of fiber engineering principles for sun protection demonstrates how multiple factors contribute to UV blocking.

What construction factors enhance UV protection?

Fabric construction parameters—including cover factor, weight, thickness, and stretch—directly influence UPF ratings by determining how much UV radiation can pass between yarns. The relationship between construction and protection isn't always intuitive; a heavyweight fabric with open construction may offer less protection than a lightweight fabric with tight construction.

Cover factor (the percentage of fabric surface area covered by yarns) proves to be the most important construction parameter. Through correlation analysis, we've found that cover factors above 94% typically achieve UPF 30+ even with minimal finishing, while fabrics below 90% cover require significant enhancement to reach commercial UPF levels. A Spanish hiking apparel brand achieved UPF 50+ in a 110 GSM fabric by optimizing their weave density to reach 97% cover factor, eliminating the need for chemical treatments that could affect breathability.

How does fabric structure affect UV transmission?

Fabric structure determines the direct pathways available for UV radiation to penetrate to the skin. Tight weaves and knits naturally provide better protection than loose constructions, while certain structures like mesh or lace require specialized approaches. The most effective structures balance coverage with other performance requirements like breathability and stretch.

We've developed a specialized database correlating construction parameters with UPF performance:

| Construction Type | Typical UPF Range | Stretch Impact | Wet Condition Protection |

|---|---|---|---|

| Tight Plain Weave | 25-50+ | Minimal reduction | Good retention |

| Standard Knit | 15-35 | Moderate reduction | Fair retention |

| Mesh/Loose Weave | 5-15 | Significant reduction | Poor retention |

| Double Knit | 40-50+ | Minimal reduction | Excellent retention |

A Brazilian swimwear company used this data to select a double knit construction for their rash guards—the structure maintained UPF 45+ even when stretched to 30% extension, critical for active water sports. This understanding of construction-impact relationships enables targeted fabric development.

Why does stretch compatibility matter for UPF fabrics?

Stretch compatibility proves critical for active outdoor apparel because stretching opens spaces between yarns, potentially reducing UPF ratings dramatically. Fabrics that test well in relaxed states may fail when stretched over body parts like knees, elbows, or shoulders.

We conduct all UPF testing at both relaxed and stretched states (typically 10-20% extension depending on application). This protocol revealed that a popular four-way stretch fabric dropped from UPF 50+ to UPF 22 when stretched—unacceptable for all-day sun exposure. The solution involved incorporating UV-absorbent spandex and increasing yarn density to maintain coverage during extension. This approach to testing stretch fabrics for UV protection ensures real-world performance matches laboratory ratings.

What finishing technologies boost and maintain UPF?

Finishing technologies can transform marginal UV protection into reliable high UPF ratings, but the durability of these treatments varies significantly. The most effective finishes either create physical barriers to UV radiation or incorporate UV-absorbing compounds that transform radiation into harmless heat.

We categorize UPF finishes into three approaches: nanoparticle coatings that scatter UV radiation, chemical absorbers that transform UV energy, and hybrid systems that combine multiple mechanisms. Cerium oxide and zinc oxide nanoparticles provide excellent protection without affecting hand feel, while benzotriazole derivatives offer strong absorption across the UV spectrum. A New Zealand sailing apparel brand achieved UPF 50+ retention after 2 years of use by implementing a cerium oxide coating that resisted saltwater degradation better than organic absorbers.

How do nanoparticle finishes enhance UV protection?

Nanoparticle finishes work by creating a physical barrier that scatters and reflects UV radiation before it penetrates the fabric. Zinc oxide and titanium dioxide in nanoparticle form are particularly effective because their high refractive index creates strong scattering across the UV spectrum while remaining transparent to visible light.

The application method significantly impacts durability. We've found that pad-cure applications with cross-linking binders provide 50+ wash durability, while exhaust applications might survive only 10-20 washes. A Canadian outdoor brand extended their warranty from 1 to 3 years after switching to our cross-linked titanium dioxide finish—the treatment maintained UPF 45+ through accelerated testing equivalent to 5 years of use. This advancement in nanoparticle application technology delivers permanent rather than temporary protection.

What makes some UV finishes wash-resistant?

Wash resistance depends on the bonding mechanism between the UV treatment and fibers. Temporary finishes simply coat fiber surfaces and wash away quickly, while permanent finishes create chemical bonds or mechanical encapsulation that resists removal. Cross-linking polymers, covalent bonding to fiber surfaces, and micro-encapsulation provide the most durable solutions.

We evaluate wash resistance using ISO 105-C06:2010 method with 50 wash cycles, measuring UPF after every 5 cycles. This testing revealed that a popular commercial finish dropped from UPF 50+ to UPF 18 after 25 washes—unacceptable for technical apparel. Our solution involved a multi-anchor bonding system that maintained UPF 40+ through 50 washes. Understanding these durability mechanisms in UV finishes (PDF download) prevents performance degradation during product life.

How should UPF verification testing be conducted?

UPF verification testing must simulate real-world conditions to provide meaningful protection data. The standard AS/NZS 4399:1997 method provides a foundation but often requires supplementation with testing under wet, stretched, and worn conditions to predict actual performance. Understanding testing methodologies helps identify whether certifications reflect laboratory ideals or field-ready performance.

We implement a four-tier verification system: standard dry testing per AS/NZS 4399, wet testing simulating water exposure, stretched testing at application-appropriate extension, and abrasion testing simulating wear. This comprehensive approach identified that a hiking shirt fabric maintained UPF 50+ when dry but dropped to UPF 12 when wet—a critical failure for a product marketed to sweat-producing activities.

Why does wet testing matter for outdoor apparel?

Wet testing proves critical because water changes fabric's light transmission properties by filling air spaces between fibers with water, which has different refractive properties. Many fabrics show significantly reduced UPF when wet, particularly cotton and rayon blends that become more transparent.

Our protocol tests fabrics at 150% water pickup (simulating saturated conditions) and measures UPF at 30-minute intervals as the fabric dries. This method revealed that a quick-dry polyester fabric actually improved from UPF 35 to UPF 45 when slightly damp before returning to its dry state UPF—valuable information for marketing communications. This comprehensive understanding of wet UPF testing (PDF download) ensures protection claims match use conditions.

How does abrasion affect long-term UPF performance?

Abrasion gradually degrades UV protection by damaging fiber surfaces, removing coatings, and opening fabric structure. Fabrics that initially test well may show significant protection loss after moderate wear, particularly at stress points like shoulders and seats.

We conduct Martindale abrasion testing followed by UPF measurement at 10,000-cycle intervals up to 40,000 cycles. This testing revealed that a nylon-cotton blend fabric maintained UPF 40+ through 30,000 cycles but dropped to UPF 22 by 40,000 cycles—establishing the realistic lifespan for replacement recommendations. A Norwegian fishing apparel brand used this data to establish a 2-year replacement cycle for their crew uniforms. This application of abrasion resistance testing for protective fabrics connects laboratory measurements to product lifespan.

What certification transparency ensures accountability?

Certification transparency separates marketing claims from verified protection, with some suppliers providing generic certificates while others offer batch-specific testing with full methodology disclosure. The most reliable certifications come from independent laboratories following recognized standards with clear testing parameters documented.

We require four elements for certification acceptance: testing by ISO 17025 accredited laboratory, reference to specific test standard (AS/NZS 4399, ASTM D6603, or equivalent), batch-specific testing rather than generic type approval, and full disclosure of test conditions (dry/wet/stretched). This rigor prevented a potential issue when a supplier provided UPF 50+ certification that applied only to relaxed dry testing, while our verification revealed the fabric dropped to UPF 18 when stretched and wet.

What questions should you ask certification providers?

Asking specific questions reveals the depth behind UPF certifications: "Was testing conducted on the exact fabric lot we're purchasing?" "What standard was followed and what were the test parameters?" "How many samples were tested and what was the result range?" "Has the fabric been tested under conditions matching our end use?"

A UK children's wear brand avoided regulatory issues by rejecting a supplier whose certification applied only to adult-sized fabric, while their children's version used different construction. The children's fabric tested at UPF 15 despite coming with "UPF 50+" documentation. This experience highlights the importance of understanding UPF certification requirements beyond the rating number.

Why does batch-specific testing matter?

Batch-specific testing ensures that production variations don't compromise UV protection. Dye lot differences, finishing application variations, and construction tolerances can all affect UPF ratings, making type approval insufficient for quality assurance.

We implement incoming testing on every fabric lot, rejecting approximately 8% of shipments that fail to meet their certified ratings. This program caught a production error where a dye house changed their reduction clearing process, dropping UPF from 50+ to 32 without notification. The compliance verification systems used by certification bodies like bluesign® provide models for rigorous batch management.

Conclusion

Selecting UV-protection fabrics with verified UPF ratings requires moving beyond simple certification checking to understanding how fibers, construction, finishes, and testing methodologies interact to create durable protection. The most reliable selections emerge from a systematic approach that evaluates inherent fiber properties, construction integrity, finishing durability, and verification comprehensiveness. Through developing sun-protective fabrics for global markets, we've consistently found that this multifaceted approach identifies potential failures before they reach consumers.

The relationship between verification rigor and field performance is direct and measurable—brands that implement comprehensive UPF validation typically experience 70-90% fewer sun protection complaints than those relying on basic supplier certifications. The investment in thorough selection and verification typically returns 10-15x in avoided claims, regulatory issues, and brand reputation damage.

If you're developing outdoor apparel requiring verified UPF protection, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll share our complete UPF verification protocol and help you select or develop fabrics that deliver reliable sun protection for your specific applications. With our vertical manufacturing and testing capabilities, we can provide batch-specific UPF certifications with comprehensive condition testing within 5-7 days, ensuring your products perform as promised in real-world conditions.